Basement outer wall post-cast strip structure and construction method

A technology for basement exterior walls and post-pouring belts, which is applied in building construction and construction, and can solve problems such as difficult construction, unfavorable health of construction personnel, and cracks, and achieve a good installation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-5 The application is described in further detail.

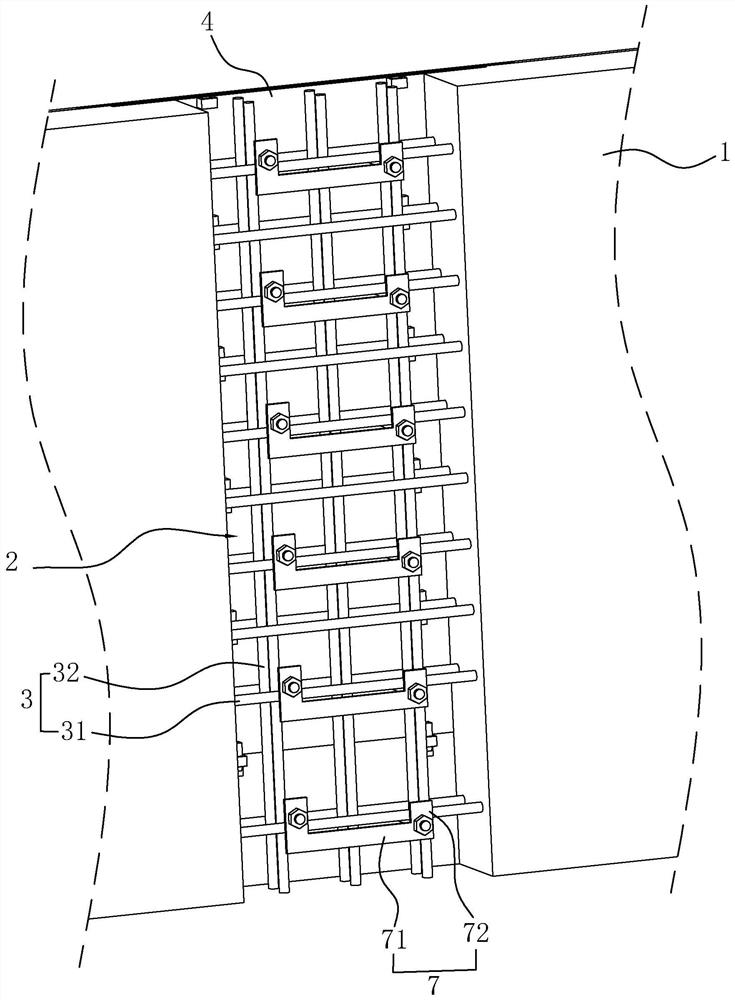

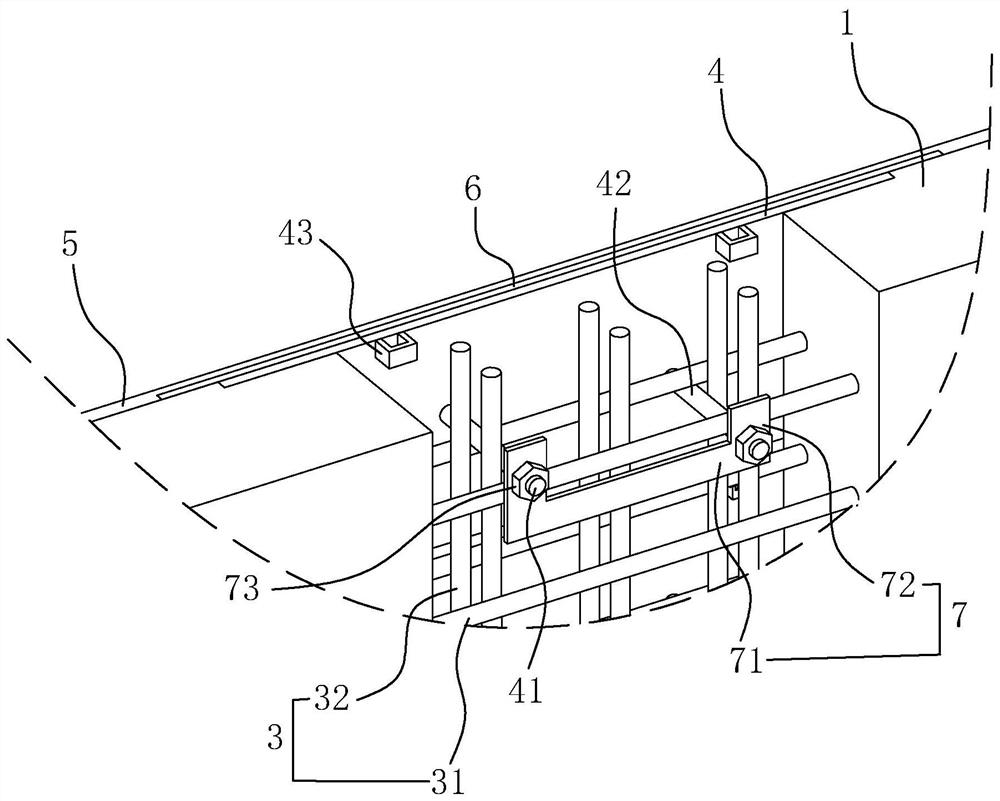

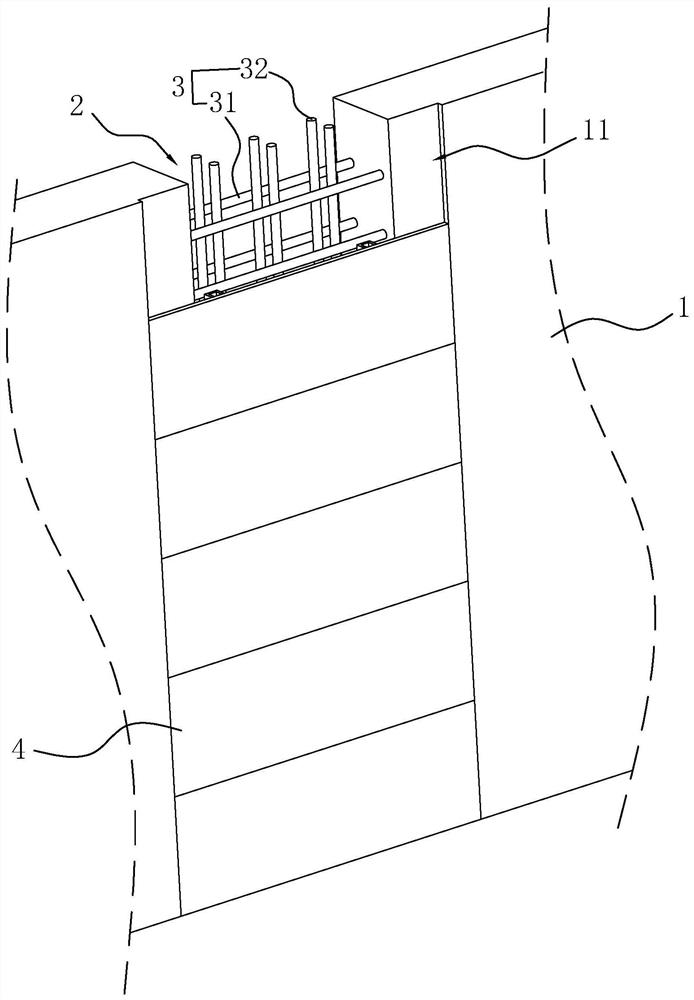

[0042] The embodiment of the present application discloses a structure of the post-cast belt of the basement exterior wall, referring to figure 1 with figure 2 , including an outer wall 1, a vertical post-casting belt 2 is arranged on the outer wall 1, and a steel mesh 3 is exposed on the post-casting belt 2. The reinforcement mesh 3 includes a transverse axis 31 and a longitudinal axis 32, and the transverse axis 31 and the longitudinal axis 32 intersect each other at right angles. A number of steel plates 4 are arranged longitudinally on the outside of the post-casting belt 2. The thickness of the steel plates 4 is 6 mm, or 8 mm. The longitudinal height of the steel plates 4 is 600 mm, or 800 mm. Such as image 3 As shown, the outer wall 1 is provided with a side groove 11 with the same thickness as the steel plate 4 on the side close to the post-casting belt 2 , and the later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com