Large-particle foreign matter detecting and discharging device for powder coating production

A powder coating and large particle technology is applied in the field of large particle foreign matter inspection and sorting devices, which can solve the problems of incomplete screening, the inspection and sorting device does not have the inspection and sorting and classification of cyclic parts, and affects the use of coatings, etc., and achieves the improvement of screening efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

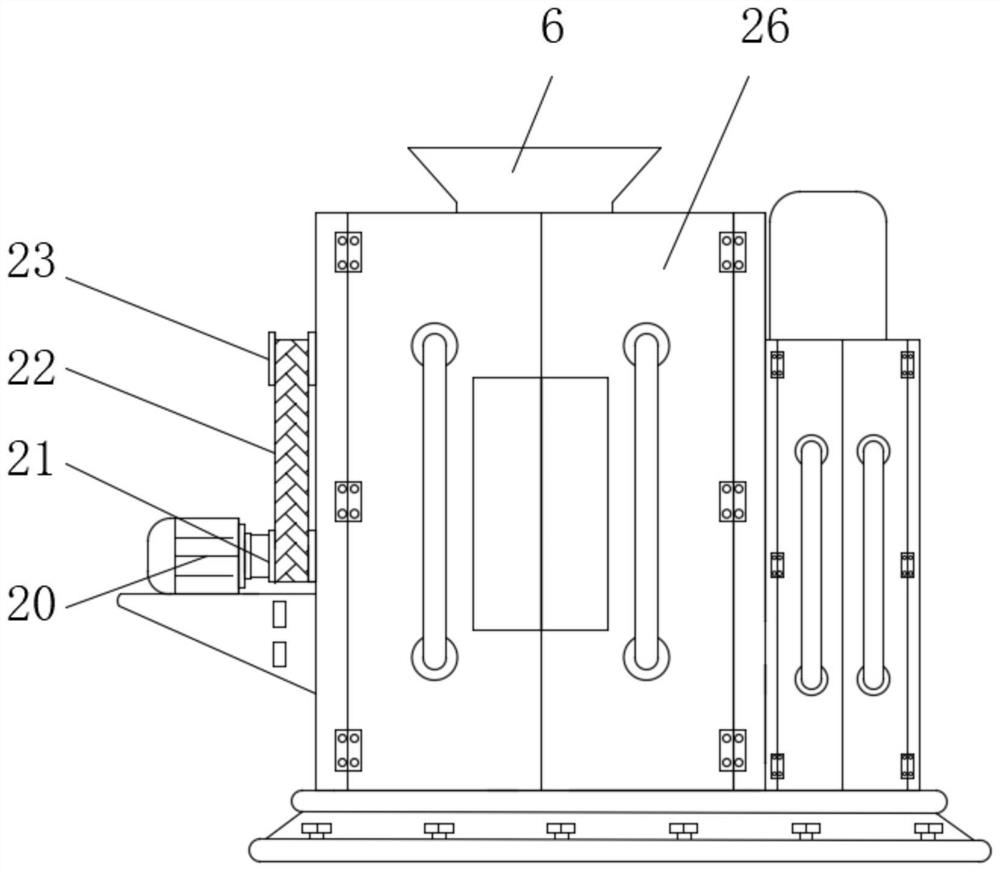

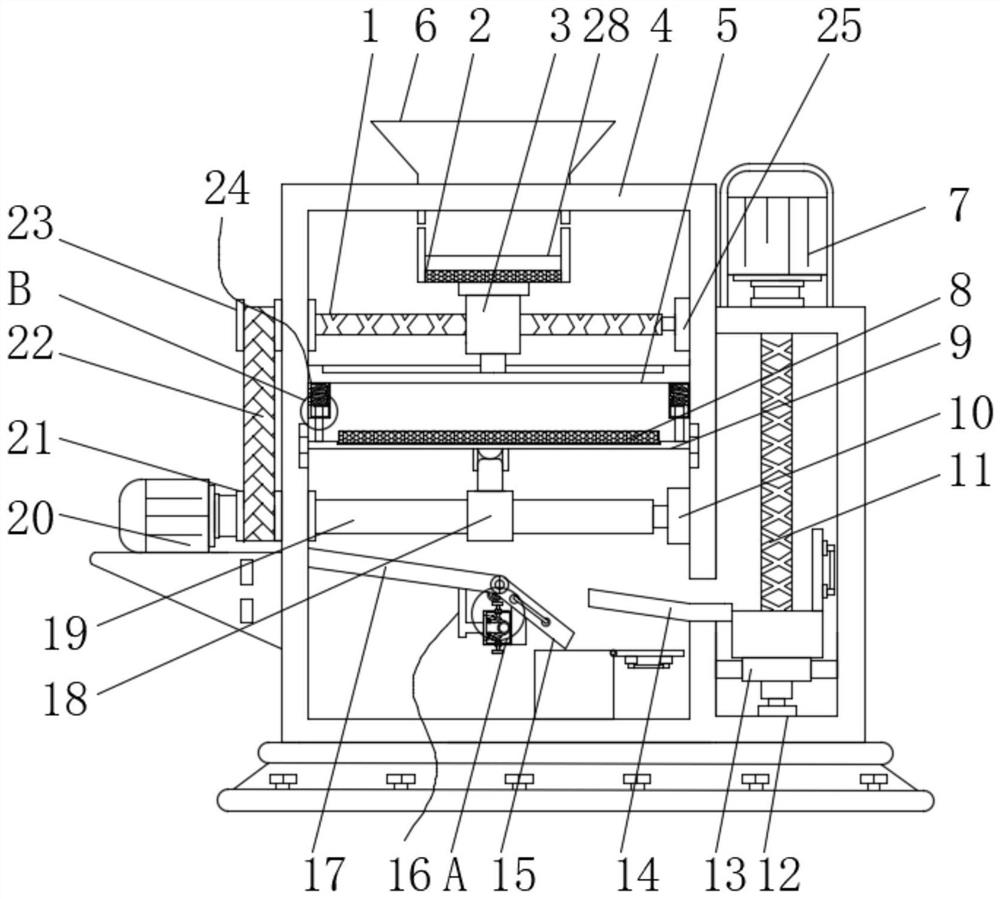

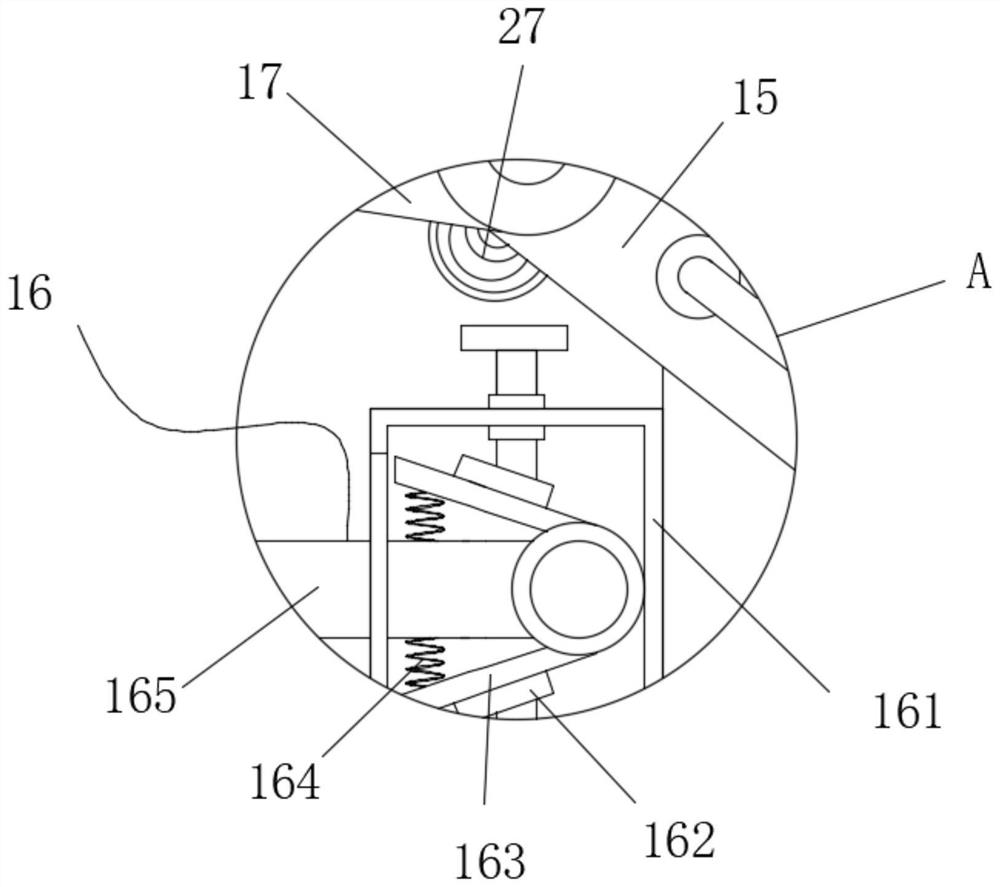

[0028] Such as Figure 1 to Figure 4 As shown, the present invention provides a large particle foreign matter detection and discharge device for powder coating production, including: a housing 4, a first motor 7 and a second motor 20, the side wall of the housing 4 is fixedly installed with the second motor 20 One end of the output shaft of the second motor 20 is fixedly mounted with a first pulley 21, and one end of the first pulley 21 is fixedly mounted with a rotating shaft 19, and one end of the rotating shaft 19 passes through and extends to the inside of the casing 4 