Pipe clamp valve

A pipe pinch valve and valve body technology, applied in the direction of diaphragm valves, valve devices, engine components, etc., can solve the problems of hidden safety hazards, pollution, and high wear rate of lining pipes, and achieve the effect of guaranteeing safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

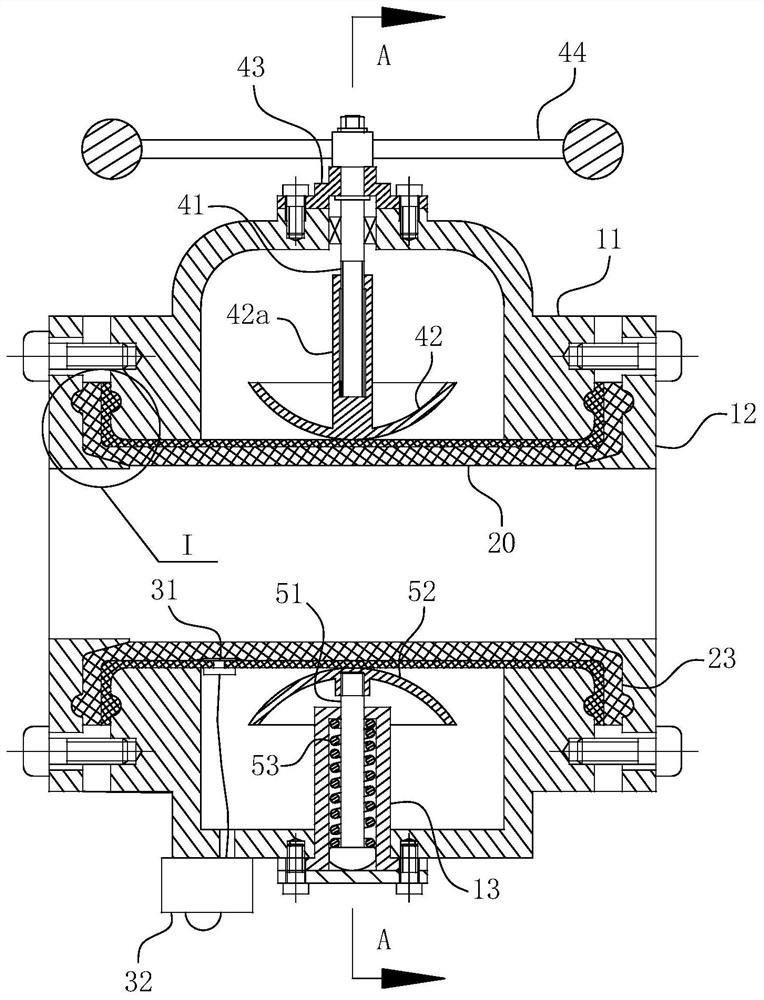

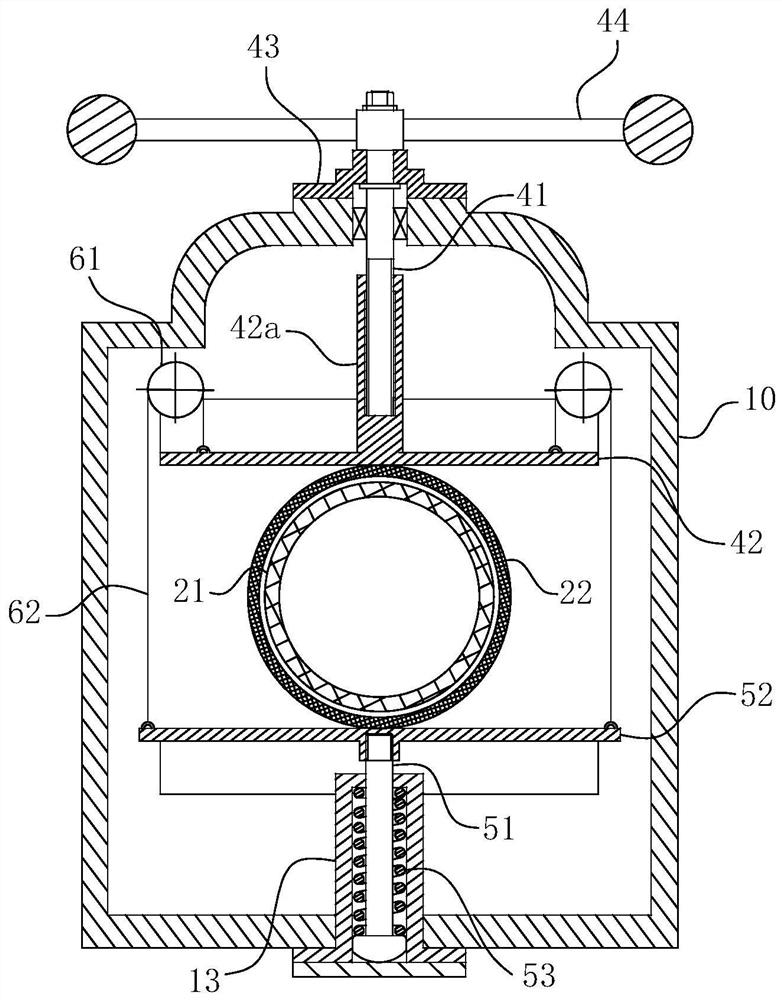

[0037] For ease of understanding, combined here Figure 1-4 , the concrete structure and working mode of the present invention are further described as follows:

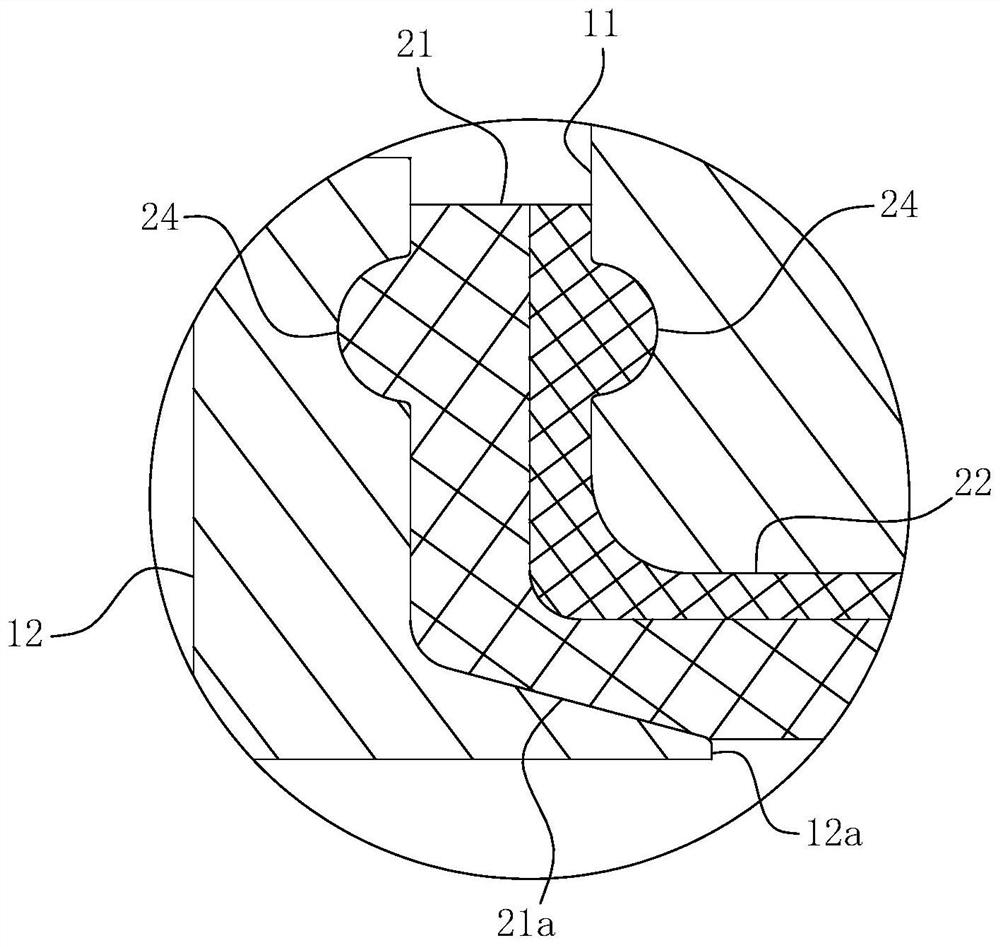

[0038] The specific structure of the present invention is as Figure 1-4As shown, the main structure includes a valve body 10, a switch part, a flow pipe 20 and a reversing assembly. Among them: the valve body 10 includes the middle valve pipe 11 and the flange end caps 12 which are located at both ends and form a flange fit; the flow pipe 20 consists of a liner pipe 21 as the inner casing and a protective pipe as the outer casing. 22 together constitute. The direction-changing assembly includes a traction rope 62 and a direction-changing wheel 61 to realize the synchronous movement of the power plate 42 at the upper pressing assembly and the follower plate 52 at the lower pressing assembly toward and away from each other.

[0039] Specific to figure 1 In the shown structure, it can be seen that: the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com