Novel steel bar mechanical connecting sleeve

A technology of mechanical connection and sleeve, which is applied in the direction of construction, building reinforcements, building components, etc., can solve the problems of inconvenient use of connecting sleeves, difficult operation for workers, and loose bite, so as to reduce construction difficulty and labor cost Investing, reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

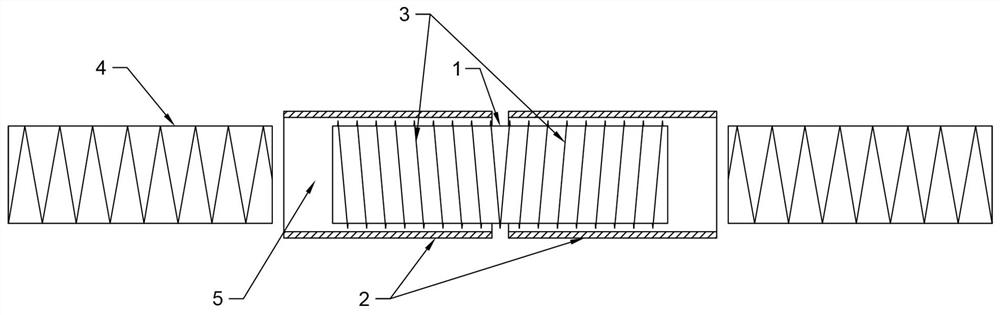

[0012] A new type of steel mechanical connection sleeve, such as figure 1 As shown, it includes a steel casting 1 and two sleeves 2. The steel casting 1 is a solid structure, and the surface of the steel casting 1 is provided with positive and negative two-way turning wires 3, so as to avoid mistakes in wire turning or placement of steel bars on site. The two sleeves 2 are respectively connected to the outer sides of the two ends of the steel casting 1 through sleeve wires. When the two sleeves 2 are completely connected with the wires of the steel casting 1, both sleeves 2 are relative to the ends of the steel casting 1. The extension is set, and a groove 5 is formed on the outer side of the end of the steel casti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap