Patents

Literature

42results about How to "Long detection period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for monitoring water-charging process and water-discharging process of washing machine

InactiveCN101929056AAvoid wastingAvoid security issuesOther washing machinesControl devices for washing apparatusWater dischargeEngineering

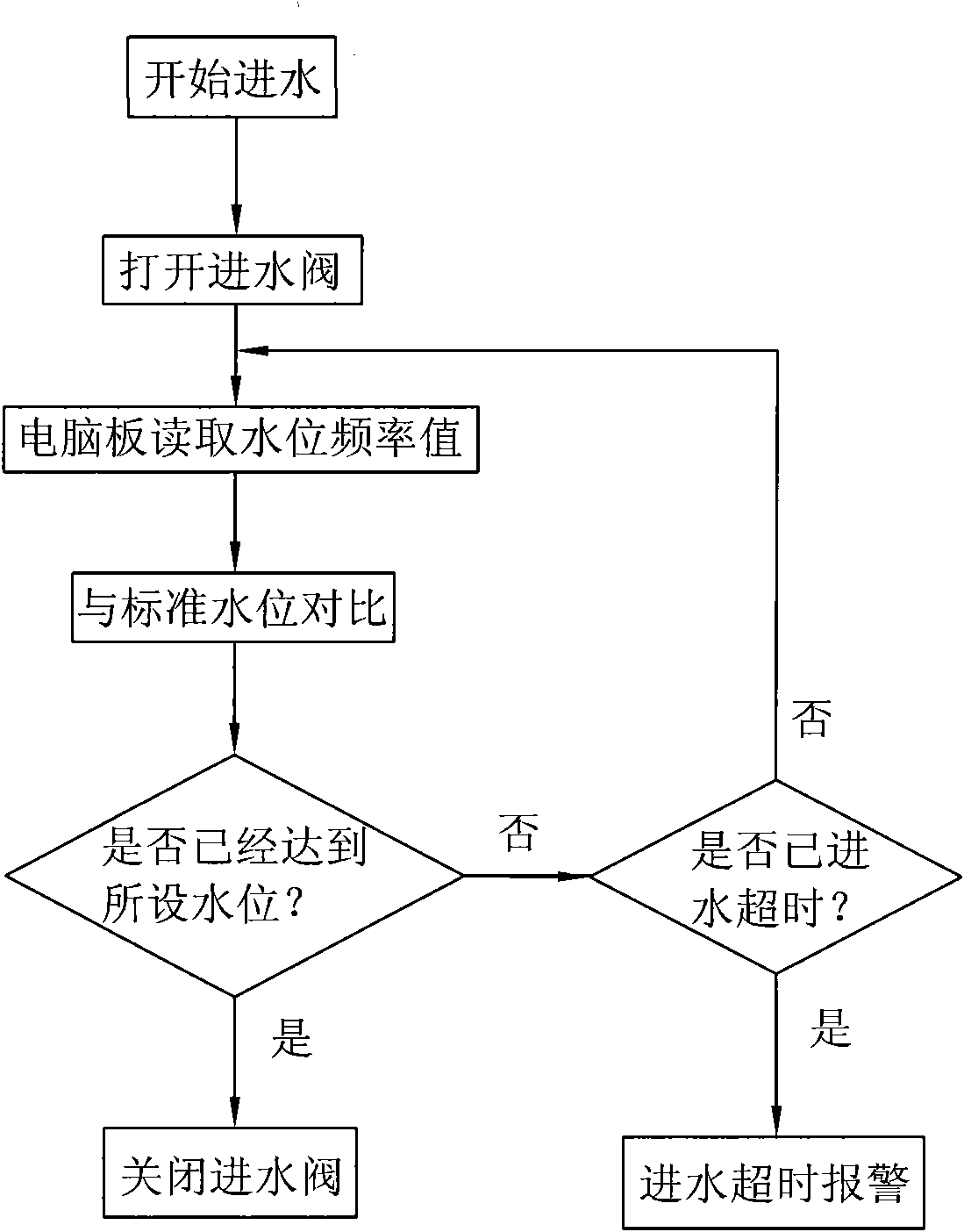

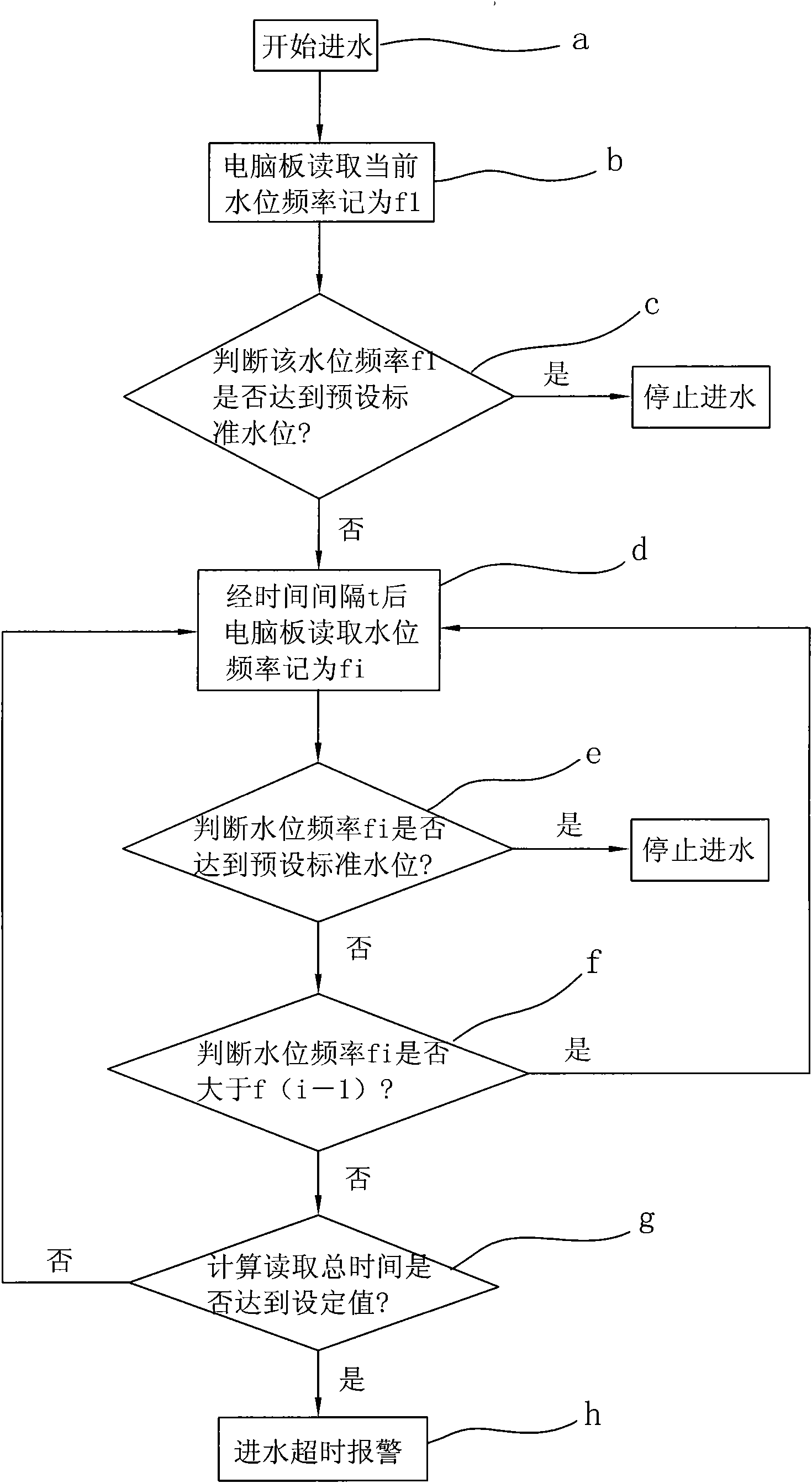

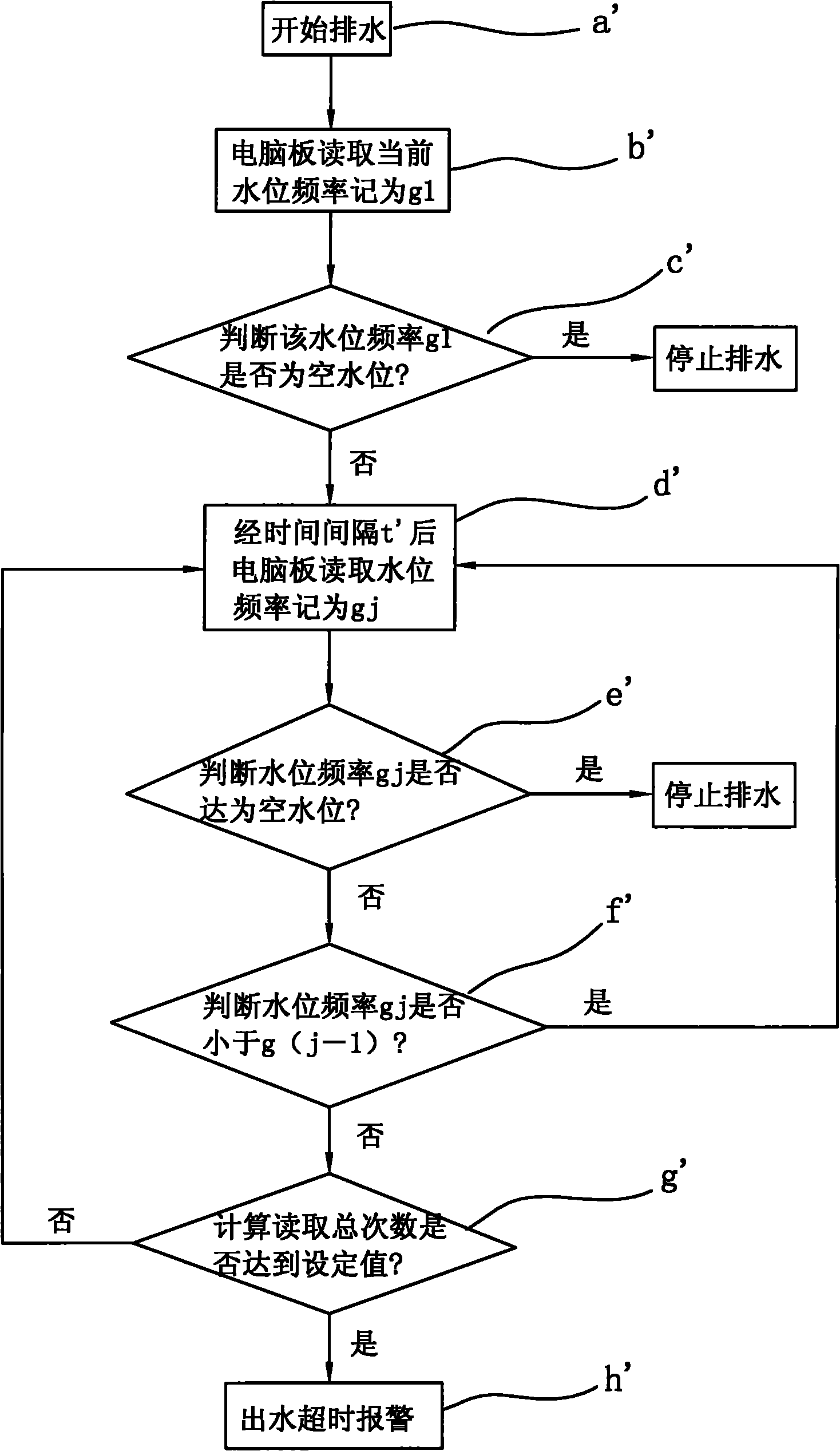

The invention discloses a method for monitoring the water-charging process and water-discharging process of a washing machine. The method comprises the following steps: in the water-charging process or water-discharging process, a computer board reads the water level frequency once after a set period of time; and if the water level frequency is not changed compared with the last water level frequency and the set total times of reading and the total time water level frequency are not changed, a water-charging overtime alarm or the water-discharging overtime alarm is executed. Every time when the computer board reads the water level frequency, the water level is compared with a preset water level to judge whether to reach the preset water level; if so, the water-charging process is stopped or the water-discharging process is started; if not, the water level frequency is compared with the next water level frequency to judge whether the water level frequency is charged; and the preset water level is the washing water level or empty water level. By adopting the method of the invention, the changes of the water level can be detected dynamically in the water-charging process or water-discharging process to judge whether the water-charging or water-discharging state is normal; and when the water-charging or water-discharging state is abnormal, the water-charging process or water-discharging process is stopped and the user is informed through the alarm.

Owner:HAIER GRP CORP +1

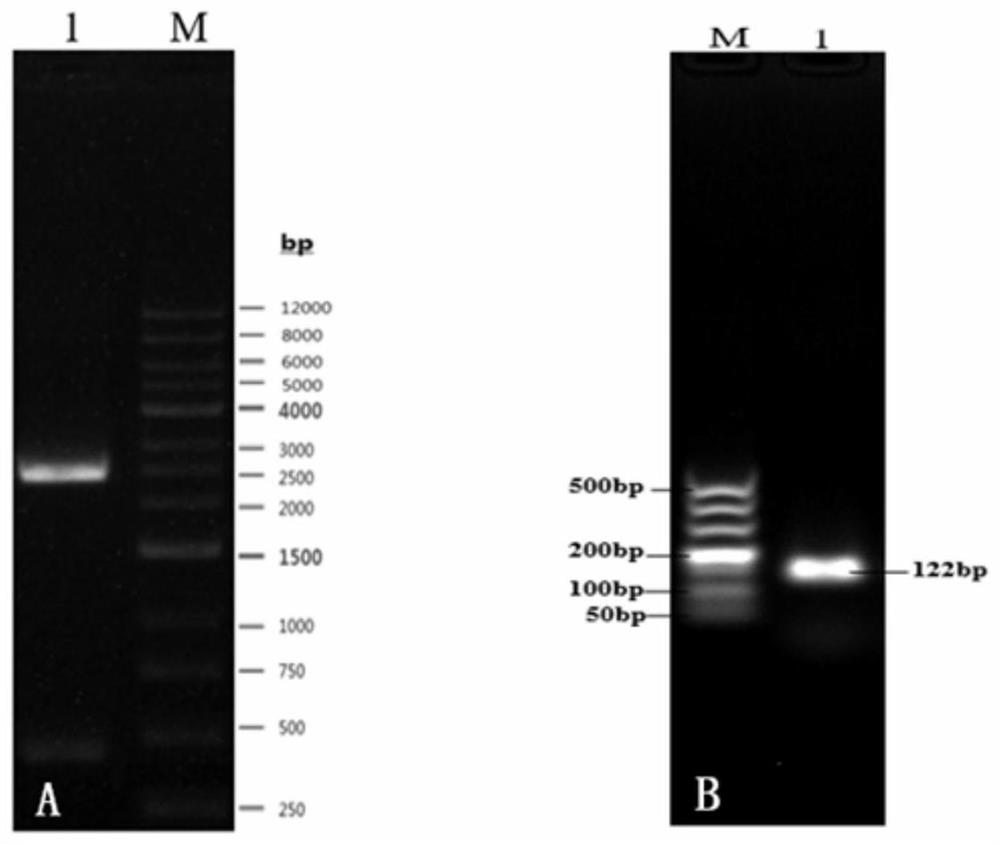

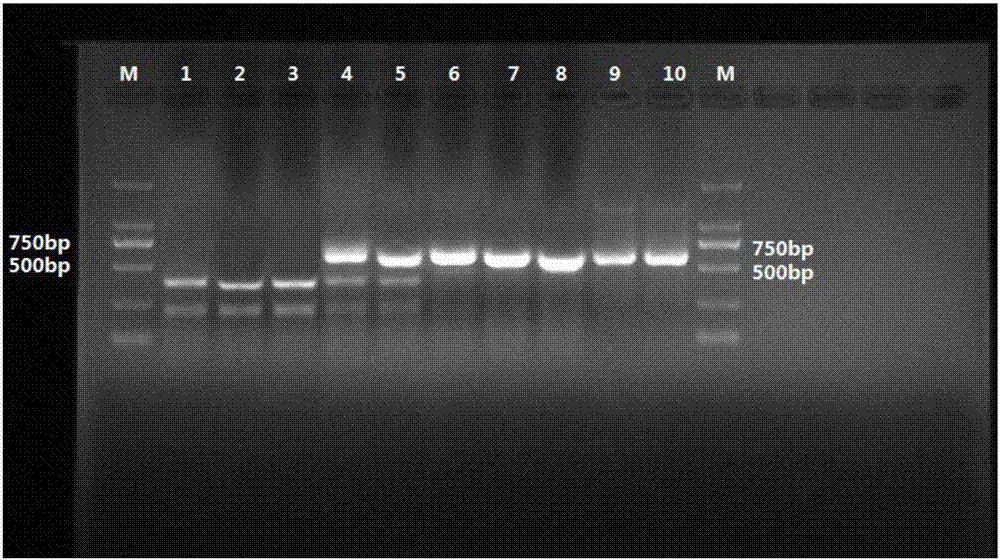

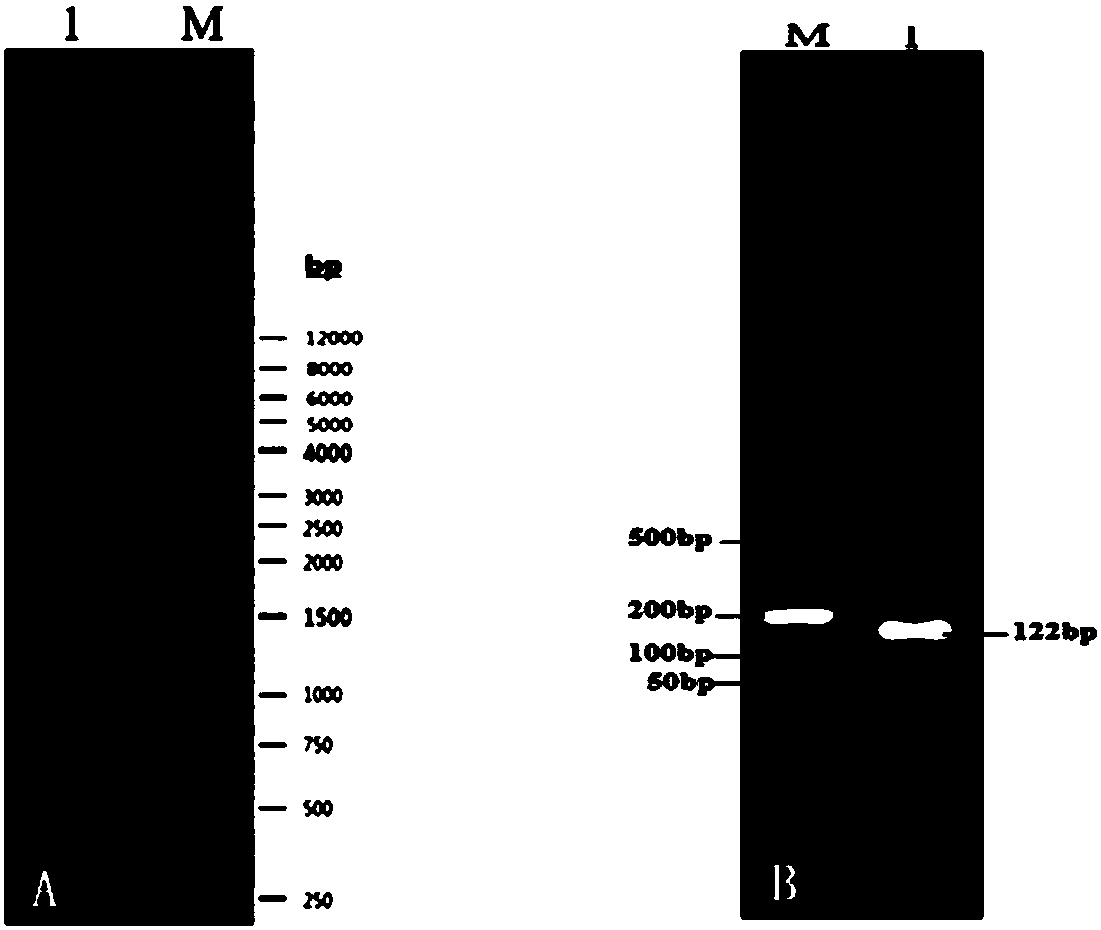

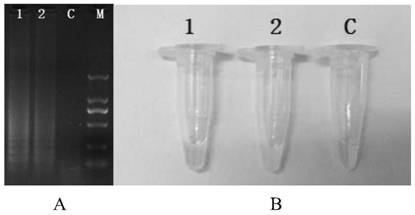

PCR detection and identification method capable of distinguishing pyricularia grise and magnaporthe oryzae

ActiveCN108707687AQuick and easy identificationRapid identificationMicrobiological testing/measurementMicroorganism based processesElectrophoresisDNA extraction

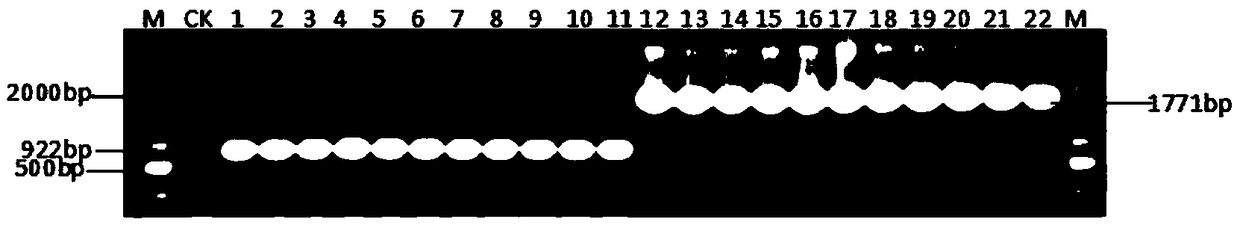

The invention discloses a PCR detection and identification method capable of distinguishing pyricularia grise and magnaporthe oryzae and belongs to the technical field of plant fungus molecule biological detection. The PCR detection and identification method includes the steps of A, extracting DNA, to be specific, respectively extracting DNA of pyricularia grise and magnaporthe oryzae; B, designing primers, to be specific, designing a pair of specific primers Mol3-F / Mol3-F by inserting two ends of the retrotransposon of 849bp into a coding region of avirulence gene PWL3 of pyricularia grise; C, performing PCR, to be specific, performing PCR amplification by taking the extracted total DNA of pyricularia grise and magnaporthe oryzae as a template, so as to obtain an amplification product; D,determiningresults, to be specific, subjecting the amplification product to electrophoresis detection, if a target band of 1771bp is detected, then determining the product as pyricularia grise; if aband of 922bp is detected, then determining the product as magnaporthe oryzae. The PCR detection and identification method can rapidly accurately distinguish pyricularia grise and magnaporthe oryzae which are difficult to distinguish, and has a great significance in field spreading, breeding and evolving of Pyricularia on natural conditions.

