Determination method of carbon content of MTO catalyst

A measurement method and catalyst technology, which is applied in the direction of measuring devices, color/spectral characteristic measurement, and material analysis through optical means, can solve the problems of synthetic color errors, long analysis time, poor repeatability, etc., and achieve easy operation and step-by-step Simple, fast analysis of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

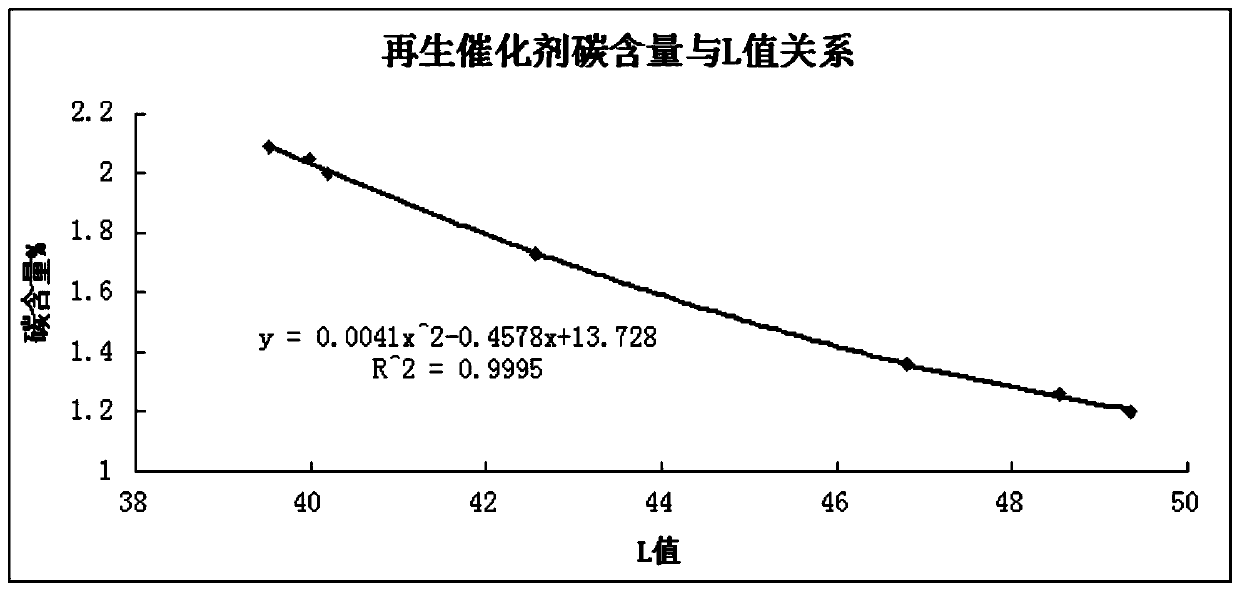

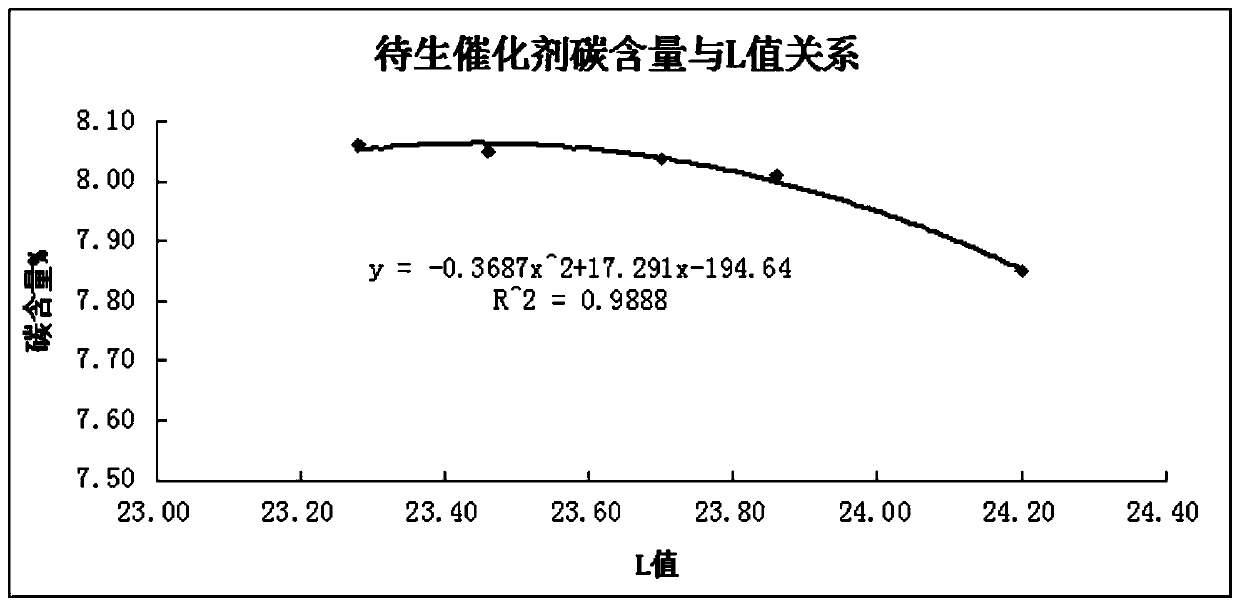

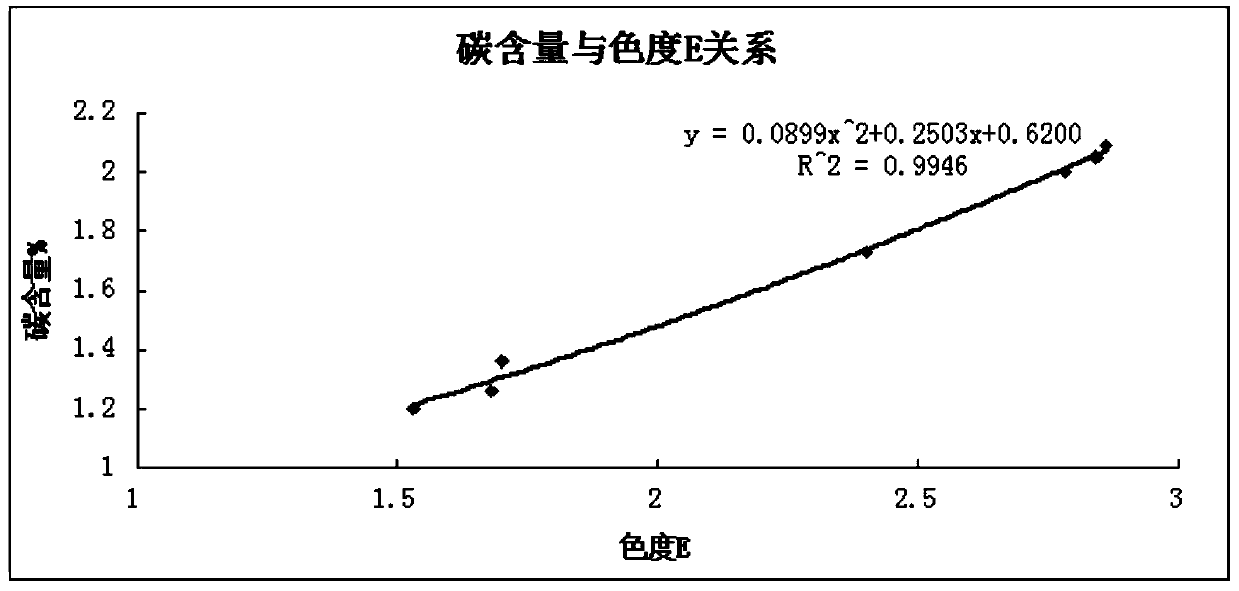

[0054] 1.1. Use the existing carbon analyzer or thermogravimetric method to analyze the data (the relative error of the combustion analysis method is not more than ± 2.0%), and collect catalyst samples with moderate gradient differences in carbon content, including regenerated catalysts and unborn catalysts. (note, 10 parallel measurements, take the average value), special attention, in the specific implementation, the regenerated catalyst and the spent catalyst are carried out separately, not mixed together, here is just to illustrate, we have two kinds of products That's all.

[0055] 1.2. Through multiple measurements, a series of catalyst samples with known carbon content were obtained. See Table 1 and Table 2 for the sample information.

[0056] 1.3. Set colorimeter parameters: use D65 light source and 10°observation angle.

[0057] 1.4. Measure the L value of each catalyst sample on a colorimeter, see Table 1 and Table 2.

[0058] Table 1. The L value measured by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com