Semi-automatic fresh oyster opening device

A semi-automatic, raw oyster technology, applied in the processing of crustaceans, slaughtering, bivalves, etc., can solve the problems of time-consuming, labor-intensive, unsafe, and easily injured hand labor load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

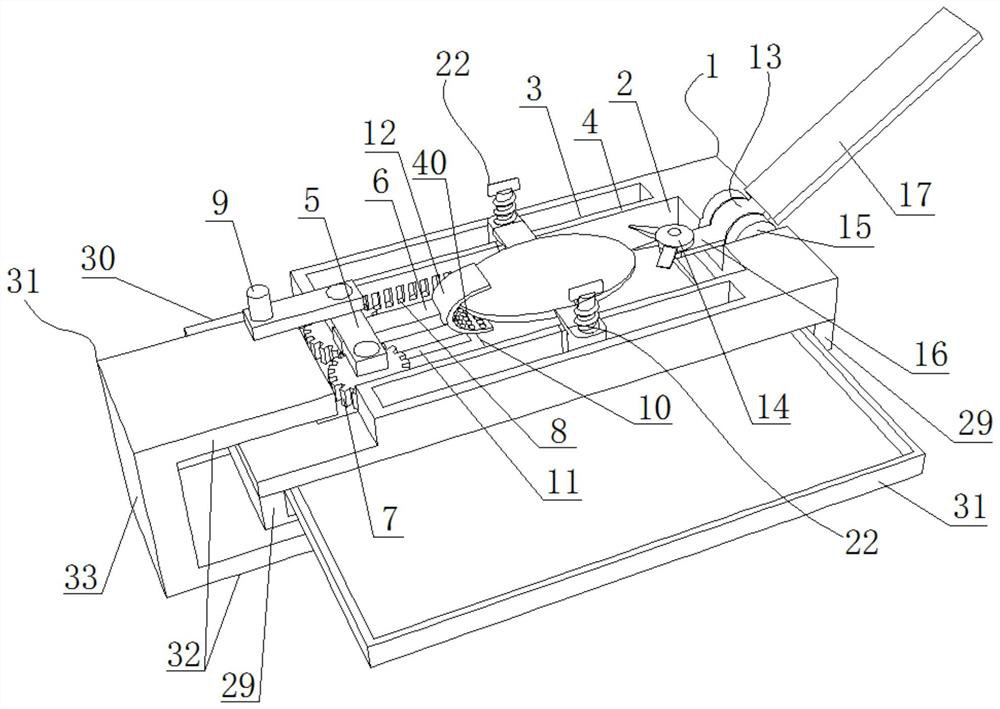

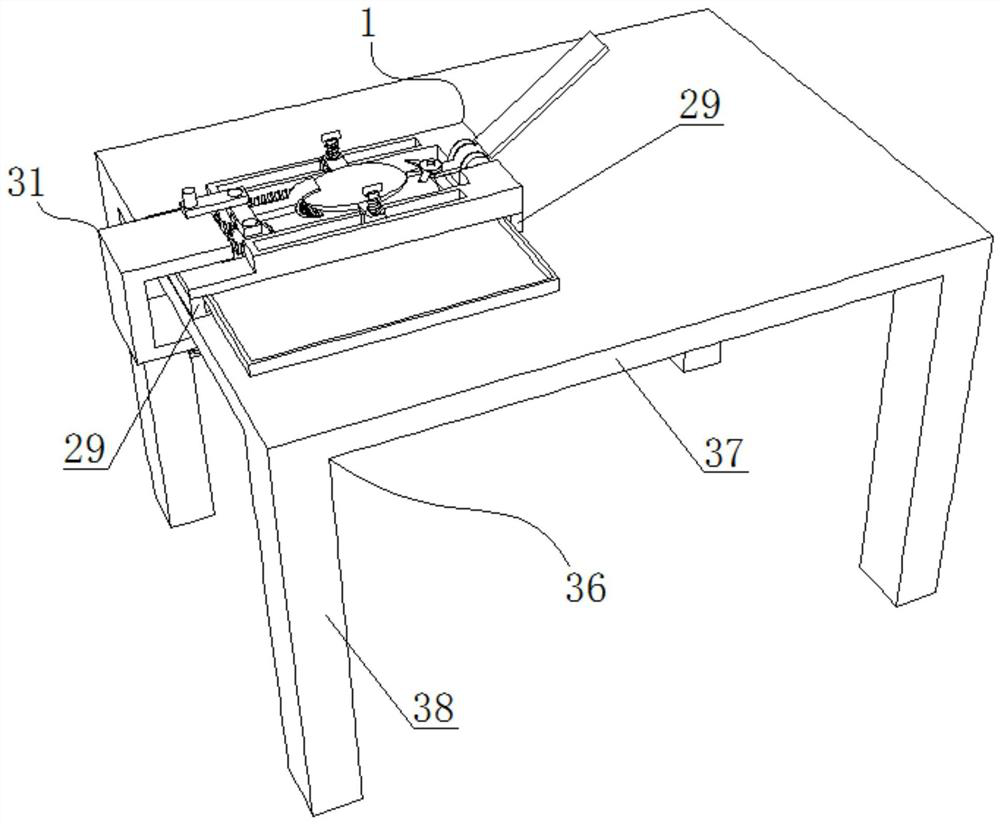

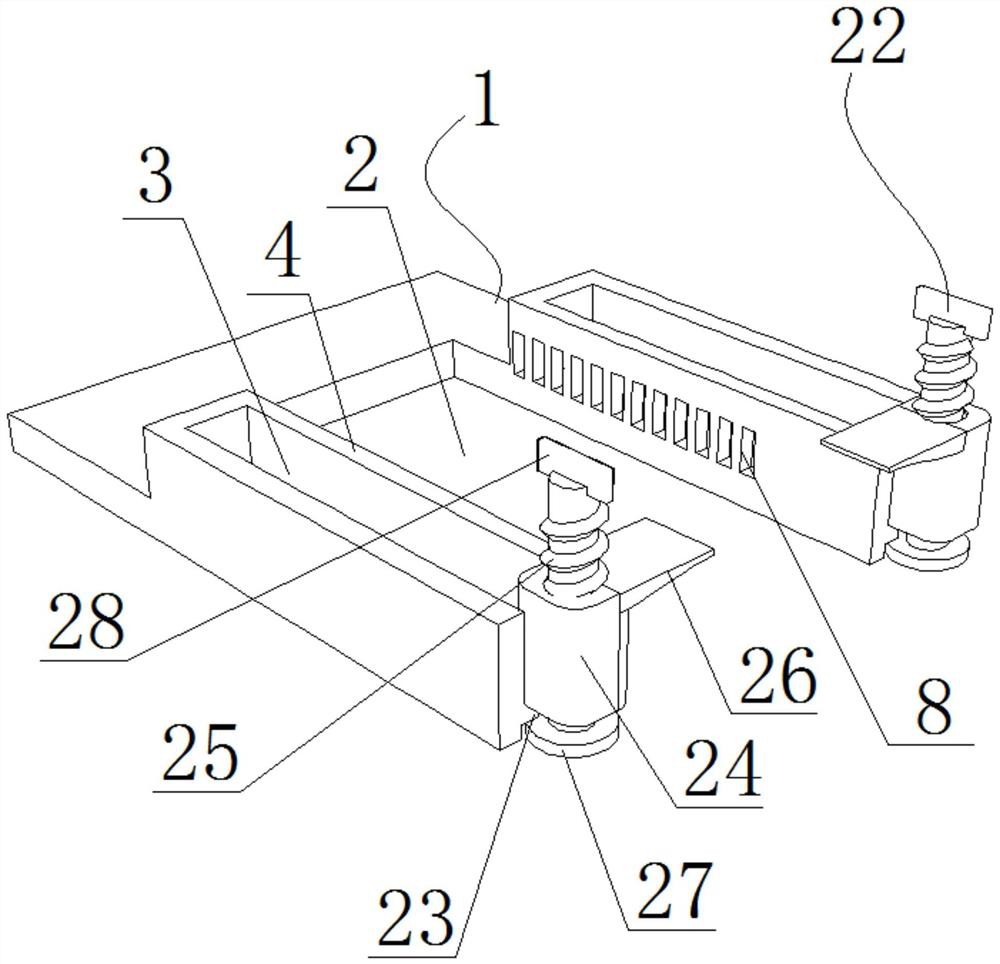

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] like Figure 1 to Figure 5 As shown, a semi-automatic oyster opening device includes a loading platform 1, a splint driving mechanism, a U-shaped splint 12, a bending handle 13, a knife head 14, a pair of side opening mechanisms 22, a pair of L-shaped limit blocks 29 and a tray 31;

[0024] The carrying table 1 is provided with a bar-shaped groove A2 extending through the thickness direction and extending left and right in the middle, and two bar-shaped grooves B3 are symmetrically opened on the front and rear sides of the bar-shaped groove A2. The middle part of the right end is fixedly connected with a hinged seat 15; as a preference, the middle part of the right end of the strip groove A2 is provided with a downwardly recessed installation gap, and the hinged seat 15 is hinged in the installation gap by a pin shaft; the left and right direction of the strip groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com