Equipment and method for on-line determination of tobacco shred structures

A shredded tobacco structure and equipment technology, which is applied in the field of on-line determination of shredded tobacco structure by weighing method, can solve problems such as difficult control, large dispersion of shredded tobacco structure, and inability to reflect structural changes of shredded tobacco in time and accurately, achieving simple and easy operation and improving controllability , Detection and transformation of convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

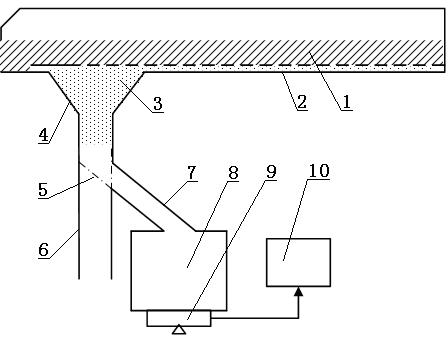

[0036] Such as figure 1 As shown, a device for measuring the structure of shredded tobacco on-line mainly includes a vibrating screen 2, an air duct 6, a pneumatic flap 5, a tobacco end pipe 7, an end product box 8, an electronic scale 9, and a control processor 10. The sieve 2 includes a feed end and a discharge end. The air duct 6 is located below the discharge end of the vibrating screen. The air duct 6 is provided with a side hole, and the tobacco powder pipe 7 connects the air duct 6 with the product through the side hole. The end box 8 is connected, the electronic scale 9 is arranged under the end product box 8, and is connected with the control processor 10, one end of the pneumatic flap 5 is fixed on the side hole of the air duct, and the other end is a free end that can be turned over arbitrarily.

[0037] The powder accumulation funnel 4 placed under the vibrating sieve 2 is respectively connected to the negative pressure air pipe 6 and the smoke powder pipe 7 throug...

Embodiment 2

[0039] Such as figure 1 As shown, the shredded tobacco 1 to be tested is passed through the vibrating sieve 2, and samples are taken 3 times at the feed end and the discharge end of the vibrating sieve 2 respectively, and each sampling amount is 1 kg. a=1.76%, the average value of end content at the discharge end b=0.73%.

[0040] thereby according to The model calculation of the shredded tobacco vibration sieving rate η=58.5%.

[0041] Pass the shredded tobacco 1 to be tested through the vibrating sieve 2, open the pneumatic flap 5, and detect the weight m of the tobacco powder screened within 5 minutes, and at the same time take a sample at the feeding end and determine the structure of the shredded tobacco to be tested in the laboratory (whole shred rate W, broken Silk rate B).

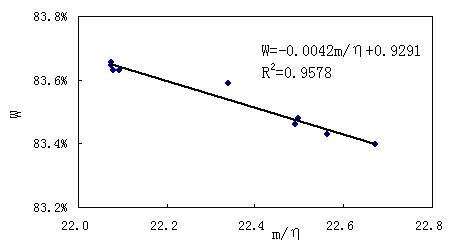

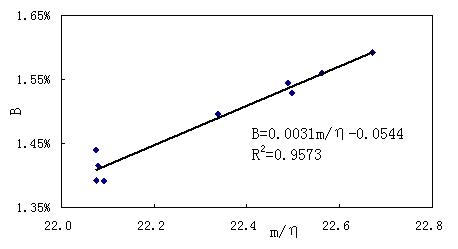

[0042] Randomly detect 10 times, establish the relationship model between the structure of the shredded tobacco to be tested, the weight m of tobacco powder, and the screening rate η, and input...

Embodiment 3

[0054] Such as figure 1 As shown, the shredded tobacco 1 to be tested is passed through the vibrating sieve 2, and samples are taken 3 times at the feed end and the discharge end of the vibrating sieve 2 respectively, and each sampling amount is 1 kg. a=1.76%, the average value of end content at the discharge end b=0.73%.

[0055] thereby according to The model calculation of the shredded tobacco vibration sieving rate η=58.5%.

[0056] Pass the shredded tobacco 1 to be tested through the vibrating sieve 2, open the pneumatic flap 5, and detect the weight m of the tobacco dust screened within 3 minutes. Silk rate B).

[0057] Randomly detect 10 times, establish the relationship model between the structure of the shredded tobacco to be tested, the weight m of tobacco powder, and the screening rate η, and input the model parameters into the control processor.

[0058] W=-0.0085m / η+0.9497

[0059] B=0.0096m / η-0.113

[0060] Among them, W-tobacco whole cut ratio, %;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com