Method for measuring polyvinyl chloride content in plastic through thermal cracking-gas chromatography mass spectrometry

A technology of gas chromatography mass spectrometry and polyvinyl chloride, which is applied in the field of polyvinyl chloride content determination, and can solve problems such as polyvinyl chloride quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

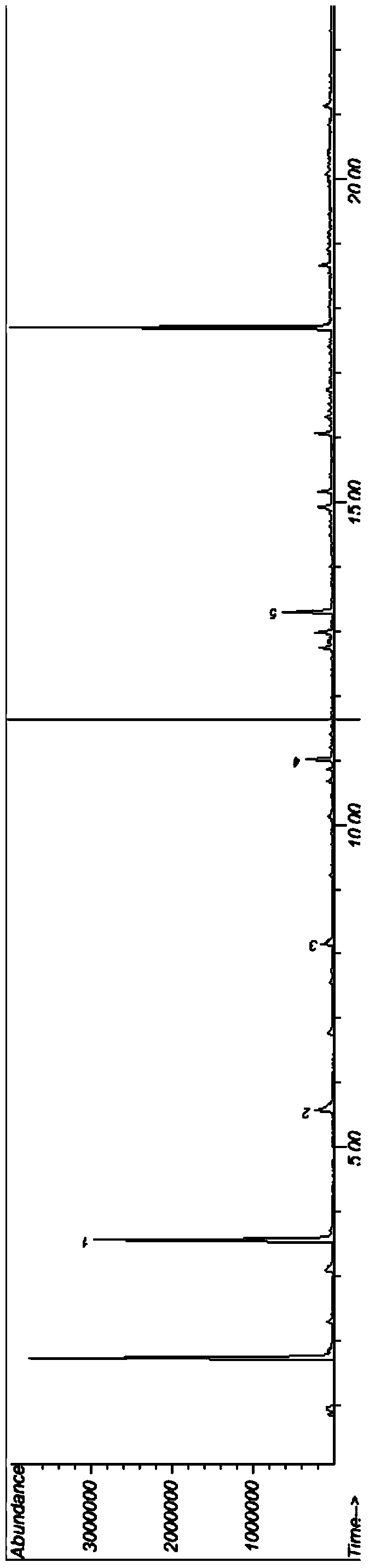

[0024] Experimental example 1, the mensuration of polyvinyl chloride in white plastic substrate (as attached figure 2 )

[0025] A sample pretreatment

[0026] (1) Cut the sample into particles smaller than 2mm×2mm×2mm in size, weigh 1.0g sample into a stoppered glass tube;

[0027] (2) Add 25mL tetrahydrofuran and shake on the shaker for 90 minutes, and pass the sample solution through a 0.45 micron polytetrafluoroethylene membrane;

[0028] (3) Pipette 50uL of the sample solution into the lysed sample boat, and evaporate it to dryness, so that the extract forms a film in the boat.

[0029] B thermal cracking - gas chromatography mass spectrometry

[0030] The sample boat is placed on the injector of thermal cracking-gas chromatography mass spectrometry, and the instrument parameters are set for automatic analysis.

[0031] The instrument conditions for gas chromatography-mass spectrometry are as follows:

[0032] (1) The gas chromatographic column adopts a weakly polar...

experiment example 2

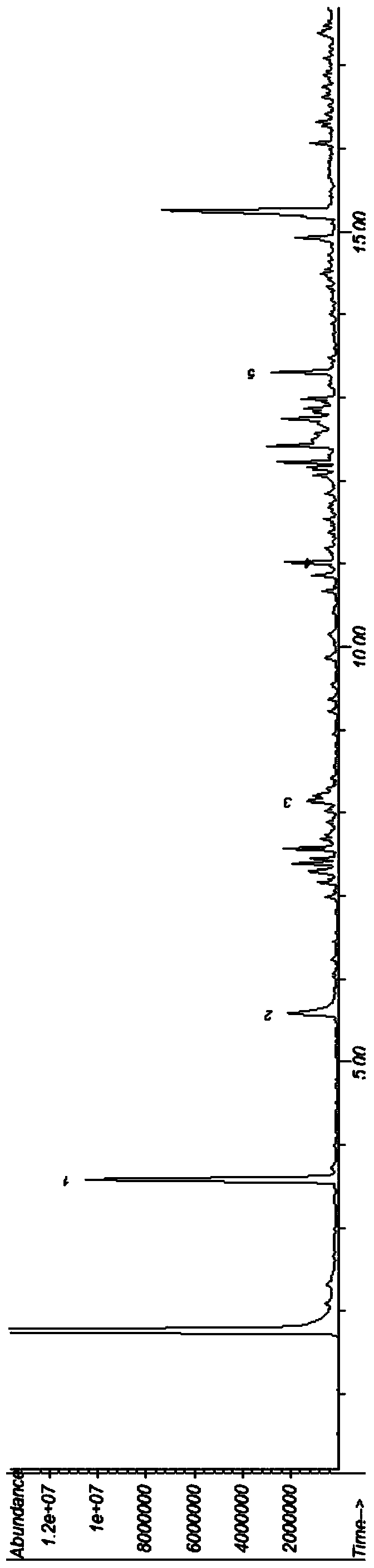

[0052] Experimental example 2, the mensuration of polyvinyl chloride in cloth (as attached image 3 )

[0053] A sample pretreatment

[0054] (1) Cut the sample into small pieces smaller than 2mm×2mm in size, weigh 1.0g of the sample into a stoppered glass tube;

[0055] (2) Add 25mL tetrahydrofuran and shake on the shaker for 90 minutes, and pass the sample solution through a 0.45 micron polytetrafluoroethylene membrane;

[0056] (3) Pipette 50uL of the sample solution into the lysed sample boat, and evaporate it to dryness, so that the extract forms a film in the boat.

[0057] B thermal cracking - gas chromatography mass spectrometry

[0058] The sample boat is placed on the injector of thermal cracking-gas chromatography mass spectrometry, and the instrument parameters are set for automatic analysis.

[0059] The instrument conditions for gas chromatography-mass spectrometry are as follows:

[0060] (1) The gas chromatographic column adopts a weakly polar HP-5ms colum...

experiment example 3

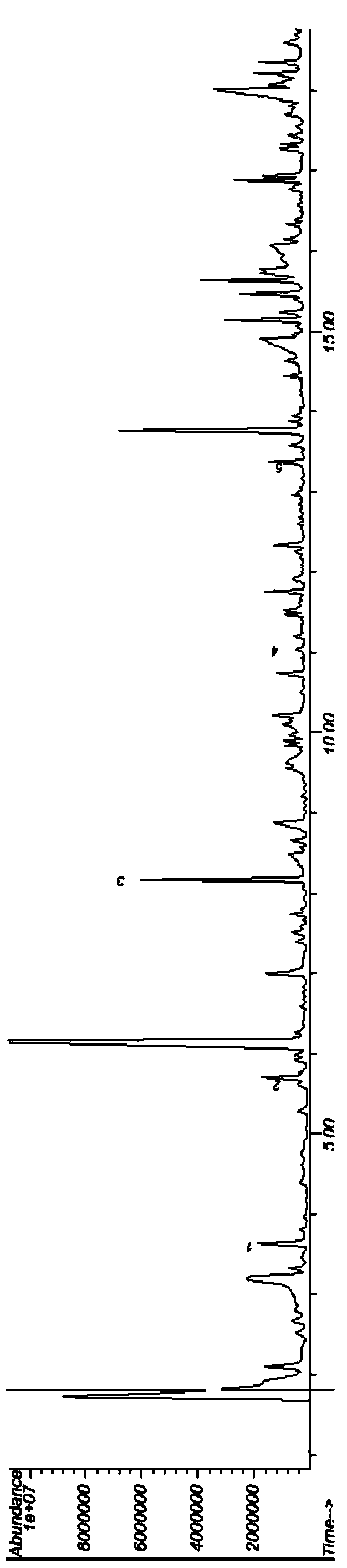

[0080] Experimental example 3, the mensuration of polyvinyl chloride in plastic tableware (as attached Figure 4 )

[0081] A sample pretreatment

[0082] (1) Cut the sample into particles smaller than 2mm×2mm×2mm in size, weigh 1.0g sample into a stoppered glass tube;

[0083] (2) Add 25mL tetrahydrofuran, and shake on the shaker for 90 minutes, and pass the sample solution through a 0.45 micron polytetrafluoroethylene membrane;

[0084] (3) Pipette 50 uL of the sample solution into the lysed sample boat, and evaporate to dryness, so that the extract forms a film in the boat.

[0085] B thermal cracking - gas chromatography mass spectrometry

[0086] The sample boat is placed on the injector of the thermal cracking-gas chromatography mass spectrometry, and the instrument parameters are set for automatic analysis.

[0087] The instrument conditions for gas chromatography-mass spectrometry are as follows:

[0088] (1) The gas chromatographic column adopts a weakly polar HP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com