Method for eliminating tiny deformation in batch forming of slender thin-wall crack line sources

A line source and crack technology, applied in the field of CNC precision machining and manufacturing, can solve the problems of delaying the alignment time of the clamping, reducing the machining quality of the line source, inconsistency between the center line of the waveguide and the machining reference, etc., so as to eliminate subtle differences and improve Processing quality and processing efficiency, avoiding the effect of excessive clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained with reference to the drawings and embodiments.

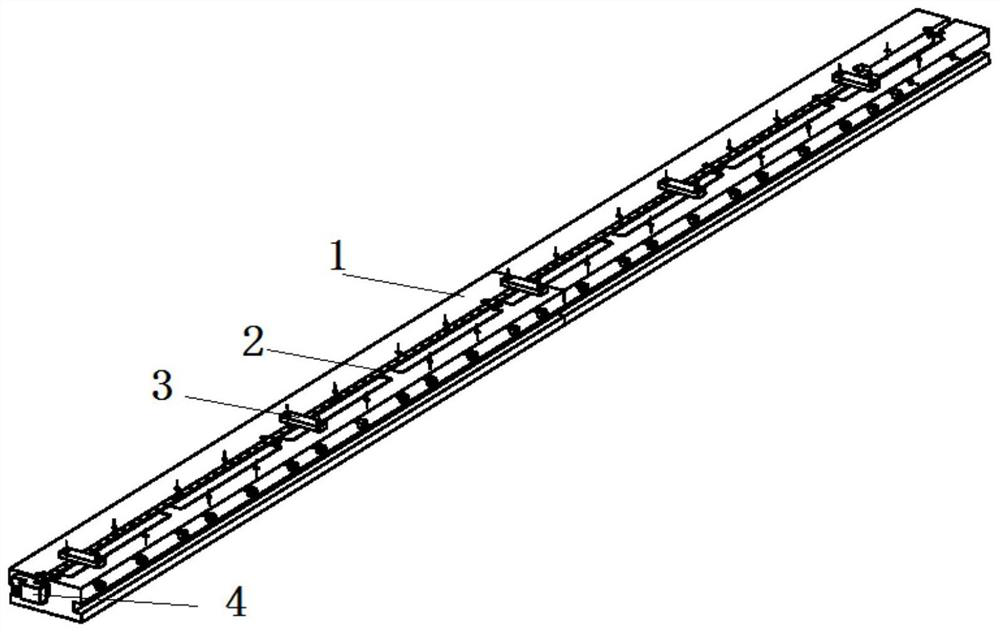

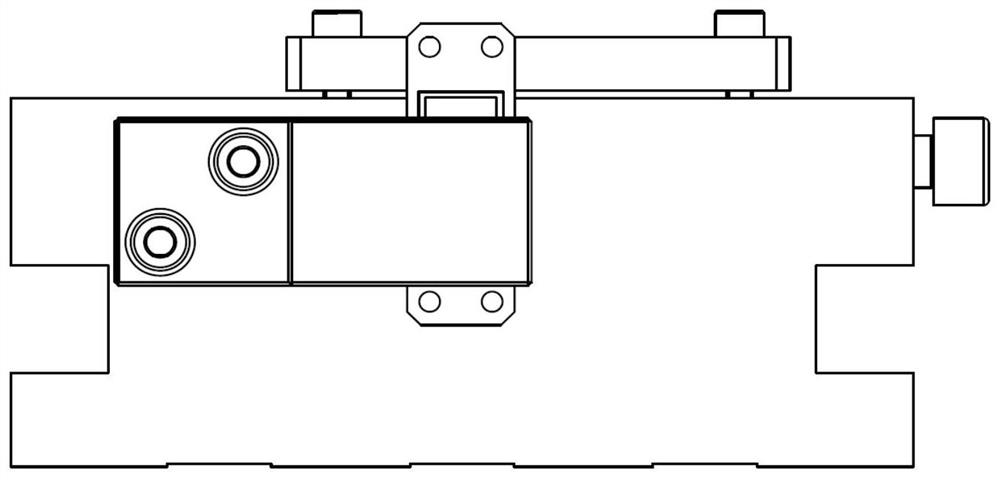

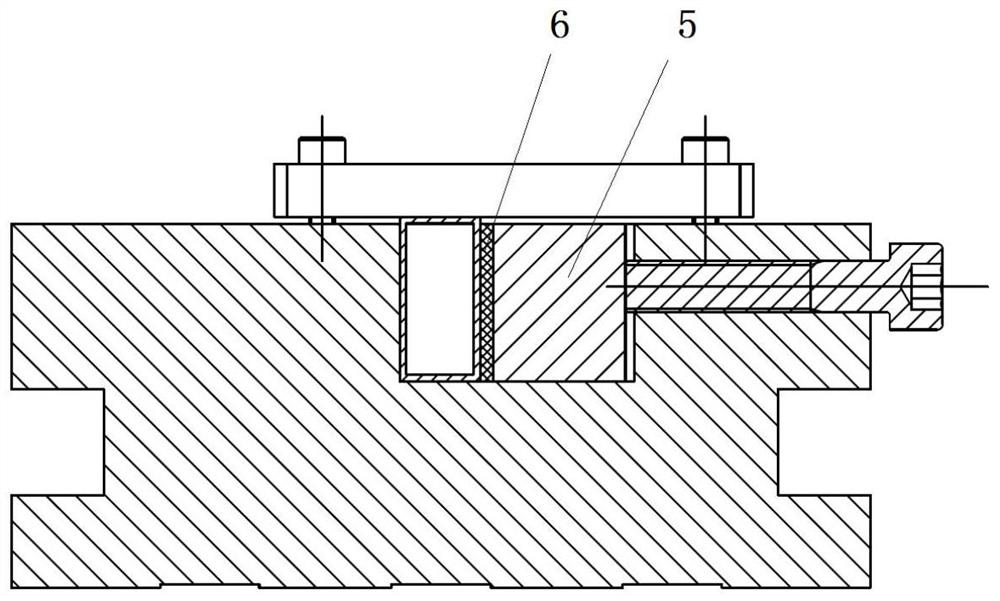

[0021] Taking the milling 3A21 crack line source with a wall thickness of 1mm and external dimensions of 12.16mm×24.86mm×2098mm as an example, the method of the present invention for eliminating the subtle difference factors in the batch forming of slender and thin-walled crack line sources includes 55mm×130mm×2080mm The special fixture is made into a whole or divided into two parts according to the specific conditions during processing. The surface is provided with a step groove for detecting the coordinates of the centerline of the line source; the 2mm thick elastic liner can be made of polytetrafluoroethylene, and placed between the side pressure plate and the Avoid rigid contact between cracked wire sources and realize flexible clamping; 15-20mm thick, 250×23.8-24.3mm aluminum side pressure plate is used to fasten the side of the wire source and reduce the clamping force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linearity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com