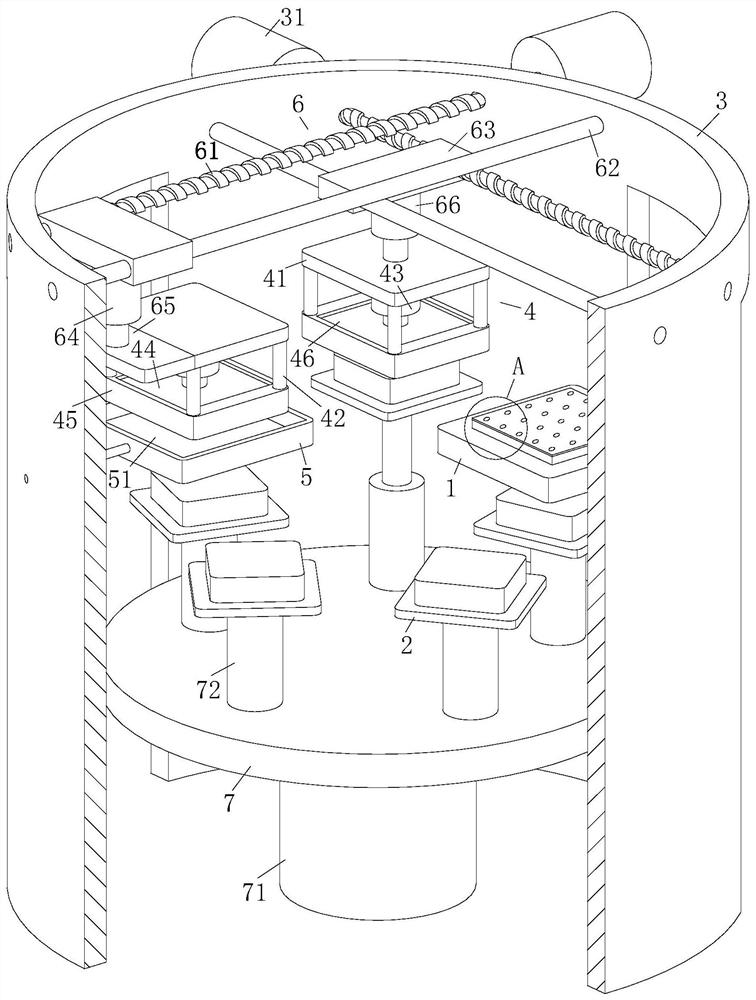

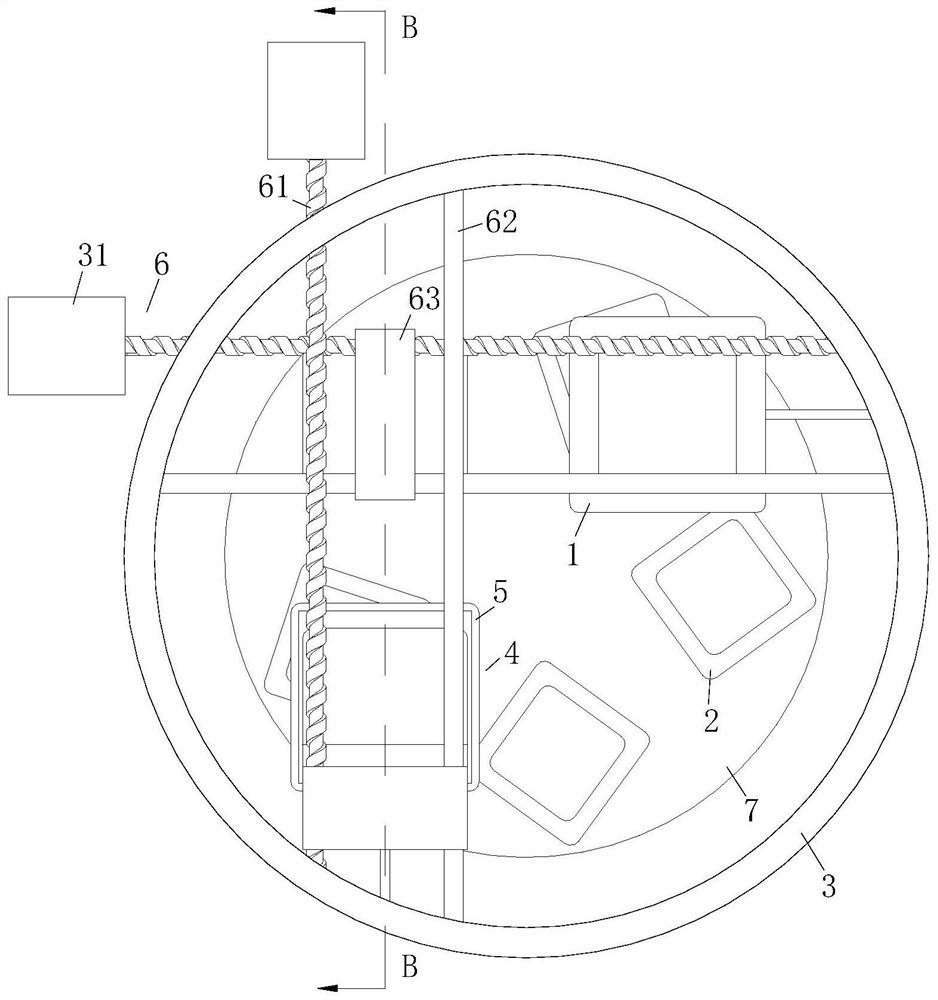

A LED high-speed crystal-bonding equipment and its automatic loading and unloading device

