Patents

Literature

37results about How to "Improve Die Bonding Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

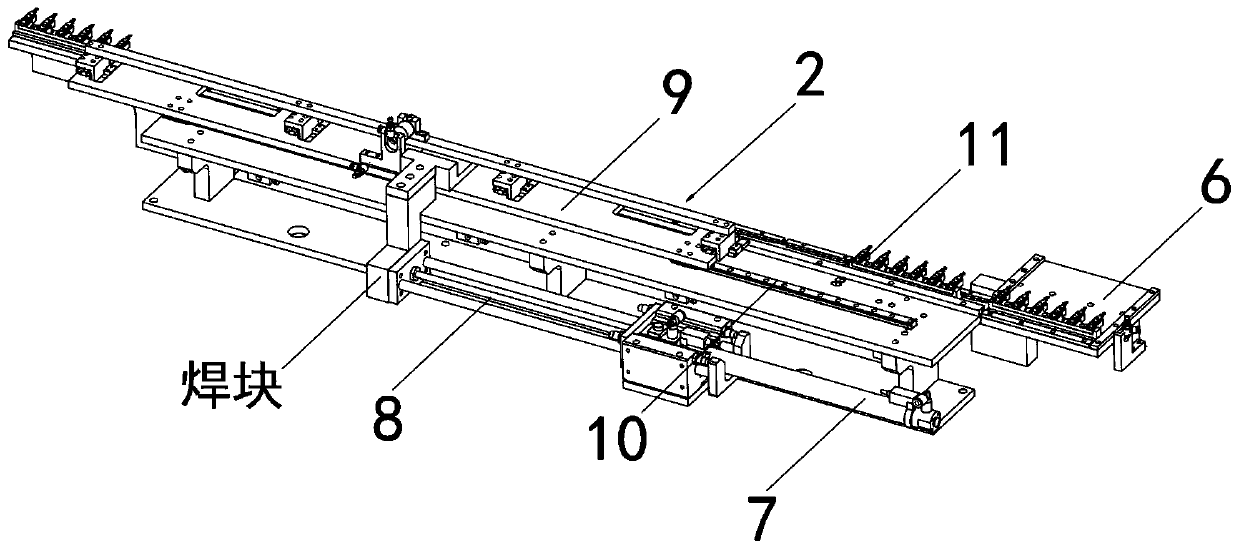

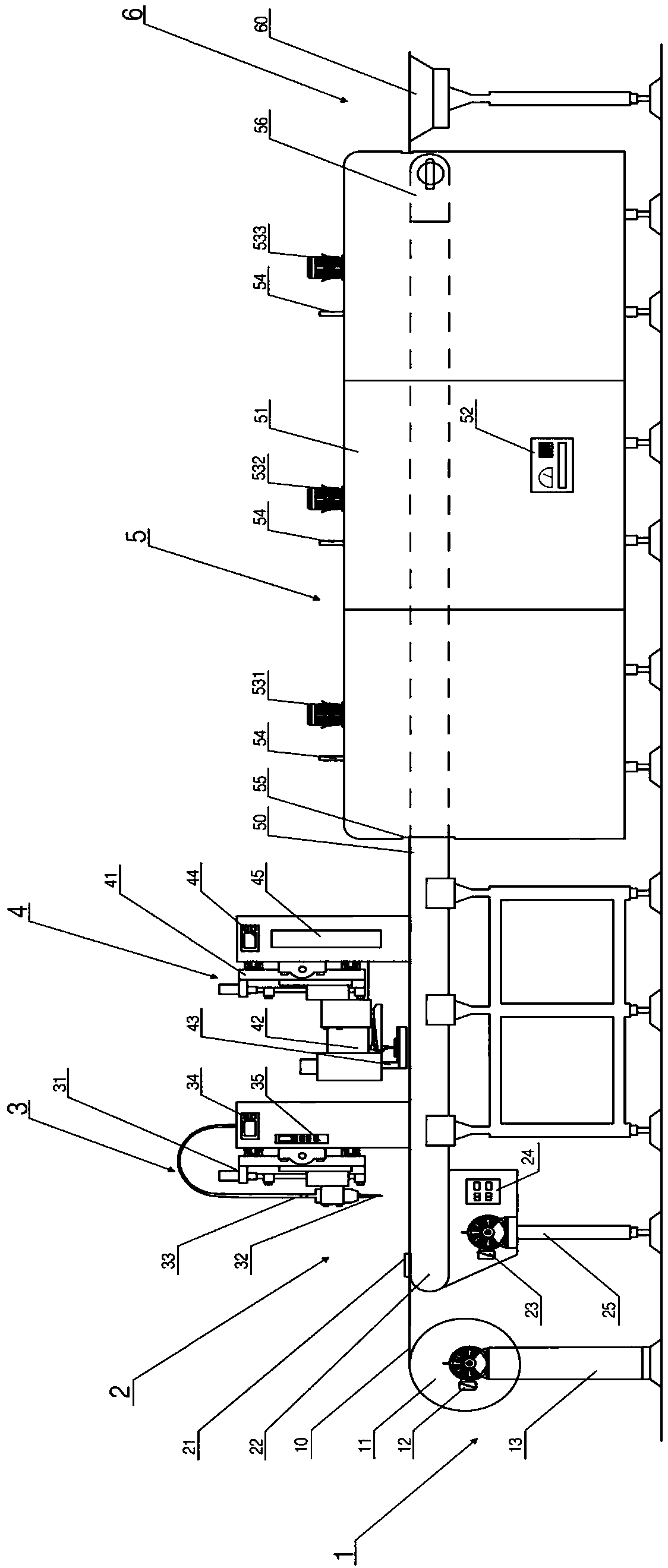

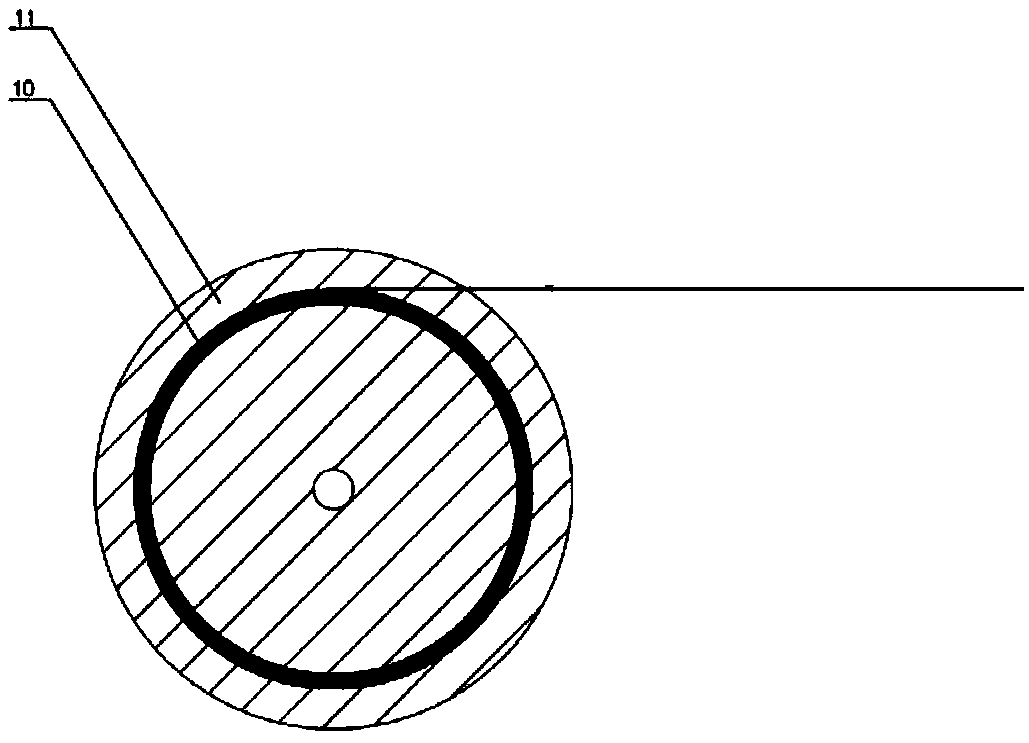

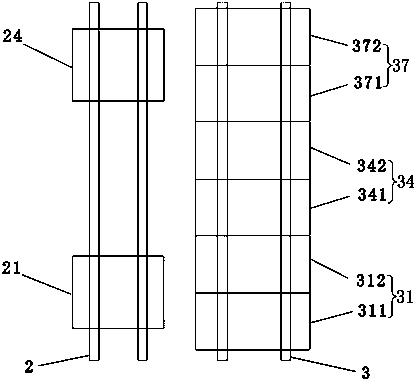

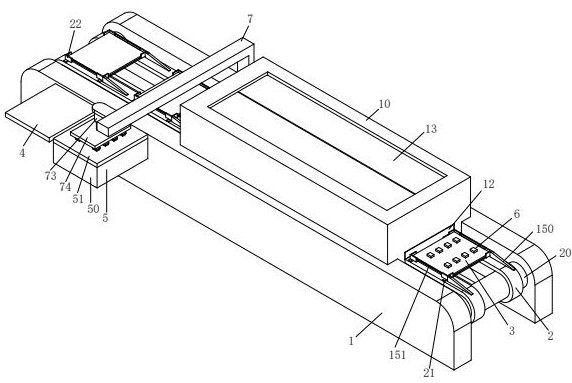

Continuous die bonding device and die bonding method of light emitting diode (LED)

InactiveCN107146839AImprove accuracyImprove Die Bonding EfficiencySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDie bonding

