Wafer processing method

A processing method and wafer technology, applied to metal processing equipment, film/sheet adhesives, manufacturing tools, etc., can solve problems such as pollution sources, reduced adhesion between chuck table and protective tape, and insufficient cleaning , to achieve the effect of solving pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, a wafer processing method according to an embodiment of the present invention will be described in detail with reference to the drawings.

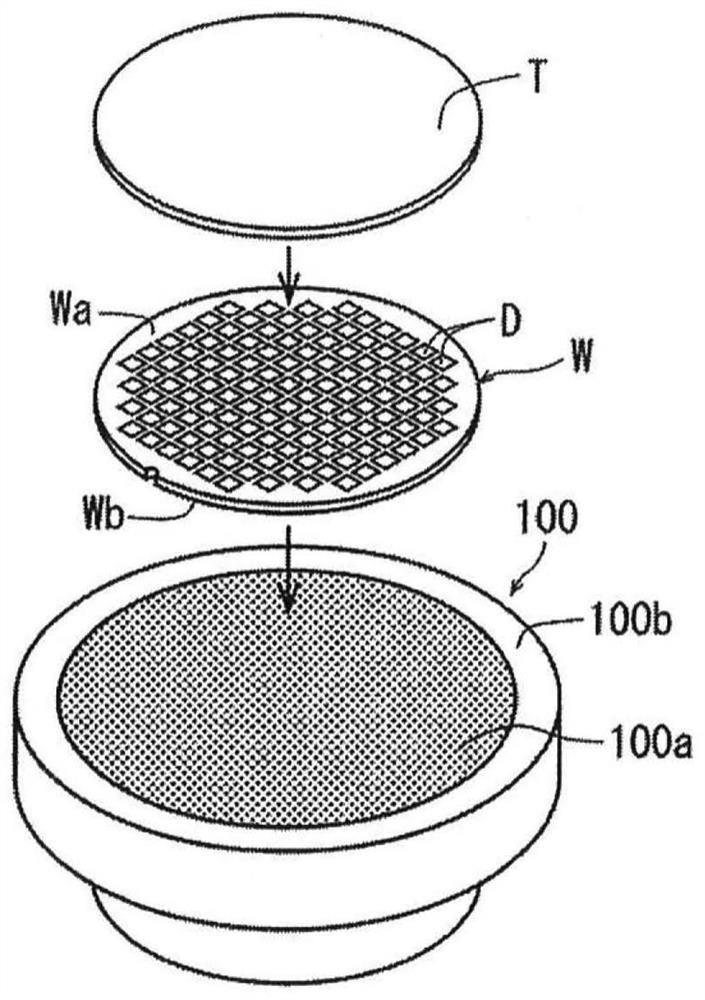

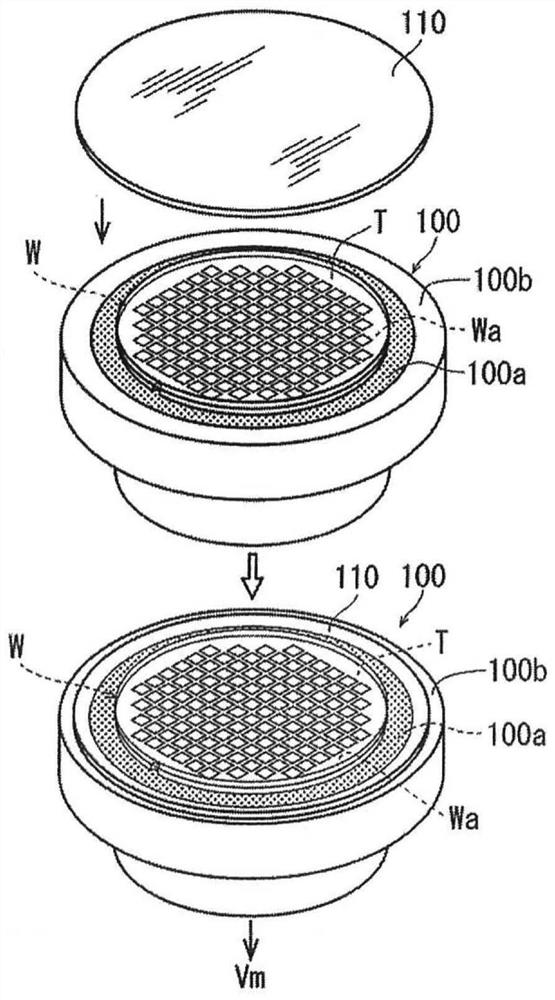

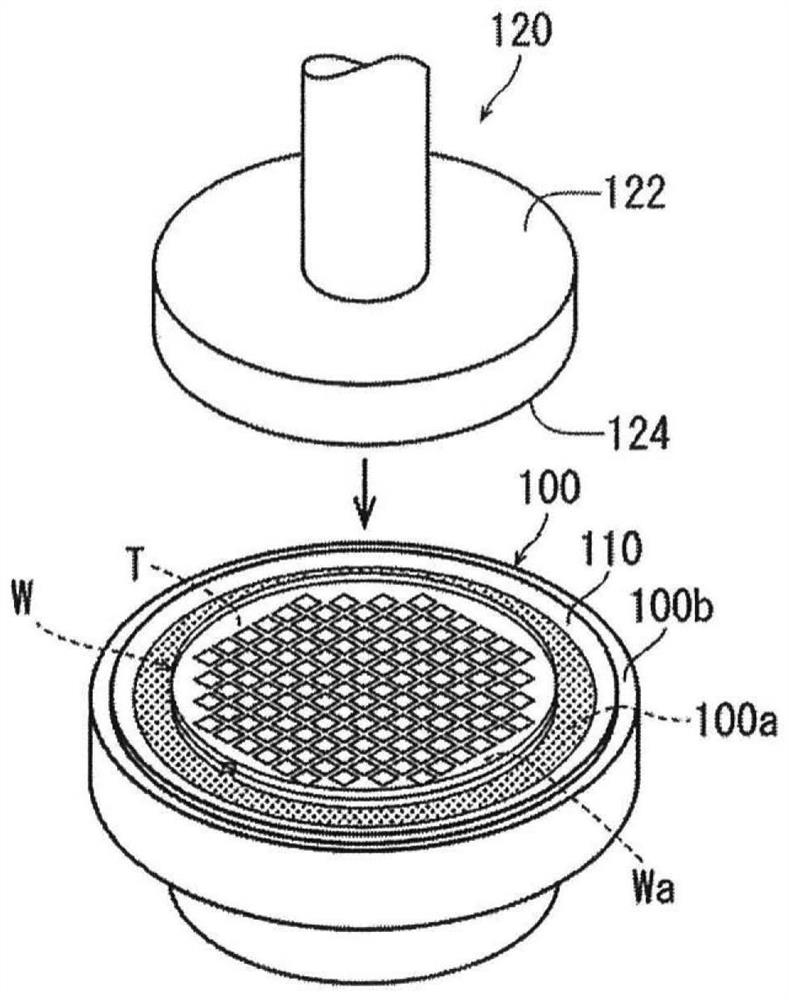

[0025] The wafer processing method of this embodiment includes the following steps: an adhesive tape sticking step, where the adhesive tape is pasted on the front surface of the wafer; Thermocompression bonding sheet; integration process, heating the thermocompression bonding sheet and pressing it with a flat member, and crimping the thermocompression bonding sheet to the adhesive tape for integration; grinding process, holding the thermocompression bonding sheet side Grinding the wafer to a desired thickness while supplying grinding water to the back surface of the wafer on the chuck table of the grinding device; Peel the thermocompression bonding sheet from the adhesive tape. Hereinafter, each step will be described in order.

[0026] (Adhesive tape sticking process)

[0027] exist figure 1 A perspective view illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com