Array resonator based on phononic crystals

A technology of phononic crystals and resonators, which is applied in the field of sound devices, can solve problems such as the inability to collect sound in the narrow range and the inability of sound power generation technology to improve the efficiency of converting sound energy into electric energy, so as to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

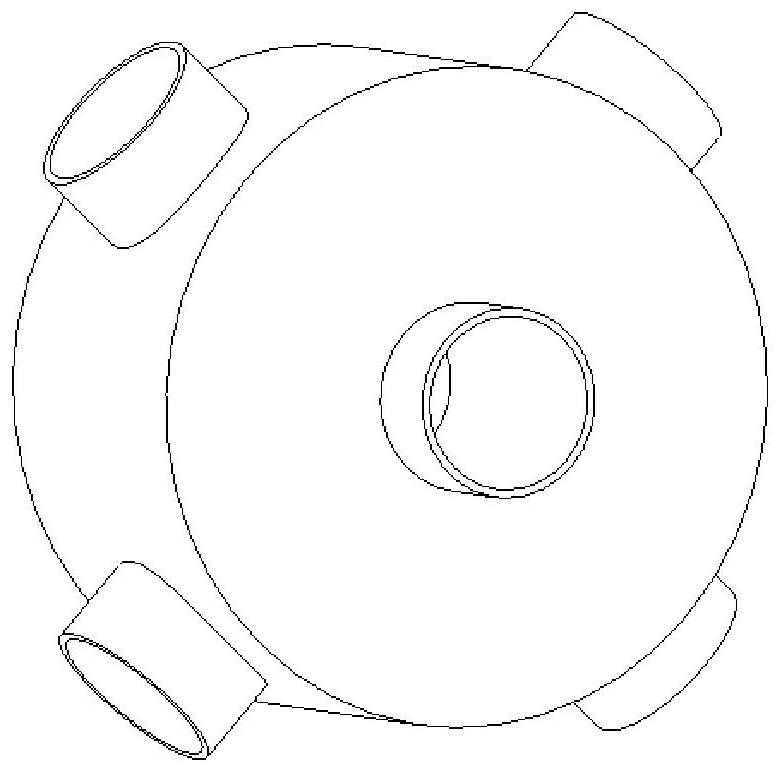

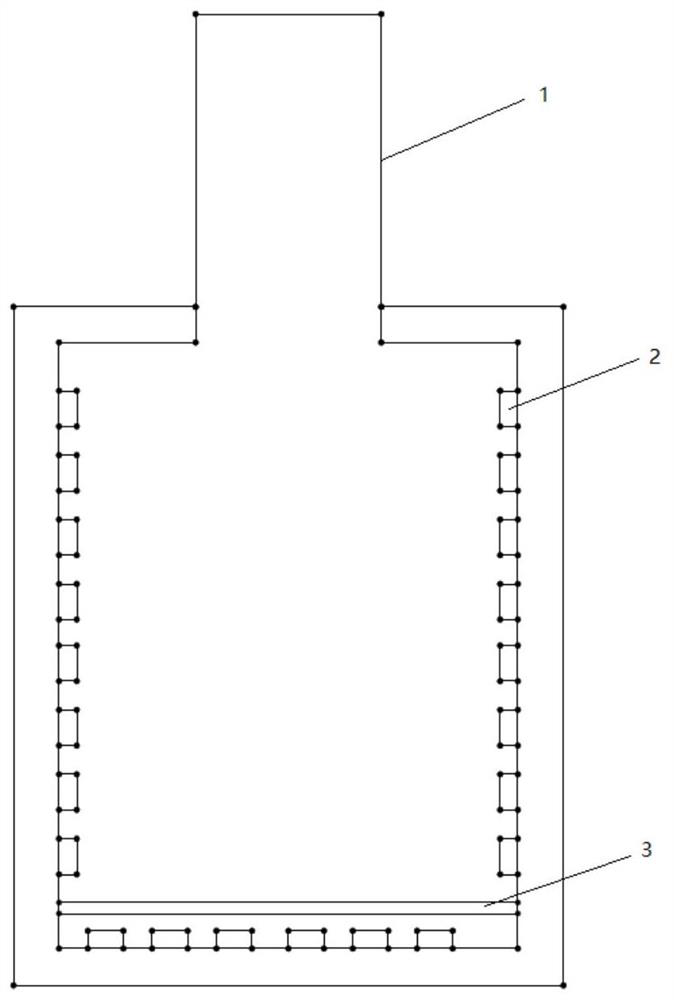

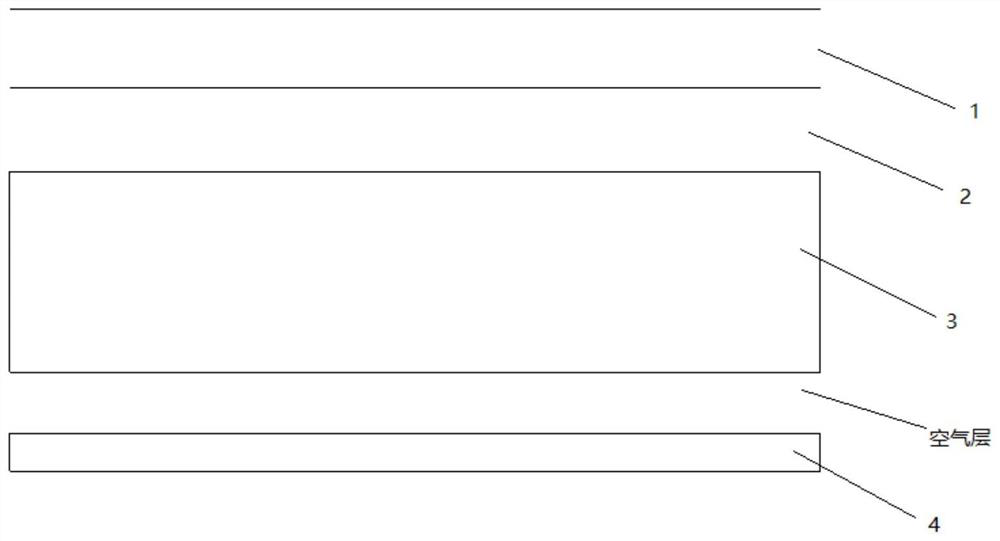

[0016] combine Figure 1-4 , a phononic crystal-based array resonator includes: a number of Helmholtz resonators, a phononic crystal base plate, a phononic crystal, and a piezoelectric film. Several Helmholtz resonators are arranged mutually by Helmholtz resonators of different sizes; the phononic crystal base plate is placed at the bottom of several Helmholtz resonators; the phononic crystals are arranged in the cavity of the several Helmholtz resonators Inside the body; the piezoelectric film is also placed at the bottom of several Helmholtz resonators, and an air layer is separated from the phononic crystal base plate, thereby improving the vibration efficiency of the piezoelectric film.

[0017] Several Helmholtz resonators are designed with different sizes to facilitate the collection of sounds of different frequencies, improve the efficiency of sound-to-ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com