Offset press

A technology of offset presses and racks, applied in printing presses, rotary presses, printing, etc., which can solve the problems of printing quality decline, change (increase or decrease, unfavorable printing patterns, etc.), and achieve the effect of less defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

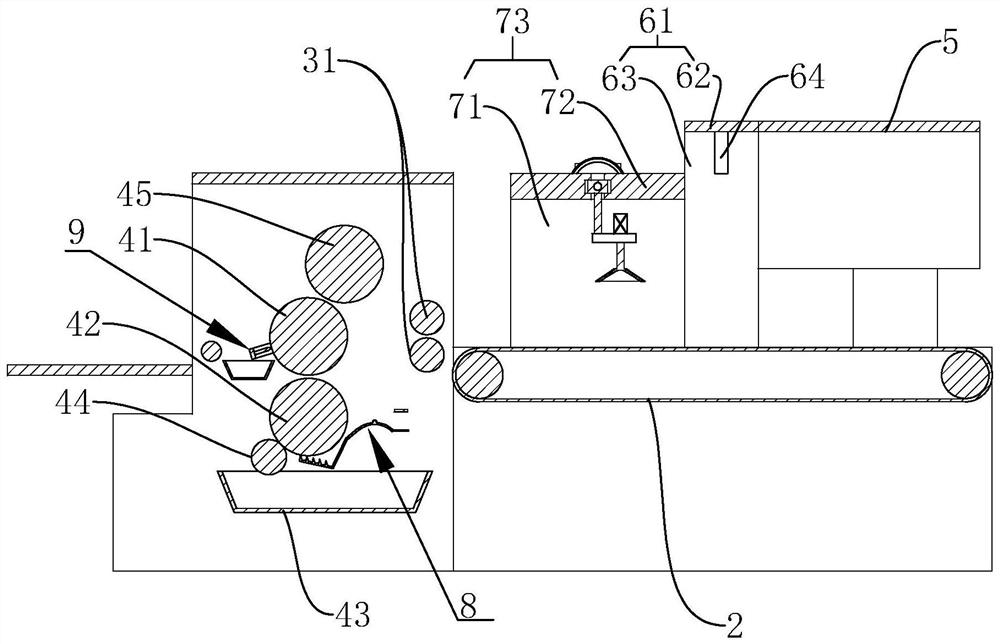

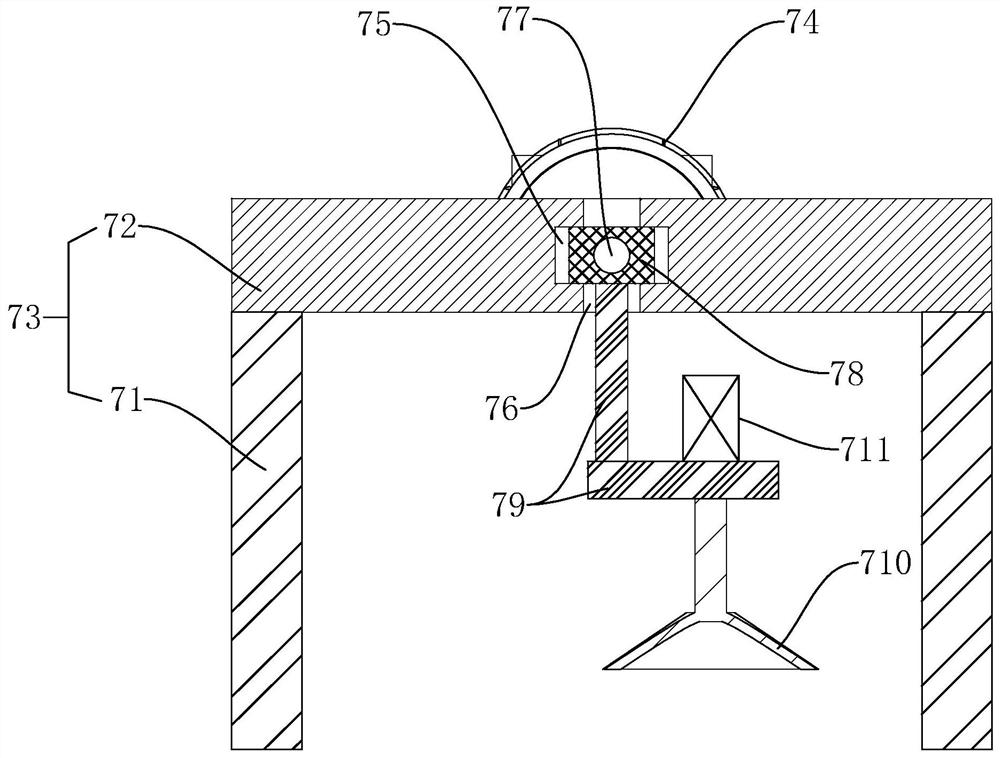

[0041] The application will be described in further detail below in conjunction with the accompanying drawings.

[0042] This application is mainly aimed at the problem that the ink density of the graphic printed on the paper will be too thick or too light due to the re-adding of ink or the continuous operation of the offset printing