Method for detecting PhIP content in frying oil

A frying oil and content technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of health hazards, high PhIP, etc., and achieve the effect of high precision, fast speed and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

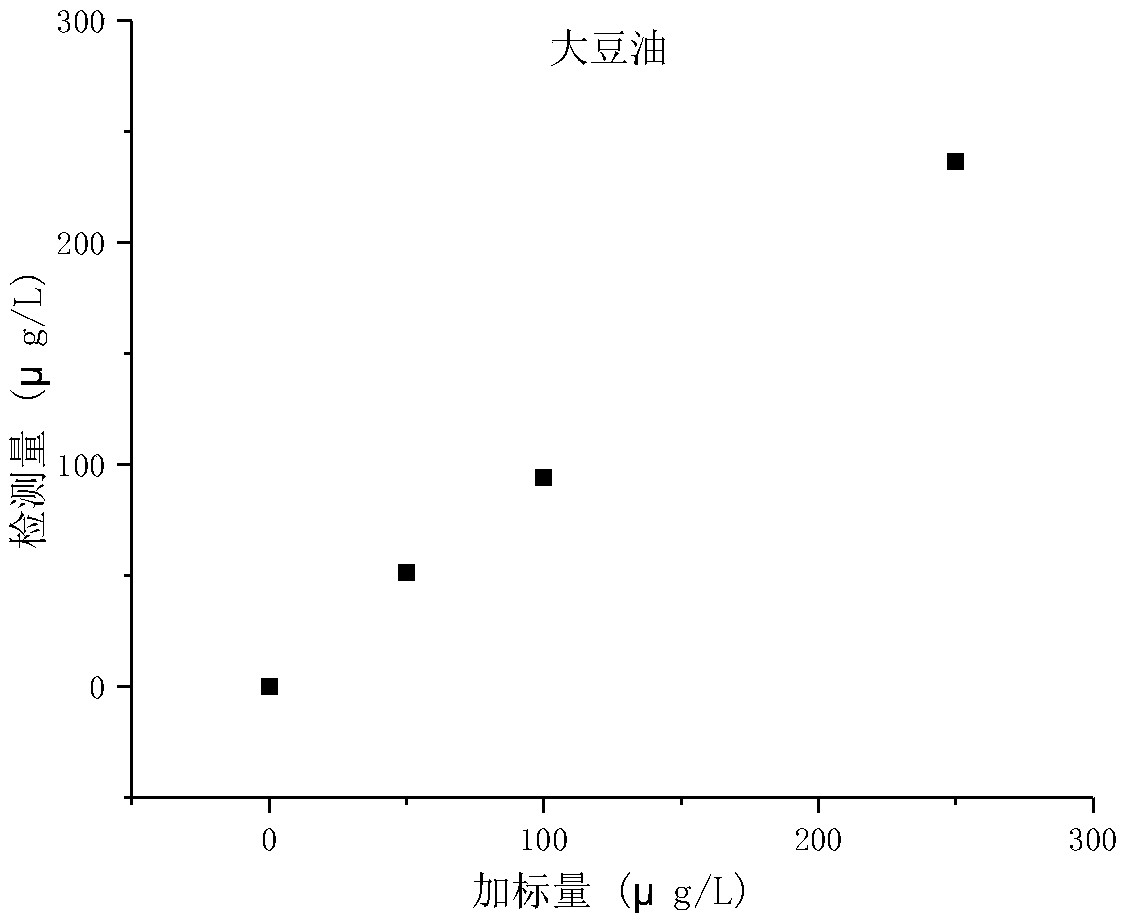

Embodiment 1

[0033] Extraction of PhIP:

[0034] Accurately weigh 3.00g of soybean oil into a Hach tube, add 10μL of PhIP standard solution with a concentration of 5mg / L, 10mg / L, and 25mg / L, respectively, and add levels of 50μg / L, 100μg / L, and 250μg / L , Add 7 mL of n-butanol and vortex mix for 5 min.

[0035] The next step is to perform propanesulfonic acid solid-phase extraction column extraction: first activate with 8mL methanol, adjust the flow rate to 1-2d / s, and when it is about to drip dry, add 8mL0.1mol / L hydrochloric acid: water (v / v=1 : 1) solution and 6mL n-butanol solution. Then, the n-butanol sample solution was loaded, and the prepared sample solution and 5mL rinse solution were added to the column, and the flow rate was adjusted to 2-3s per drop to ensure that the sample solution was adsorbed on the column packing as much as possible. After the sample in the column is dripped clean, rinse the column with 5mL0.01mol / L hydrochloric acid solution and 5mL0.1mol / L hydrochloric a...

