High-flowability high-performance concrete with low cementing material content, and preparation method thereof

A high-performance concrete and high-fluidity technology, applied in the field of concrete preparation, can solve problems such as large self-shrinkage of concrete, economic problems of concrete, and impact on the durability of structures, so as to reduce overall costs, reduce concrete quality defects, and reduce water The effect of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

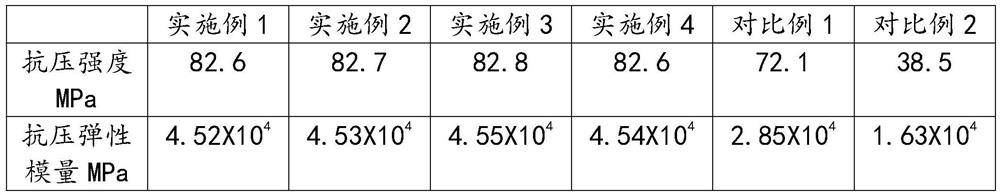

Examples

Embodiment 1

[0026] A low-glue high-fluidity high-performance concrete, including the following raw materials in parts by weight: 520 parts of cementitious material, 626 parts of medium sand, 1061 parts of gravel, 130 parts of water, and 4.88 parts of water reducing agent;

[0027] The low-glue high-fluidity high-performance concrete is made by the following method:

[0028] Add medium sand, gravel and cementitious materials into the mixer, and stir at a speed of 50r / min for 1min to prepare a mixture, then add water and water reducer to the mixer in turn, and continue stirring at this speed for 5min to prepare To obtain high-performance concrete with low glue and high fluidity.

[0029] The water reducer is a polycarboxylate water reducer, and the gravel is blended from two grades of materials with a particle size of 5mm and 10mm in a weight ratio of 1:1.

[0030] The cementitious material is made by the following methods:

[0031]Step S1. Add acrylic acid and polyethylene glycol monomet...

Embodiment 2

[0037] A high-performance concrete with low glue material and high fluidity, including the following raw materials in parts by weight: 530 parts of cementitious material, 650 parts of medium sand, 1080 parts of crushed stone, 135 parts of water, and 5.25 parts of water reducer;

[0038] The low-glue high-fluidity high-performance concrete is made by the following method:

[0039] Add medium sand, gravel and cementitious materials into the mixer, and stir at a speed of 50r / min for 1min to prepare a mixture, then add water and water reducer to the mixer in turn, and continue stirring at this speed for 5min to prepare To obtain high-performance concrete with low glue and high fluidity.

[0040] The water reducer is a polycarboxylate water reducer, and the gravel is blended from two grades of materials with a particle size of 5mm and 10mm in a weight ratio of 1:1.

[0041] The cementitious material is made by the following methods:

[0042] Step S1. Add acrylic acid and polyethy...

Embodiment 3

[0048] A high-performance concrete with low glue material and high fluidity, including the following raw materials in parts by weight: 550 parts of cementitious material, 686 parts of medium sand, 1130 parts of crushed stone, 138 parts of water, and 7.25 parts of water reducing agent;

[0049] The low-glue high-fluidity high-performance concrete is made by the following method:

[0050] Add medium sand, gravel and cementitious materials into the mixer, and stir at a speed of 50r / min for 1min to prepare a mixture, then add water and water reducer to the mixer in turn, and continue stirring at this speed for 5min to prepare To obtain high-performance concrete with low glue and high fluidity.

[0051] The water reducer is a polycarboxylate water reducer, and the gravel is blended from two grades of materials with a particle size of 5mm and 10mm in a weight ratio of 1:1.

[0052] The cementitious material is made by the following methods:

[0053] Step S1. Add acrylic acid and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com