and is mounted on the casing through the rotation of the rotating shaft 4 Inside of the first bearing 10 fixedly installed on the inner wall; the first reciprocating screw 1 is inserted and installed on the inner wall of the housing 4, and one end of the first reciprocating screw 1 is installed on the third bearing 10 fixedly installed on the inner wall of the housing 4 through the rotation of the rotating sh...

Embodiment 2

[0033] Such as figure 1 , figure 2 and Figure 4 As shown, this embodiment provides a large-particle foreign matter detection and discharge device for powder coating production. The difference from Embodiment 1 is that a sieve plate 9 is slidingly installed in the chute provided on the inner wall of the housing 4, so A second screen 8 is fixedly installed on the upper surface of the sieve plate 9 , and a tensile assembly 24 is provided on the inner wall of the casing 4 .

[0034]Preferably, in one of the preferred technical solutions of this embodiment, the tension assembly 24 includes a second spring 241, a second installation shell 242, a piston plate 243 and a support shaft 244, and the inner wall of the shell 4 is fixedly installed with The second installation shell 242 , the piston plate 243 is slidably installed inside the second installation shell 242 , and the second spring 241 is installed inside the second installation shell 242 .

[0035] Preferably, in one of t...

Embodiment 3

[0038] Such as Figure 4 As shown, this embodiment provides a large-particle foreign matter detection and discharge device for powder coating production. The difference from Embodiment 2 is that a first motor 7 is fixedly installed on the upper surface of the housing 4, and the first motor 7 One end of the output shaft of the output shaft is fixedly installed with a second reciprocating screw 11, and one end of the second reciprocating screw 11 is installed in the inside of the second bearing 12 fixedly installed on the inner wall of the housing 4 through the rotation of the rotating shaft, and the second reciprocating screw 11 The outer surface of the second moving block 13 is threadedly installed, and the side wall of the second moving block 13 is slidably installed in the chute provided on the inner wall of the housing 4 through the slider.

[0039] Preferably, in one of the preferred technical solutions of this embodiment, the inner wall of the housing 4 is fixedly equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com