Processing method for wafer

A processing method and wafer technology, applied in the direction of film/flaky adhesives, semiconductor devices, electrical components, etc., can solve the problems of reduced adhesion between the chuck table and the protective tape, pollution sources, and insufficient cleaning, etc. Achieves the effect of suppressing adhesion to the thermocompression bonding sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

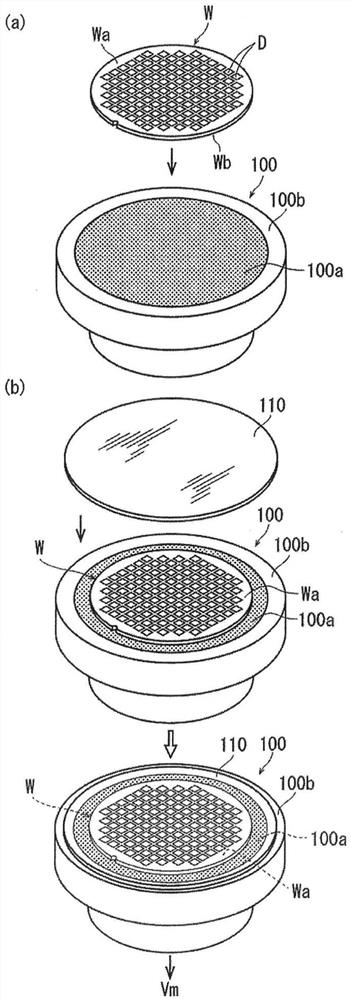

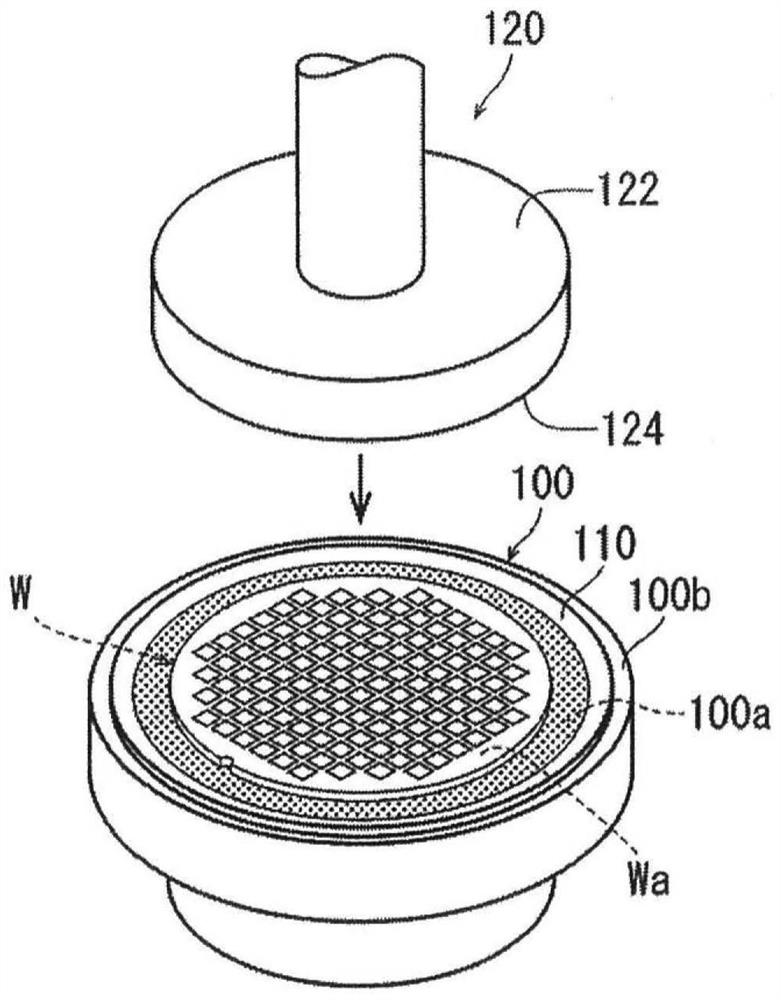

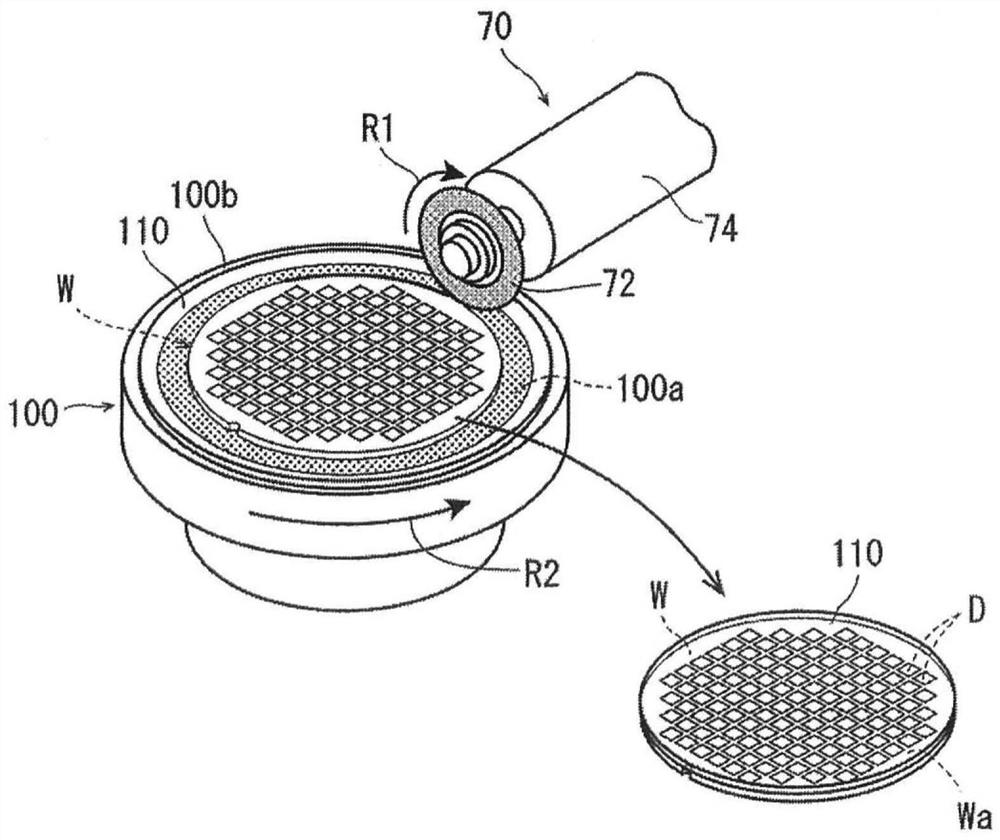

[0024] Hereinafter, an embodiment of a wafer processing method according to an embodiment of the present invention will be described in detail with reference to the drawings.

[0025] The wafer processing method of the present embodiment includes the following steps: a thermocompression bonding sheet arrangement step, disposing a thermocompression bonding sheet of the size covering the wafer on the front surface of the wafer; an integration step, flattening the thermocompression bonding sheet, In addition, the thermocompression bonding sheet and the wafer are integrated; in the grinding process, the thermocompression bonding sheet side is kept on the chuck table of the grinding device, and grinding is performed to a desired thickness while supplying grinding water to the back of the wafer; And a thermocompression bonding wafer cleaning step, carrying out the wafer integrated with the thermocompression bonding wafer from the chuck table, and cleaning the thermocompression bondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com