Owner:GRAIN RES INST HEBEI ACAD OF AGRI & FORESTRY SCI

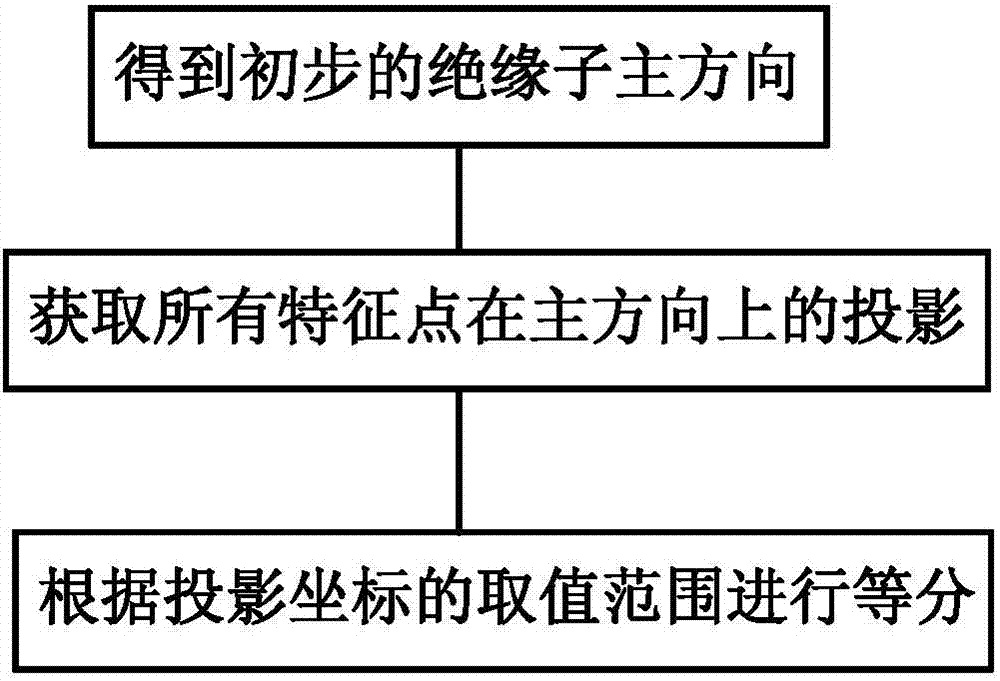

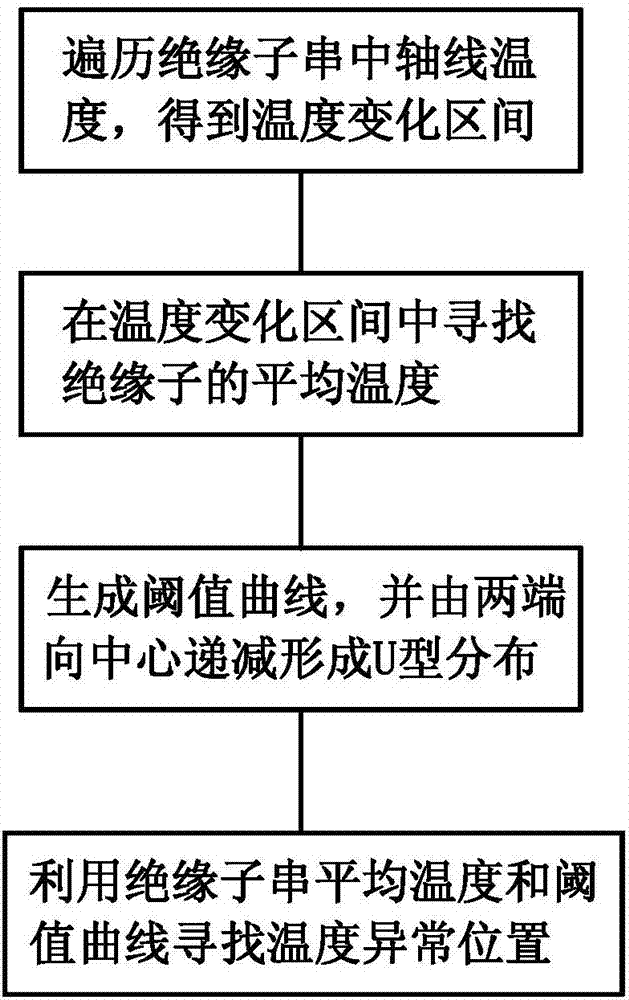

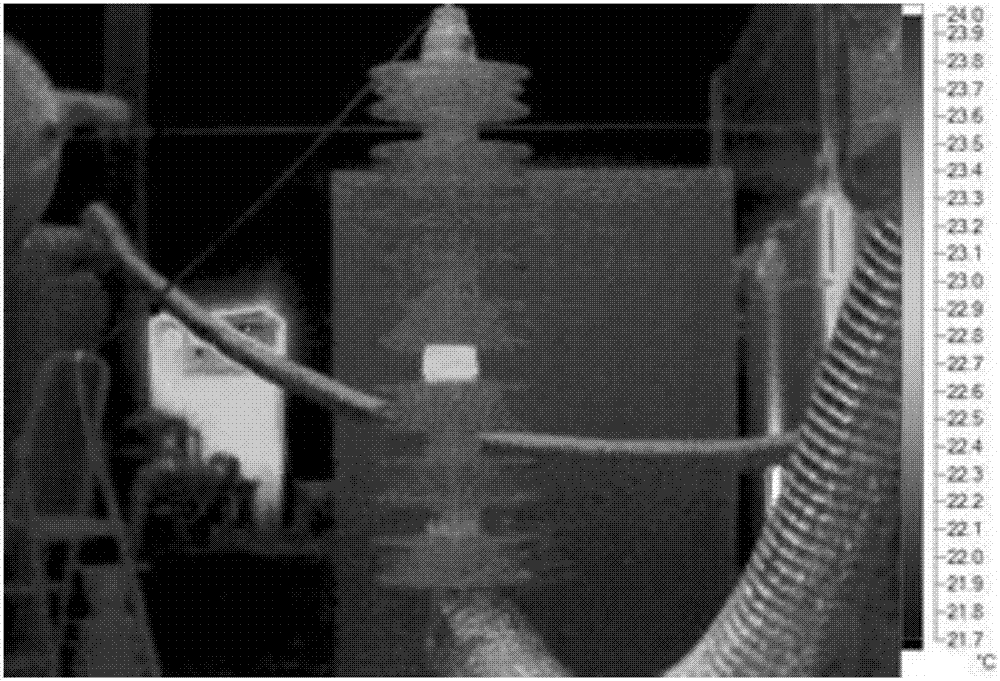

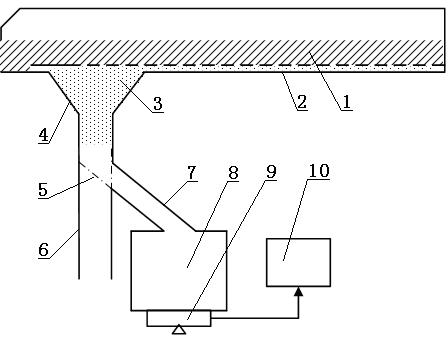

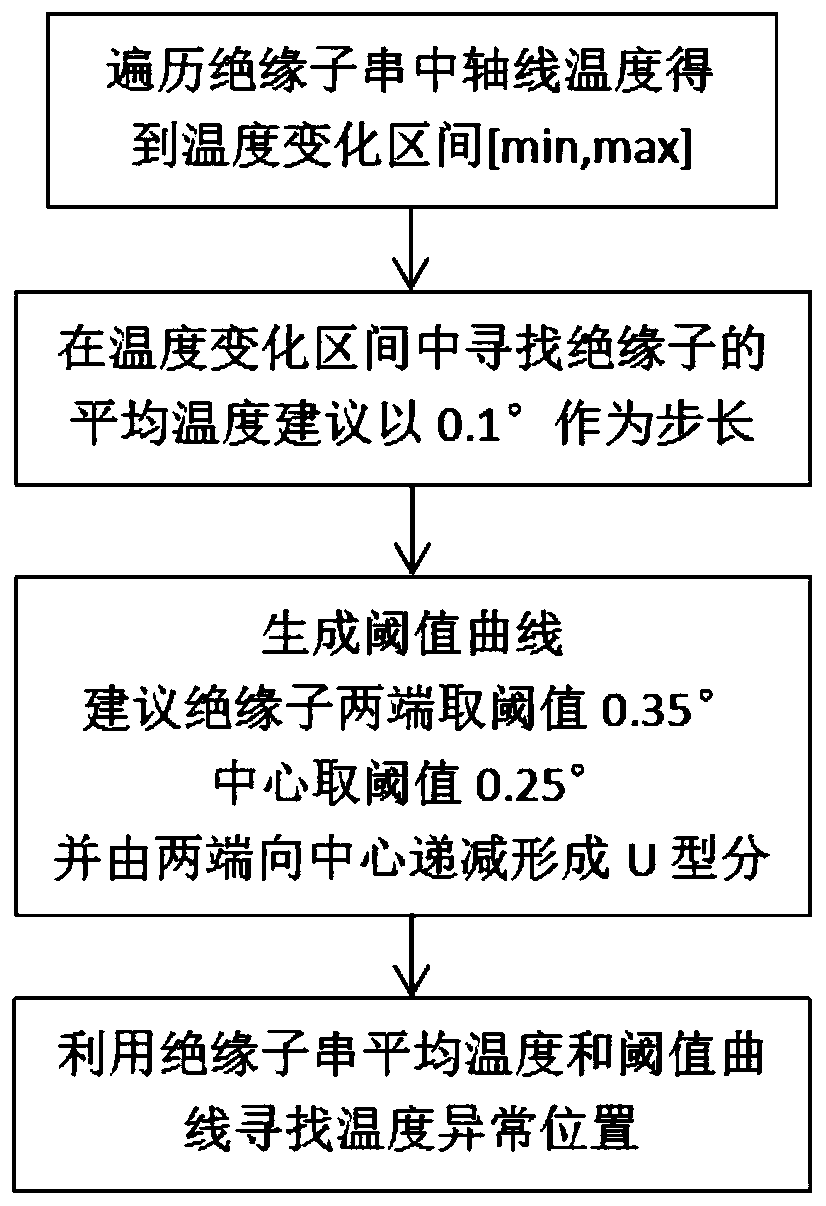

Insulator recognition and fault diagnosis method based on infrared image

InactiveCN106920240AIncrease security risksSave the steps of manual identificationImage enhancementImage analysisComputer graphics (images)Diagnosis methods

The invention discloses an insulator recognition and fault diagnosis method based on an infrared image. The method comprises the following steps of A, performing photographing on an insulator and performing image recognition for differentiating different insulators; and B, analyzing temperature characteristics of the different insulators in displaying in the image, and determining the insulator with the abnormal temperature characteristic as a faulted insulator. The insulator recognition and fault diagnosis method can settle defects in prior art and furthermore has advantages of high suitability of automatic checking in a complicated environment and low error determining rate.

