Method for controlling temperature of single plate

A control method and single-board technology, applied in the direction of temperature control using electric methods, can solve problems such as not being able to follow temperature changes in time, delay in normal working status, and invalidation, so as to avoid high-temperature protection failure, save adjustment time, and reduce The effect of system occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

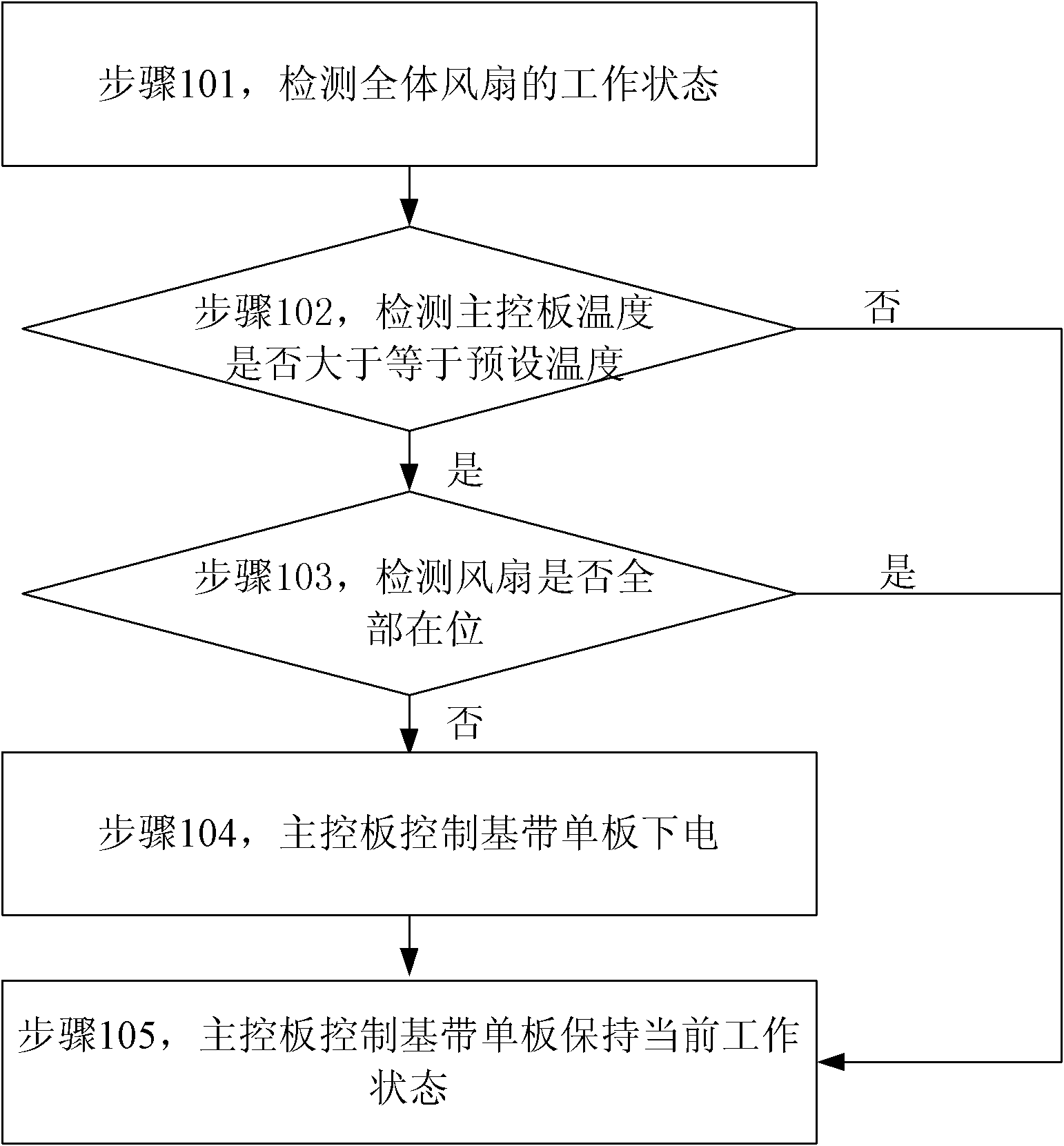

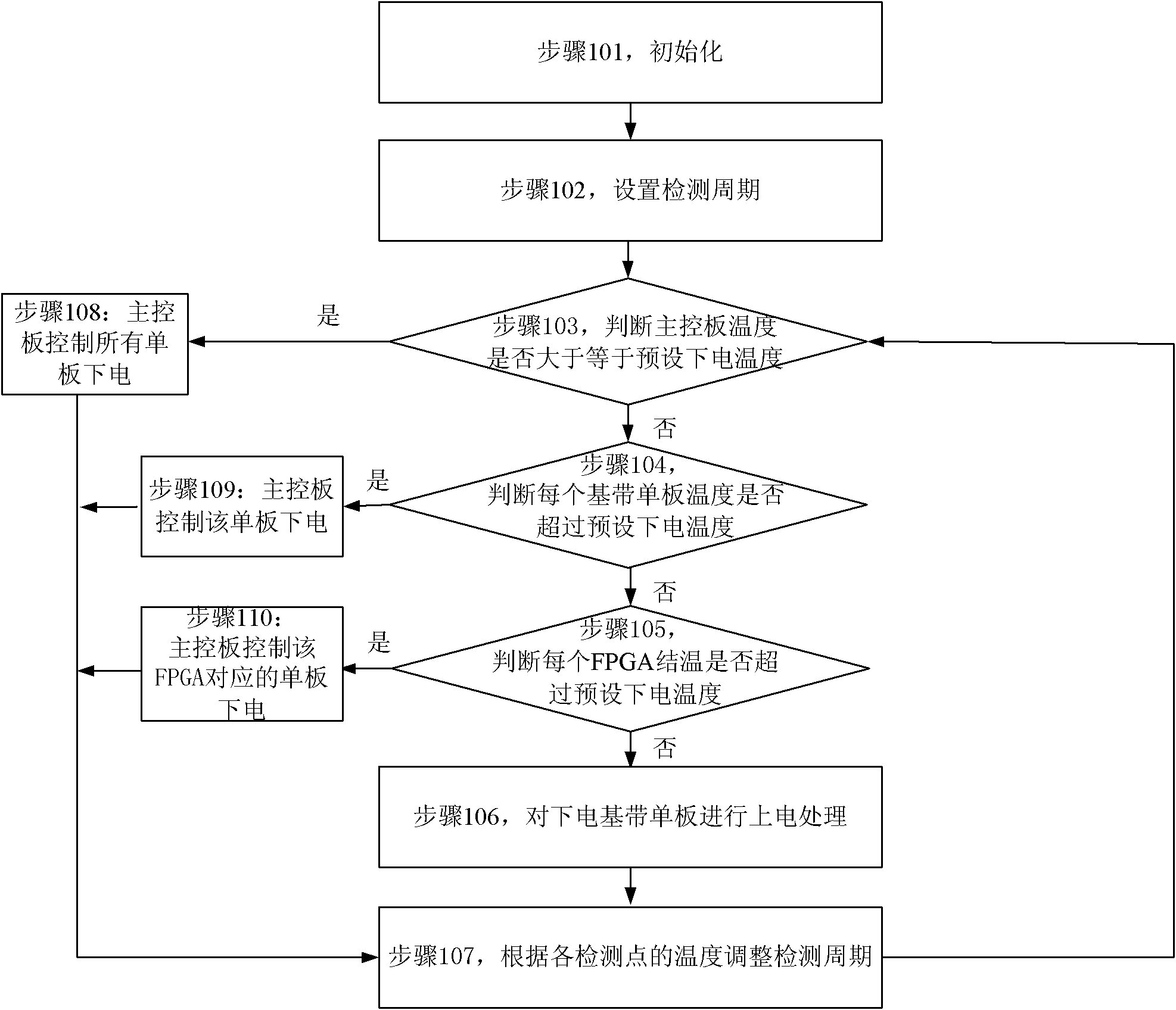

