A variable heat source cascade phase change energy storage control device

A control device and phase-change energy storage technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of inefficient storage of heat, heat loss in cascade heat storage systems, etc., and achieve reduction loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

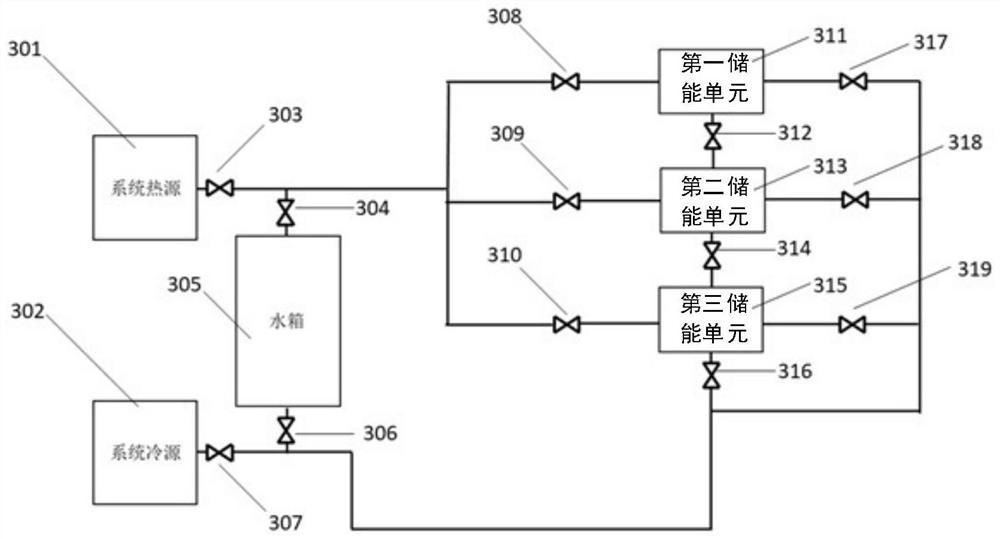

[0021] Example 1: as figure 1 Shown is a schematic diagram of a heat storage device in an embodiment of the present invention, wherein the system heat source 301, the system cold source 302, the system heat source outlet valve 303, the water tank system heat source side valve 304, the water tank 305, the water tank system cold source side valve 306, System cold source outlet valve 307, first energy storage unit inlet valve 308, second energy storage unit inlet valve 309, third energy storage unit inlet valve 310, first energy storage unit 311, first energy storage unit outlet valve 312 , the second energy storage unit 313, the second energy storage unit outlet valve 314, the third energy storage unit 315, the third energy storage unit outlet valve 316, the first energy storage unit another outlet valve 317, the second energy storage unit another One outlet valve 318, and another outlet valve 319 of the third energy storage unit. The phase change material in the energy storage...

Embodiment 2

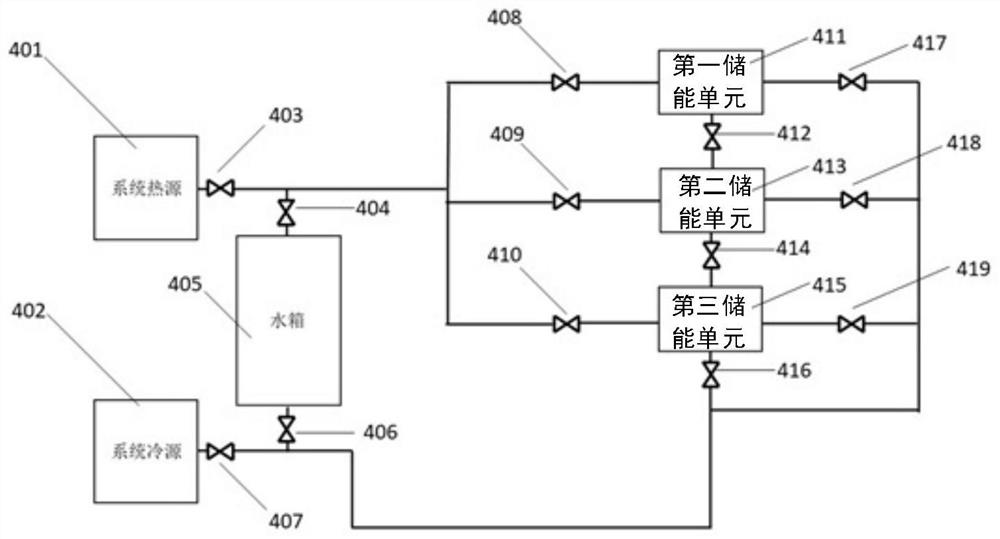

[0024] Example 2: as figure 2 Shown is a schematic diagram of a cold storage device in an embodiment of the present invention, the system heat source 401, the system cold source 402, the system heat source outlet valve 403, the water tank system heat source side valve 404, the water tank 405, the water tank system cold source side valve 406, and the system cold source side valve 406. Source outlet valve 407, first energy storage unit outlet valve 408, second energy storage unit outlet valve 409, third energy storage unit outlet valve 410, first energy storage unit 411, first energy storage unit inlet valve 412, Two energy storage units 413, the second energy storage unit inlet valve 414, the third energy storage unit 415, the third energy storage unit inlet valve 416, the first energy storage unit another inlet valve 417, the second energy storage unit another inlet Valve 418, third energy storage unit inlet valve 419. Among them, for the smooth progress of the cascade cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com