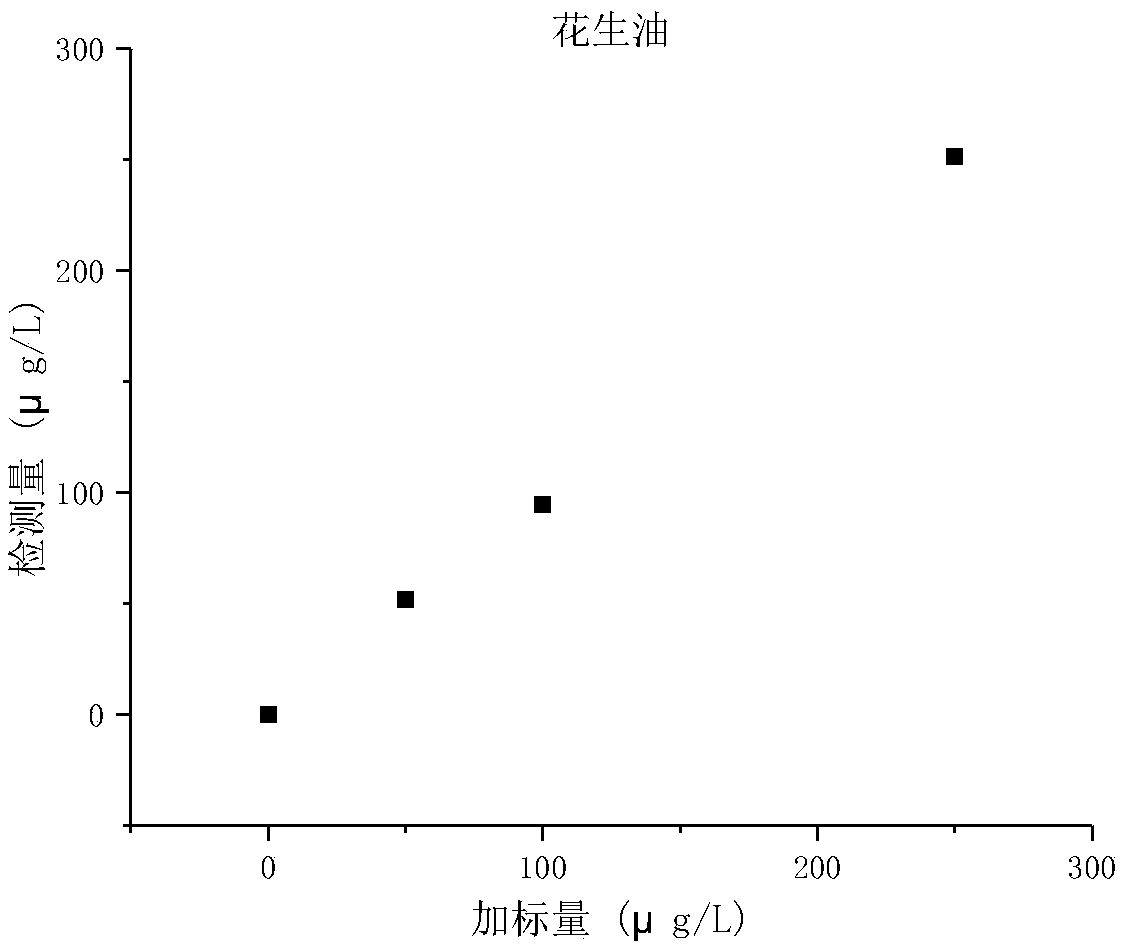

Embodiment 2

[0062] Extraction of PhIP:

[0063] Accurately weigh 3.00 g of peanut oil into a Hash tube, add 10 μL of PhIP standard solution with a concentration of 5 mg / L, 10 mg / L, and 25 mg / L, and add levels of 50 μg / L, 100 μg / L, and 250 μg / L, respectively. Add 7 mL of n-butanol and vortex mix for 5 min.

[0064] The next step is to perform propanesulfonic acid solid-phase extraction column extraction: first activate with 8mL methanol, adjust the flow rate to 1-2d / s, and when it is about to drip dry, add 8mL0.1mol / L hydrochloric acid: water (v / v=1 : 1) solution and 6mL n-butanol solution. Then, the n-butanol sample solution was loaded, and the prepared sample solution and 5mL rinse solution were added to the column, and the flow rate was adjusted to 2-3s per drop to ensure that the sample solution was adsorbed on the column packing as much as possible. After the sample in the column is dripped clean, rinse the column with 5mL0.01mol / L hydrochloric acid solution and 5mL0.1mol / L hydrochl...