Owner:STATE GRID CORP OF CHINA +2

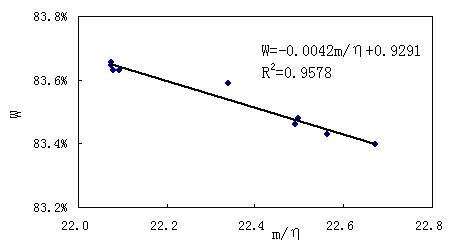

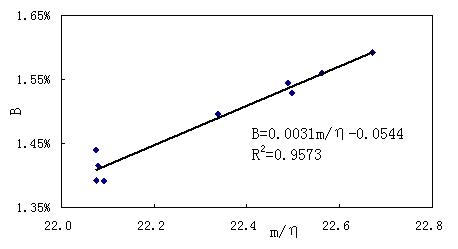

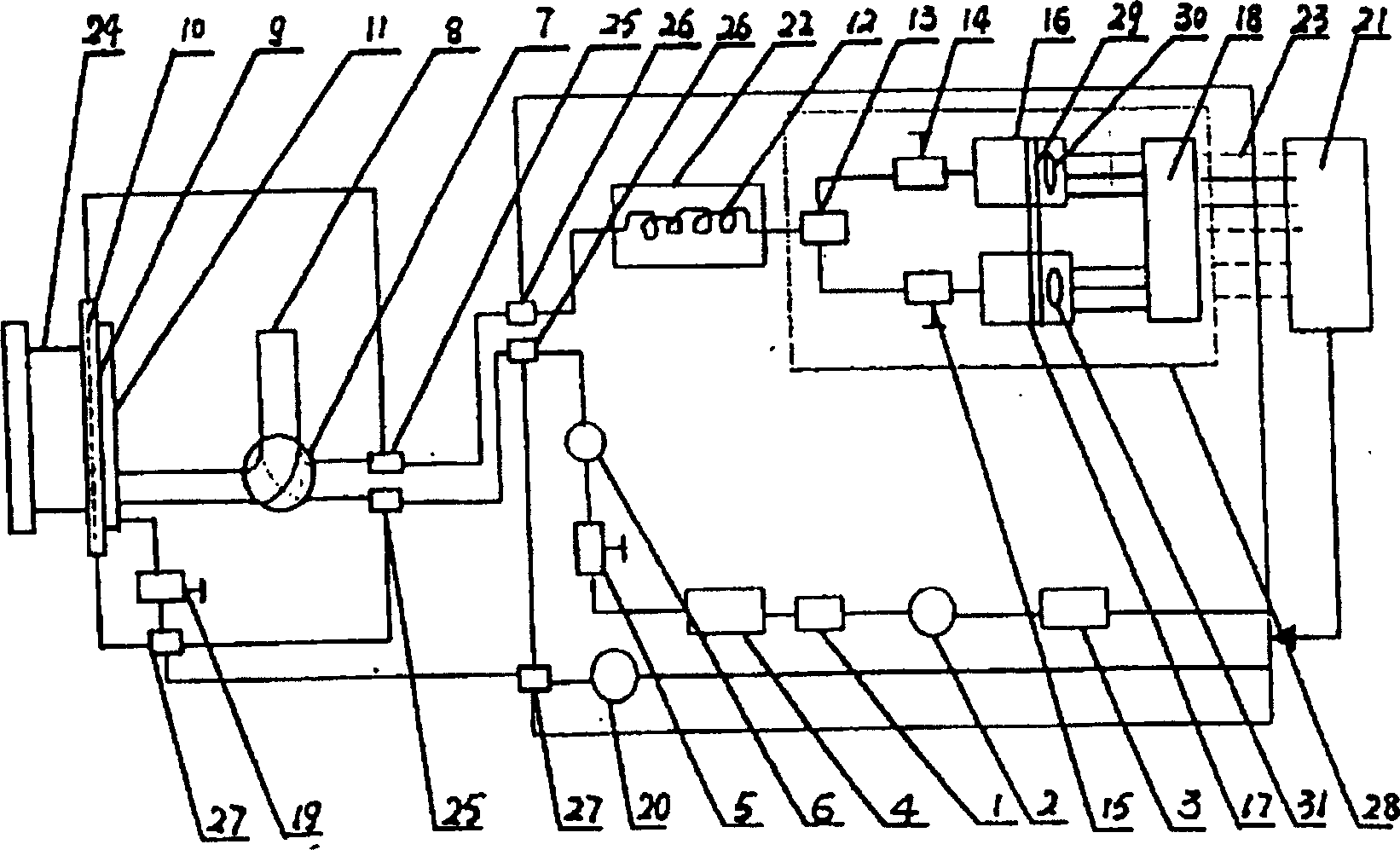

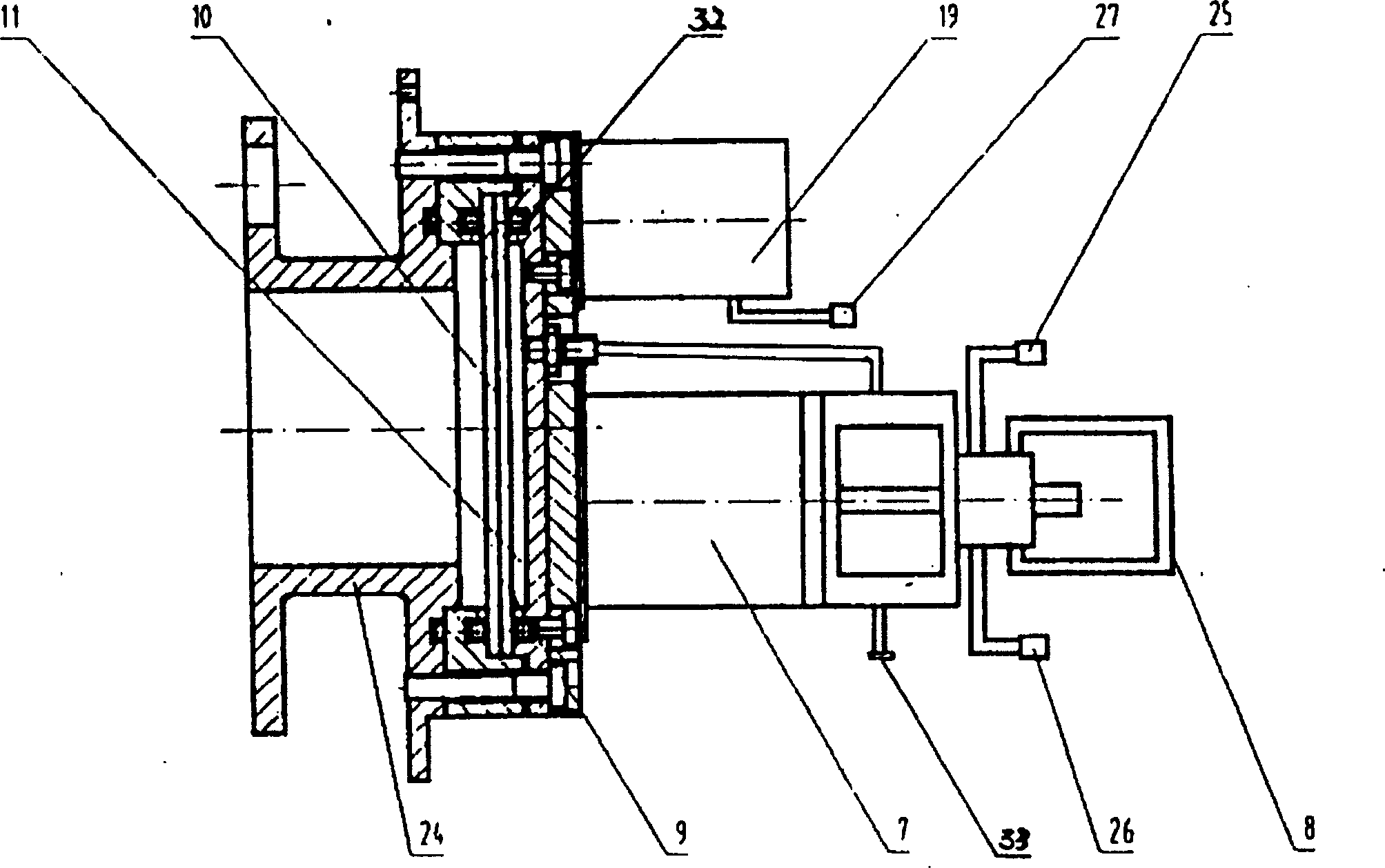

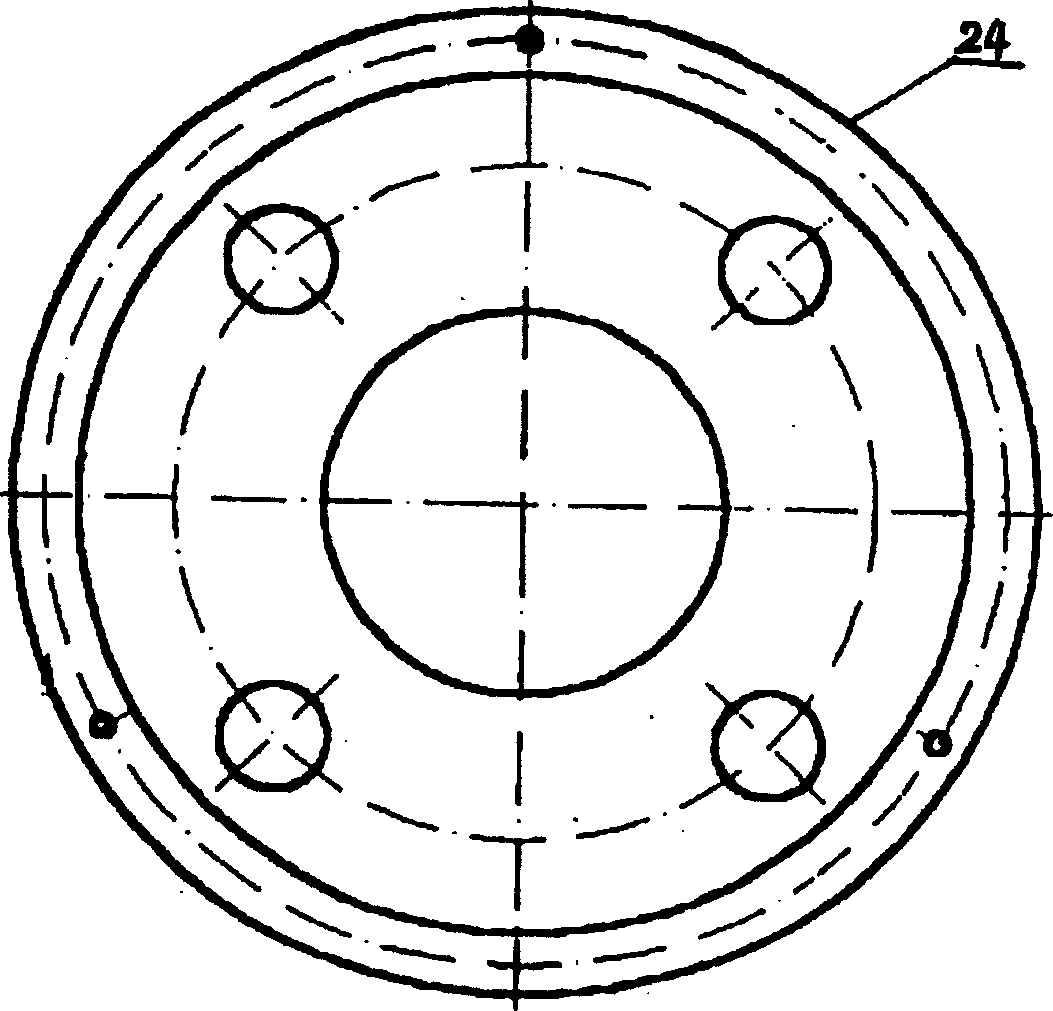

Equipment and method for on-line determination of tobacco shred structures

InactiveCN102539273ASmall amount of sampleReasonable detectionWeighing by removing componentEngineeringSieve

The invention relates to tobacco processing technology and equipment, in particular to a method and equipment for the on-line determination of tobacco shred structures by a weighing method. In order to solve the technical problem, the invention provides the method and the equipment for the on-line determination of the tobacco shred structures, so the tobacco shred structures can be accurately detected on line in real time. In order to realize the goal, the equipment for the on-line determination of the tobacco shred structures provided by the invention mainly comprises a vibration sieve, an air pipe, a pneumatic turning plate, a tobacco powder collection pipe, a powder accumulating box, an electronic scale and a control processor, and a matched determination method is provided, stability, reliability, harmlessness, simplicity and convenience are realized, the operation is easy, and simultaneously, the accuracy is high.

Owner:CHINA TOBACCO JIANGSU INDAL

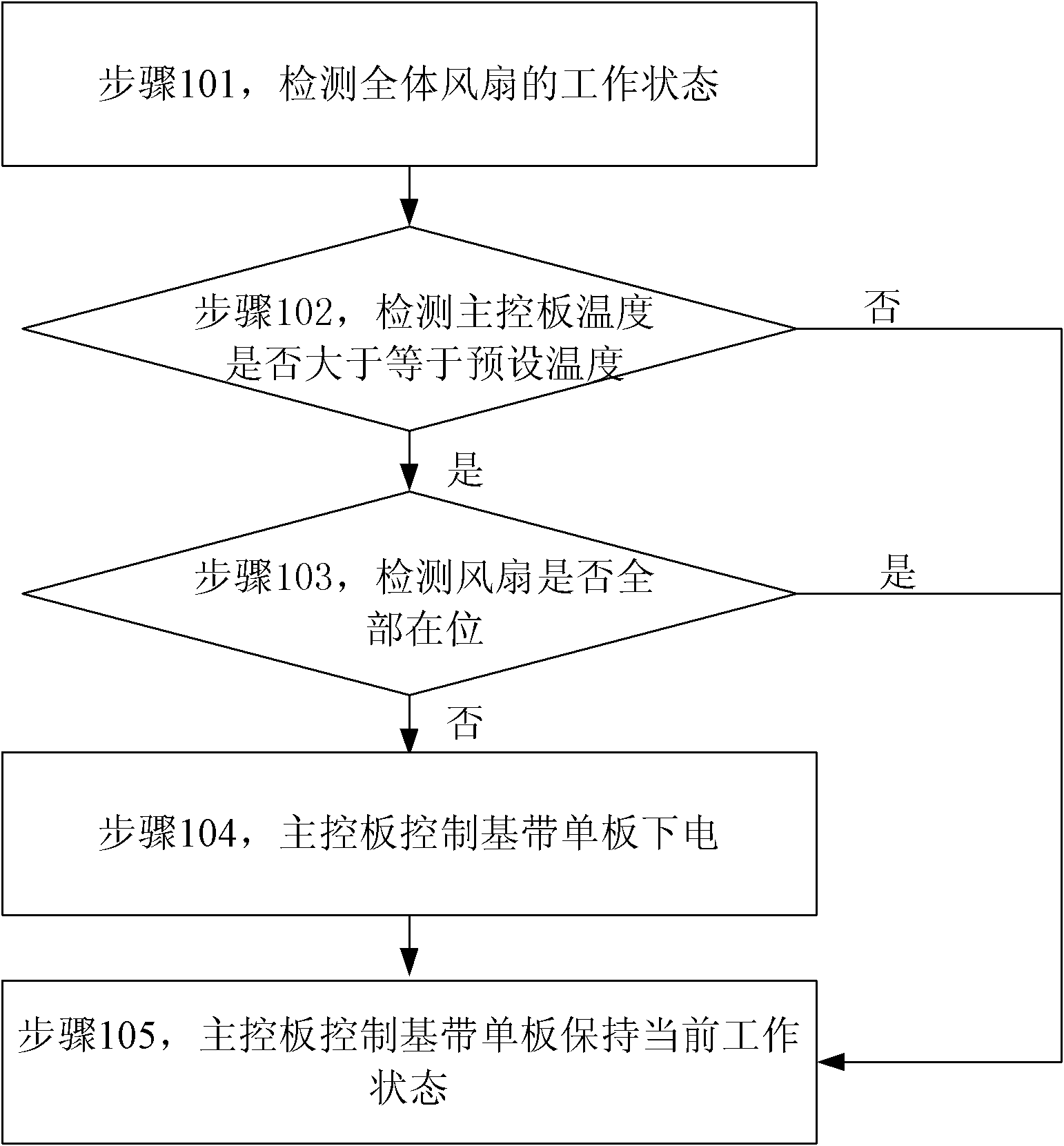

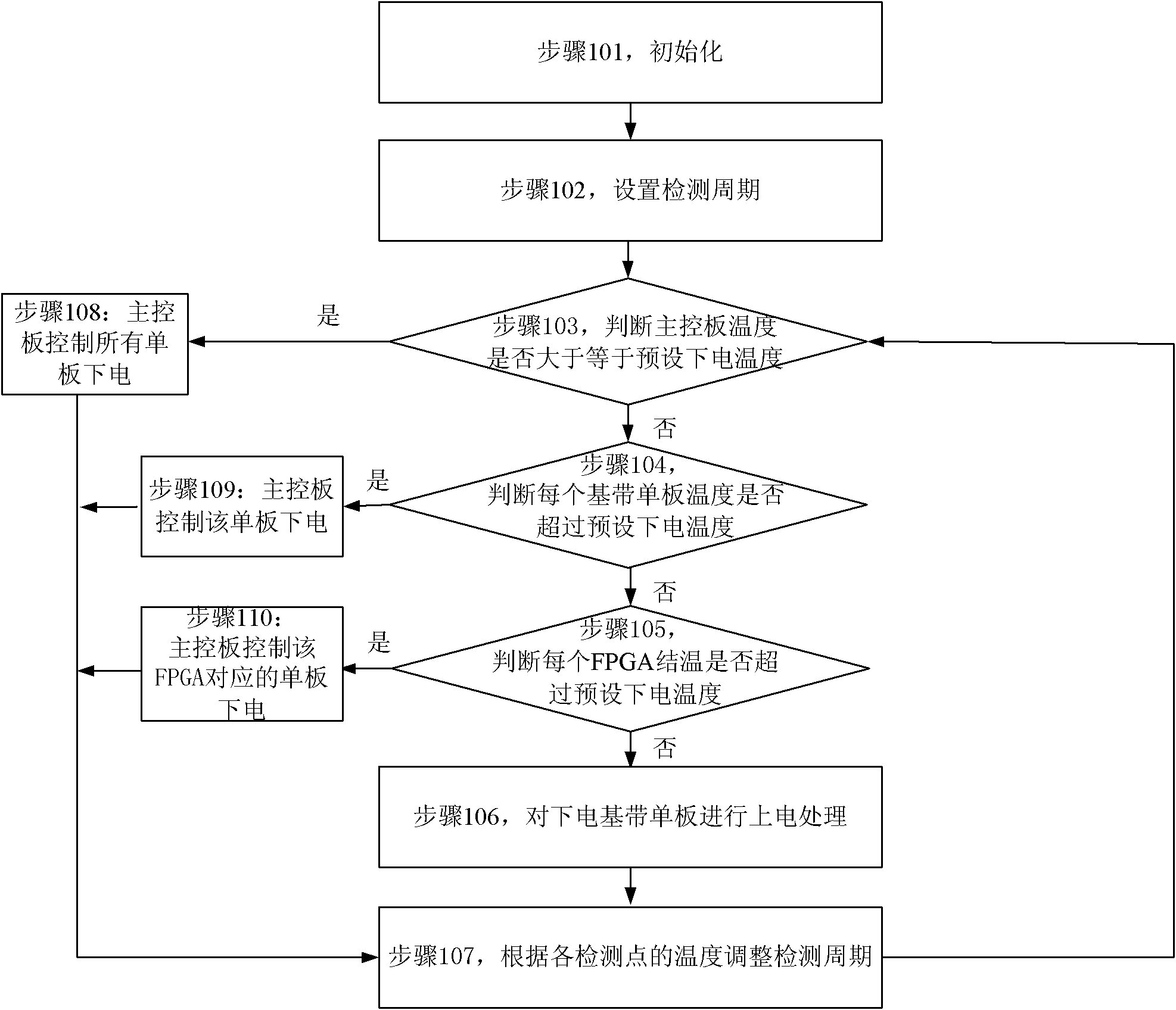

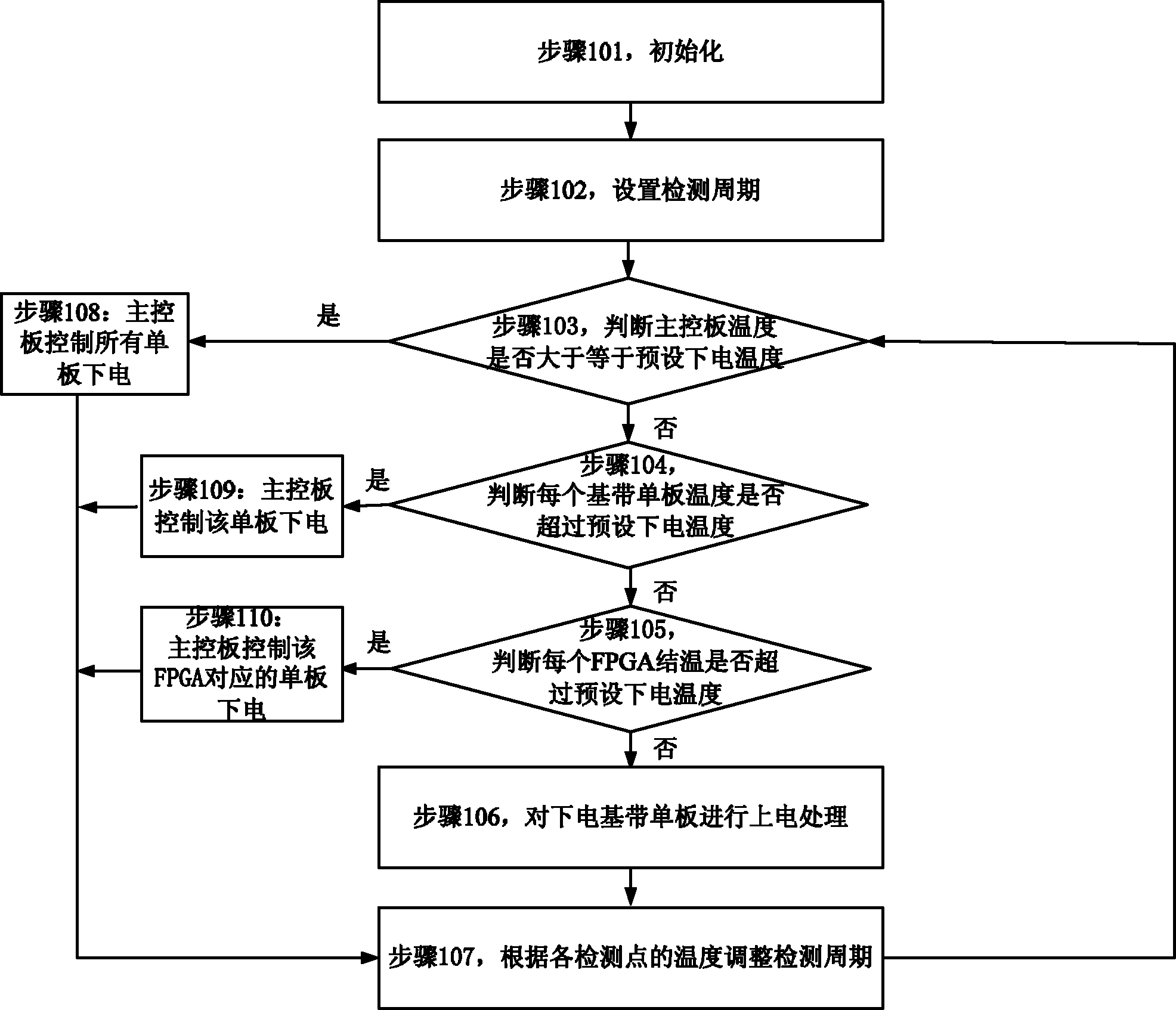

Method for controlling temperature of single plate

ActiveCN102609014AEffective protectionEffective recoveryTemperature control using electric meansElectricitySingle plate

The invention provides a method for controlling the temperature of a single plate. In each detection period, a main control panel is used for detecting the temperature of a main control panel, the temperature of each single plate, the field programmable gata array (FPGA) junction temperature of each single plate, and the working condition of a fan, when the temperature of the main control panel exceeds preset disconnection temperature, the disconnections of all the single plate are controlled by the main control panel; and when the temperature of the single plate or the FPGA junction temperature exceeds the preset disconnection temperature, the disconnection of the single plate is controlled by the main control panel. According to the method for controlling the temperature of the single plate, the working condition of the single plate is controlled by combining a plurality of parameters, such as the temperature of the main control panel, the temperature of the single plate, the FPGA junction temperature and the working condition of the fan, therefore, the high temperature protection and recovery can be effectively carried out on the single plate, and invalidation of high temperature protection caused by the invalidation of each device, such as sensors and the like can be avoided.

Owner:TD TECH COMM TECH LTD

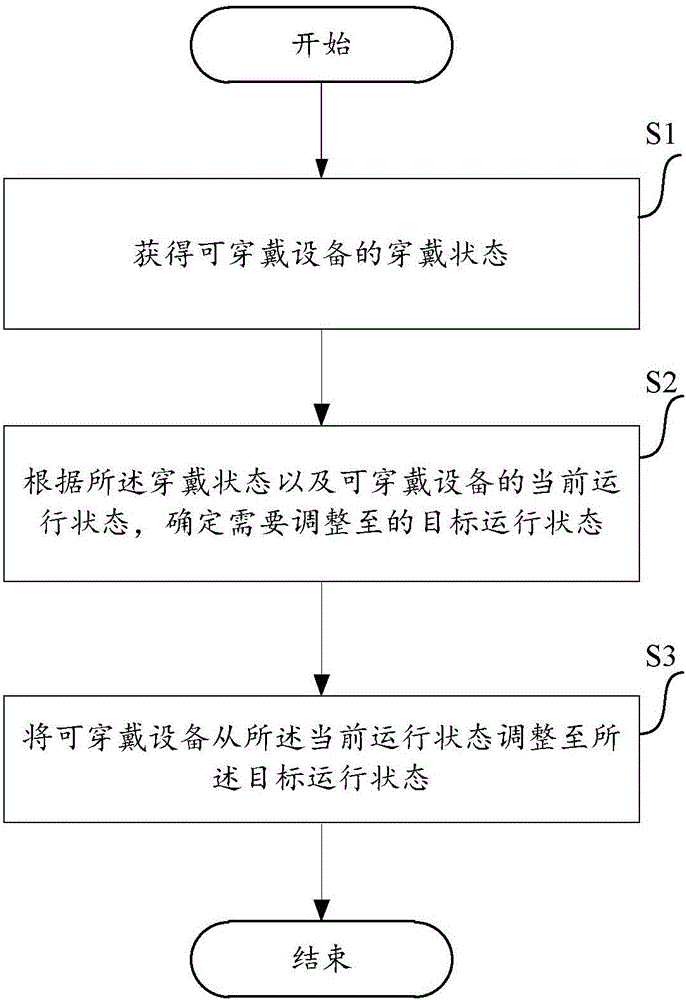

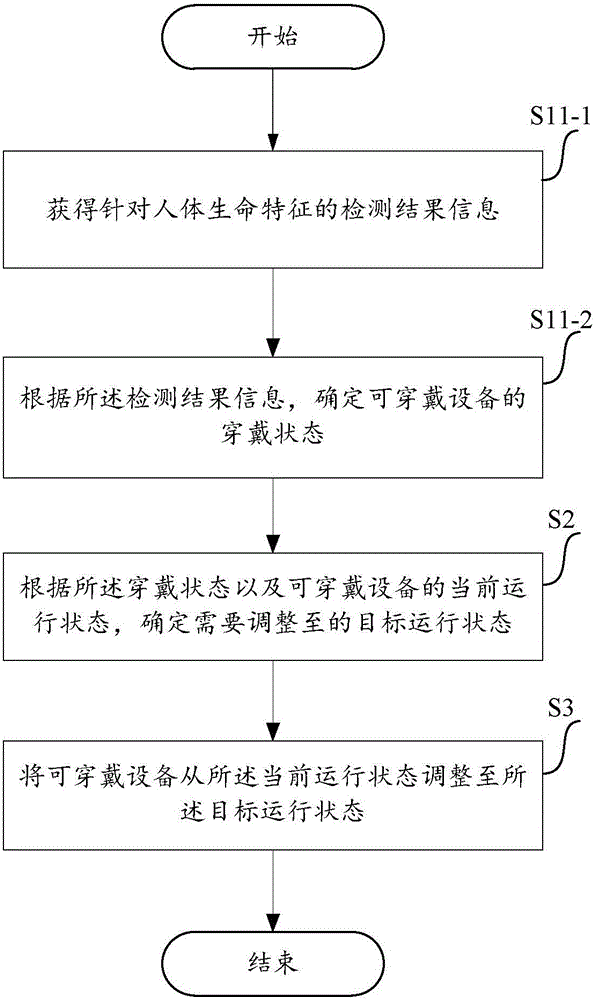

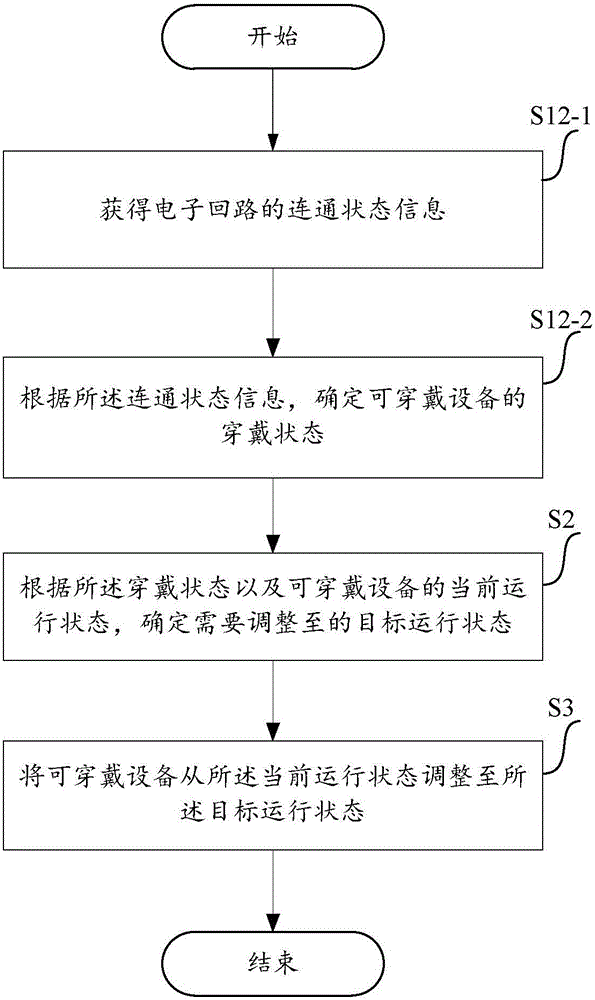

Method and device for adjusting operation state of wearable device

InactiveCN105094277AImprove intelligenceExtend standby timePower supply for data processingDetails for portable computersEmbedded system