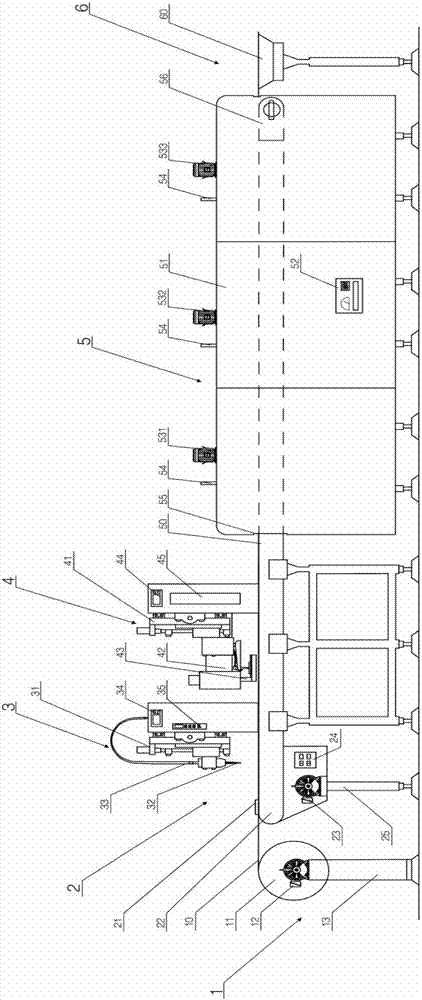

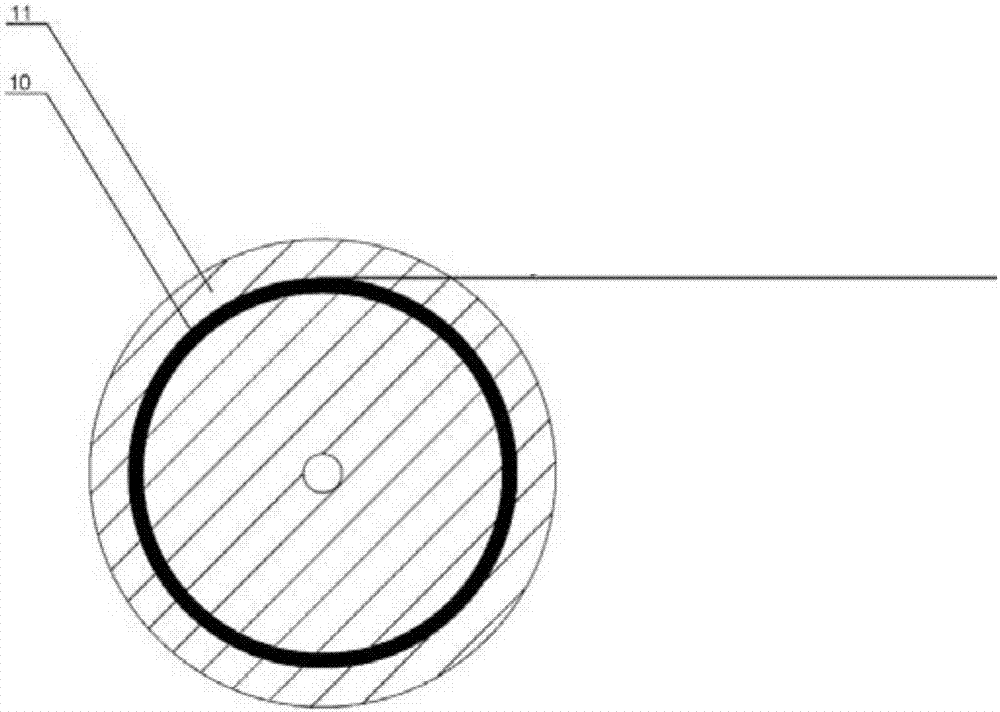

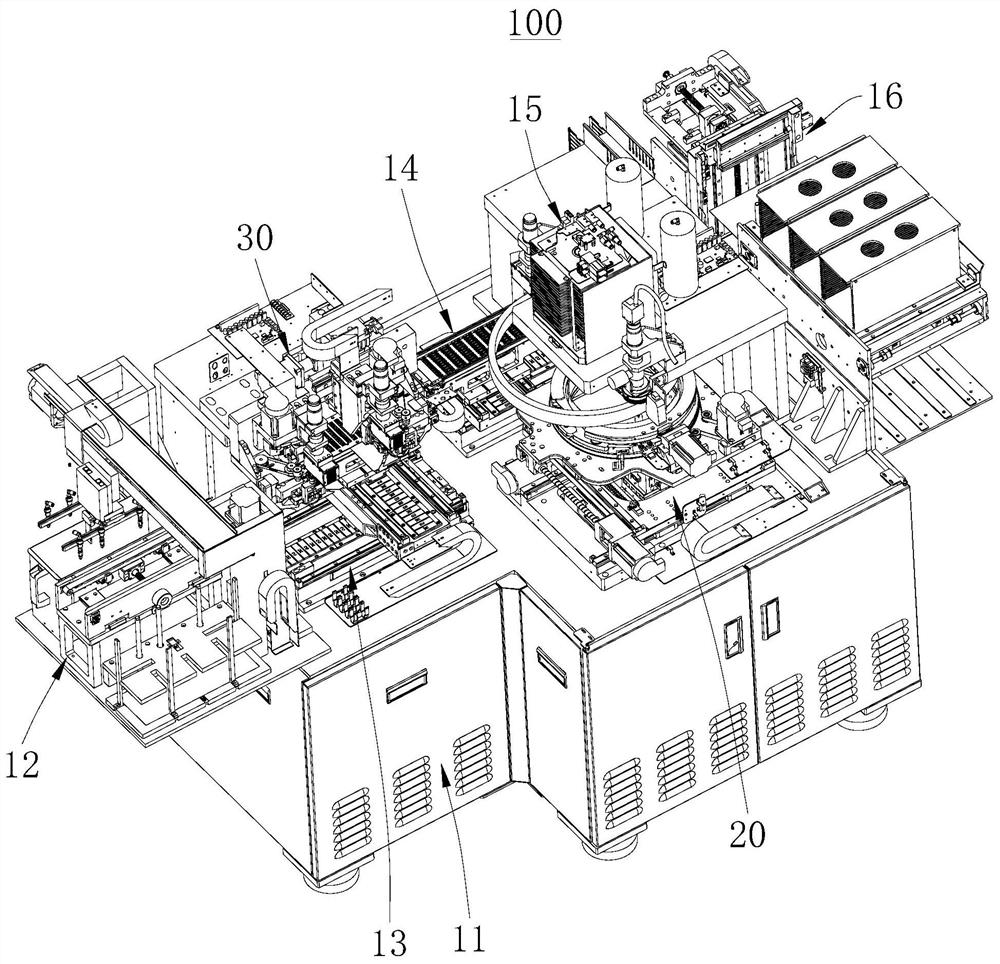

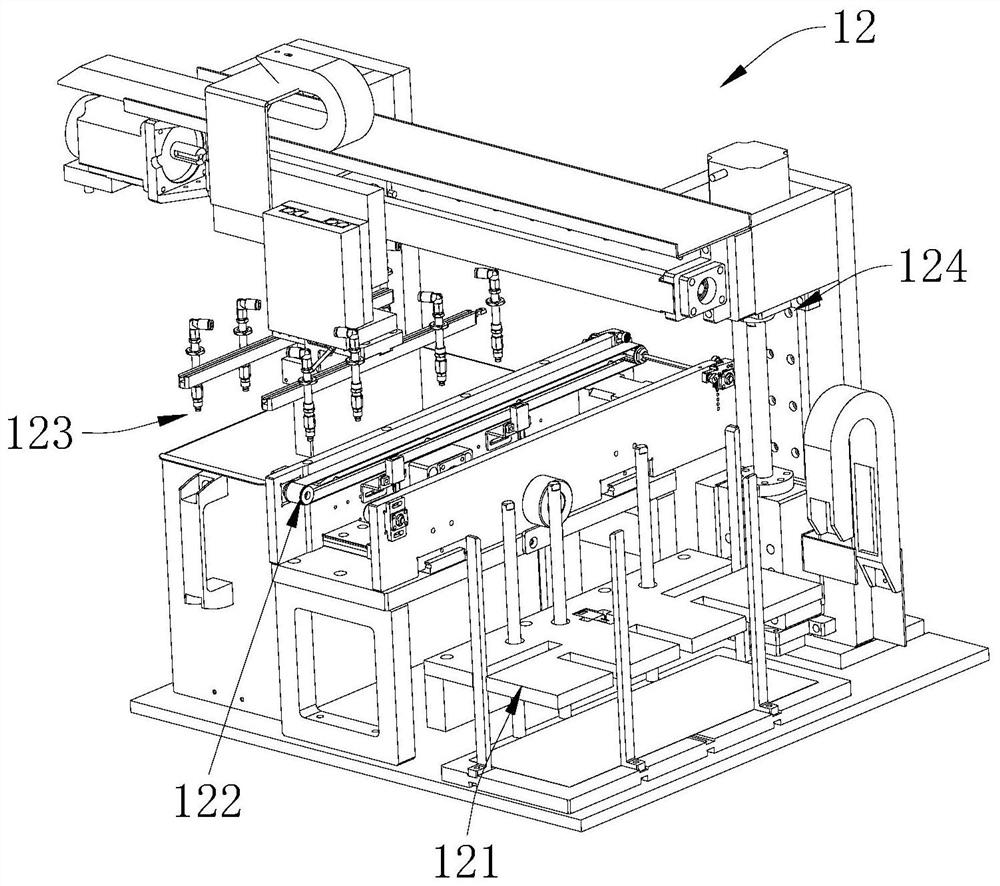

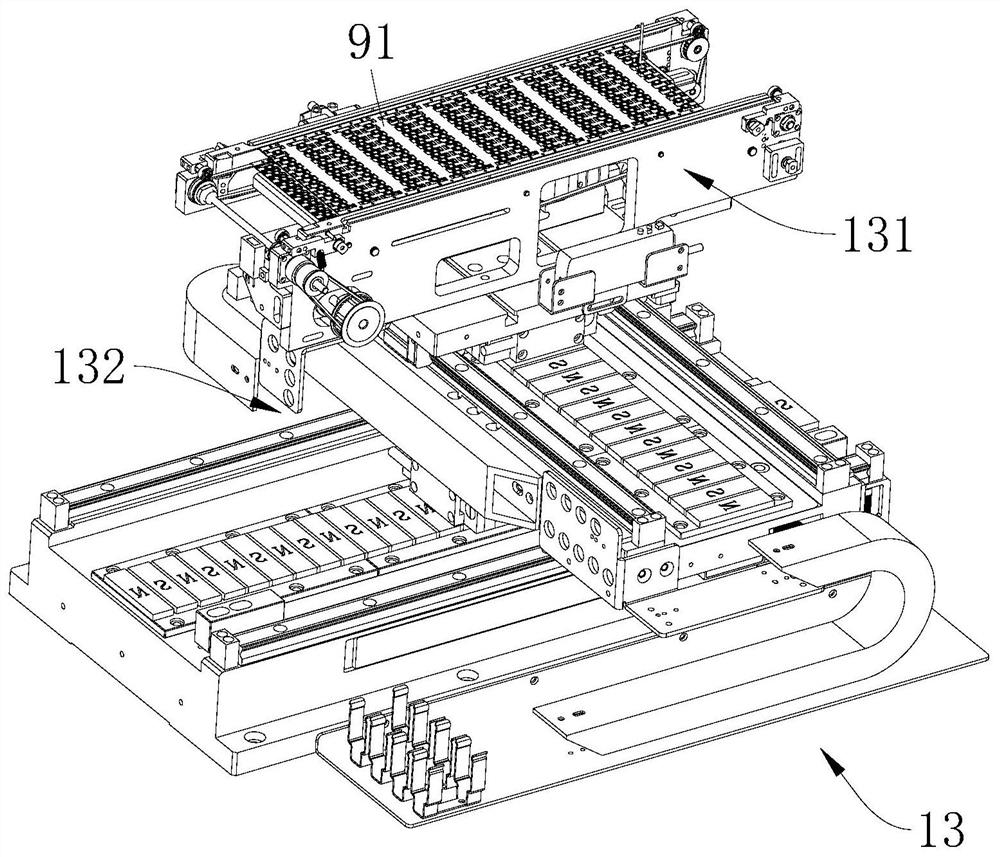

The invention provides a continuous die bonding device and die bonding method of a light emitting diode (LED), and relates to package of an LED chip. The device is provided with a substrate film sending