A chip bonding method and terminal

A chip and die-bonding technology, which is applied in chip die-bonding methods and terminal fields, can solve the problems of high die-bonding cost, high consumption of testing costs, a large number of sorting costs and chip picking costs, etc., so as to save the cost of die-bonding and increase the cost of die-bonding. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

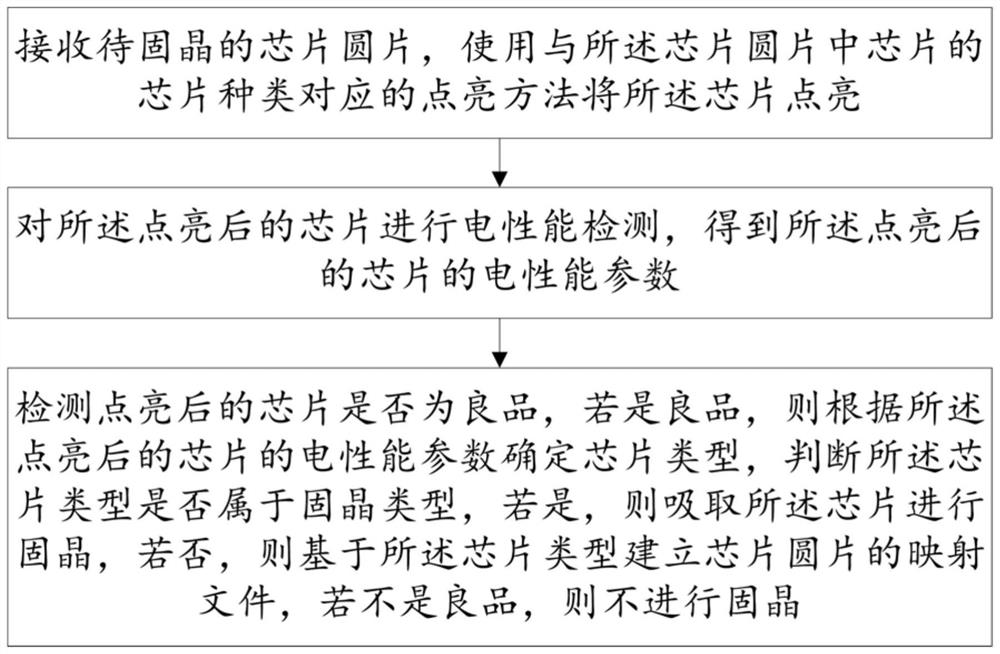

[0076] Please refer to figure 1 , a chip bonding method, comprising the steps of:

[0077] S1. Receive the chip wafer to be solidified, and use the lighting method corresponding to the chip type of the chip in the chip wafer to light up the chip;

[0078] Wherein, the types of chips include front-mounted blue-green chips, front-mounted red chips, and flip-chips;

[0079] If the type of chip is a blue-green light chip, control the electrode on the suction nozzle in the suction crystal swing arm to align with the electrode of the blue-green light chip;

[0080] If the chip type is a front-mounted red light chip, control the electrode on the suction nozzle and the electrode on the thimble in the suction crystal swing arm to align with the electrode of the front-mounted red light chip;

[0081] If the chip type is a flip chip, then control the electrode on the thimble in the suction crystal swing arm to align with the electrode of the flip chip;

[0082] Specifically, in this e...

Embodiment 2

[0099] The difference between this embodiment and Embodiment 1 is that it specifically defines how to perform secondary die-bonding on unbonded chips:

[0100] Wherein, after establishing the mapping file of the chip wafer based on the chip type, it includes:

[0101] Receive the type of chip to be bonded, automatically select the chip corresponding to the type of chip to be bonded based on the mapping file and perform the chip;

[0102] Specifically, after receiving the type of chip to be bonded, the Mapping diagram automatically selects the corresponding chip according to the type of chip to be bonded, and performs die bonding, chip arrangement, or batch transfer of chips according to the chip type, so only You need to select the chip type to bond the remaining unbonded chips, which can quickly complete the chip bonding and save the chip picking process in the bonding process, thereby improving the efficiency of bonding and reducing the cost of bonding.

Embodiment 3

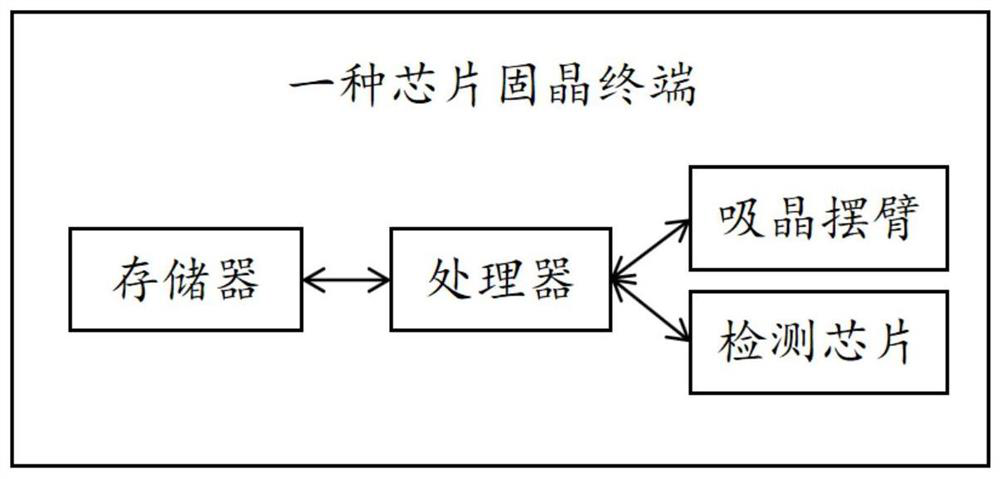

[0104] Please refer to figure 2 , a chip-bonding terminal, comprising a memory, a processor, and a computer program stored on the memory and operable on the processor, when the processor executes the computer program, the embodiment 1 or embodiment 2 is realized The various steps of the chip bonding method.

[0105] To sum up, the chip bonding method and terminal provided by the present invention receive the chip wafer to be bonded, and select the corresponding lighting method to light the chip according to the type of chip in the chip wafer. Electrodes are added to the suction nozzle and thimble of the arm, and different chip lighting methods are used for the difference in the structure of the front chip and the flip chip, so as to realize the adaptive matching of the chip lighting method according to the chip type; use the suction nozzle and the thimble to obtain the lighting The data information of the final chip is detected, and the electrical performance parameters of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com