Sealing structure with clearance compensation function for duplicate gear pump

A duplex gear pump and clearance compensation technology, which is applied in the field of hydraulic pumps, can solve problems such as complex structures, achieve good sealing effects, be economical and practical, and simplify structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

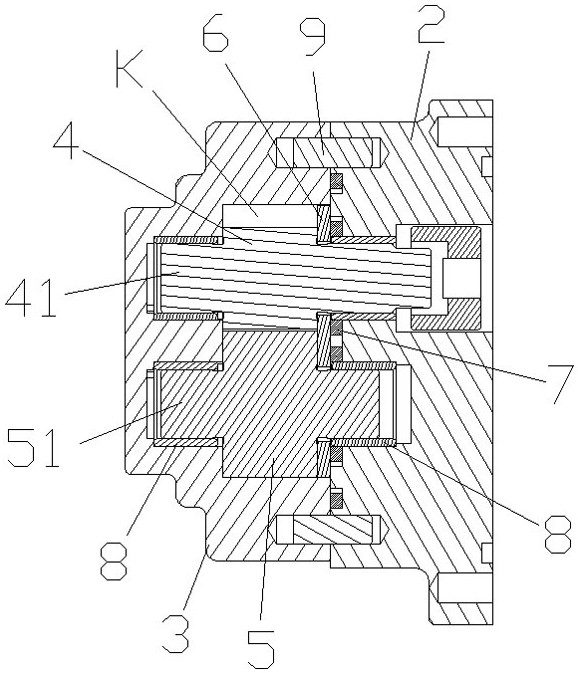

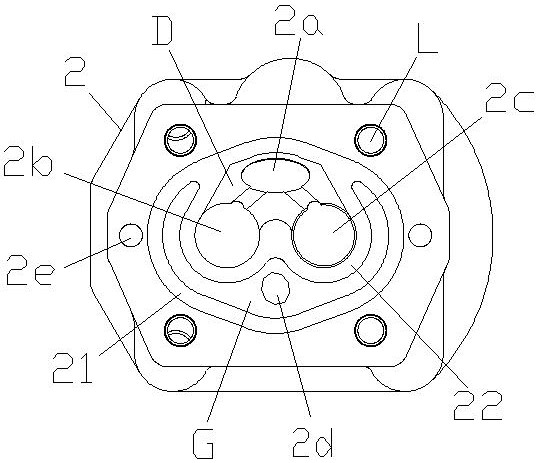

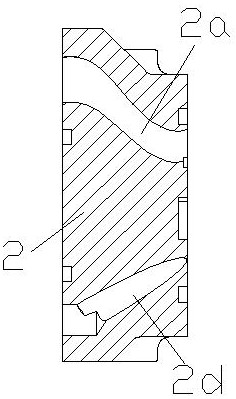

[0029] Figures 1 to 10 It is a structural representation of the present invention.

[0030] The reference signs are: low pressure area D, high pressure area G, pump cavity K, gear installation cavity K1, bolt hole L, front pump cover 1, pump body 2, oil inlet hole 2a, first shaft hole 2b, second Shaft hole 2c, oil outlet 2d, first positioning pin hole 2e, outer seal groove 21, inner seal groove 22, rear pump cover 3, oil inlet hole 3a, third shaft hole 3b, fourth shaft hole 3c, Oil outlet hole 3d, second positioning pin hole 3e, rear driving gear 4, driving gear shaft 41, rear driven gear 5, driven gear shaft 51, floating side plate 6, main shaft hole 6a, driven shaft hole 6b, base Steel plate 61, wear-resistant alloy plate 62, rubber sealing ring 7, outer sealing ring body 71, inner sealing ring body 72, oil-free bearing 8, positioning pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com