Machine-made sand automatic loading system

A machine-made sand and automatic technology, which is applied in the direction of conveyors, loading/unloading, conveyor objects, etc., can solve the problems that the loading effect cannot be achieved, it is difficult to lay materials evenly, and the amount of loading beams is affected, so as to reduce the loading and unloading The effect of unloading operation process, high automation intensity and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

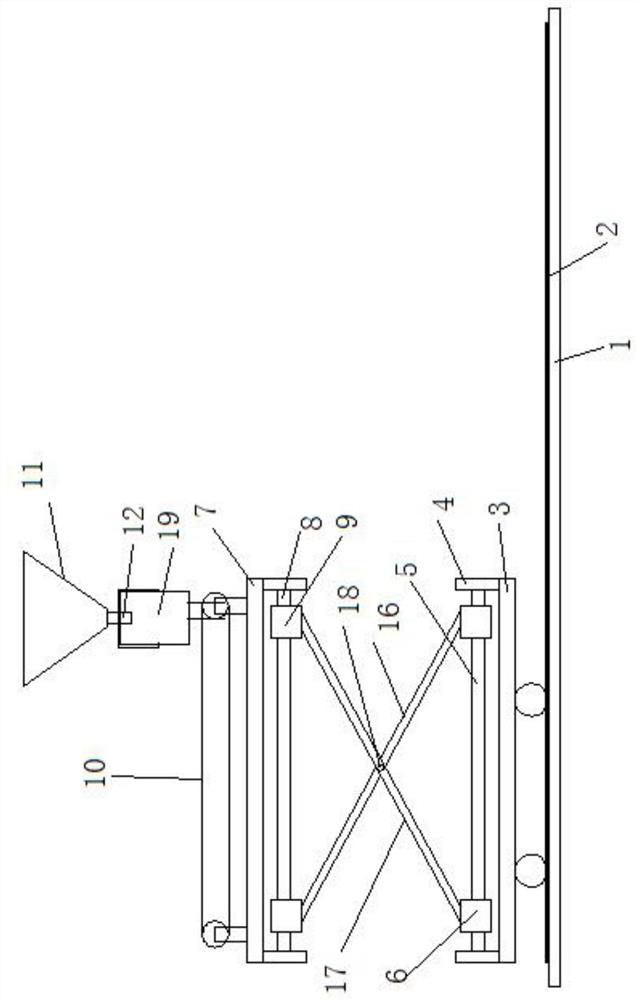

[0029]See attached picture.

