Ruminant rumen microorganism sampling device

A technology of rumen microorganisms and sampling devices, which is applied in the field of sampling devices, can solve the problems affecting the accuracy of measurement results of rumen chyme, sampling difficulties, and difficulty in uniformity, and achieve good user experience, simple operation, and uniform sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

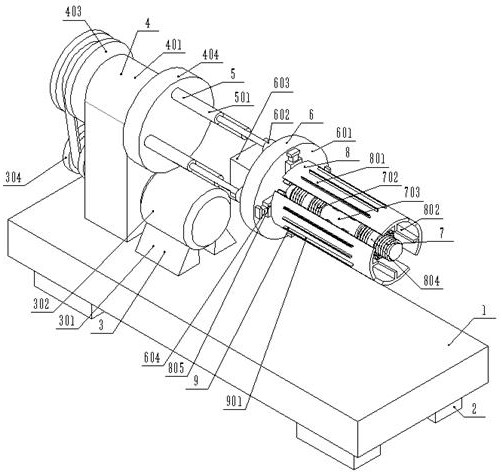

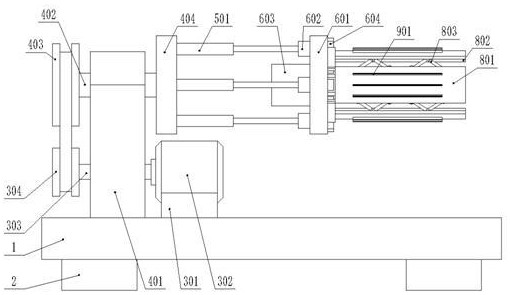

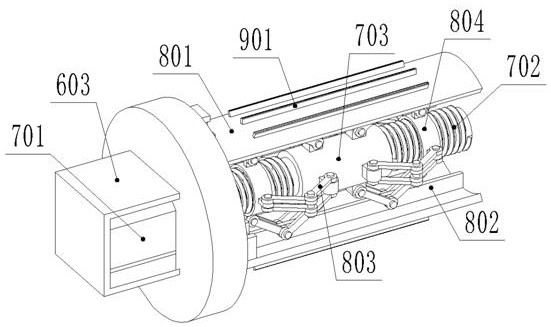

[0023] Example 1: Please refer to Figure 1-4 , a rumen microbial sampling device for ruminants, comprising a base 1, foot plates 2 are fixedly connected to the four corners below the base 1; a driving mechanism 3 is fixedly connected to the left side of the upper middle part of the base 1, and the driving mechanism 3 is driven by a pulley A rotating mechanism 4 is connected, and the rotating mechanism 4 is fixedly connected with a telescoping mechanism 5;

[0024] When in use, the hydraulic telescopic shaft 501 is turned on, and the hydraulic telescopic shaft 501 starts to drive the support plate 601 to move, and then the prime mover 7, the adjustment mechanism 8 and the sampling mechanism 9 fixedly connected to the support plate 601 are sent into the rumen of the animal; Then turn on the prime mover motor 701, the output end of the prime mover motor 701 rotates and then drives the double-headed screw 702 to rotate, and then the threaded sleeves 804 on the left and right side...

Embodiment 2

[0036] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the diameter of the driving wheel 304 is half of the diameter of the driven wheel 403 .

[0037]The working principle of the present invention is: when in use, the hydraulic telescopic shaft 501 is opened, and the hydraulic telescopic shaft 501 starts to drive the support plate 601 to move, and then the prime mover mechanism 7, the adjustment mechanism 8 and the sampling mechanism 9 fixedly connected to the support plate 601 are sent to the into the rumen of the animal; then turn on the prime mover motor 701, the output end of the prime mover motor 701 rotates and drives the double-ended screw 702 to rotate, and then the threaded sleeves 804 on the left and right sides move relatively, and then the adjustment plate 801 is propped up, Until the sampling frame 901 is attached to the rumen surface of the animal; then the drive motor 302 is controlled to start, and the output end of the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com