Grouting material initial fluidity detection system

A detection system and grouting technology, applied in the directions of flow characteristics, measuring devices, analyzing materials, etc., can solve problems such as large manual measurement errors, and achieve the effect of meeting the requirements of field applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

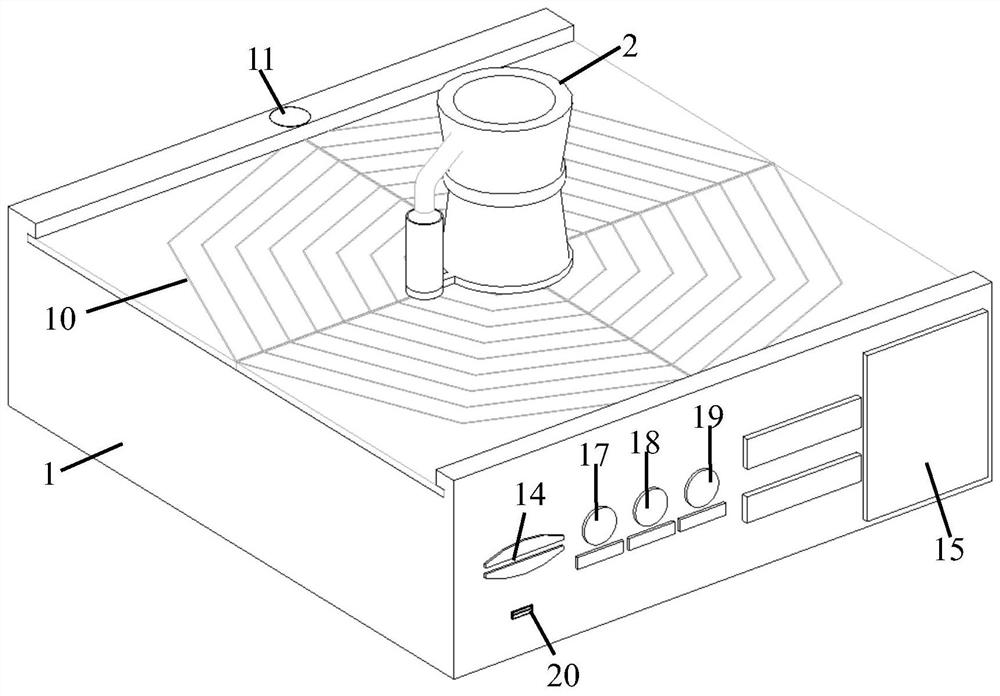

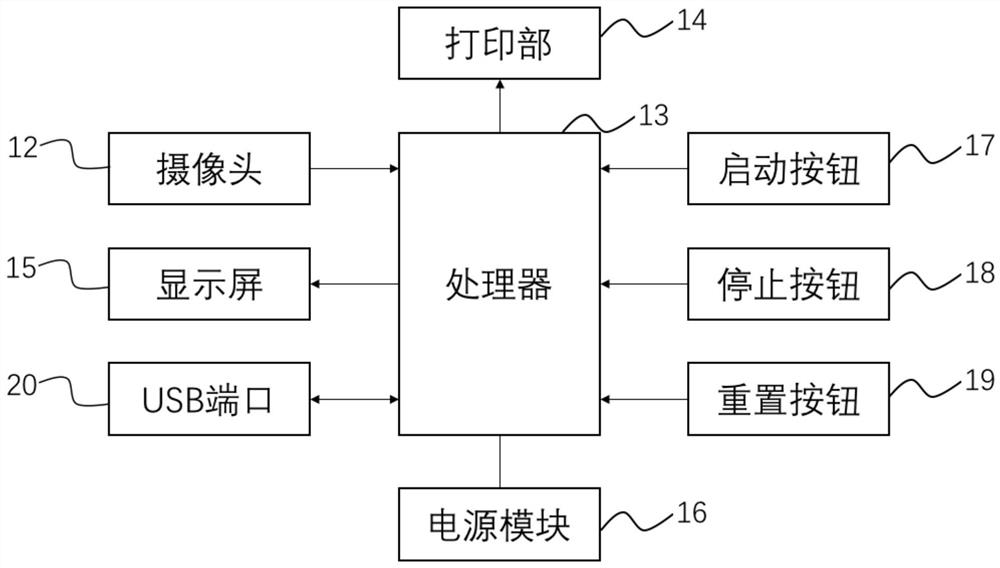

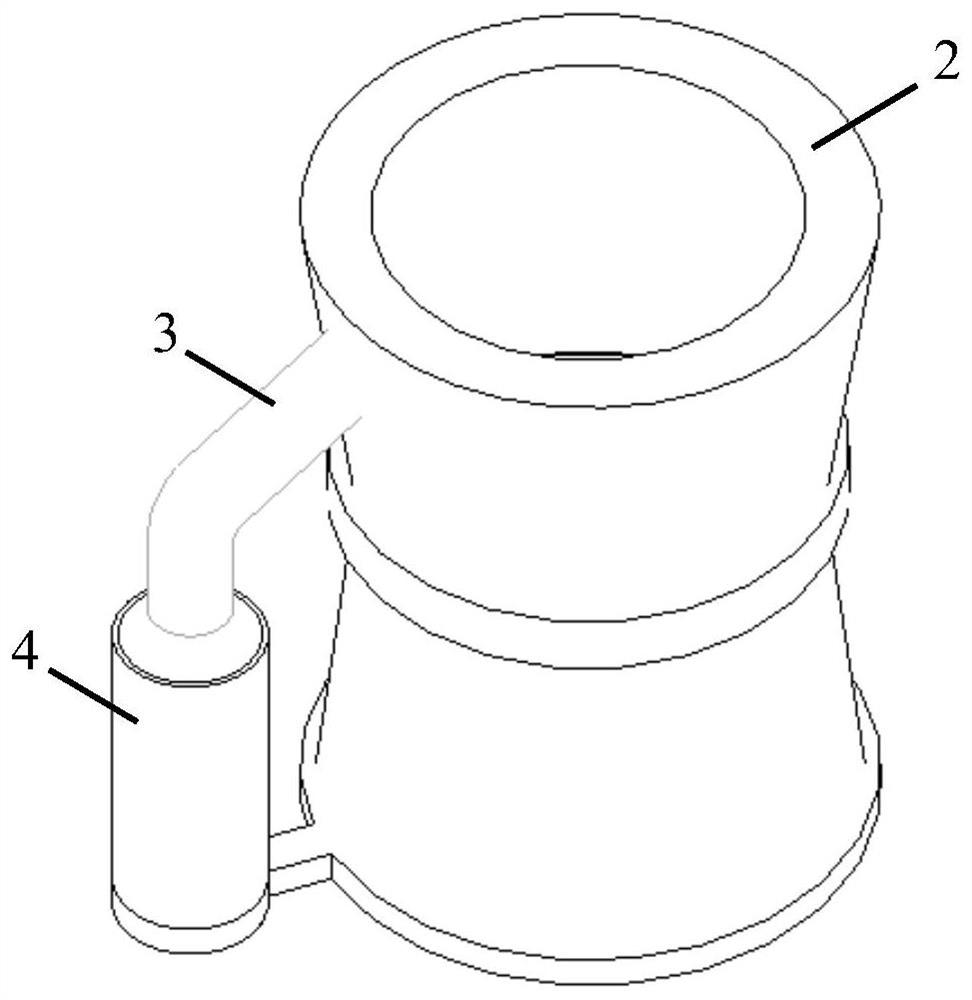

[0021] Such as figure 1 with figure 2 A grouting material initial fluidity testing system includes a test bench 1, a conical round mold 2, and a processing system. The upper surface of the test bench 1 is a scale plate 10 made of glass. There is also a spirit level 11 indicating levelness on the test bench 1 . Described processing system is arranged on the test bench 1, comprises: the camera 12 of collecting grouting material image information on the scale plate 10; According to the image information that camera 12 gathers, calculates the processor 13 of grouting material initial fluidity; Processor 13 obtains The printing unit 14 that prints out the initial fluidity of the initial fluidity in the form of a receipt; the display screen 15 that displays the initial fluidity obtained by the processor 13; the power supply module 16; the start button 17 for starting the system; the stop button 18 for closing the system; A reset button 19 for resetting measurement data; and a US...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com