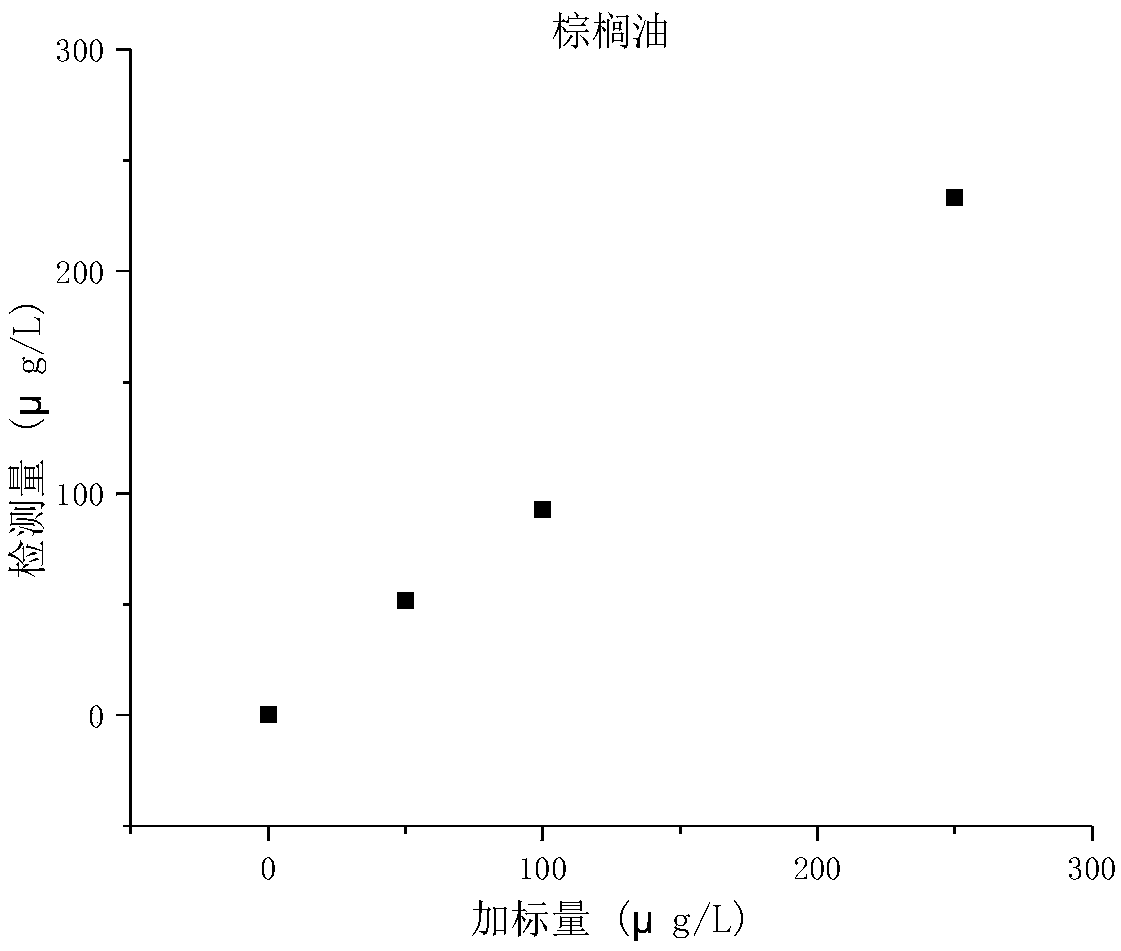

Embodiment 3

[0091] Extraction of PhIP:

[0092] Accurately weigh 3.00g of palm oil into a hash tube, add 10μL of PhIP standard solution with a concentration of 5mg / L, 10mg / L, and 25mg / L, and add levels of 50μg / L, 100μg / L, and 250μg / L respectively , Add 7 mL of n-butanol and vortex mix for 5 min.

[0093] The next step is to perform propanesulfonic acid solid-phase extraction column extraction: first activate with 8mL methanol, adjust the flow rate to 1-2d / s, and when it is about to drip dry, add 8mL0.1mol / L hydrochloric acid: water (v / v=1 : 1) solution and 6mL n-butanol solution. Then, the n-butanol sample solution was loaded, and the prepared sample solution and 5mL rinse solution were added to the column, and the flow rate was adjusted to 2-3s per drop to ensure that the sample solution was adsorbed on the column packing as much as possible. After the sample in the column is dripped clean, rinse the column with 5mL0.01mol / L hydrochloric acid solution and 5mL0.1mol / L hydrochloric acid:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com