machine in the existing offset printing machine, and provides an offset printing machine, which By adjusting the thickness of the ink on the impression cylinder, and then adjusting the ink concentration of the graphic on the paper to a moderate level, the printing quality of the offset printing machine can be improved.

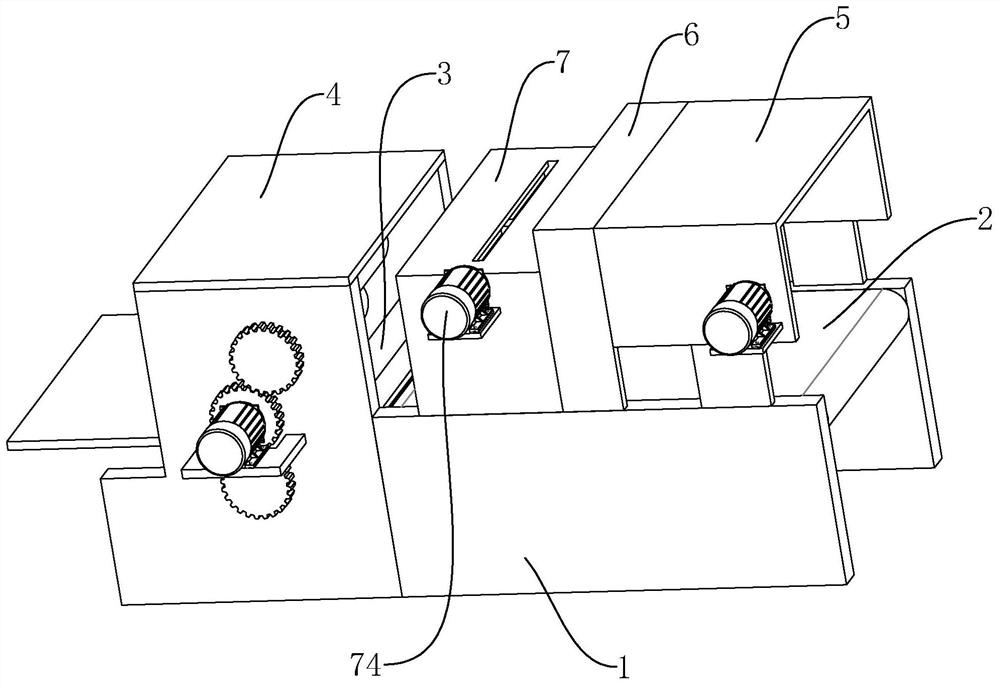

[0043] like figure 1 and figure 2 As shown, the offset printing machine of the present application includes a frame 1, and the frame 1 is sequentially installed with a paper transmission device 2, a paper guide device 3 and an inking device 4 along the moving direction of the paper, and the feeding end of the paper guide device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com