A technology of crystal bonding and equipment, applied in the field of LED high-speed crystal bonding equipment and its automatic loading and unloading device, can solve the problems of low LED preparation efficiency and affecting LED output, so as to improve the actual application effect, improve the crystal bonding efficiency, increase the Effect of degree of particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

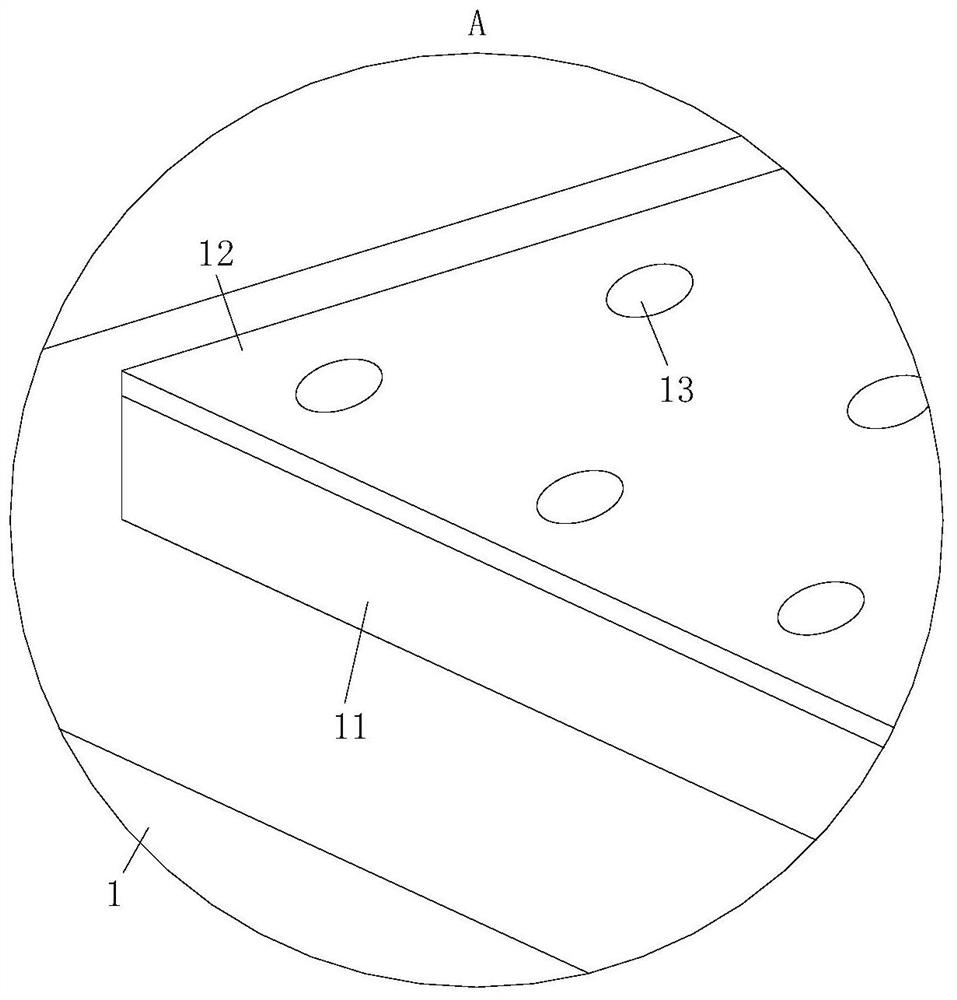

[0030] As an embodiment of the present invention, the rotating rod 53 is twisted between the two groove walls of the rectangular groove 51 through a torsion spring 52; blades 54 are fixedly connected to the outer wall of the rotating rod 53; the blades 54 are evenly distributed On the outer wall of the rotating rod 53; the middle part of the rotating rod 53 is wound with a wire rope 55; the wire rope 55 is in a tightened state under the action of the torsion spring 52, and the other end of the wire rope 55 is connected to the injection plate 45 When working, one of the No. 1 motors 31 drives the injection plate 45 away from the dispensing plate 5, and the injection plate 45 will pull the wire rope 55 to move, so that the rotating rod 53 moves along the wire rope 55. When the two groove walls of the rectangular groove 51 rotate, the rotation of the rotating rod 53 will drive the blade 54 to rotate, thereby stirring the adhesive in the rectangular groove 51 through the blade 54, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com