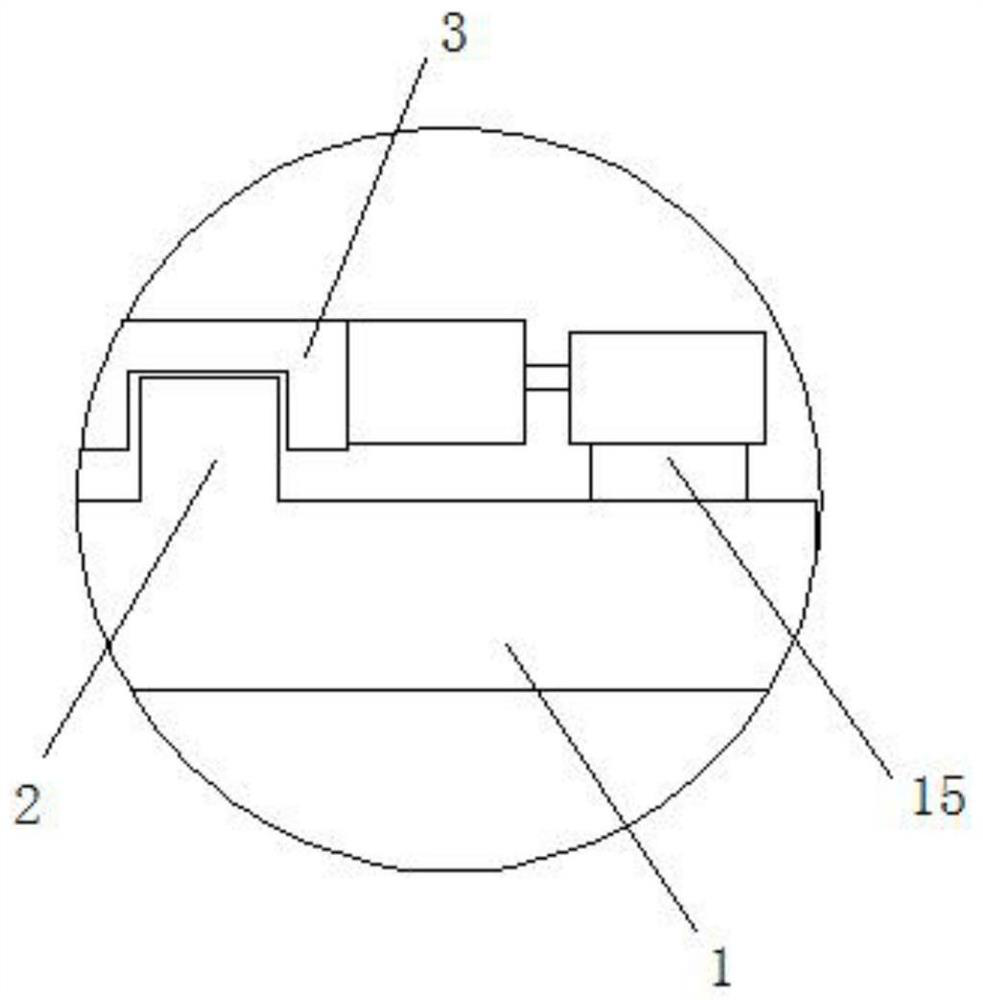

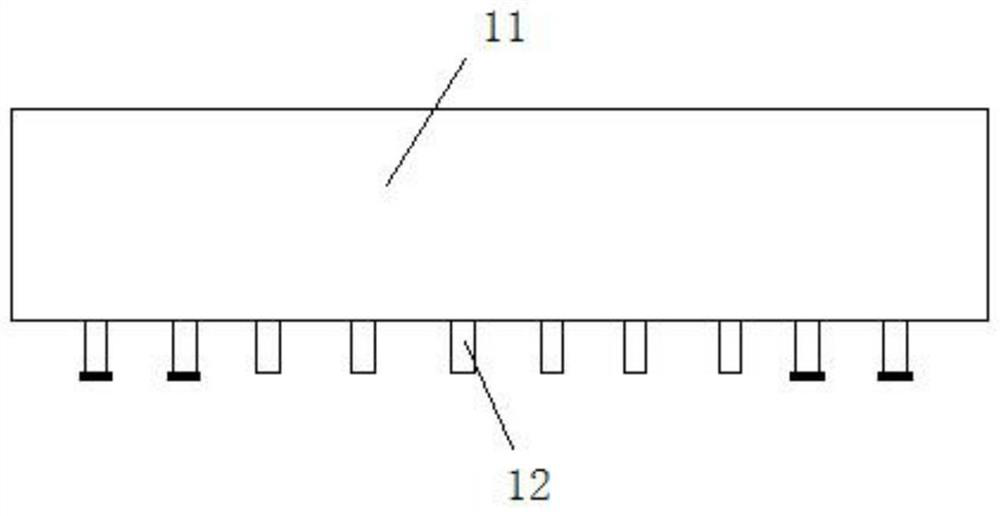

[0030]An automatic loading system for machine-made sand includes two bases 1 arranged side by side. The bases 1 are respectively laid with guide rails 2 and the guide rails 2 are guided and installed with a movable seat 3, and the movement of the movable seat 3 is driven by a driving mechanism on the outside thereof. The two ends of the moving seat 3 are respectively installed with fixed supports 4, between the fixed supports 4 are installed a screw rod 5, the screw rod 5 is installed with two spaced sliders 6, the sliders 6 are facing or facing each other synchronously. Relatively moving, a fixed beam 7 is installed above the movable base 3, and a screw rod 2 8 corresponding to the screw rod 1 5 is installed below the fixed beam 7, and two spaced sliding blocks 9 are installed on the screw rod 2 8. The block two 9 and the corresponding sliding block one 6 are connected and fixed by a lifting frame. A horizontally movable circulating conveyor belt 10 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com