After-sales equipment predictive maintenance cooperation system based on digital twinning

A collaborative system and predictive technology, applied in forecasting, data processing applications, instruments, etc., can solve problems such as low collaboration efficiency, and achieve the effect of timely service and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

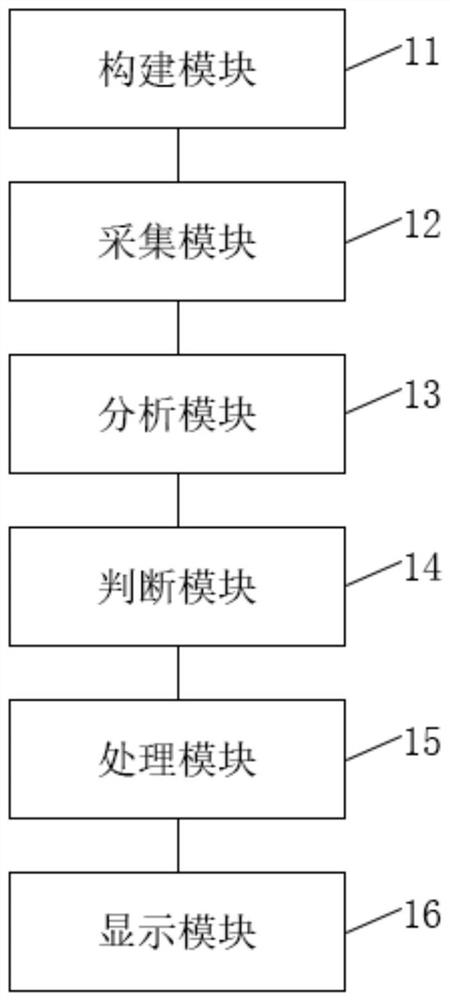

[0052] This embodiment provides a collaborative system for predictive maintenance of after-sales equipment based on digital twins, such as figure 1 shown, including:

[0053] Building block 11, used to build a collaborative maintenance seven-dimensional model based on the digital twin of the equipment manufacturer;

[0054] The acquisition module 12 is used for the real-time acquisition and transmission of operating state parameters of the equipment based on the collaborative maintenance of the constructed digital twin to maintain the seven-dimensional model;

[0055] The analysis module 13 is used to predict and analyze the collected equipment operating parameters based on the constructed digital twin collaborative maintenance seven-dimensional model, and obtain equipment prediction results;

[0056] Judging module 14, for judging whether the state of current equipment is normal according to the obtained equipment prediction result;

[0057] The processing module 15 is used...

Embodiment 2

[0126] A digital twin-based after-sales equipment predictive maintenance collaboration system provided in this embodiment is different from Embodiment 1 in that:

[0127] In this embodiment, a certain bottled water production process is taken as an example for illustration.

[0128] The Markov chain model is a dynamic stochastic model named by the Russian mathematician A.A.Markov. It predicts the future movement of these variables by analyzing the actual movement of random variables. This process requires no aftereffect, that is, the probability distribution of the next state can only be determined by the current state, and has nothing to do with the previous state. That is to say: the past only affects the present, not the future, and only the present affects the future.

[0129] The state of a device can be modeled simply as Figure 7 Shown: normal state (N), degraded state (Abn) and fault state (F). Failure rate λ and repair rate μ are the reciprocals of mean time to fai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com