Dosing machine for hard gelatin capsules

A technology of metering device and hard capsule, applied in the direction of capsule conveying, packaging, transportation and packaging, etc., can solve the problems of inaccurate dose, device stuck performance, unsuccessful and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

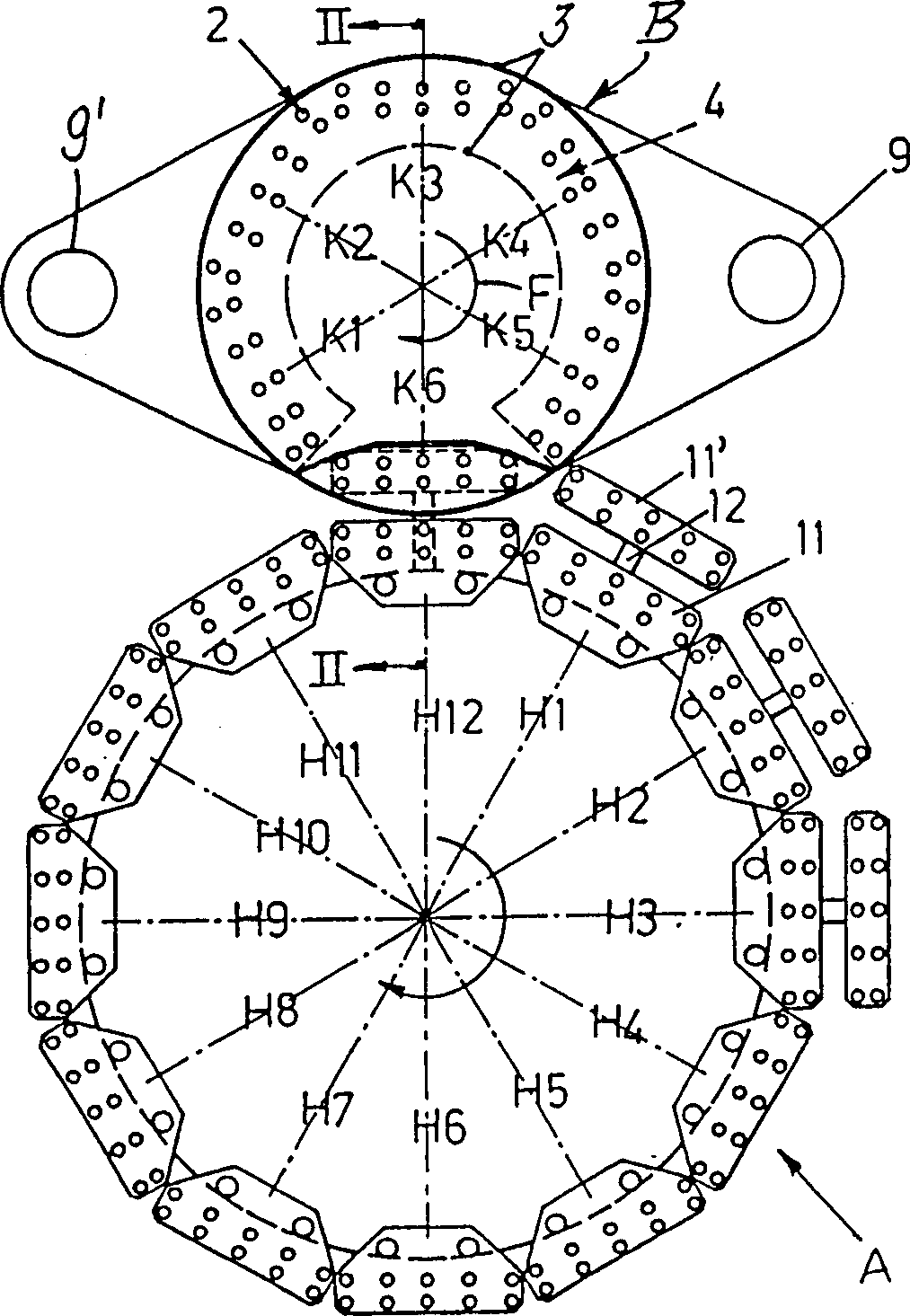

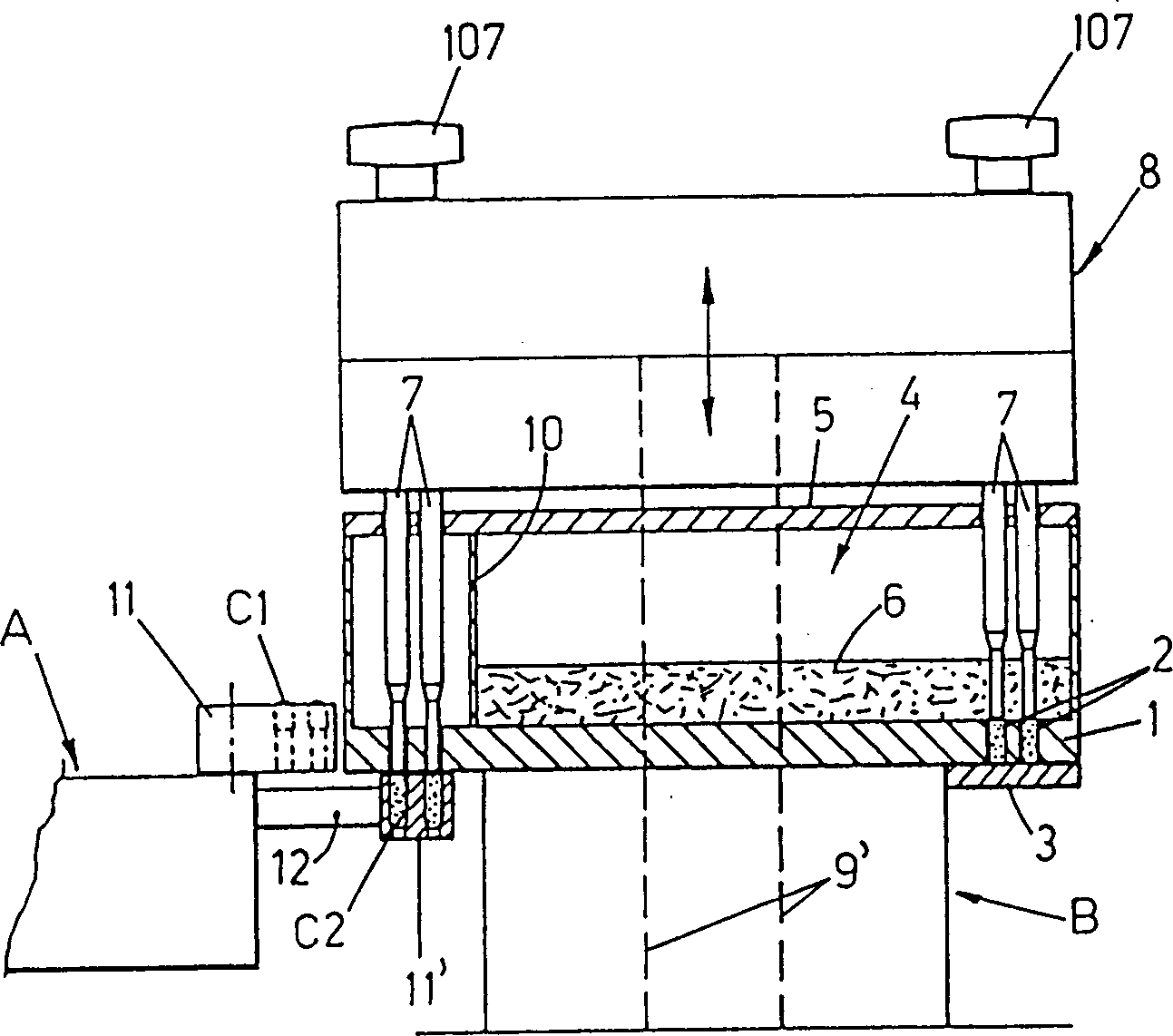

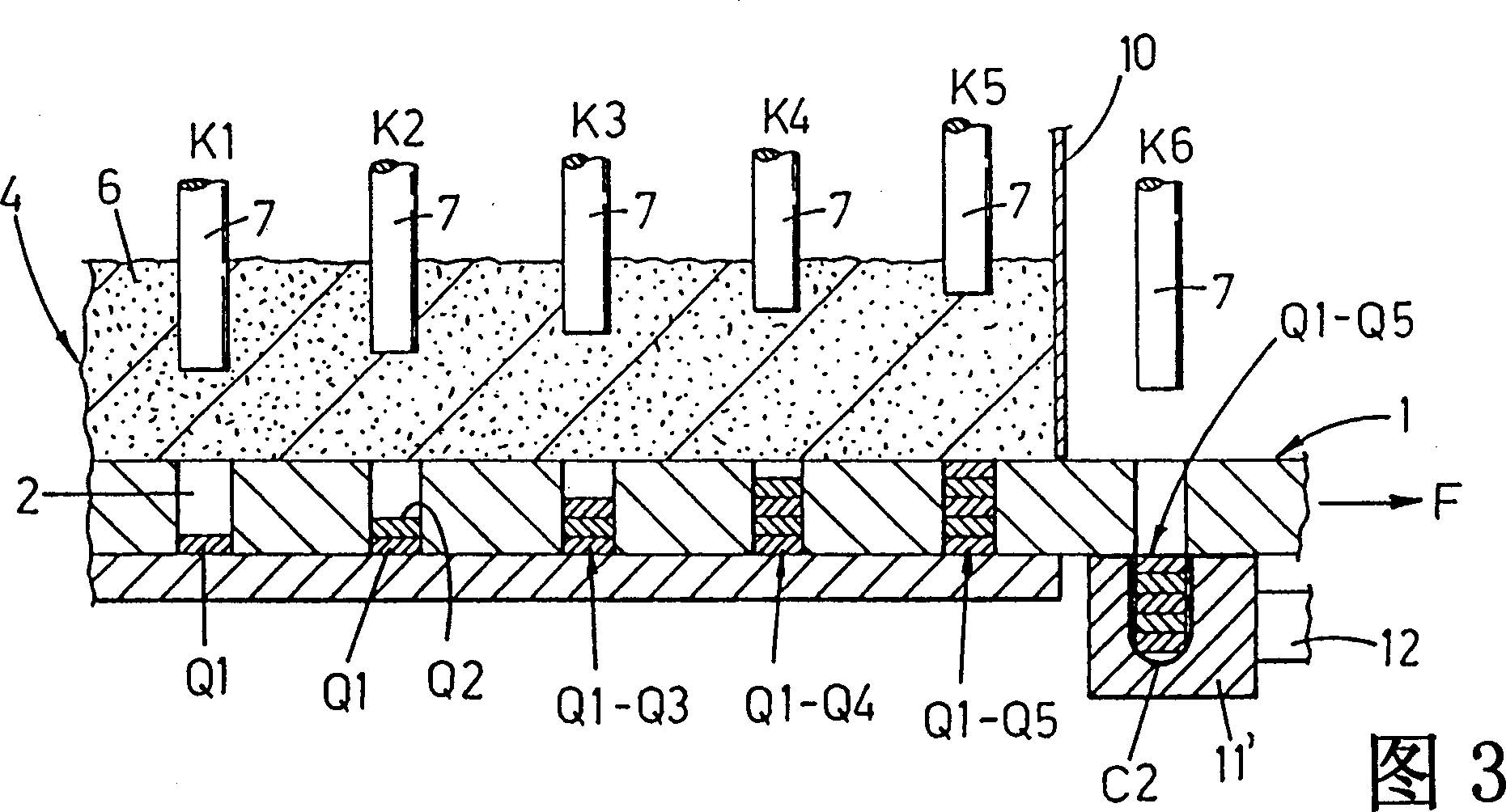

[0016]These and other features of the present invention and the advantages obtained therefrom will become more apparent in the following description with reference to FIGS. 4 and 5 . In these figures, 13 denotes a fixed vertical axis on which a combined carousel 14 turns, for example counterclockwise, and supports at its top a carousel 1 with an array of metering holes 2, said The metering holes are provided at appropriate equal intervals and in appropriate quantity, for example, 12 groups. As can be seen in FIG. 4 , in each group of holes 2 , the holes are arranged in multiple rows, such as two rows, and the holes of one row are staggered relative to the holes of adjacent rows. A seat 11 is fixed radially around the periphery of the disc 1 and protrudes therefrom, said seat with a seat for supporting the top C1 of the capsule, but which allows the bottom of the capsule to pass underneath and which is open at the bottom. Below these seats are movable seats 11', which carry se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com