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

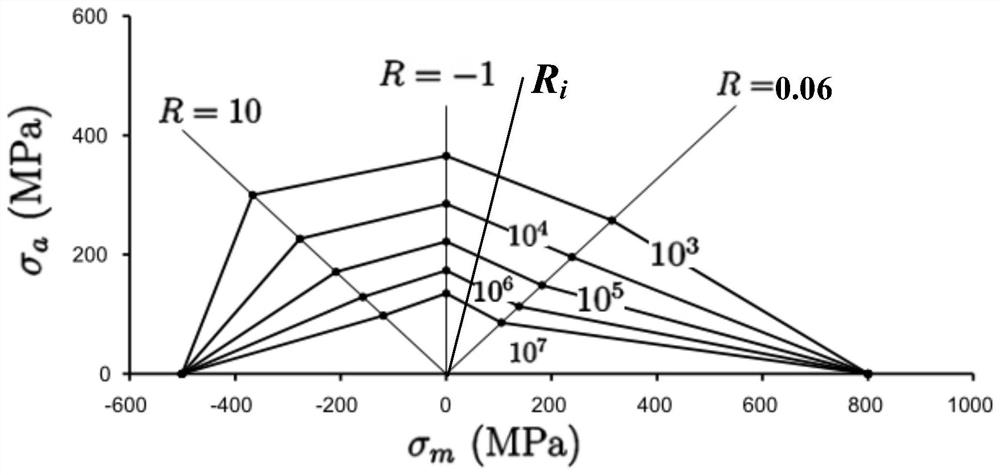

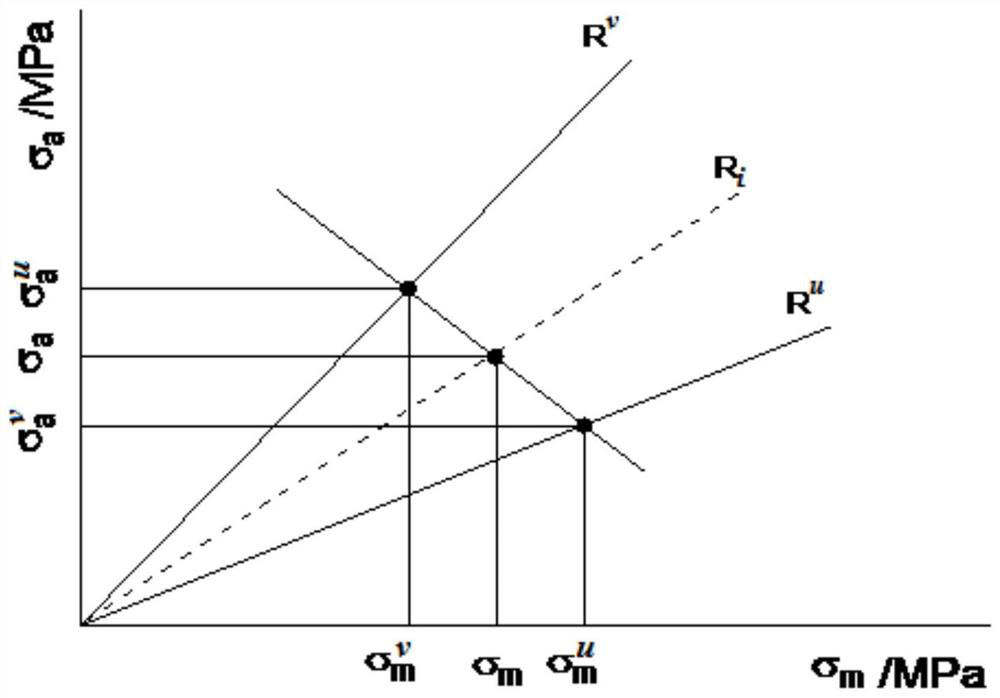

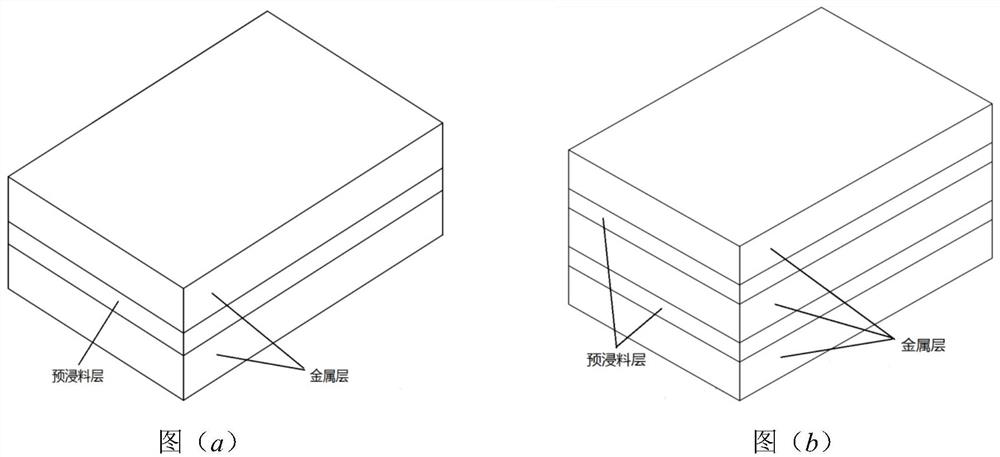

Fatigue life prediction method for fiber metal laminate under complex load

PendingCN112051146AImprove performanceA deep understanding of fatigueMaterial strength using tensile/compressive forcesFiber metal laminateLoad spectrum

The invention provides a fatigue life prediction method for a fiber metal laminate under a complex load. Firstly, a fatigue life test with the stress ratio of cyclic stress of 0.06, -1 and 10 is applied to a fiber metal laminate, a static tensile test and a static compression test are carried out on the fiber metal laminate, and then a constant-amplitude fatigue life value under each cyclic stressin a complex load spectrum is calculated based on a piecewise linear difference method. Finally, the cumulative damage rate of the complex load spectrum to the fiber metal laminate is calculated to obtain the fatigue life of the fiber metal laminate under any complex load. The average stress correction model suitable for the fiber metal laminate is provided, the fatigue life value under any stress ratio can be accurately solved, the irregular load spectrum characteristics are considered, the damage accumulation model considering the residual strength is corrected on the basis of the Hashin hypothesis and in combination with the Miner damage accumulation theory, the fatigue life predicted by the method is more effective, and the implementation process is simpler and more convenient.

Owner:SHENYANG JIANZHU UNIVERSITY

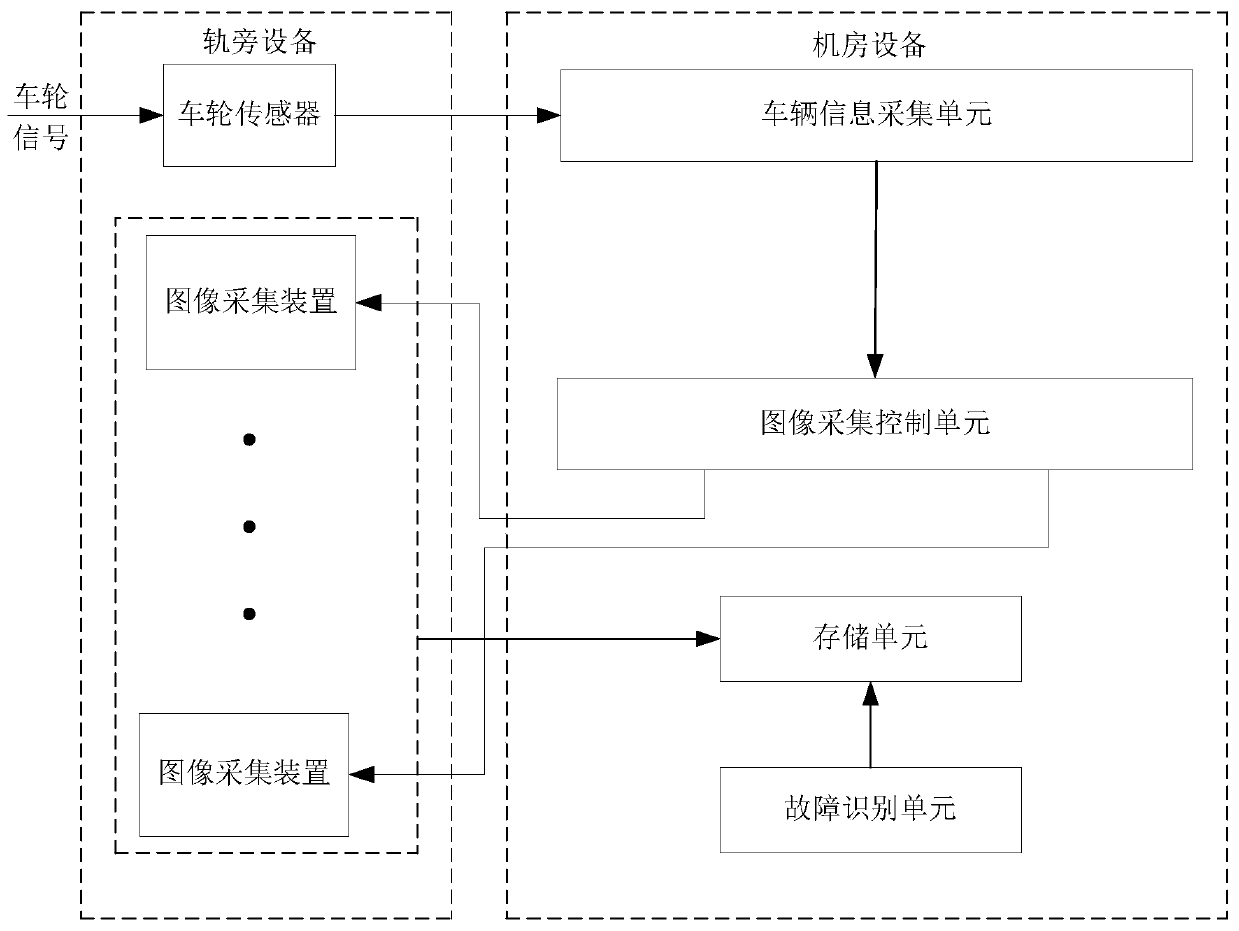

Locomotive running part equipment detection system

PendingCN110316222ALong detection periodReduce workloadRailway signalling and safetyRailway auxillary equipmentStart timeFault recognition

The invention provides a locomotive running part equipment detection system and belongs to the detection of locomotive running parts. The locomotive running part equipment detection system is to solvethe problem that false checking and missed checking are easily caused because the checking of an existing locomotive running part depends on manual operation. The locomotive running part equipment detection system comprises trackside equipment and engine room equipment; the trackside equipment comprises a wheel sensor and an image collection device; the engine room equipment comprises a locomotive information collection unit, an image collection control unit, a storage unit and a fault recognition unit; the wheel sensor collects a wheel signal and transmits the wheel signal to the locomotiveinformation collection unit when a locomotive passes; the locomotive information collection unit calculates a locomotive speed and a wheel base; the image collection control unit controls a starting time of the image collection device and a shooting frequency of the image collection device according to the locomotive speed and correspondingly shoots images of a speed sensor, a machine sensing coiland an electronic label; the storage unit stores the images shot by the image collection device; and the fault recognition unit recognizes faults of the images stored in the storage unit. The locomotive running part equipment detection system is used for checking railway locomotives.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

Immunofluorescent rapid test strip of zearalenone and preparation method and use thereof

The invention discloses an immunofluorescent rapid test strip of zearalenone and a preparation method and use of the immunofluorescent rapid test strip of zearalenone. The test strip disclosed by the invention comprises a sample pad, a fluorescent microsphere probe joint pad, a nitrocellulose membrane, absorbent paper and a plastic bottom plate. According to the invention, zearalenone pollution of foods, grains, feed and the like can be detected on the basis of an immune principle of an antigen-antibody. The immunofluorescent rapid test strip of zearalenone, provided by the invention, can be used for fast detection of a field of zearalenone by just 5-10 minutes, and can achieve quantitative detection if being combined with a quantitative fluorescence detector (card reader), and an operator does not need professional training. Therefore, the immunofluorescent rapid test strip has a good market prospect.

Owner:JINAN UNIVERSITY

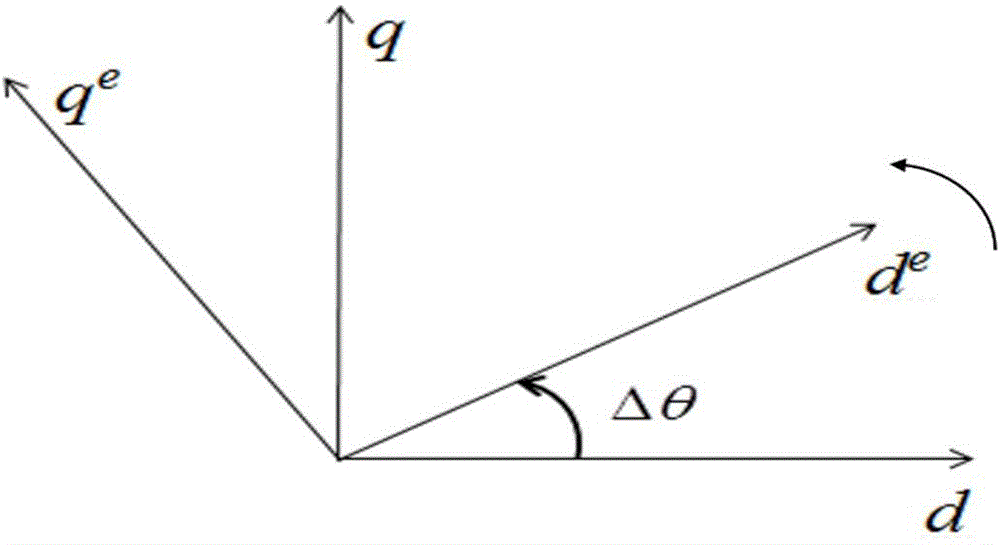

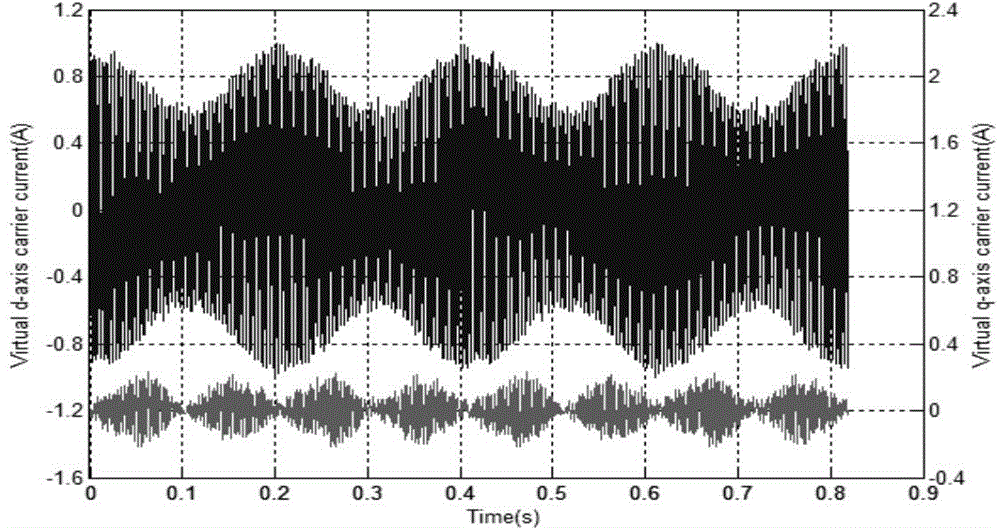

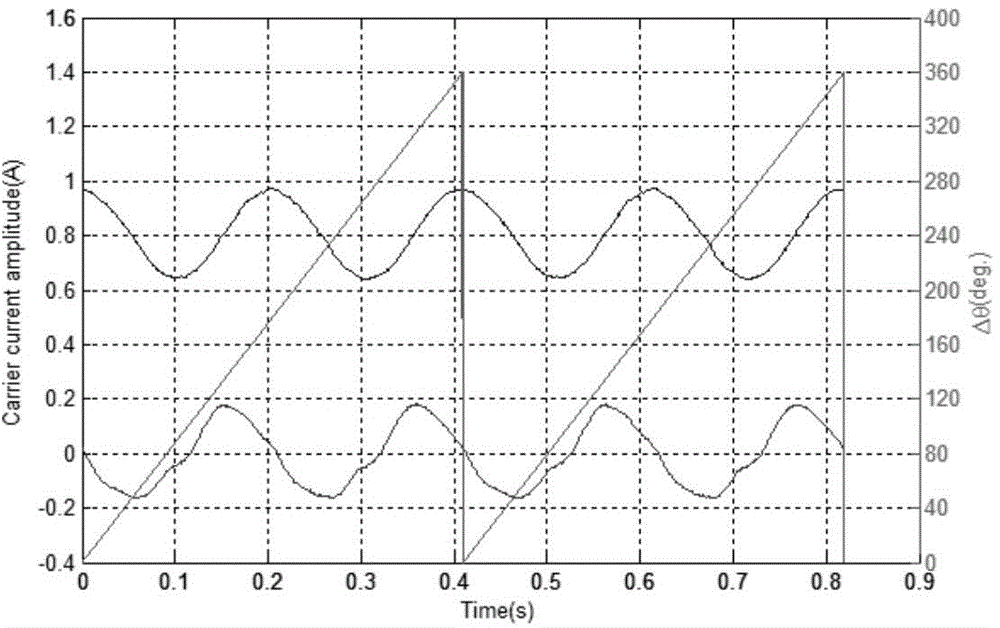

Permanent magnet synchronous motor salient pole property detection method based on pulsating high frequency voltage injection

ActiveCN104407292AMeet the needs of running optimizationLong detection periodDynamo-electric machine testingElectricityPermanent magnet synchronous motor

The invention provides a permanent magnet synchronous motor salient pole property detection method based on pulsating high frequency voltage injection. The permanent magnet synchronous motor salient pole property detection method based on the pulsating high frequency voltage injection includes following steps: fixing the position of a rotor of a permanent magnet synchronous motor to be detected, and preventing the position of the rotor from changing when the rotor is under external force; respectively forming a d axis current id and a q axis current iq under corresponding work points on the d axis and the q axis of the permanent magnet synchronous motor to be detected by using current closed loop control after the permanent magnet synchronous motor and a drive device are powered on; building an estimated de-qe axis coordinate system, anticlockwise and periodically rotating the de-qe axis coordinate system at low frequency relatively to a d-q axis coordinate system of the permanent magnet synchronous motor, representing an intersection angle between the de-qe axis coordinate system and the d-q axis coordinate system as delta theta, and increasing the intersection angle delta theta from 0 to 2pi by rotating the de-qe axis coordinate system by one revolution around the d-q axis coordinate system; applying high frequency voltage signals and the like on the de axis in the de-qe axis coordinate system which keeps rotation anticlockwise through space vector pulse width modulation. The permanent magnet synchronous motor salient pole property detection method based on the pulsating high frequency voltage injection not only simplifies and conveniently detects salient pole properties of the permanent magnet synchronous motor under different work points, but also can detect influences of cross saturation effects on salient pole shifting of the permanent magnet synchronous motor under the different work points.

