Printed gravure device used for rolling print stock, gravure device component and printer

A technology of gravure printing and printing materials, which is applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

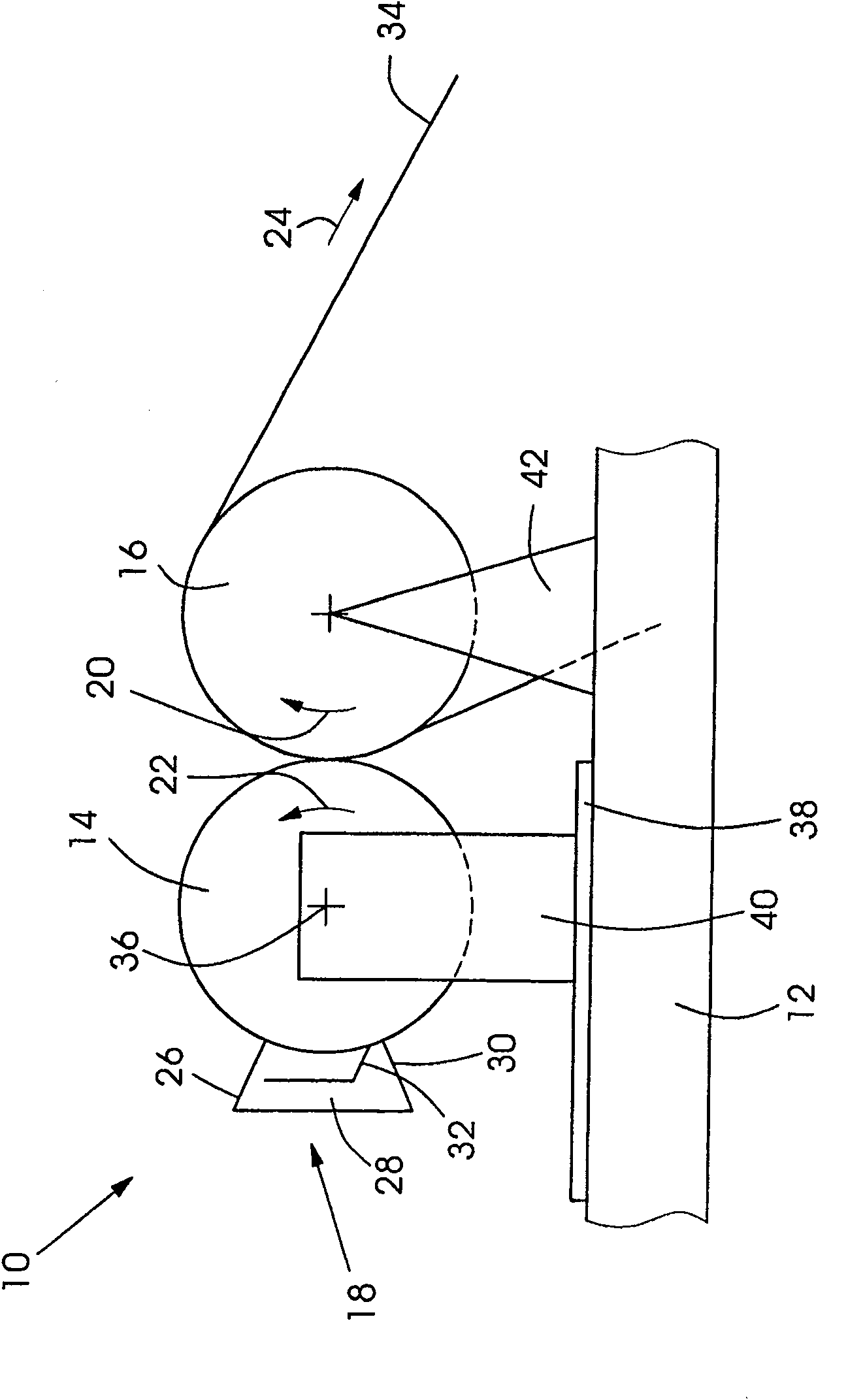

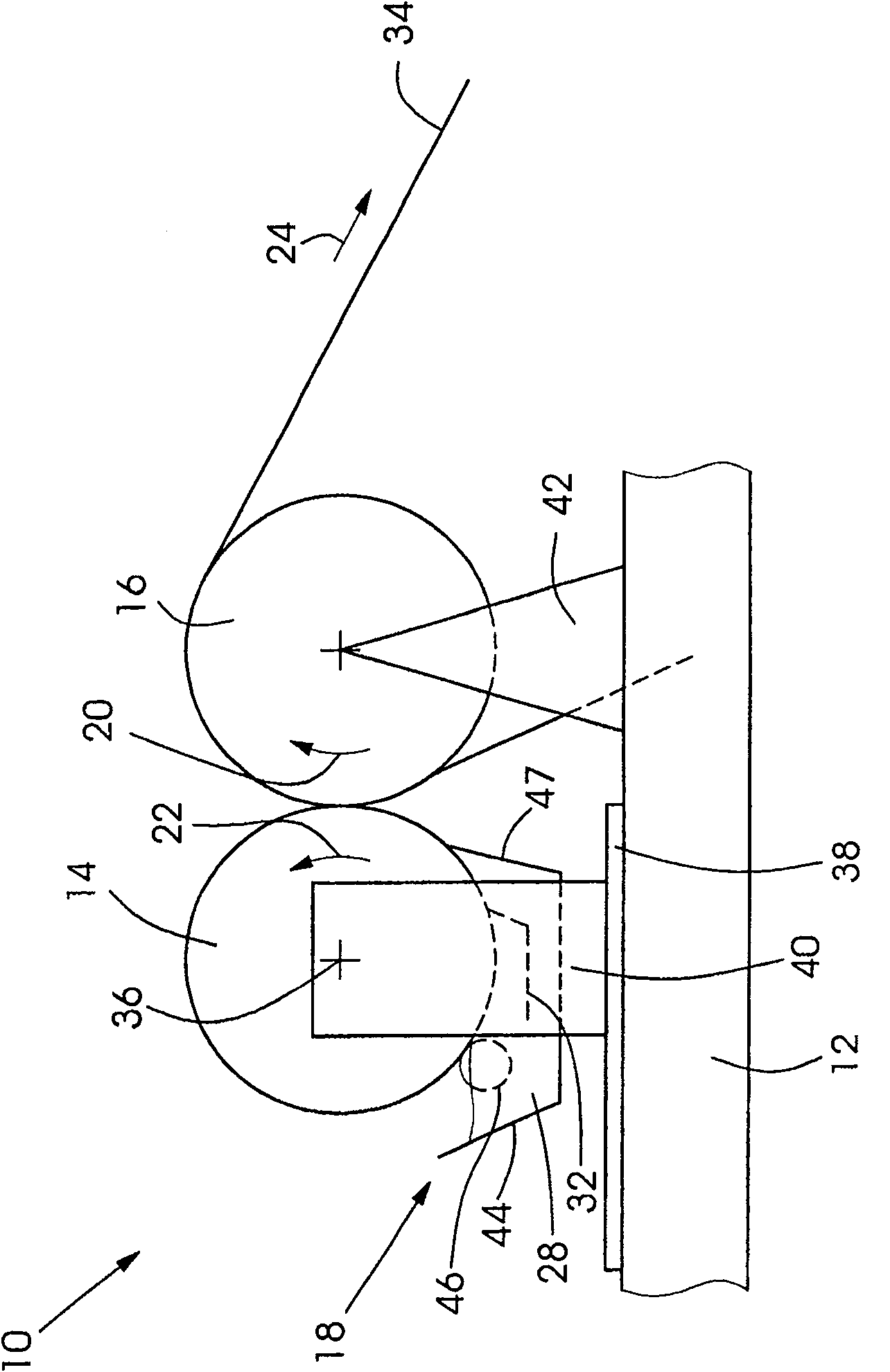

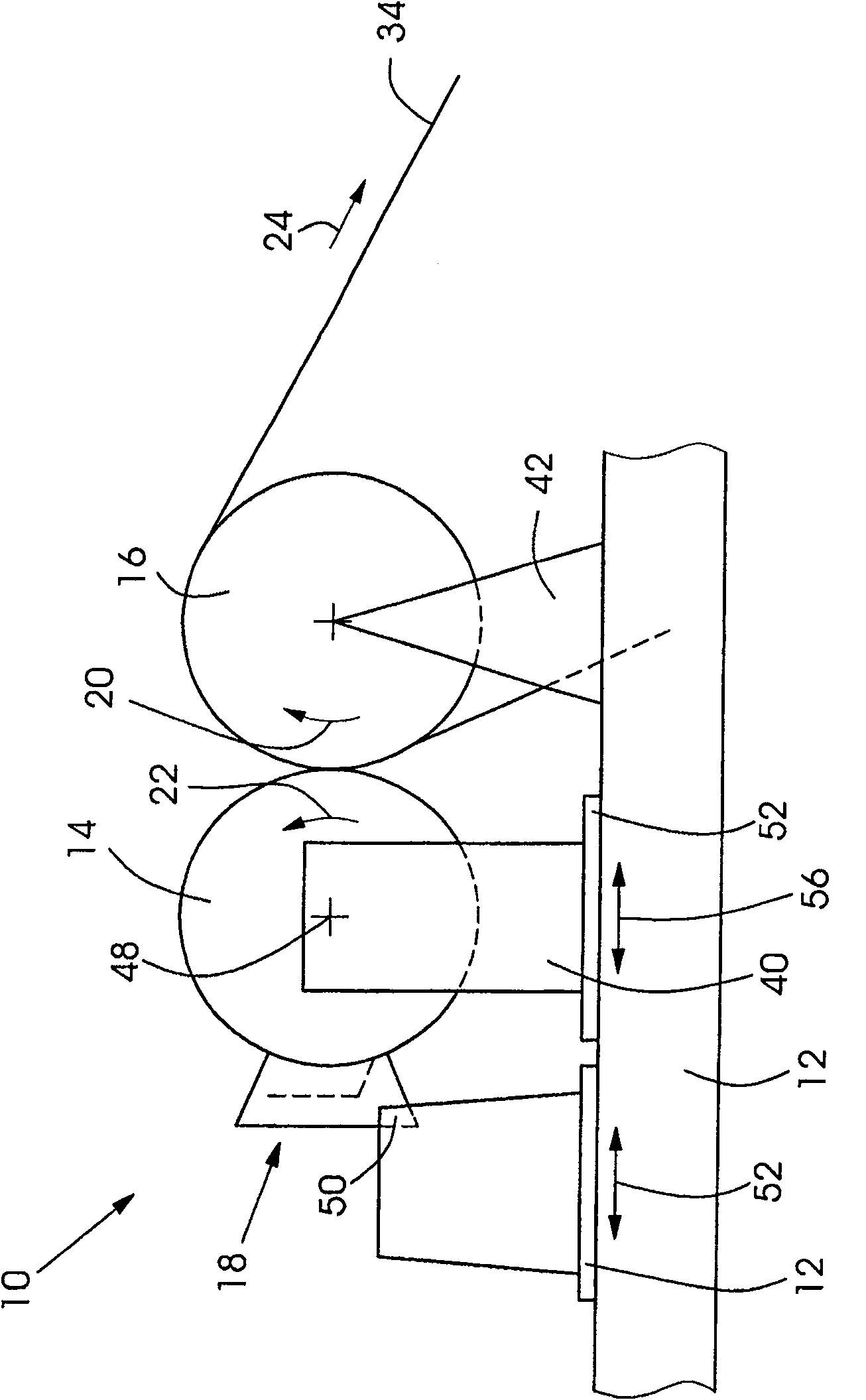

[0030] figure 1 A first embodiment of the gravure printing unit 10 according to the invention is shown schematically in a printing press 12 , in particular in a combined or hybrid printing press. An embodiment of the gravure printing unit 10 has a printing cylinder 14 (gravure printing cylinder) which cooperates with an impression cylinder 16 to form a printing nip and against which an inking unit 18 rests. The path of a web of printing material 34 extends across the printing nip. When the intaglio printing unit 10 is in operation, the impression cylinder 16 rotates in the direction of rotation 20 and the printing cylinder 14 rotates in the direction of rotation 22 , while the printing web moves along its path in the direction of transport 24 . In this embodiment, the axes of rotation of the two rollers lie in a substantially horizontal plane. The inking device 18 is designed as an ink fountain scraper 26, which is filled with gravure ink 28 and is arranged on the left secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com