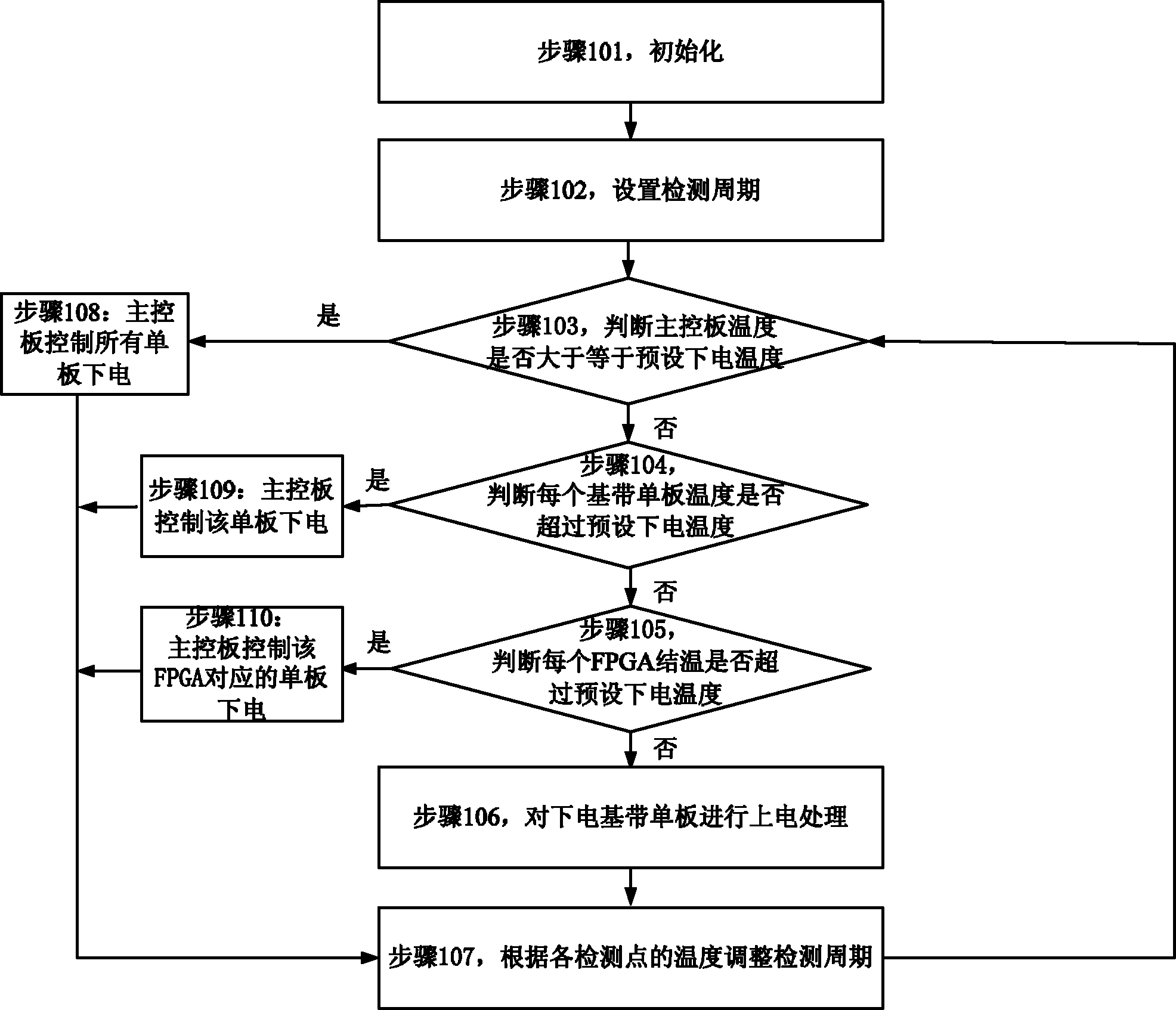

[0035] The invention provides a single board temperature control method, which controls the working state of the single board in combination with multiple parameters such as single board temperature, FPGA junction temperature and fan working state, and can effectively protect and recover the single board from high temperature , and can avoid failure of high temperature protection due to failure of individual components such as sensors.

[0036] The core idea of the present invention is: in each detection cycle, the main control board controls the working state of the single board according to multiple parameters such as the temperature of the main control board, the temperature of the single board, the FPGA junction temperature and the working state of the fan. When the board temperature exceeds the preset power-off temperature, all boards are powered off. When the temperature of any single board or FPGA junction exceeds the preset power-off temperature, the board is powered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com