Sealing device for hub bearing

A technology for sealing devices and wheel hub bearings, applied to shafts and bearings, bearing components, casters, etc., can solve problems such as seal wear failure, general sealing performance, grease leakage, muddy water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

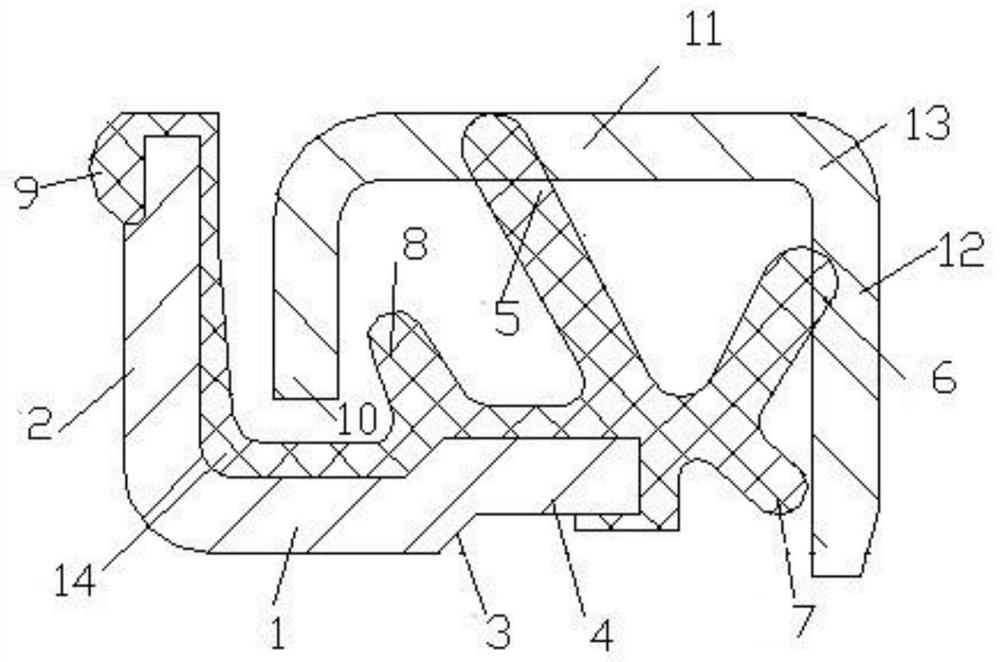

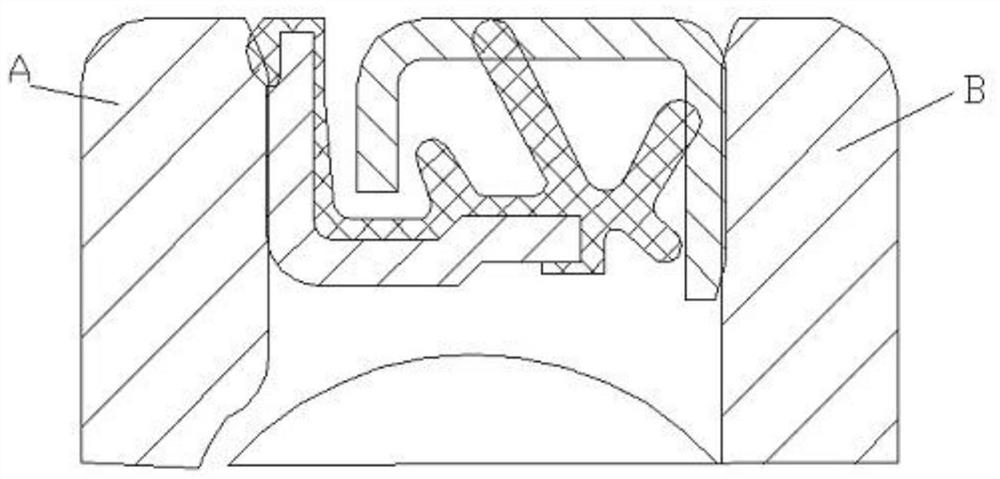

[0029] Such as figure 1 As shown, a sealing device for hub bearings includes a rigid frame 1 for the outer ring, a retaining ring 13 for the inner ring, and a rubber layer 14. The rigid frame 1 for the outer ring is fixedly connected to the rubber layer 14, and the rubber layer 14 has four A protruding sealing lip, the port of the sealing lip is arc-shaped, wherein at least two sealing lips are obliquely abutting against the inner retaining ring 13 .

[0030] The design of the inclined sealing lip can reduce the contact area and reduce energy consumption, and the design of multiple inclined sealing lips can improve its sealing performance. The sealing device for the wheel hub bearing and the wheel hub bearing with this structure can improve the sealing failure caused by wear and improve the sealing performance.

[0031] It can be understood that, in order to match the annular shape of the bearing, the rigid frame 1 of the outer ring, the retaining ring 13 of the inner ring, t...

Embodiment 2

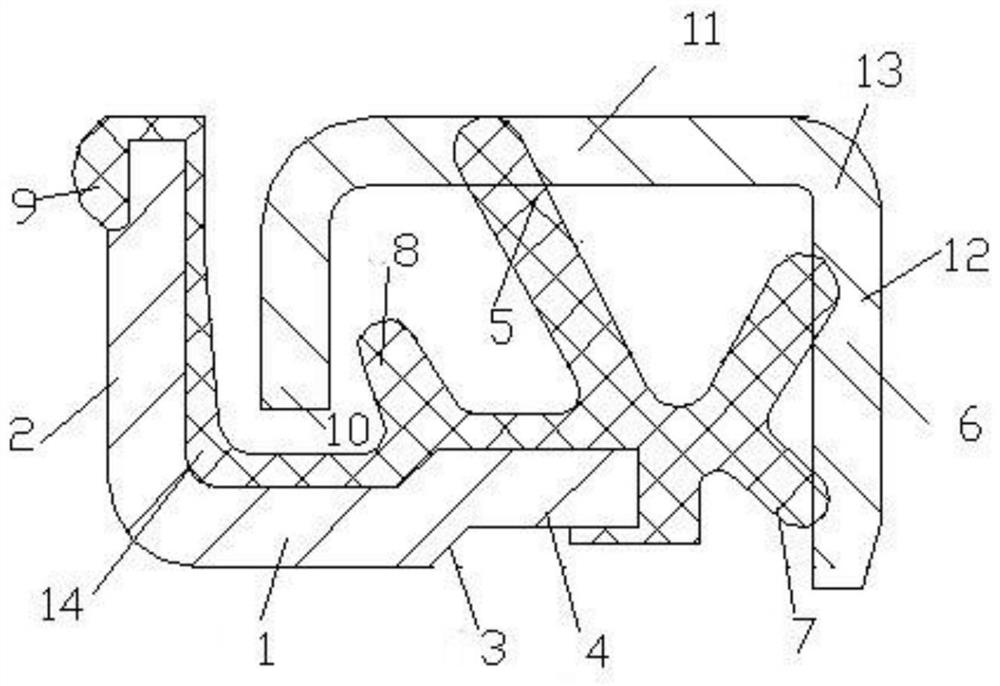

[0041] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that three sealing lips abut against the inner ring retaining ring 13, wherein the first sealing lip 7 and the second sealing lip 6 abut against the inner ring clamping The third sealing lip 5 abuts against the second connecting plate 11 .

Embodiment 3

[0043]Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that four sealing lips abut against the inner ring 13, wherein the first sealing lip 7 and the second sealing lip 6 abut against the inner ring The third sealing lip 5 abuts against the second connecting plate 11 , and the fourth sealing lip 8 abuts against the first blocking plate 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com