Ceramic fiber modified wear-resistance adhesive

A technology of ceramic fibers and adhesives, applied in the directions of adhesives, adhesive additives, epoxy resin adhesives, etc., can solve the problems of delaying production time, inability to solve on-site problems, and lack of better solutions, and improve wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

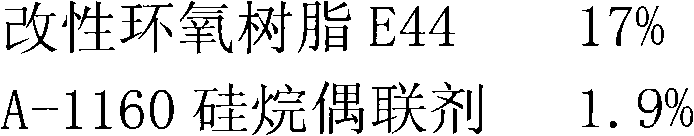

[0033] A ceramic fiber modified wear-resistant adhesive, comprising the following components (by mass percentage):

[0034] Component A (main agent):

[0035]

[0036]

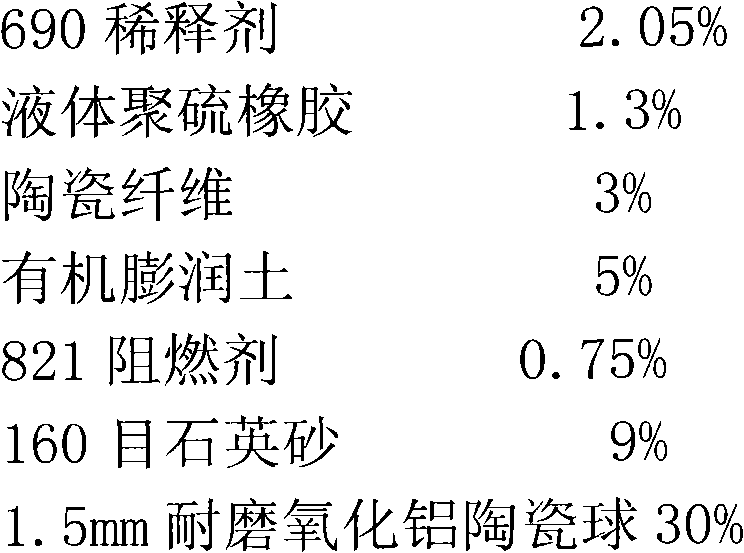

[0037] Component B (curing agent):

[0038]

[0039] In the coal centrifuges commonly used in coal washing plants, the outer opening of the casing screen is often severely worn. For a coal washing plant with an annual washing capacity of 5 million tons, after the centrifuge shell is worn out, it is repaired with a 30mm thick 16 manganese steel plate, which wears out after 20 days, resulting in coal slime water leakage. After 10 days, the worn-off steel plate fell and caused the conveyor belt under the centrifuge to tear.

[0040] The beneficial effects of this embodiment are: use the ceramic fiber modified wear-resistant adhesive of the present invention to cooperate with wear-resistant ceramics for repairing, fill the worn holes and grooves with the ceramic fiber modified wear-resistant adhesive, a...

Embodiment 2

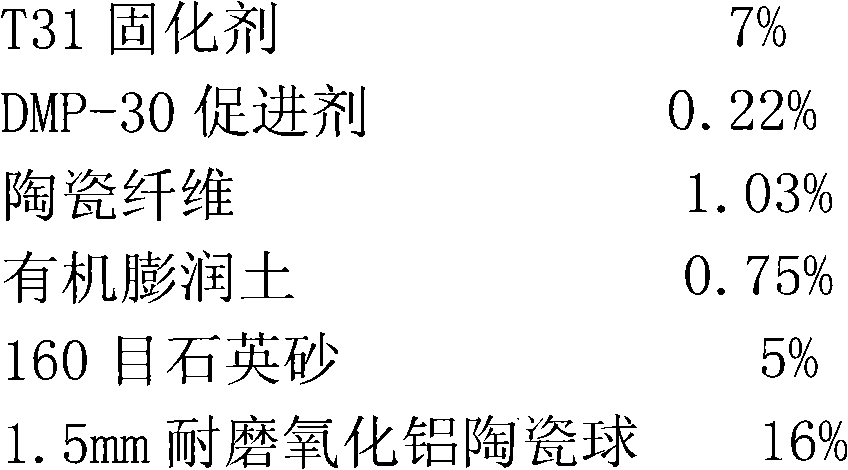

[0043] A ceramic fiber modified wear-resistant adhesive, comprising the following components (by mass percentage):

[0044] Component A (main agent):

[0045]

[0046] Component B (curing agent):

[0047]

[0048] The beneficial effects of this embodiment are: the concentrator is an important equipment for coal slime water treatment and recycling in coal washing plants, the feed pipeline is an overhead pipeline, the diameter is usually 327mm-800mm, the medium is coal slime water, and there are more points after 2 years of use The bit is worn out, and then repaired by replacement and welding methods, which cannot solve the wear problem, and cause problems that affect the appearance of the workshop equipment.

[0049] Use the material ceramic fiber modified wear-resistant adhesive of the present invention to repair, use the material ceramic fiber modified wear-resistant adhesive of the present invention to repair directly from the inner wall, mixing ratio: weight ratio / vo...

Embodiment 3

[0051] A ceramic fiber modified wear-resistant adhesive, comprising the following components (by mass percentage):

[0052] Component A (main agent):

[0053]

[0054] Component B (curing agent):

[0055]

[0056] The beneficial effect of this embodiment is: the feed pipe of the filter press in the coal washing plant, the internal medium is coal slime water, the medium leaks due to the wear of the elbow joint and the flange, and the thickness of the pipe wall is only 2mm, which cannot be welded.

[0057] Use the ceramic fiber modified wear-resistant adhesive material of the present invention to repair, and use the ceramic fiber modified wear-resistant adhesive material of the present invention to directly apply the repair from the outer wall, mixing ratio: weight ratio / volume ratio (main agent: curing agent) 1.5:1 / 1.2:1; the viscosity after mixing is paste; the operating time is 45-60 minutes; the curing time is 9 hours; the hardness (Shore D) after curing is 87; the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com