Operation table for hardware tool machining and using method of operation table

A hardware tool and operating table technology, applied in the field of operating table, can solve the problems of shaking raw materials, unable to clean iron filings, and unable to adjust height freely, etc., and achieve the effect of compact structure, strong practicability, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

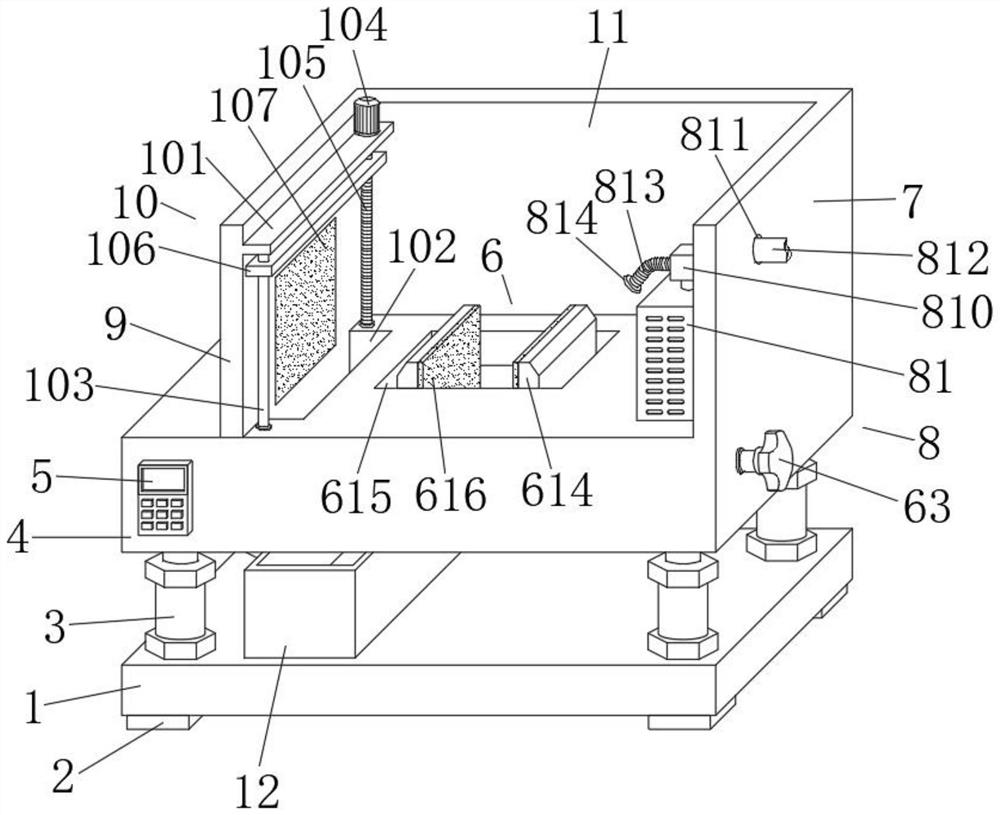

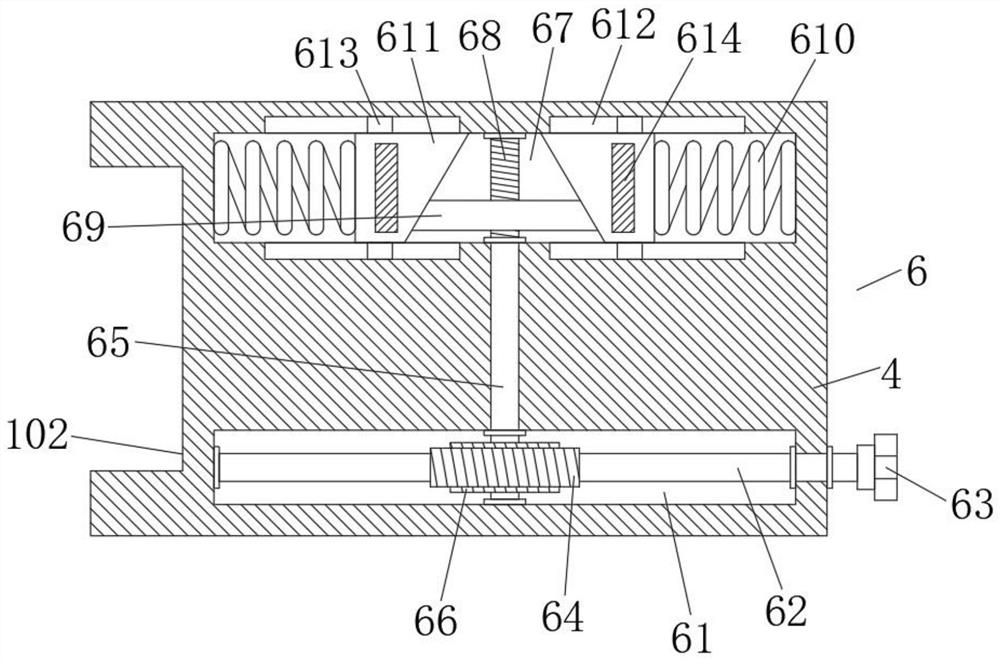

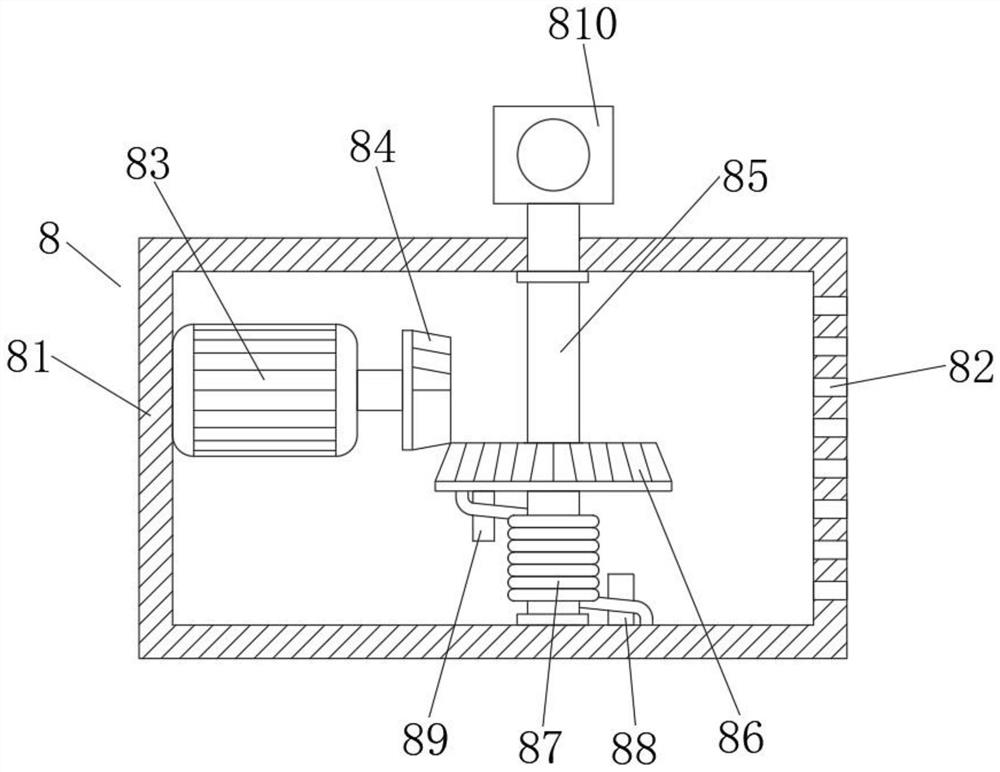

[0027]An operation table for processing hardware tools, comprising a base plate 1, the four corners of the bottom of the base plate 1 are fixedly connected with support feet 2, and the support feet 2 facilitate the stable placement of the whole equipment; the four corners of the top of the base plate 1 All are fixedly installed with a hydraulic cylinder 3, and a base 4 is fixedly connected between the piston rods of the hydraulic cylinder 3, and the height of the base 4 can be better adjusted through the hydraulic cylinder 3, so that the equipment can be used by people of different heights; A control panel 5 is fixedly installed on the outside of the base 4, a clamping mechanism 6 is arranged inside the base 4, a first baffle 7 is fixedly connected to one end of the top of the base 4, and the inside of the first baffle 7 A cleaning mechanism 8 is provided, and the end of the top of the base 4 away from the first baffle 7 is fixedly connected with a second baffle 9 , and the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com