Fatigue life prediction method for fiber metal laminate under complex load

A technology for fiber metal laminates and fatigue life prediction, applied in the direction of using stable tension/compression to test material strength, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

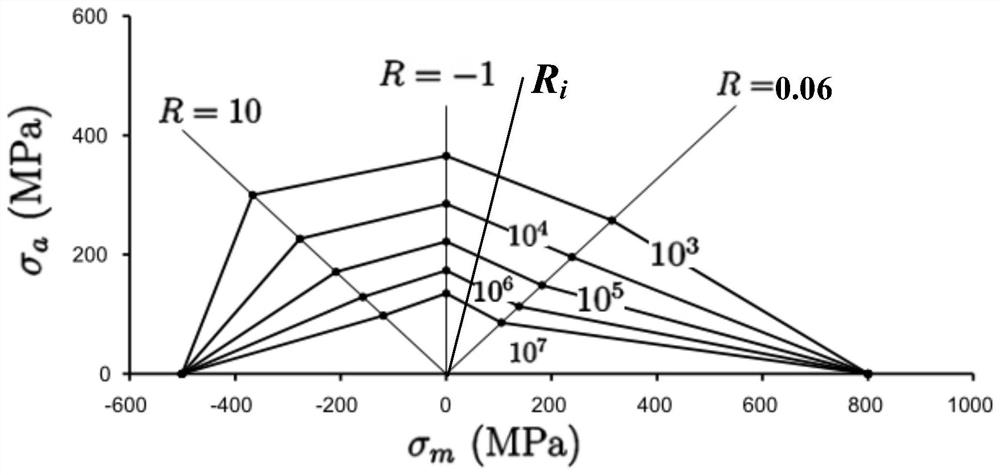

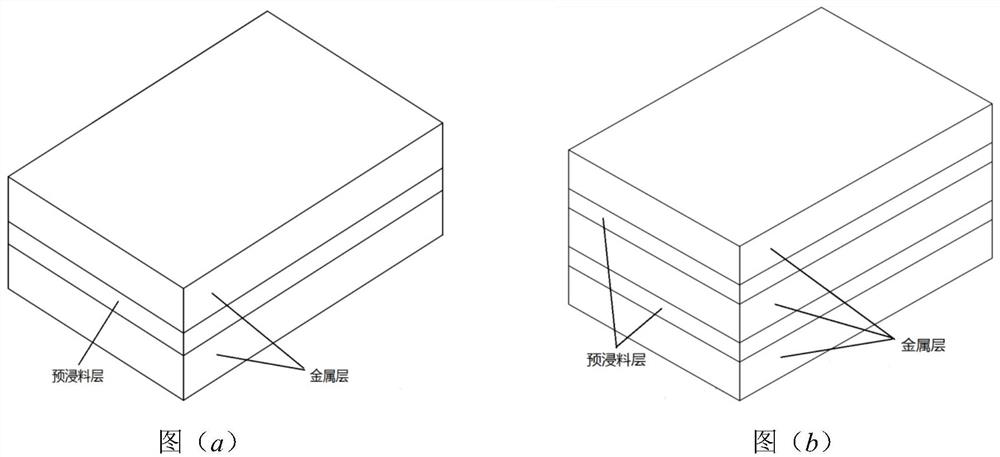

[0064] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples. The average stress correction model—Constant Life Diagrams (CLD) is a predictive tool for evaluating the fatigue life of materials under constant amplitude loading. It can reflect the comprehensive influence of material properties and average stress on fatigue life performance. Among them, the main parameters used to construct the CLD model are: stress amplitude, average stress and stress ratio, and the stress ratio is the ratio of the trough value to the peak value of the cyclic stress.

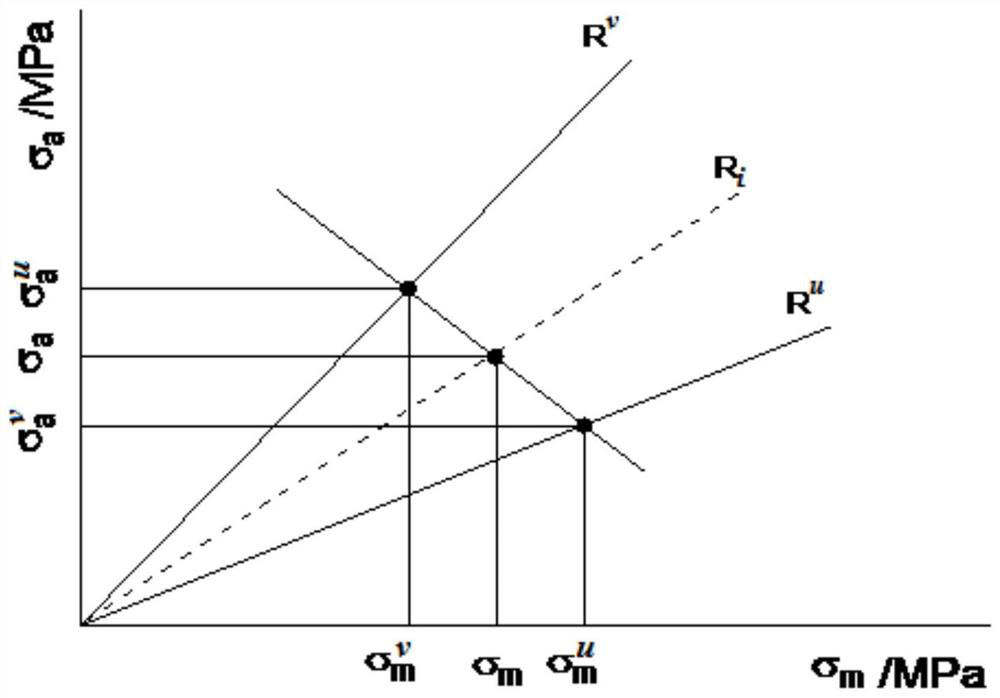

[0065] The piecewise linear difference method (also known as the piecewise linear CLD model) is developed by σ m -σ a The different S-N curves on the coordinate plane are deduced by the principle of linear interpolation, and the model is constructed by the ultimate compressive strength, ultimate tensile strength and some known S-N curves. The stress ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com