Crankshaft journal cone angle detection device and using method thereof

A technology of angle detection and crankshaft journal, which is applied in the field of auto parts manufacturing, can solve the problems of low measurement accuracy of measurement methods, inability to use online detection of three coordinates, large detection errors, etc., and achieve simple structure, online and rapid detection, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

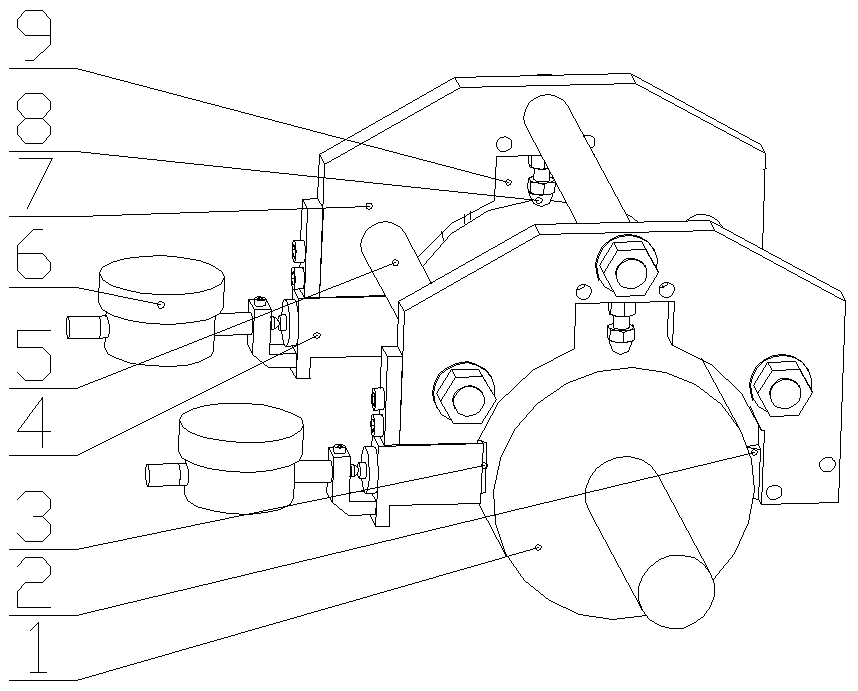

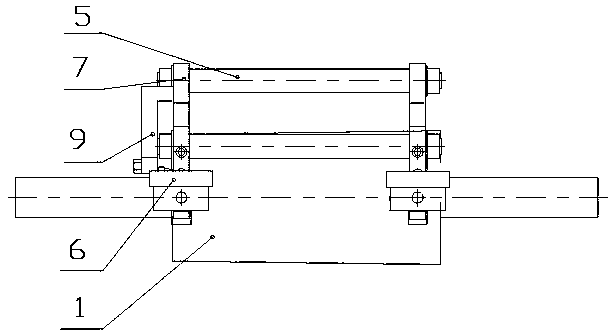

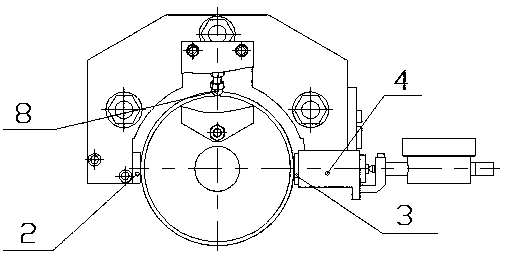

[0025] Such as Figure 1-3 As shown, a crankshaft journal cone angle detection device is mainly composed of two positioning plates 7, two gauge frames 4 and two dial gauges 6; the gauge frame 4 is fixedly mounted on the front end side of the positioning plate 7 above; the dial indicator 6 is fixedly installed on the meter frame 4; the positioning plate 7 is symmetrically arranged, and is fixedly installed together through three connecting rods 5, and the three connecting rods 5 are symmetrically and evenly arranged in the center and installed on two Between the block positioning plates 7; the positioning plate 7 is opened from the bottom, and a quasi-circular groove is set; three fulcrums are arranged on the groove surface of the quasi-circular groove, which are respectively arranged on the quasi-circular groove. The adjustable fulcrum 8 on the top, the movable fulcrum 3 arranged on the side of the table frame and having a radial preload, and the fixed fulcrum 2 arranged on th...

Embodiment 2

[0027] A crankshaft journal cone angle detection device, mainly composed of two positioning plates 7, two gauge frames 4 and two dial gauges 6; the gauge frame 4 is fixedly mounted on the front end side of the positioning plate 7; The above-mentioned dial indicator 6 is fixedly installed on the meter frame 4; the above-mentioned positioning plate 7 is symmetrically arranged, and is fixedly installed together through four connecting rods 5, and the four connecting rods 5 are symmetrically and evenly arranged in the center and installed on two positioning plates 7; the positioning plate 7 is opened from the bottom, and a quasi-circular groove is set; three fulcrums are arranged on the groove surface of the quasi-circular groove, which are respectively arranged on the top of the quasi-circular groove. The fulcrum 8, the movable fulcrum 3 arranged on the side of the watch frame and having a radial preload force, and the fixed fulcrum 2 arranged on the opposite side of the movable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com