Oil storage double-lip sealing ring

A technology for sealing rings and oil storage tanks, which is applied in the direction of engine sealing, electromechanical devices, casings/covers/supports, etc. It can solve problems such as loss of sealing ability, degradation, and surface wear of sealing rings, and achieve good sealing and lubrication effects. Easy production and processing, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

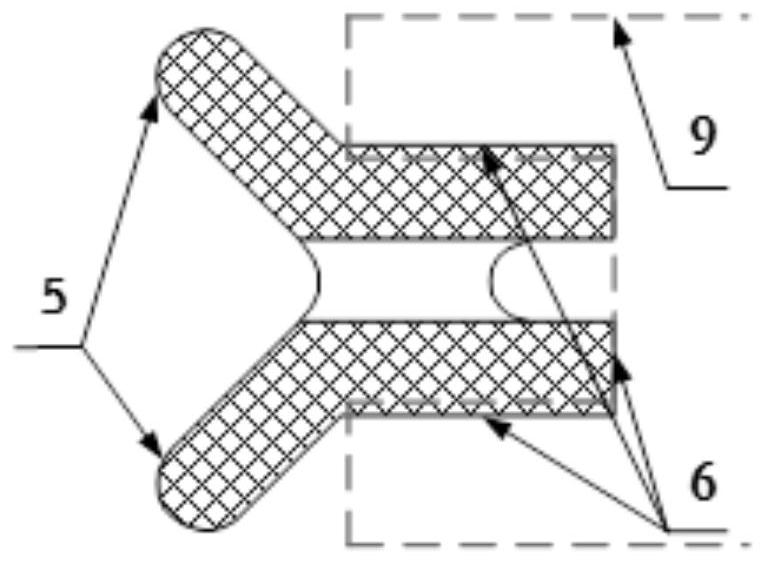

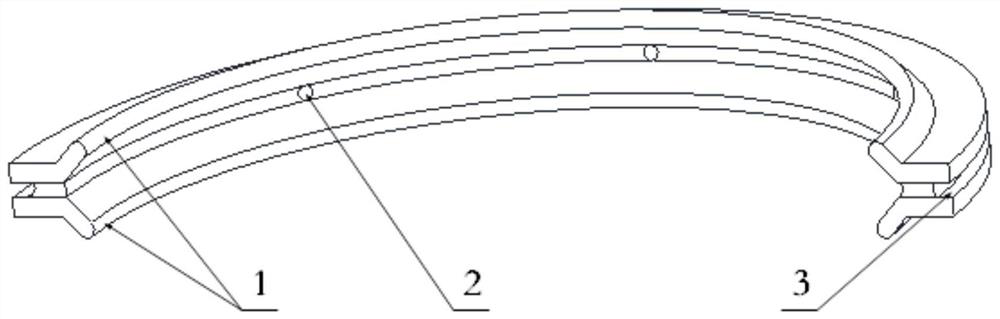

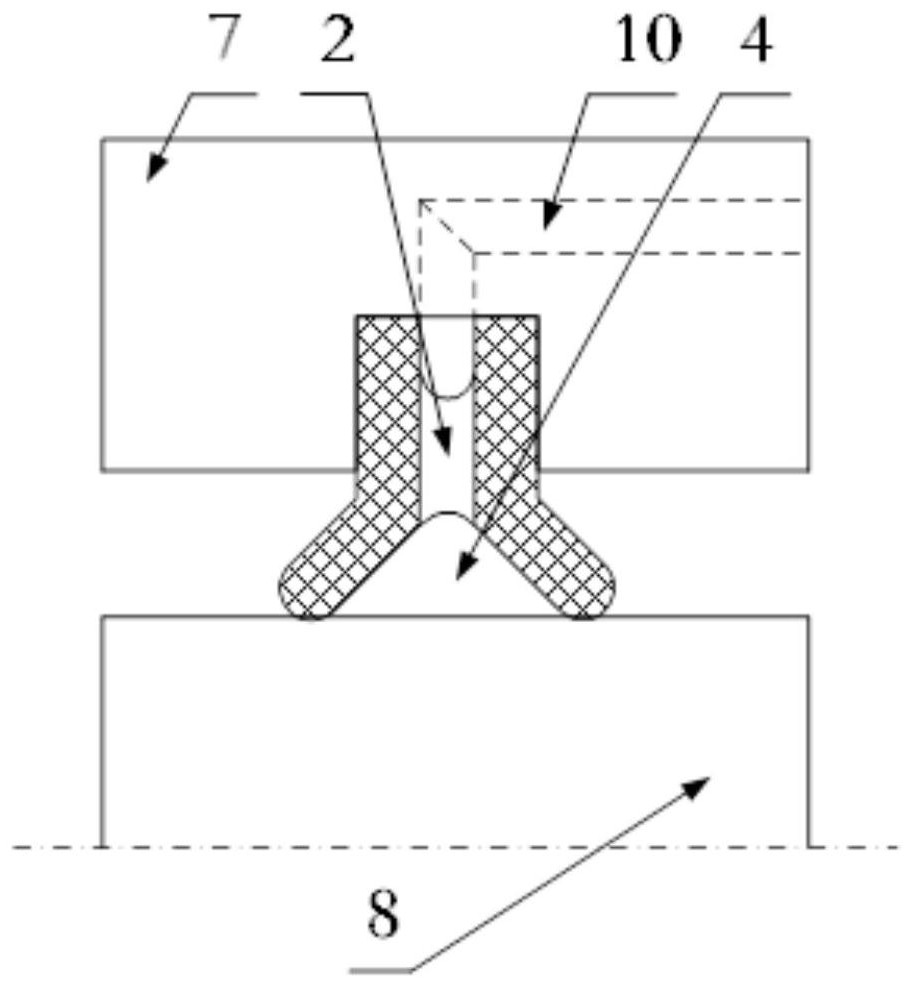

[0024] The oil storage double lip sealing ring of the present invention, such as figure 1 , 2 , as shown in 4, including the sealing ring body and the sealing lip 1 on one side of the sealing ring body, the sealing lip 1 is provided with two upper and lower arrangement; the side of the sealing ring body with the sealing lip is a dynamic seal The other side is the static sealing side 6, and the oil guide hole 2 communicating with the dynamic sealing side 5 is provided between the static sealing side 6 and the dynamic sealing side 5. In the present invention, an oil storage cavity 4 is formed between the sealing lips 1 , and an oil storage tank 3 is provided on the static sealing side 6 . Both the oil storage chamber 4 and the oil storage tank 3 are annularly arranged along the sealing ring. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com