Damping type oil pump support

A technology of oil pump and support, which is applied in the field of shock-absorbing oil pump support, can solve the problems of shortening the service life of the oil pump and damage to the oil pump body, and achieve the effects of increasing applicability, shortening service life and tight vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

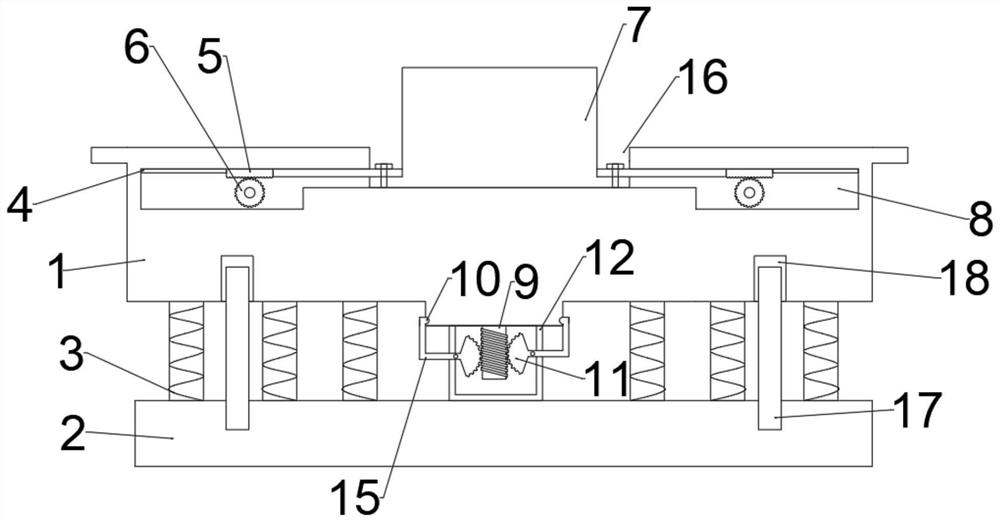

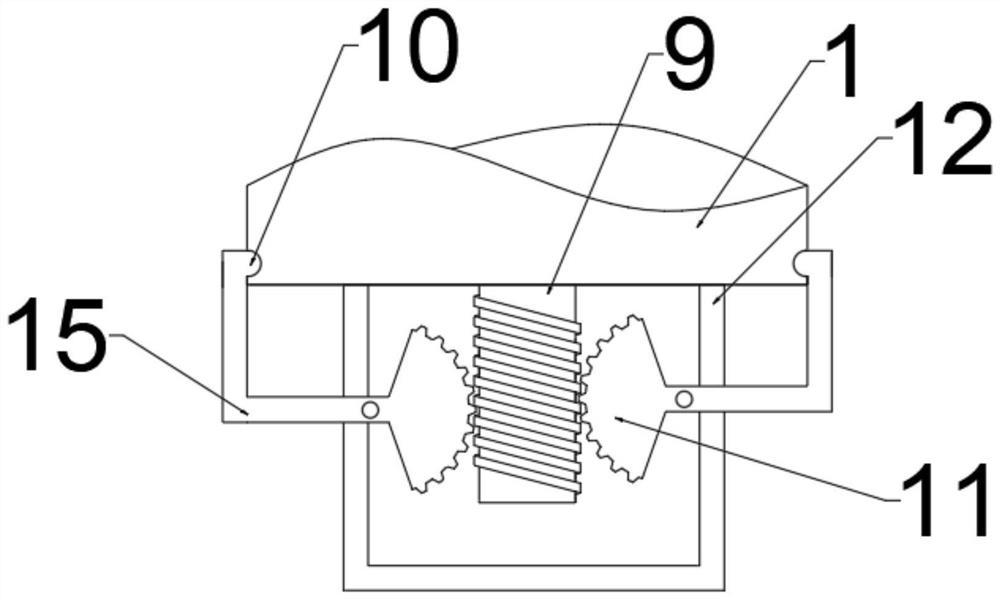

[0028] refer to Figure 1 ~ Figure 3 , a shock-absorbing oil pump support, including a bottom plate 2, a support box 12 is connected with bolts above the bottom plate 2, a placement plate 1 is bolted on the side of the support box 12 away from the bottom plate 2, and a fixing plate is provided above the placement plate 1. Cavity 16, the oil pump 7 is connected with the bolts in the fixed cavity 16, and the interior of the support box 12 is provided with a shock absorbing mechanism, which includes a screw rod 9, a clamping head 10, a sector gear 11 and a connecting rod 15, placed under the plate 1 The screw rod 9 is connected to the center bolt, and the screw rod 9 runs through the upper shell wall of the support box 12. The left and right sides of the screw rod 9 are meshed with a sector gear 11, and the end of the sector gear 11 away from the screw rod 9 is bolted to a connecting rod. 15. The end of the connecting rod 15 close to the sector gear 11 is rotatably connected to t...

Embodiment 2

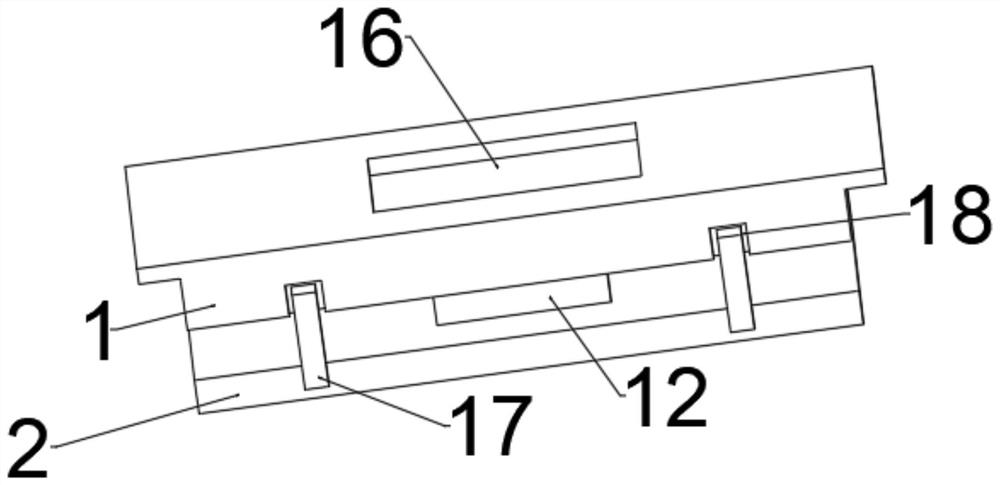

[0034] refer to Figure 4 , a shock-absorbing oil pump support. Compared with Embodiment 1, this embodiment is provided with a cover plate 13 above the placement plate 1, and one end of the cover plate 13 close to the oil pump 7 is connected with a connecting block 14 by bolts. The connecting block 14 It is connected with the oil pump 7 by bolts, and the end of the cover plate 13 away from the oil pump 7 is bolted to a clamping plate 19. The clamping plate 19 and the upper boss of the placement plate 1 are embedded and connected. When the oil pump 7 is placed in the fixed cavity 16, the clamping The plate 19 and the upper boss on which the plate 1 is placed are embedded with each other, and then the connecting block 14 is fixedly connected with the oil pump 7 to limit the position of the oil pump 7, so that the shock absorption effect is better and its applicability is increased.

[0035] Working principle: when the oil pump 7 is put into the fixed cavity 16, the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com