Owner:SHANGHAI HUACHENG ELEVATOR TECH CO LTD

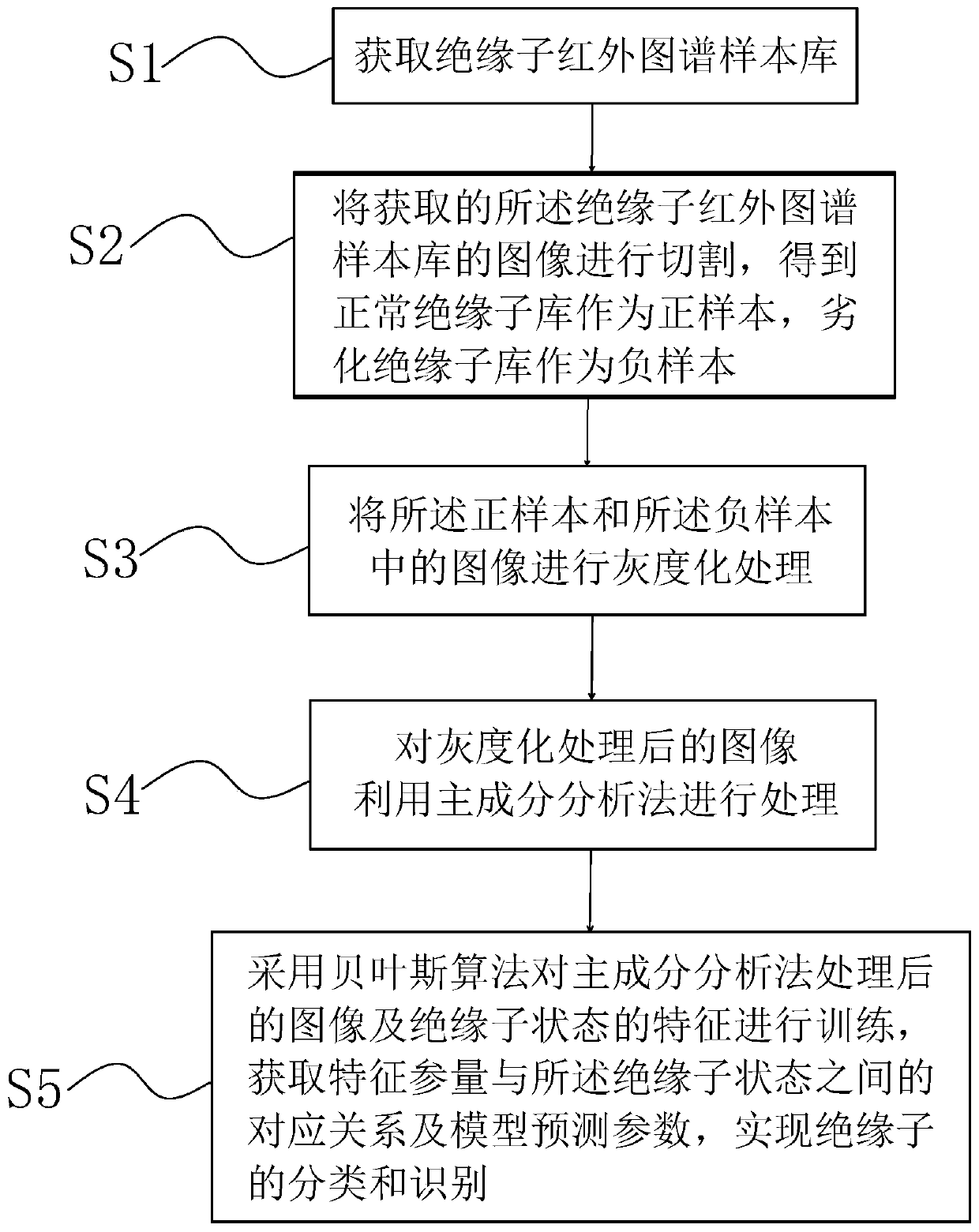

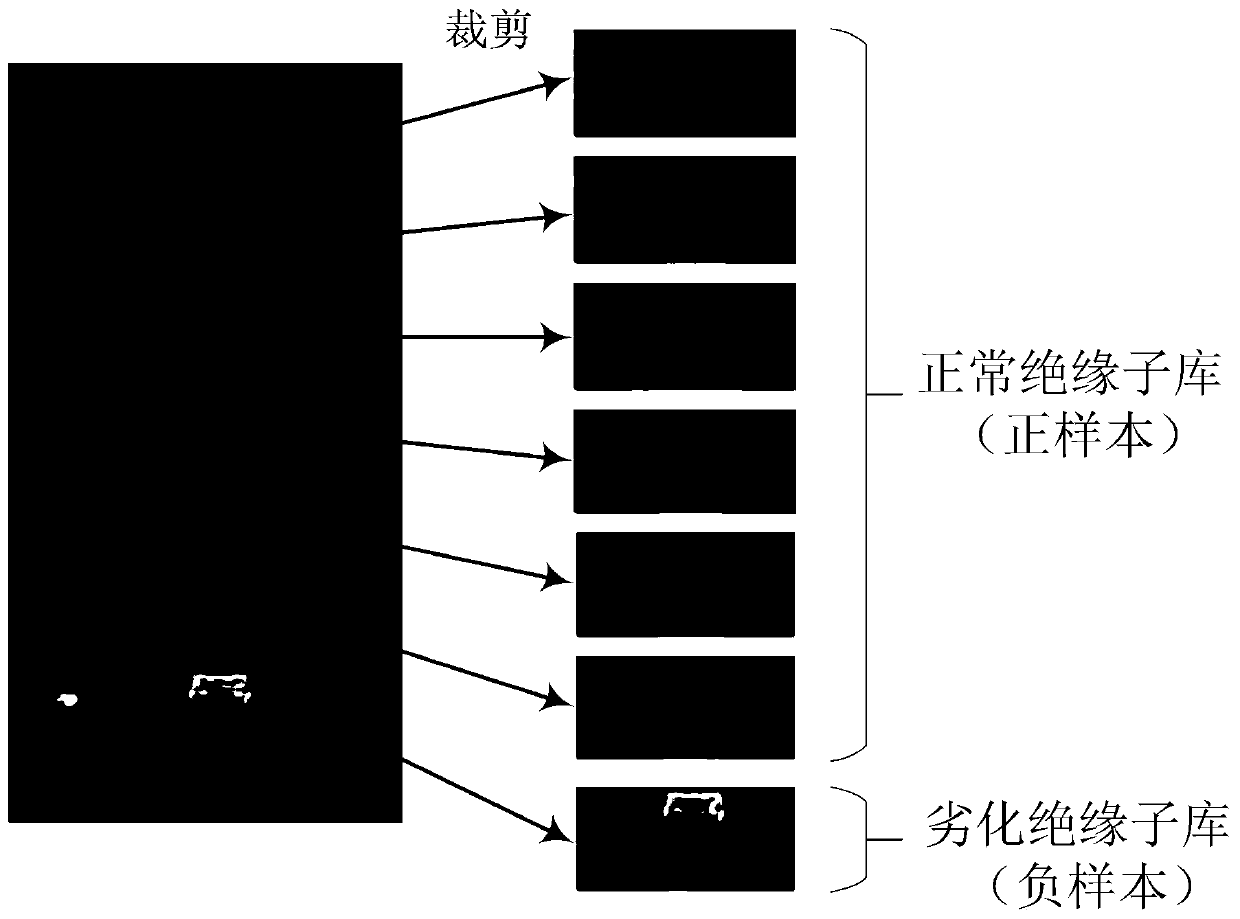

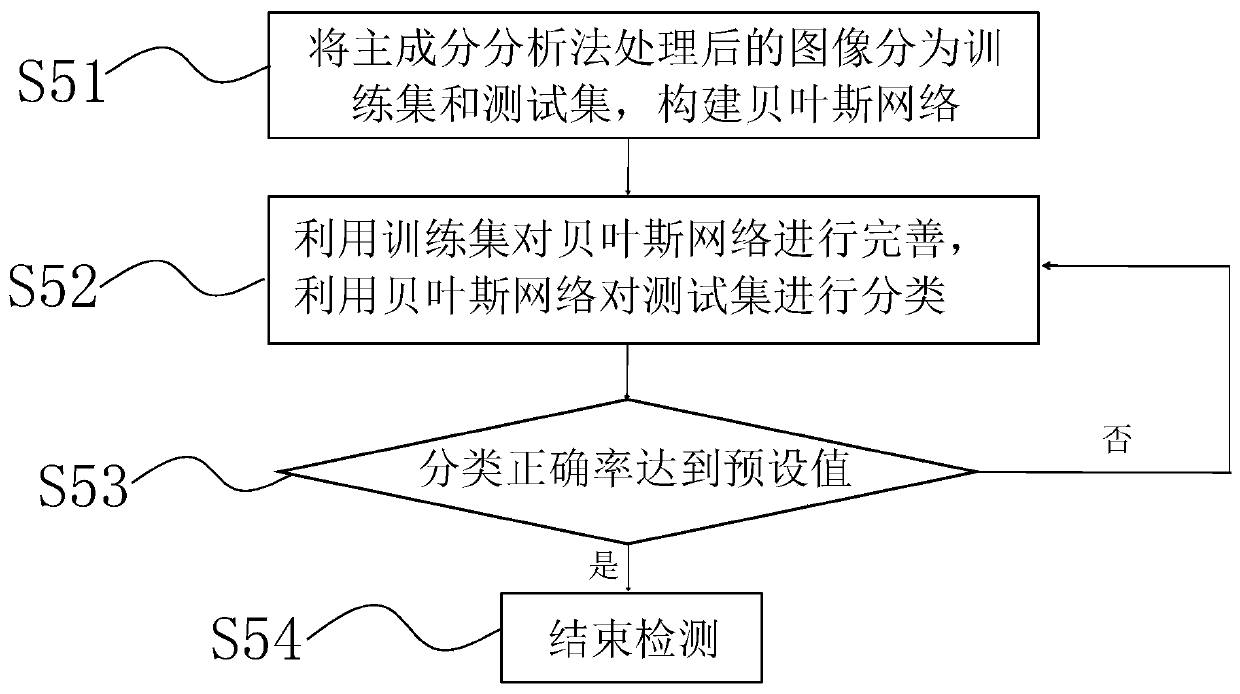

Insulator evaluation and classification method and device based on infrared image

PendingCN110889435ARealize the recognition functionRealize the diagnosis functionCharacter and pattern recognitionPositive samplePrincipal component analysis

The invention discloses an insulator evaluation and classification method and device based on infrared images. The method comprises the steps of acquiring an insulator infrared spectrum sample library; cutting the obtained images of the insulator infrared spectrum sample library to obtain a normal insulator library as a positive sample and a deteriorated insulator library as a negative sample; graying the images in the positive sample and the negative sample; processing the image after graying processing by using a principal component analysis method; and training the image processed by the principal component analysis method and the characteristics of the insulator state by adopting a Bayesian algorithm to obtain a corresponding relationship between characteristic parameters and the insulator state and model prediction parameters, thereby realizing classification and identification of the insulator. According to the technical scheme of the invention, the method can adapt to a complexfield environment, achieves the automatic recognition and diagnosis of the insulator in the infrared image, effectively reduces the false detection, and improves the efficiency and accuracy.

Owner:MAINTENANCE BRANCH OF STATE GRID HEBEI ELECTRIC POWER +1

Method for determining pendimethalin content in agricultural products by liquid chromatography

ActiveCN107941964AEasy extractionLong detection periodComponent separationOther chemical processesAlkaline waterMicrosphere

The invention discloses a method for determining pendimethalin content in agricultural products by liquid chromatography, belonging to the technical field of agricultural product detection. The methodmainly comprises the steps of (1) agricultural product steam explosion treatment: firstly using a composite enzymatic hydrolysate to perform primary treatment, then using alkaline water vapor to perform steam explosion treatment, so as to obtain agricultural product slurry and condensed fluid containing pendimethalin; (2) agricultural product slurry treatment: treating the agricultural product slurry subjected to the steam explosion to obtain supernate; (3) constant volume filtration: mixing the supernate and the condensed fluid, then performing adsorption purification treatment by using a purification microballoon; (4) liquid chromatograph detection; (5) result analysis. In a word, the method provided by the invention is high in analysis speed, high in accuracy rate and low in detectionlimit, the added recovery rate is stabilized at 91% or above, the relative standard deviation is low and the work efficiency is greatly improved.

Owner:江苏中宜金大分析检测有限公司

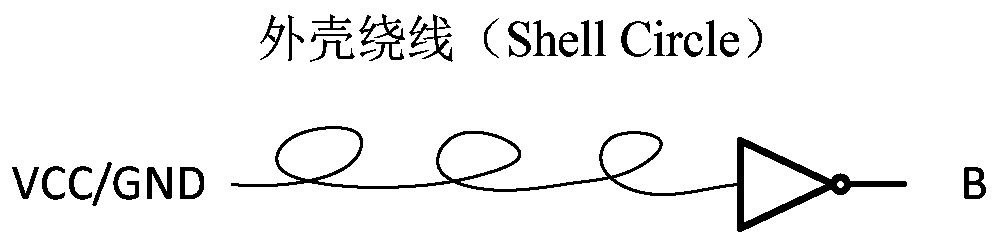

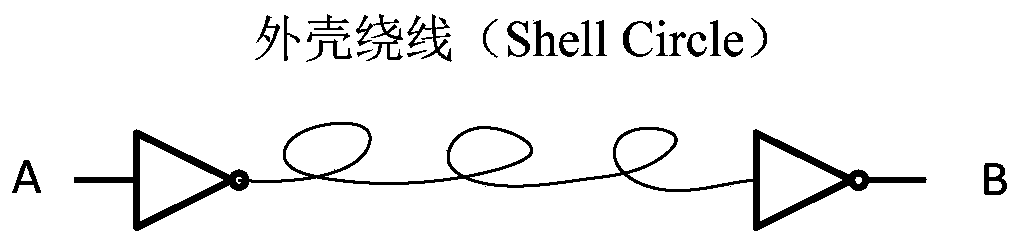

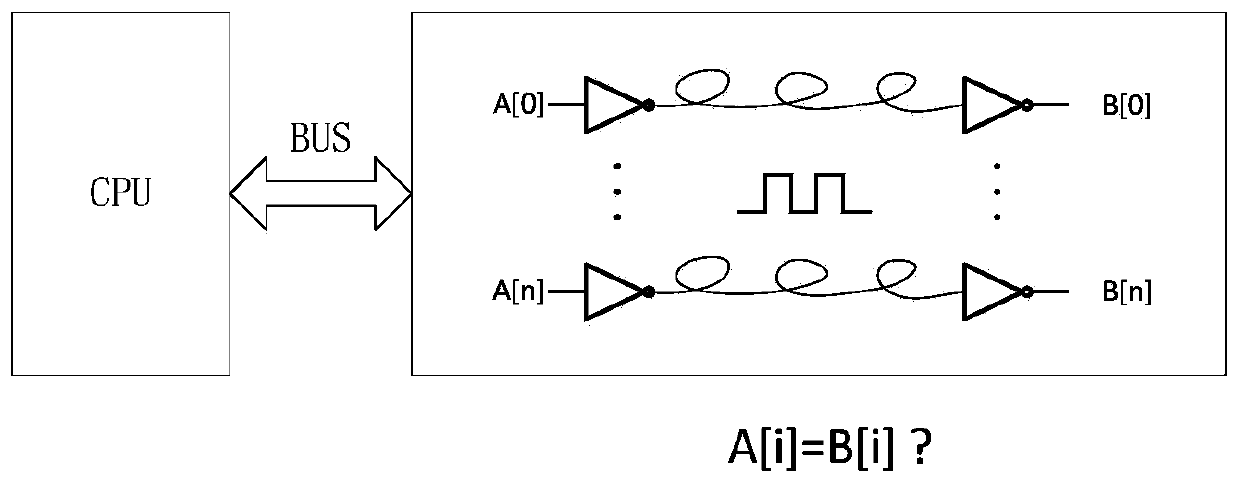

Anti-dismantling detection and protection circuit, implementation method and anti-dismantling chip

InactiveCN109782154AReduce power consumptionImprove compatibilityRandom number generatorsCurrent/voltage measurementDynamic dataComputer science

The invention discloses an anti-dismantling detection and protection circuit, an implementation method and an anti-dismantling chip. The anti-dismantling detection and protection circuit includes a dynamic data generating module, a dynamic sampling module, a dynamic sampling detection module and an output module; the data generating module is used for generating dynamic data, and outputting the dynamic data to one end of each housing wound wire; the dynamic sampling module is used for collecting data from the other ends of the housing wound wires; the dynamic sampling detection module is connected with the dynamic data generating module and the dynamic sampling module, and is used for comparing the dynamic data outputted by the dynamic data generating module with the data collected by thedynamic sampling module, and outputting a comparison result; the output module is connected with the dynamic sampling detection module and is used for outputting total alarm signals when the comparison result outputted by the dynamic sampling detection module indicates that the dynamic data outputted by the dynamic data generating module are different from the data collected by the dynamic sampling module. According to the anti-dismantling detection and protection circuit provided by the embodiments of the invention, dynamic data are outputted, so that the security of anti-dismantling detection and protection can be improved.

Owner:DATANG MICROELECTRONICS TECH CO LTD

Method for rapidly detecting chemical component tadalafil and derivatives thereof and method for developing detection card

InactiveCN107144564AHigh professional quality requirementsHigh detection costMaterial analysis by observing effect on chemical indicatorTadalafilEngineering

The invention discloses a method for rapidly detecting a chemical component tadalafil and derivatives thereof and a method for developing a detection card. The detection method comprises the following steps: firstly, soaking a to-be-detected sample with an extracting solution, fully and uniformly mixing and standing; secondly, filtering the supernatant by using a microfiltration membrane, wherein the filtrate is a treatment solution of the to-be-detected sample; thirdly, taking a certain amount of the filtrate, adding a detection solution in a volume of 4 times for uniformly mixing, standing and developing; fourthly, transferring 50microliters of mixed solution to a middle position of a detection card observation window, timing for a minute, and reading the detection result on an instrument. The method for developing a detection card comprises the following steps: preparing a test paper base material, preparing a soaking solution, soaking the test paper base material, preparing detection test paper and preparing the detection card. The method is suitable for rapid field detection of the chemical component tadalafil and derivatives thereof in foods, drugs and health care products.

