66 kV torsion-resistant cable for fan power transmission, and preparation method and application of 66 kV torsion-resistant cable

A 66kv cable technology, applied in the field of torsion-resistant cables for 66kV fan power transmission and its preparation, to achieve good practical value and promotion value, improve service life, and excellent anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

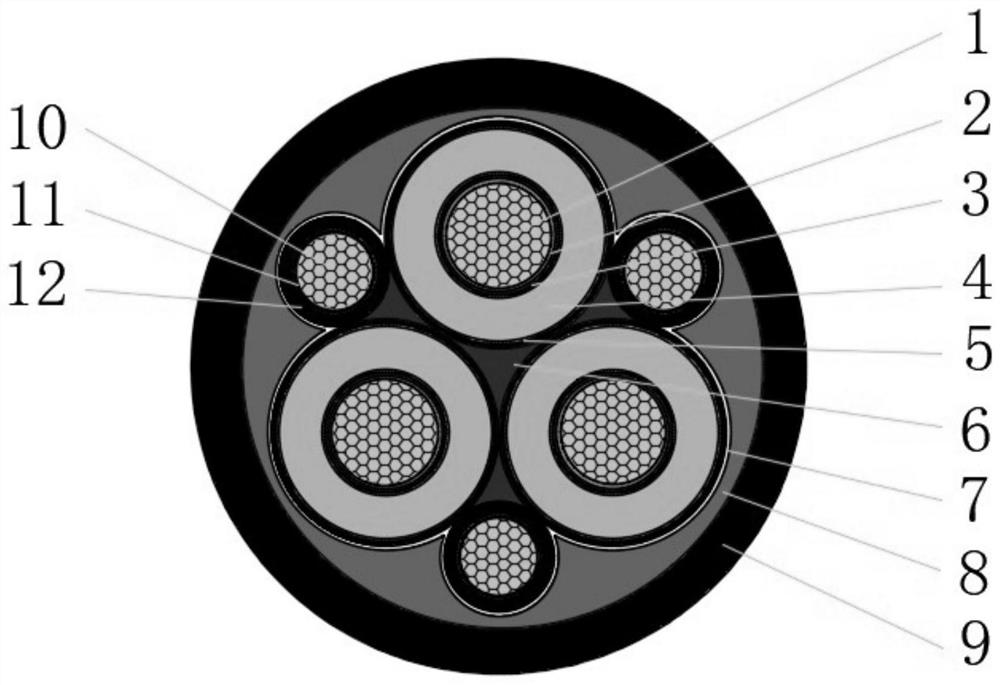

[0114] This embodiment provides a twist-resistant cable for power transmission of a 66kV fan, such as figure 1 As shown, the cable includes a cable core layer, a wrapping tape 7, a first sheath layer 8 and a second sheath layer 9 from inside to outside in sequence;

[0115] The cable core layer includes a main wire core and a ground wire core; the main wire core includes a first central conductor 1, a first semiconductive nylon tape layer 2, a conductor shielding layer 3, an ethylene-propylene rubber insulating layer 4 and Insulation shielding layer 5; the ground wire core includes a second central conductor 10, a second semiconductive nylon tape layer 11 and a semiconductive covering layer 12 from inside to outside; the material of the second sheath layer 9 is polyolefin rubber; the number of main cores and ground cores in the cable core layer is the same; the first central conductor 1 is an annealed copper conductor; the second central conductor 10 is an annealed copper cond...

Embodiment 2

[0133] This embodiment provides a twist-resistant cable for power transmission of a 66kV fan. The cable includes a cable core layer, a wrapping tape, a first sheath layer and a second sheath layer in sequence from the inside to the outside;

[0134] The cable core layer includes a main wire core and a ground wire core; the main wire core sequentially includes a first central conductor, a first semiconductive nylon tape layer, a conductor shielding layer, an ethylene-propylene rubber insulating layer, and an insulating shielding layer from inside to outside; The ground wire core includes a second central conductor, a second semiconductive nylon tape layer and a semiconductive covering layer from the inside to the outside; the material of the second sheath layer is polyolefin rubber; the main wire in the cable core layer The number of cores and ground cores is the same; the first central conductor is a soft copper conductor; the second central conductor is a soft copper conductor...

Embodiment 3

[0151] This embodiment provides a twist-resistant cable for power transmission of a 66kV fan. The cable includes a cable core layer, a wrapping tape, a first sheath layer and a second sheath layer in sequence from the inside to the outside;

[0152] The cable core layer includes a main wire core and a ground wire core; the main wire core sequentially includes a first central conductor, a first semiconductive nylon tape layer, a conductor shielding layer, an ethylene-propylene rubber insulating layer, and an insulating shielding layer from inside to outside; The ground wire core includes a second central conductor, a second semiconductive nylon tape layer and a semiconductive covering layer from the inside to the outside; the material of the second sheath layer is polyolefin rubber; the main wire in the cable core layer The number of cores and ground cores is the same; the first central conductor is a soft copper conductor; the second central conductor is a soft copper conductor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com