The Realization Method of Equipment Inspection System of Locomotive Running Section

An implementation method and a technology for equipment detection, which are applied in railway car body parts, railway auxiliary equipment, railway vehicle shape measuring instruments, etc., and can solve problems such as error detection and missed detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

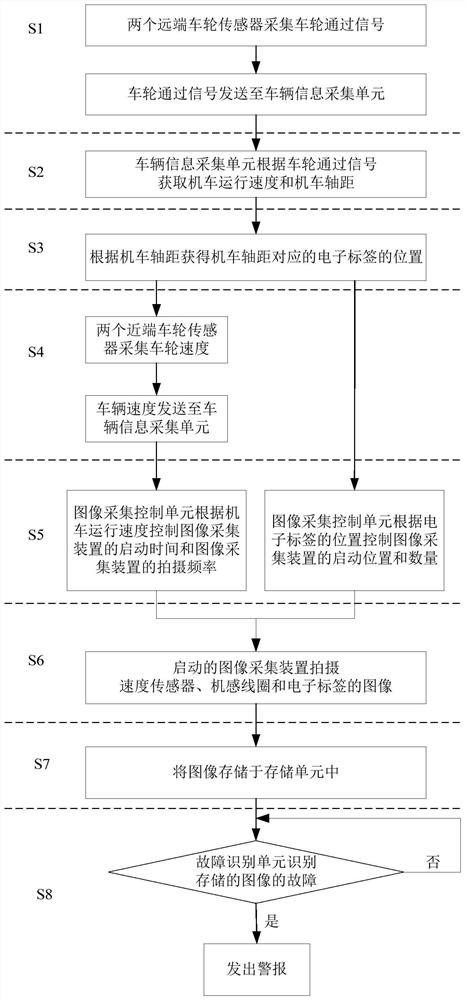

[0017] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the implementation method of the locomotive running equipment detection system described in this embodiment, the detection system implementation method is based on the locomotive running equipment detection system, and the locomotive running equipment detection system includes trackside equipment and machine room equipment; The wayside equipment includes wheel sensors and image acquisition devices; the machine room equipment includes vehicle information acquisition units, image acquisition control units, storage units and fault identification units.

[0018] The wheel sensor includes two remote wheel sensors. The two remote wheel sensors are set on the side of the rail far from the detection system. The two remote wheel sensors detect the speed of the wheels when the locomotive passes. According to the two remote wheel sensors Get the wheel speed to get the locomotive wheelbas...

specific Embodiment approach 2

[0032] Embodiment 2: In this embodiment, Embodiment 1 is further explained. The fault recognition unit in S8 recognizes the fault of the image stored in the storage unit by adopting automatic image recognition technology.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment further explains Embodiment 1. In S5, the image acquisition control unit controls the start-up of the compensation light source according to the start time of the image acquisition device and the shooting frequency of the image acquisition device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com