Owner:北京倍肯恒业科技发展股份有限公司

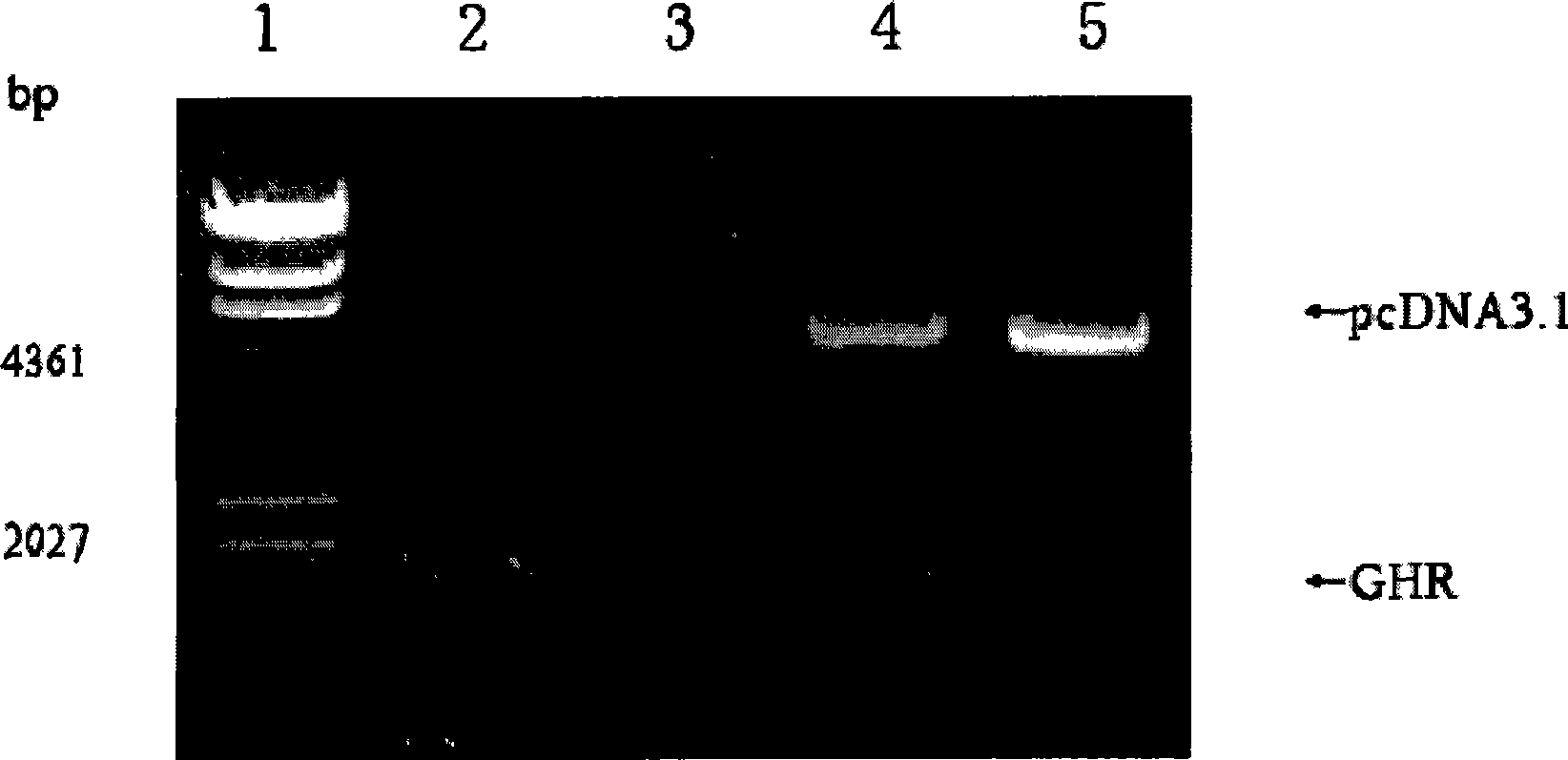

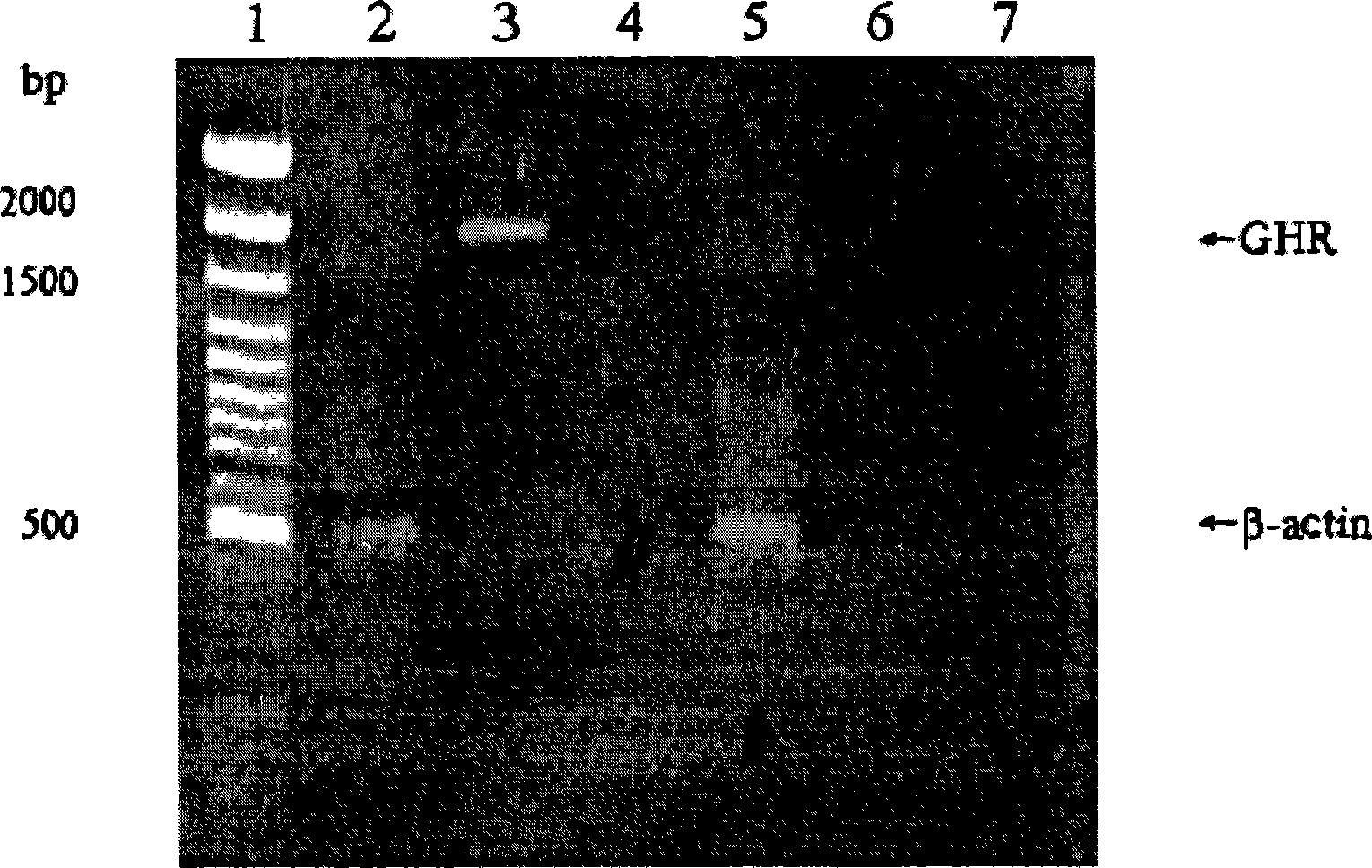

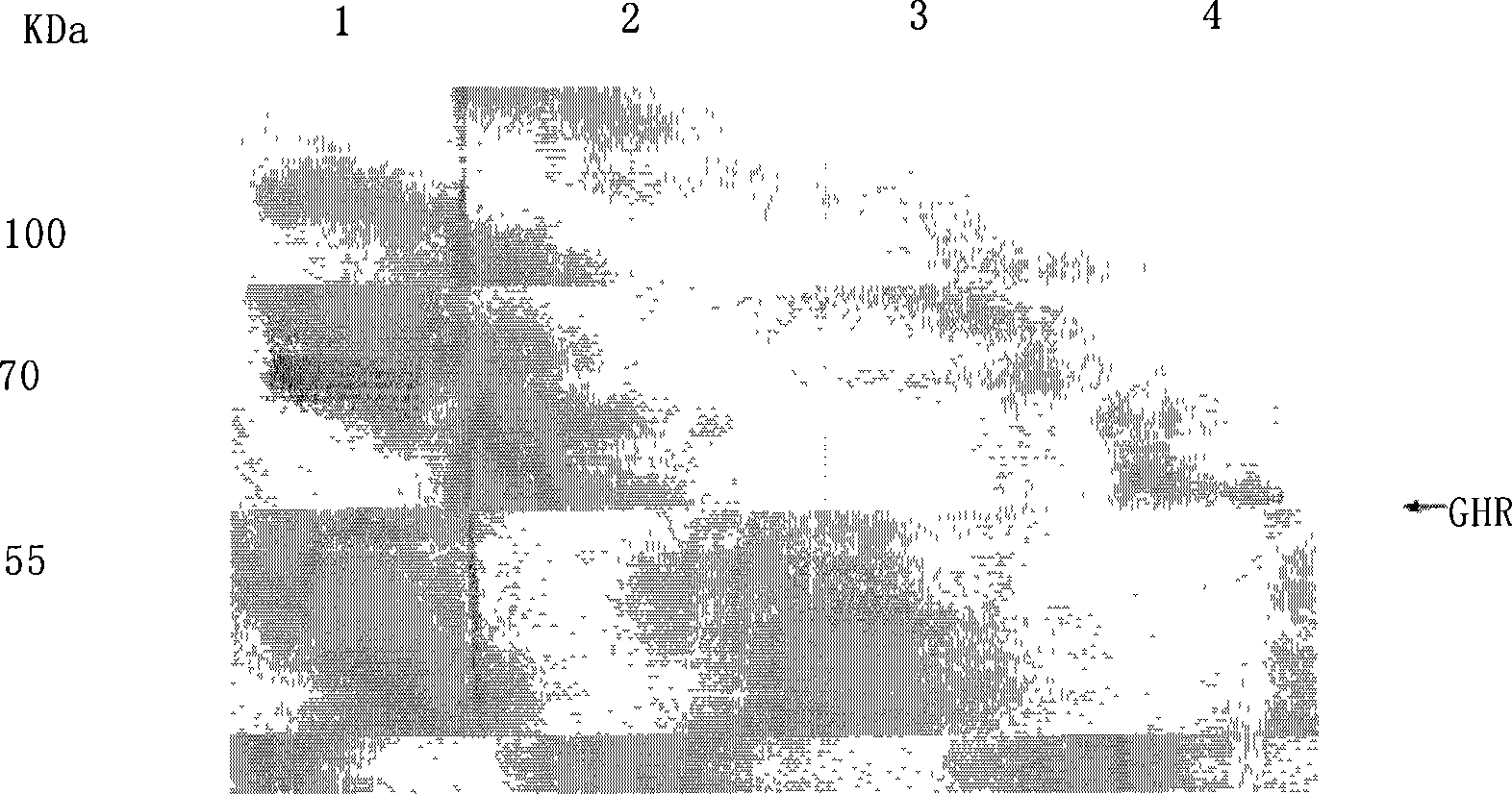

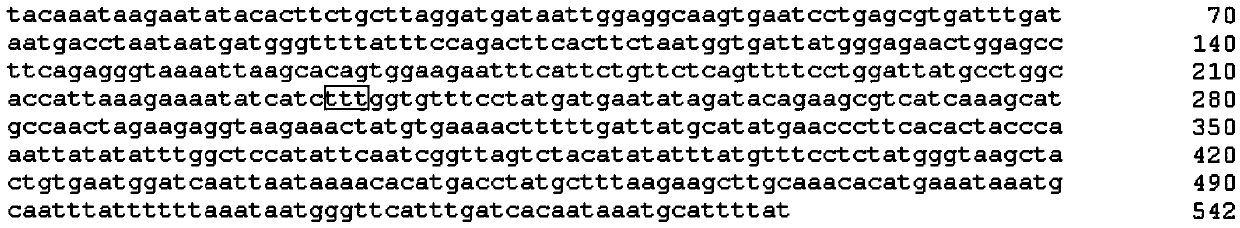

Detection method for protein activity of fish growth hormone

InactiveCN101397338AHigh activityGood biological configurationMicrobiological testing/measurementDepsipeptidesHormones regulationFish growth

The invention discloses a novel fish growth hormone receptor suitable for constructing a cell model used in the detection of fish growth hormone protein activity and a coding gene thereof. After a fish growth hormone receptor gene is switched to a host cell CH0, a reformed CH0 cell which can express the fish growth hormone receptor is obtained. The fish growth hormone receptor expressed by the cell reserves favorable biological construction, which can be favorably applied to detecting the activity of the fish growth hormone protein.

Owner:上海中科伍佰豪生物工程有限公司

Novel chlorobenzene production process

InactiveCN109096042AHigh conversion selectivityReduce outputHalogenated hydrocarbon preparationGeneration rateChlorobenzene

The invention provides a novel chlorobenzene production process. Chlorobenzene used in the novel chlorobenzene production process comprises the following raw materials: anhydrous benzene, chlorine, acatalyst and a positioning agent. The novel production process comprises the following steps: preparing the anhydrous benzene; enabling the anhydrous benzene to flow out from the bottom of a benzene high-level tank, metering by using a flowmeter, and continuously putting into a chlorinator from the bottom of the chlorinator; buffering qualified chlorine made after gasification of liquid chlorine by using a chlorine buffer tank, introducing into the chlorinator from the bottom of the chlorinator to flow upwards together with the anhydrous benzene along flows in a same direction, carrying out areaction under the action of the catalyst and the positioning agent in the chlorinator so as to generate a chlorination liquid, and carrying out aftertreatment on the chlorination liquid, thereby obtaining chlorobenzene. By adopting the novel production process provided by the invention, the problem that a great deal of wastewater is generated from water washing and alkali washing in the conventional method can be avoided, no wastewater is generated, in addition, the catalyst is long in service life, the equipment is long in service life, the detection cycle can be prolonged, a product made byusing the process is high in purity, and due to adoption of an iron catalyst and chelate EDTA-Fe with iron as the center as the positioning agent, the process is low in wastewater generation rate andgreen, environmentally friendly and fee of pollution.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

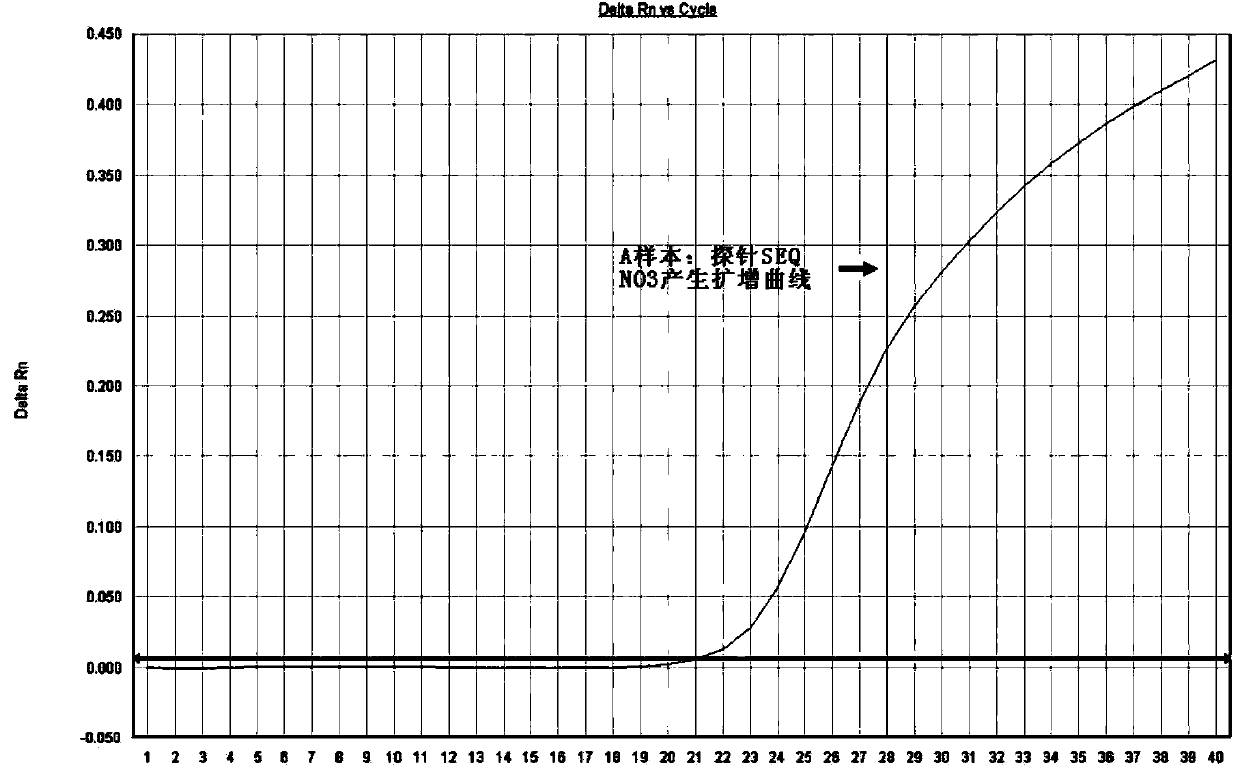

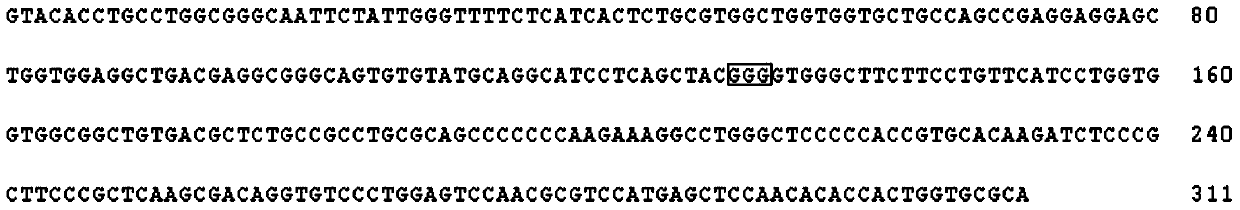

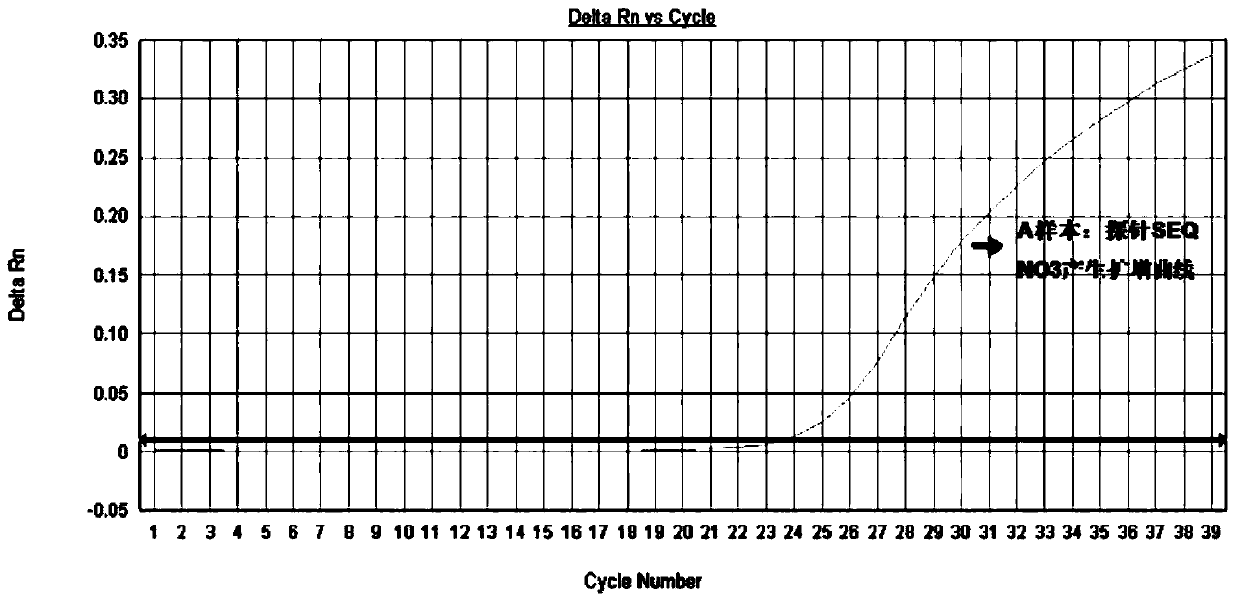

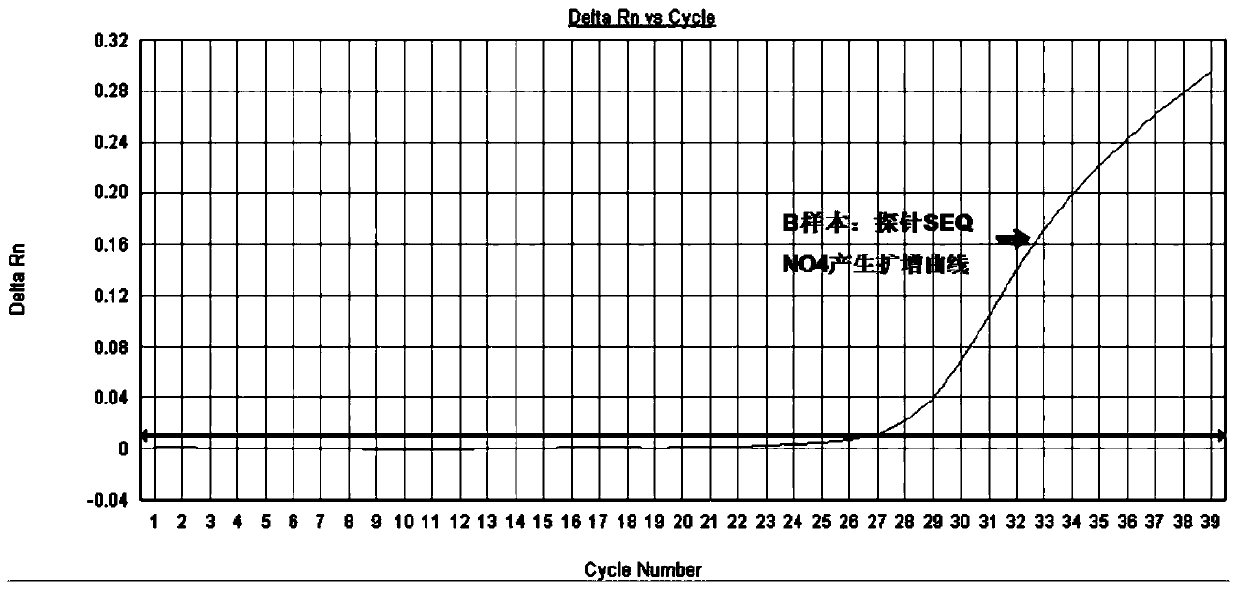

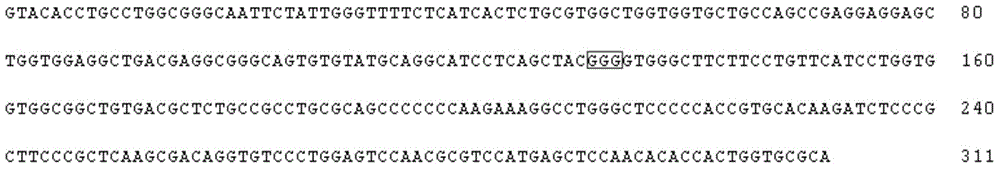

Method for detecting mutation on locus deltaF508 of CFTR (Cystic Fibrosis Transmembrane Regulator) gene and oligonucleotide

ActiveCN103789415AIncrease the Tm valueSimplify the design processMicrobiological testing/measurementDNA/RNA fragmentationMale infertilitySpecific detection

The invention discloses a method for detecting mutation on the locus deltaF508 of a CFTR (Cystic Fibrosis Transmembrane Regulator) gene and an oligonucleotide, relating to a pair of specific amplification primers SEQ NO 1 and SEQ NO 2 and a pair of specific detection probes SEQ NO 3 and SEQ NO4. The method has the advantages of short detection period, high specificity, high accuracy, high sensitivity, low conditional dependency, low pollution risk and the like, and can be used for assisting in accurately and rapidly diagnosing cystic fibrosis and male infertility.

