Transient electromagnetic sleeve damage three-dimensional imaging method

A transient electromagnetic and three-dimensional imaging technology, which is applied in the fields of material magnetic variables, image data processing, and instruments, can solve the problems of three-dimensionally displaying the spatial position of the casing and cannot intuitively reflect the change of the inner diameter of the casing, so as to achieve intuitive and real Shape and position, improve the accuracy, and the effect of strong three-dimensional image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

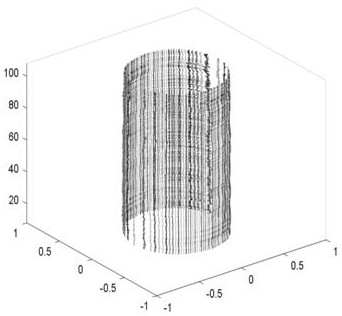

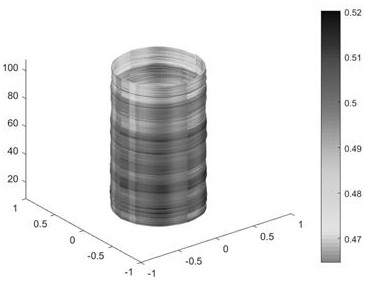

[0040] The present invention makes the two-dimensional data visually display its form in three dimensions by performing algorithmic correction and space regular arrangement.

[0041] 1. Read all the data of the casing measured by the electromagnetic flaw detector, and place the corresponding data under the corresponding name;

[0042] 2. Divide the measured casing damage data into regions so that the data are distributed in the specified regions;

[0043] 3. Set the threshold to remove the bad point data in the transient electromagnetic bushing damage data. To avoid the impact of the measured bad point data on the overall effect of 3D imaging;

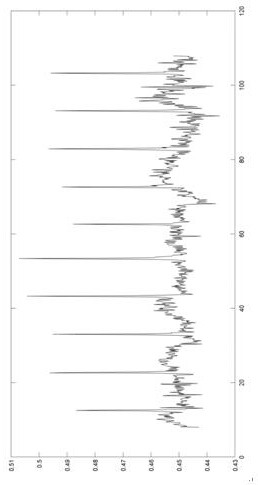

[0044] 4. The depth data is corrected by the stretching algorithm so that it basically corresponds to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com