Owner:广州艾迪康医学检验所有限公司

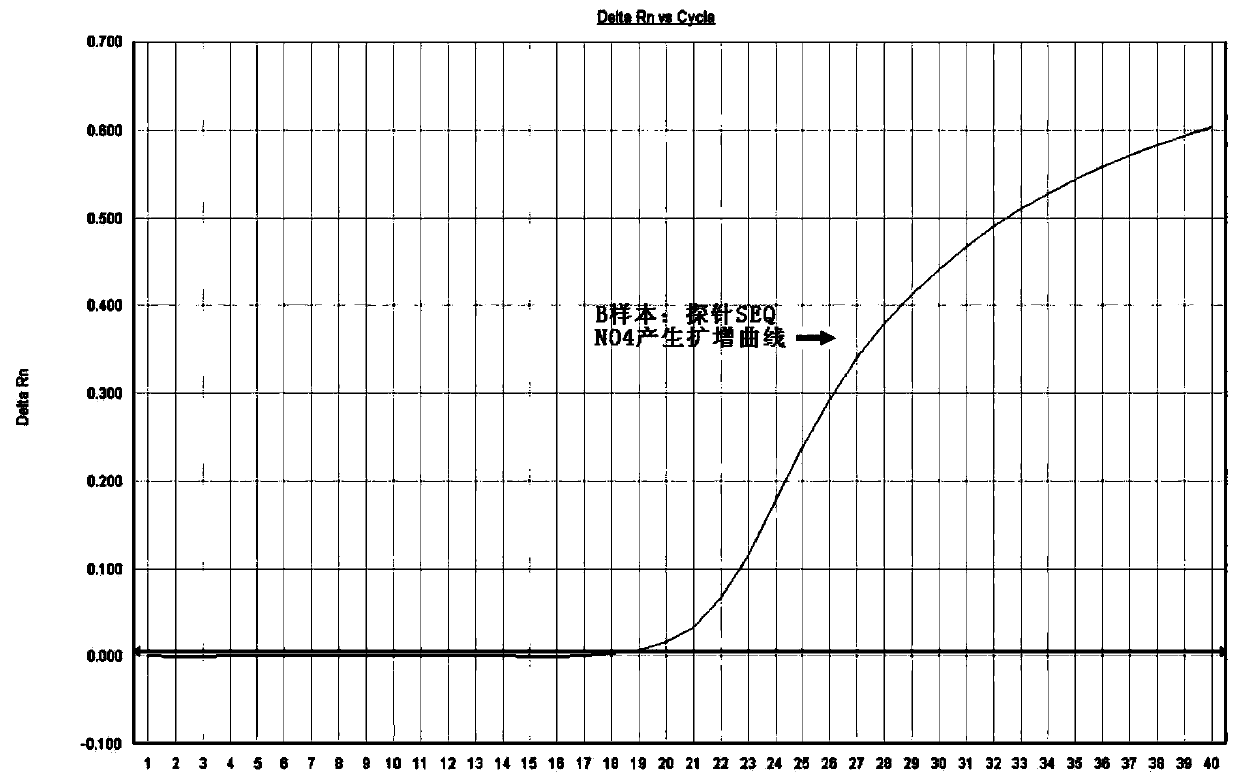

Method and oligonucleotide for detecting FGFR3 gene G380R site mutation

ActiveCN103789416AReached diagnosisDifferential diagnosis reachedMicrobiological testing/measurementDNA/RNA fragmentationFgfr3 geneSpecific detection

The invention discloses a method and oligonucleotide for detecting FGFR3 gene G380R site mutation, and relates to a pair of specific amplification primers SEQ NO 1 and SEQ NO 2, and a pair of specific detection probes SEQ NO 3 and SEQ NO 4. By adopting the method and oligonucleotide, congenital achondroplasia can be rapidly diagnosed and identified, and the method and oligonucleotide have the advantages of being short in detection cycle, good in specificity, high in accuracy, high in sensitivity, less in condition dependence, low in pollution risk and the like.

Owner:杭州艾迪康医学检验中心有限公司

Immunofluorescent rapid test strip of zearalenone and preparation method and use thereof

The invention discloses an immunofluorescent rapid test strip of zearalenone and a preparation method and use of the immunofluorescent rapid test strip of zearalenone. The test strip disclosed by the invention comprises a sample pad, a fluorescent microsphere probe joint pad, a nitrocellulose membrane, absorbent paper and a plastic bottom plate. According to the invention, zearalenone pollution of foods, grains, feed and the like can be detected on the basis of an immune principle of an antigen-antibody. The immunofluorescent rapid test strip of zearalenone, provided by the invention, can be used for fast detection of a field of zearalenone by just 5-10 minutes, and can achieve quantitative detection if being combined with a quantitative fluorescence detector (card reader), and an operator does not need professional training. Therefore, the immunofluorescent rapid test strip has a good market prospect.

Owner:JINAN UNIVERSITY

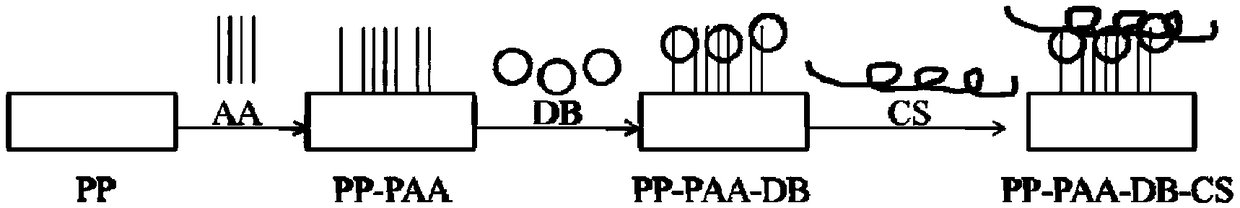

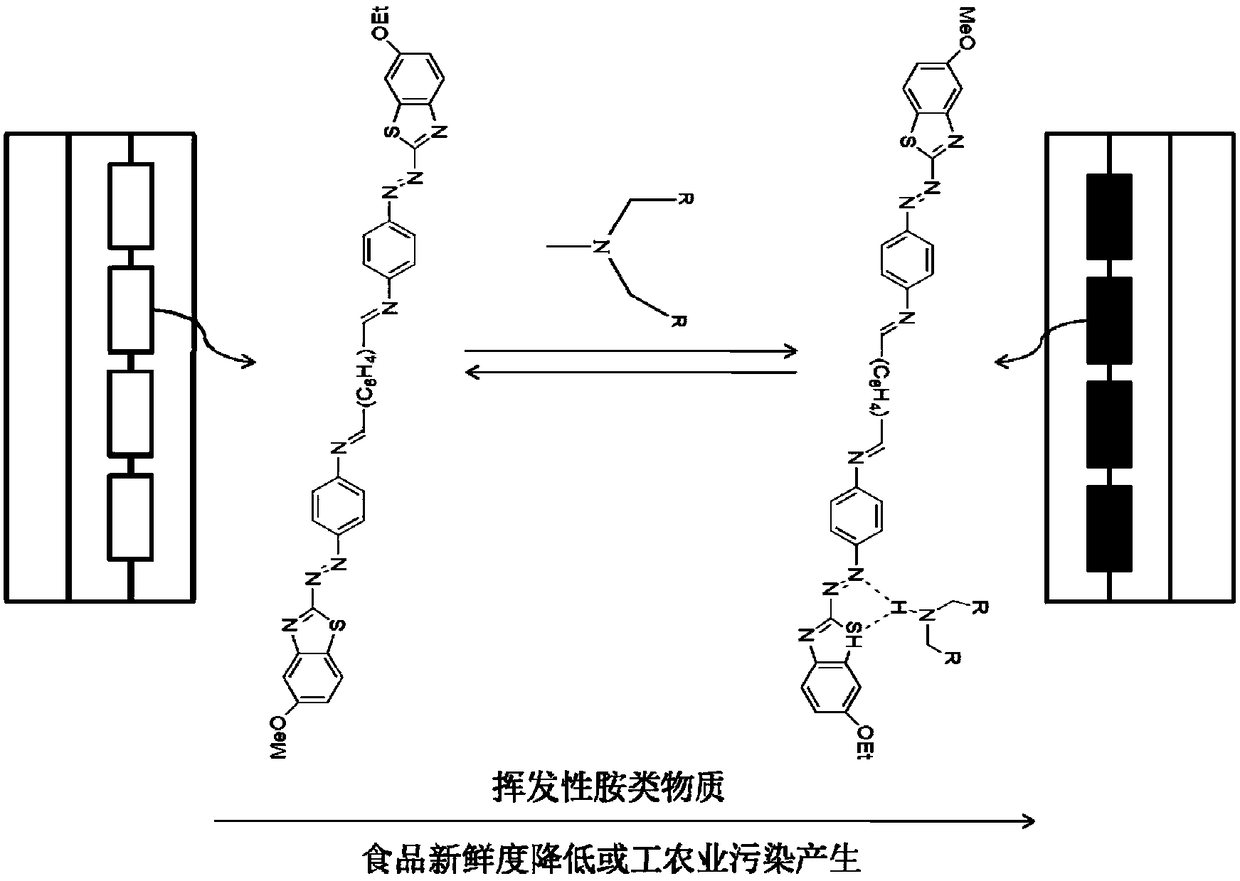

A colorimetric sensor containing benzothiazole base dye, its preparation method and its application in detection

ActiveCN106323959BHigh operating requirementsLong detection periodMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPhysisorptionPolyacrylamide

The invention relates to the technical field of volatile amine substance detection, in particular to a colorimetric sensor containing a benzothiazole alkaline dye, a preparation method and application of the sensor in detection. The colorimetric sensor comprises a polyacrylamide film, polyacrylic acid, the benzothiazole alkaline dye and a chitosan chain, wherein one end of the polyacrylic acid is bonded on the polyacrylamide film, the other end of the polyacrylic acid is connected with the benzothiazole alkaline dye through a Van der Waals' force and physical absorption, and the chitosan chain and the polyacrylic acid are subjected to electrostatic bonding, so that the benzothiazole alkaline dye is further coated to form a polyacrylamide film-polyacrylic acid-benzothiazole alkaline dye-chitosan chain structure. According to a sensor technology related to the invention, qualitative analysis can be conducted on volatile amine substances through naked eyes without any device, and quantitative analysis can be conducted on volatile amine substances by utilizing UV-VIS instrument device.

Owner:CHUZHOU UNIV

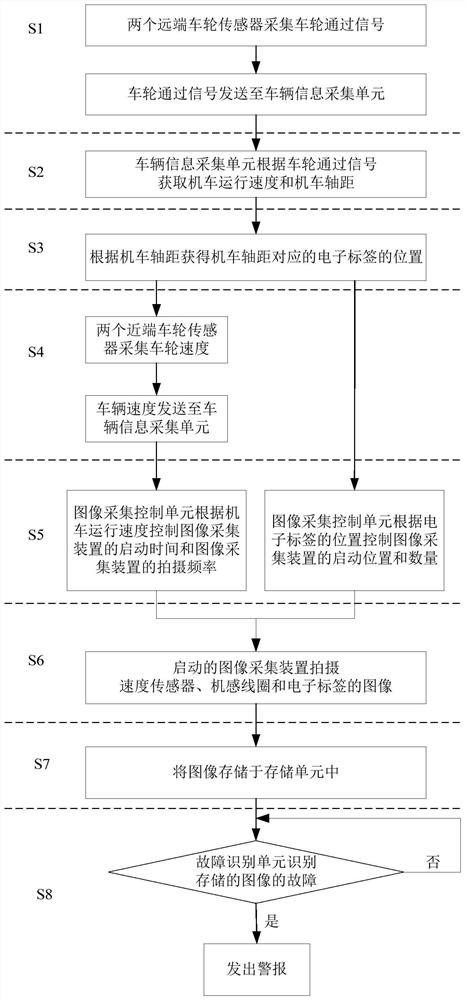

The Realization Method of Equipment Inspection System of Locomotive Running Section

ActiveCN110316221BLong detection periodReduce workloadRailway signalling and safetyRailway auxillary equipmentControl cellEngineering

The invention relates to a method for realizing a detection system of a running part of a locomotive, which belongs to the detection field of the running part of a locomotive. The invention solves the problem that the existing inspection of the running part of a locomotive relies on manual work, which is prone to false detection and missed detection. The specific process is: the remote wheel sensor collects the wheel passing signal and sends it to the vehicle information collection unit; the vehicle information collection unit obtains the locomotive running speed and locomotive wheelbase; obtains the position of the electronic tag corresponding to the locomotive wheelbase; the proximal wheel sensor collects the wheel The speed is sent to the vehicle information acquisition unit; the image acquisition control unit controls the start time of the image acquisition device and the shooting frequency of the image acquisition device; the image acquisition control unit controls the start position and quantity of the image acquisition device according to the position of the electronic tag; the image of the start The acquisition device takes pictures of the speed sensor, the induction coil and the electronic tag; the images are stored in the storage unit; the fault identification unit identifies the fault. The invention is used for the inspection of railway locomotives entering the warehouse.

Owner:HARBIN KEJIA GENERAL MECHANICAL & ELECTRICAL CO LTD

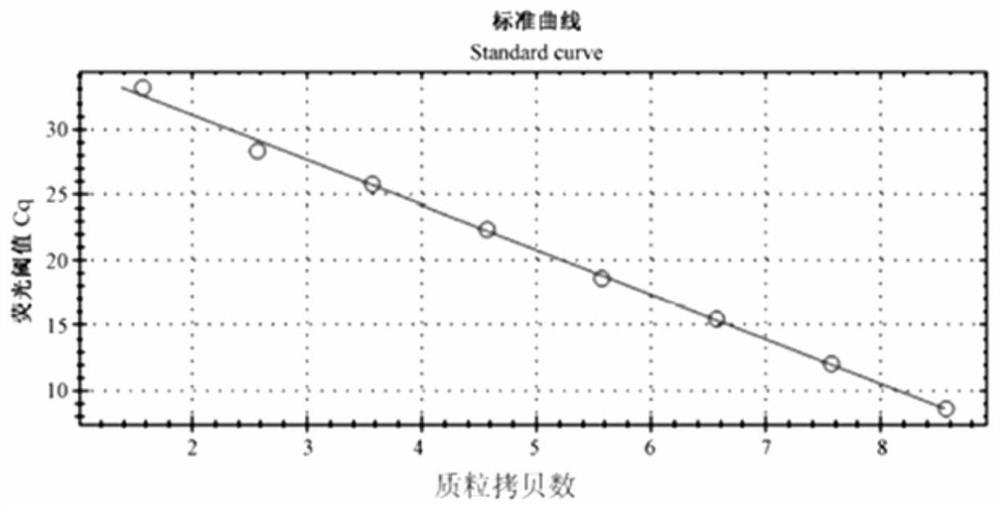

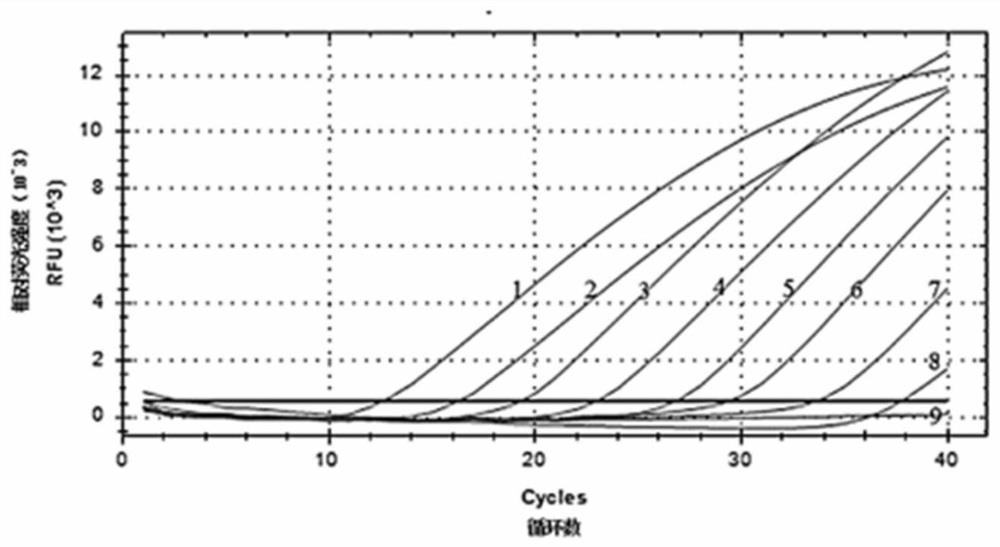

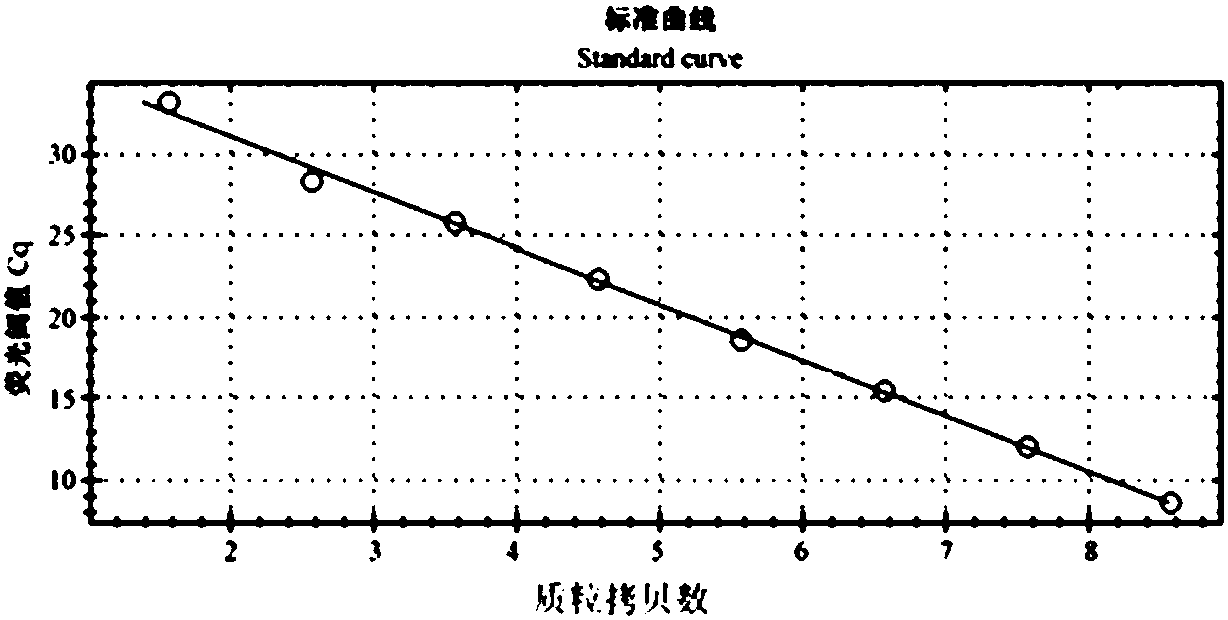

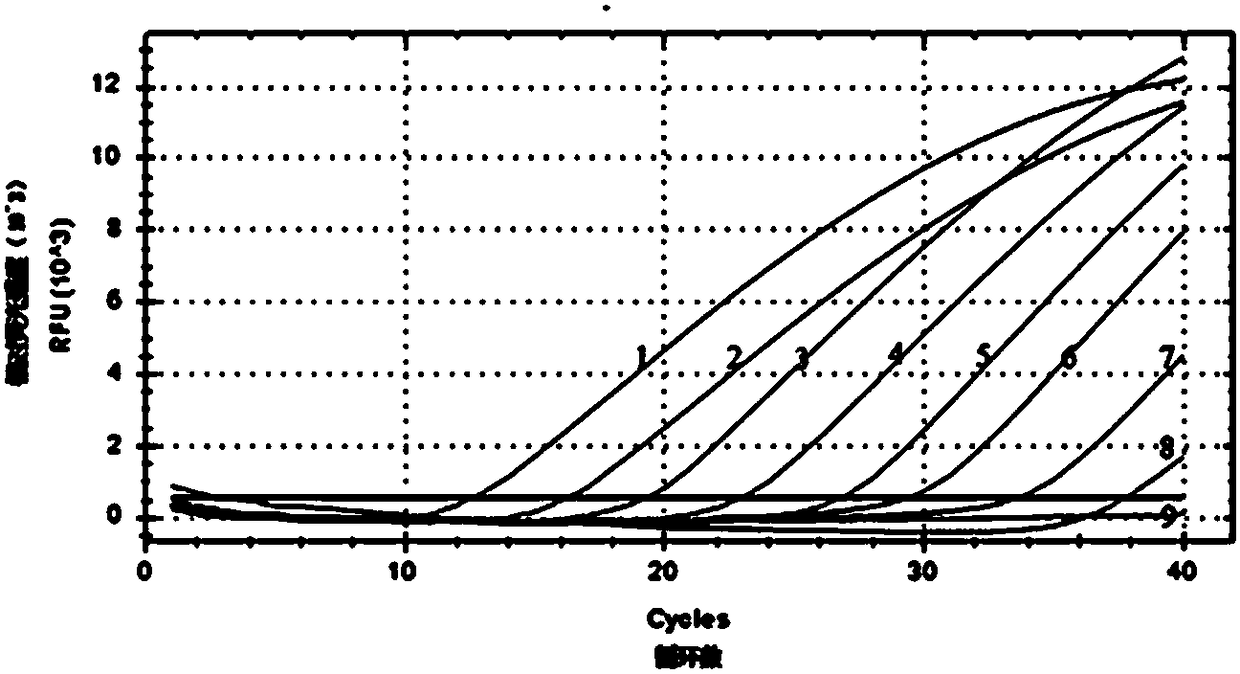

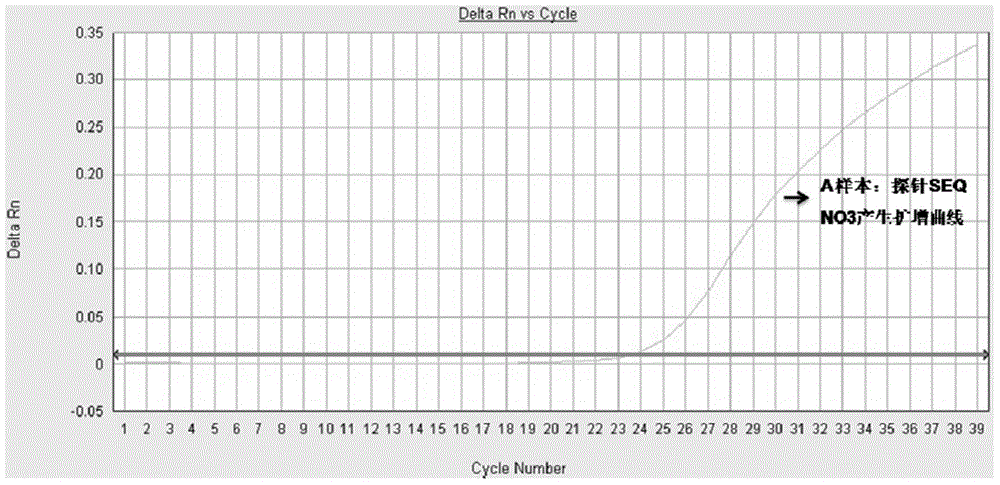

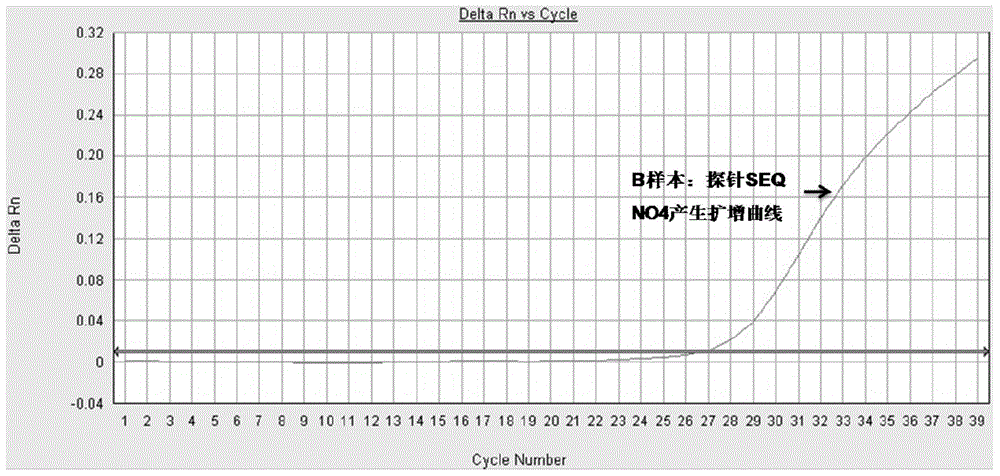

A real-time fluorescent quantitative PCR primer, probe and kit for detecting tree shrew adenovirus

ActiveCN108315480BIncrease the cost of experimentsIncreased sensitivityMicrobiological testing/measurementMicroorganism based processesConserved sequenceBasic research

The invention relates to real-time fluorescent quantitative PCR primers, a probe and a kit for detecting tupaia adenoviruses and belongs to the field of biotechnology. The primers are designed and synthesized according to the end 3' conserved sequence of the tupaia whole genome isolated and identified in this laboratory. The primers do not undergo a cross reaction with a tupaia source and common viruses belonging to other species. The end 5' of the probe is connected to a fluorescent reporting group and the end 3' of the probe is connected to a fluorescence quenching group. The kit produces accurate and reliable results, has good stability, good repeatability and high sensitivity, can fast and accurately quantify, has a wide detection range, can be used for epidemiological investigation caused by tupaia adenoviruses, provides the technical support for related basic research and has a wide application prospect.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

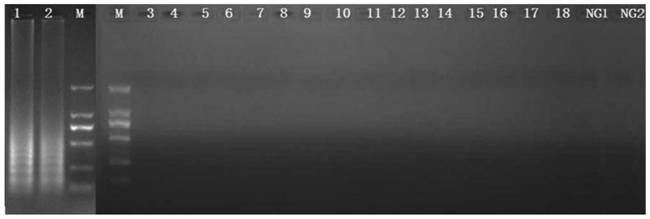

Detection kit applicable for controlling gait of amble of Yanqi horse and application

ActiveCN107151701AEasy to operateThe method of operation is quickMicrobiological testing/measurementEnzyme digestionElectrophoresis

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI +2

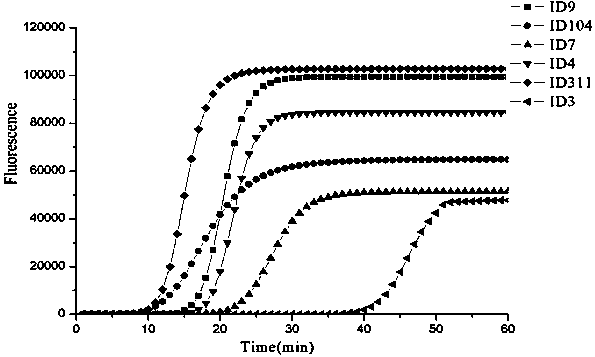

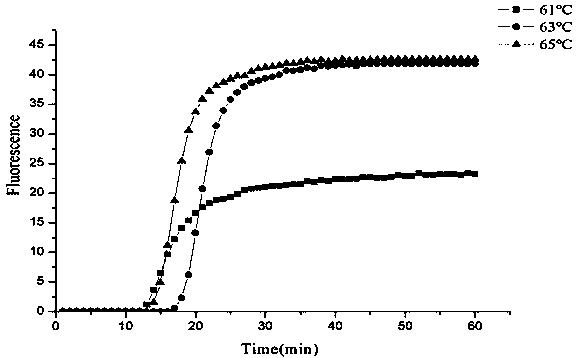

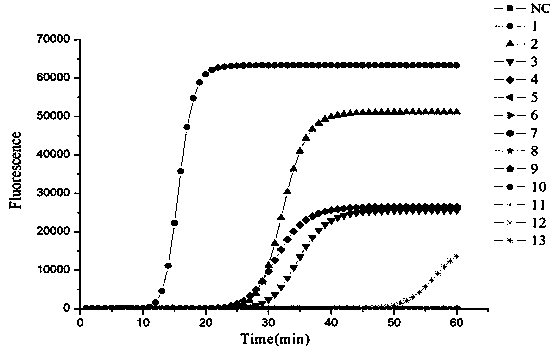

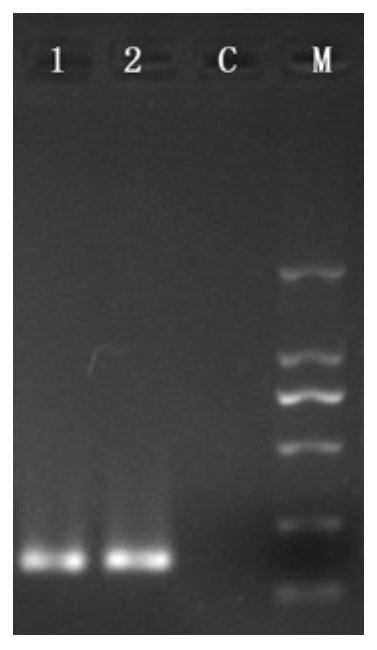

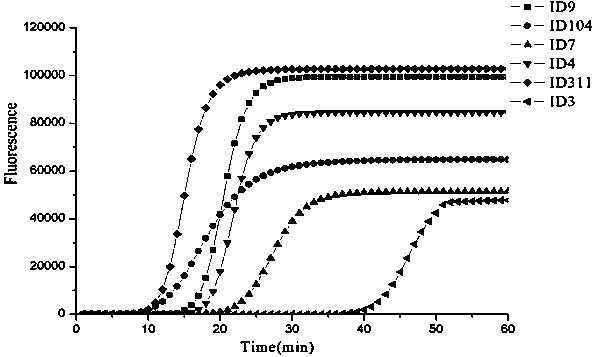

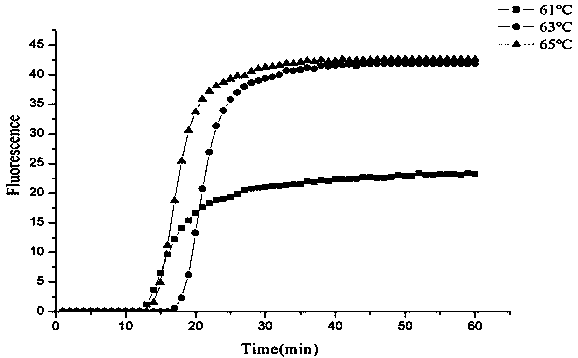

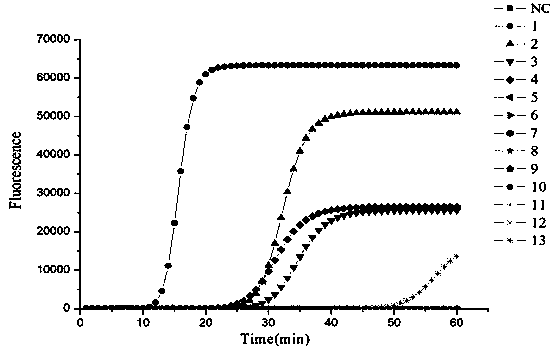

A primer for the detection of Bacillus subtilis by loop-mediated isothermal amplification and its application

ActiveCN110273017BShort detection cycleImprove accuracyMicrobiological testing/measurementMicroorganism based processesMicrobiologyGyra gene

The invention discloses primers for detecting bacillus subtilis through a loop-mediated isothermal amplification method. The primers are designed and obtained with the gyrA gene and gyrB gene of the bacillus subtilis as target sequences and include a group of external primers F3 / B3, a group of internal primers FIP / BIP and a group of loop primers LF / LB. The invention further discloses application of the primers to detecting the bacillus subtilis. It is proved through experiments that the three groups of LAMP primers have quite high specificity and has the sensitivity at least one magnitude order higher than that of an existing method in a contrast test. The detecting process only needs to be conducted under the constant-temperature water bath conditions without the aid of expensive variable-temperature instruments, the result can be judged with naked eyes or by adding a simple indication agent, the reaction time is 40 minutes or shorter, the detection cycle is shorter, and the experiment cost is lower.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION +1

Real-time fluorescent quantitative PCR primers, probe and kit for detecting tupaia adenoviruses

ActiveCN108315480AThe result is accurateReliable resultsMicrobiological testing/measurementMicroorganism based processesConserved sequenceFluorescence

The invention relates to real-time fluorescent quantitative PCR primers, a probe and a kit for detecting tupaia adenoviruses and belongs to the field of biotechnology. The primers are designed and synthesized according to the end 3' conserved sequence of the tupaia whole genome isolated and identified in this laboratory. The primers do not undergo a cross reaction with a tupaia source and common viruses belonging to other species. The end 5' of the probe is connected to a fluorescent reporting group and the end 3' of the probe is connected to a fluorescence quenching group. The kit produces accurate and reliable results, has good stability, good repeatability and high sensitivity, can fast and accurately quantify, has a wide detection range, can be used for epidemiological investigation caused by tupaia adenoviruses, provides the technical support for related basic research and has a wide application prospect.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

CPA primer for killing leukotoxin positive staphylococcus aureus, kit and detection method

PendingCN113512604ALong detection periodReduce sensitivityMicrobiological testing/measurementAgainst vector-borne diseasesNucleotideWhite blood cell

The invention discloses a CPA primer for killing leukotoxin positive staphylococcus aureus, a detection kit and a detection method of the CPA primer. The CPA primer designed aiming at a target spot pvl comprises stripping primers 4s and 5a, a cross amplification primer 2a1s and specific primers 2a and 3a; the nucleotide sequences of the primers are respectively as shown in SEQ ID NO.1 to SEQ ID NO.5. According to the invention, a pair of stripping primers, cross primers and specific primers are designed aiming at a specific target sequence pvl of the leukotoxin-killing staphylococcus aureus, a cross primer isothermal amplification reaction system is constructed, the staphylococcus aureus carrying the leukotoxin-killing gene pvl can be detected in about 60 minutes, and the detection limit reaches the level of pg / [mu]L; the defects of long period, low sensitivity, high cost, difficulty in field application and the like of the existing detection technology are overcome.

Owner:SOUTH CHINA UNIV OF TECH

Device for in-line intelligent monitor and diagnosis of dissolved gas and its method

InactiveCN1160561CImprove anti-interference abilityLong detection periodMaterial resistanceFailure diagnosisProcess engineering

A method for in-line intelligent monitor and diagnosis of the gas dissolved in the oil filled in electric equipment includes in-line intelligent monitor method and failure diagnosis method. Its apparatus is composed of oil-gas separator, gas detector connected to oil-gas separator, and microcomputer controlled diagnosis mechanism connected with the gas detector. Its advantages are in-situ monitor and diagnosis, high sensitivity and accuracy, high anti-interference power and short monitor period.

Owner:CHONGQING UNIV

Primers for detecting bacillus subtilis through loop-mediated isothermal amplification method and application thereof

ActiveCN110273017AShort detection cycleImprove accuracyMicrobiological testing/measurementMicroorganism based processesWater bathsMicrobiology

The invention discloses primers for detecting bacillus subtilis through a loop-mediated isothermal amplification method. The primers are designed and obtained with the gyrA gene and gyrB gene of the bacillus subtilis as target sequences and include a group of external primers F3 / B3, a group of internal primers FIP / BIP and a group of loop primers LF / LB. The invention further discloses application of the primers to detecting the bacillus subtilis. It is proved through experiments that the three groups of LAMP primers have quite high specificity and has the sensitivity at least one magnitude order higher than that of an existing method in a contrast test. The detecting process only needs to be conducted under the constant-temperature water bath conditions without the aid of expensive variable-temperature instruments, the result can be judged with naked eyes or by adding a simple indication agent, the reaction time is 40 minutes or shorter, the detection cycle is shorter, and the experiment cost is lower.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION +1

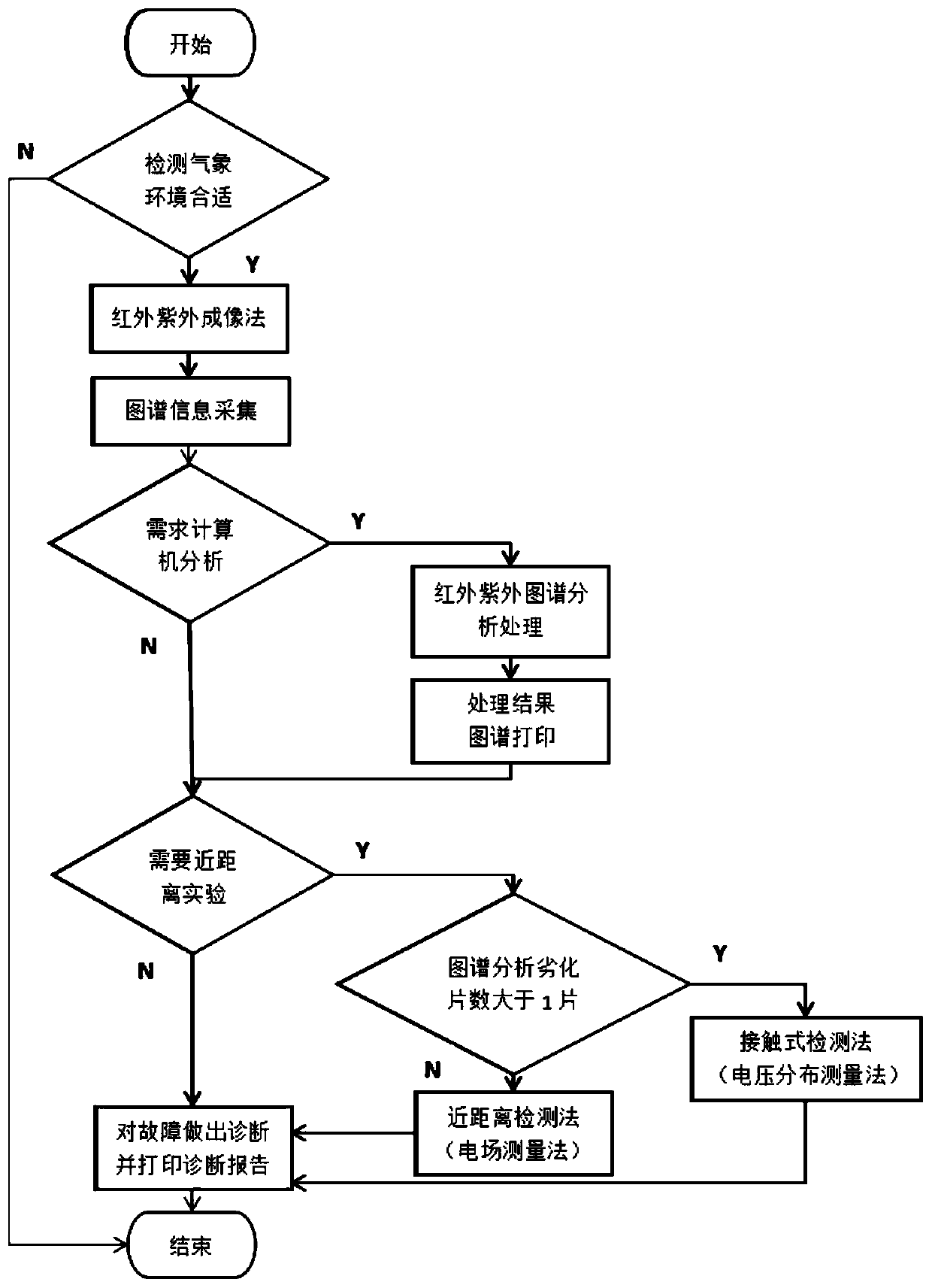

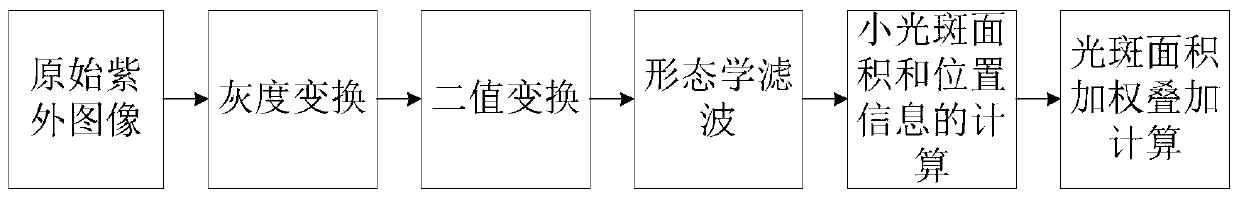

An Insulator Detection Method Based on Infrared and Ultraviolet Imaging

ActiveCN106950472BReduce security risksAvoid potential hazardsTesting dielectric strengthRadiation pyrometryUltravioletLeak detection

The invention discloses an insulator detection method based on infrared and ultraviolet imaging. An infrared ultraviolet imaging comprehensive detection method is adopted, and advantages of all kinds of deteriorated insulator detection methods are combined, so based on the infrared imaging method, mistaken and leaked detection occurring in use of the infrared imaging method or the ultraviolet imaging method can be avoided. According to the invention, by use of infrared and ultraviolet double monitoring and related quantitative adjustment method, probability of the mistaken and leaked detection can be reduced, detection efficiency is improved, the detection period is increased, hidden safety hazards in the deteriorated insulators are reduced, and hidden dangers in power transmission line inspection imposed by mistaken and leaked detection are avoided.

Owner:JIANGSU ELECTRIC POWER RES INST +3

Method and oligonucleotide for detecting fgfr3 G380R site mutation

ActiveCN103789416BIncrease the Tm valueSimplify the design processMicrobiological testing/measurementDNA/RNA fragmentationFgfr3 geneSpecific detection

The invention discloses a method and oligonucleotide for detecting FGFR3 gene G380R site mutation, and relates to a pair of specific amplification primers SEQ NO 1 and SEQ NO 2, and a pair of specific detection probes SEQ NO 3 and SEQ NO 4. By adopting the method and oligonucleotide, congenital achondroplasia can be rapidly diagnosed and identified, and the method and oligonucleotide have the advantages of being short in detection cycle, good in specificity, high in accuracy, high in sensitivity, less in condition dependence, low in pollution risk and the like.

Owner:杭州艾迪康医学检验中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com