system, a transmission system, a dispersion glue system, a die bonding system, a heating system and a substrate film outlet system, wherein substrate film sending system, a transmission system, the dispersion glue system, the die bonding system, the heating system and the substrate film outlet system are sequentially arranged on a ground surface. The die bonding method comprises the steps of installing the substrate film sending system and the transmission system, and transmitting a substrate by the substrate film sending system and the transmission system; performing dispersion glue on the substrate by the dispersion glue system; performing LED die bonding on the substrate by the die bonding system; curing silver glue by the heating system; and firmly pasting the LED chip on the substrate. By the device and the die bonding method, a high-quality continuous silicon carbide ceramic substrate package product can be obtained, continuous and automatic die bonding of the LED chip on a board of the continuous silicon carbide thin film substrate and industrial production of the package product are achieved, and an LED finished device with more excellent performance is obtained.

Owner:XIAMEN UNIV

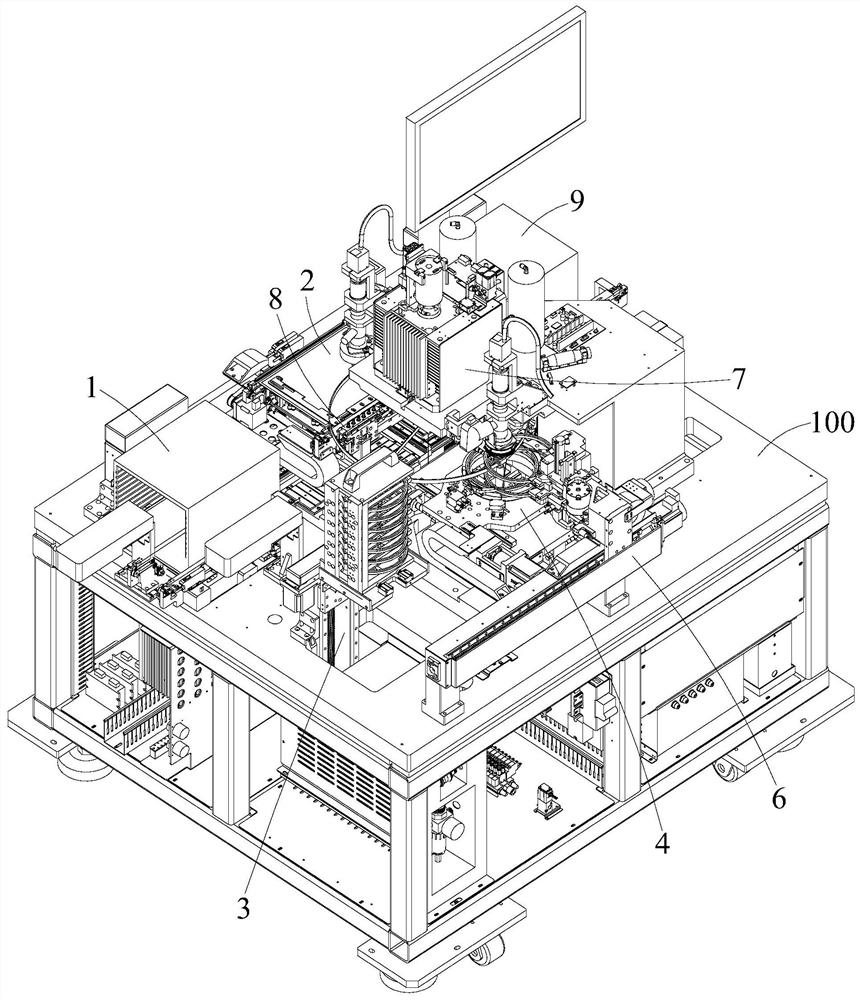

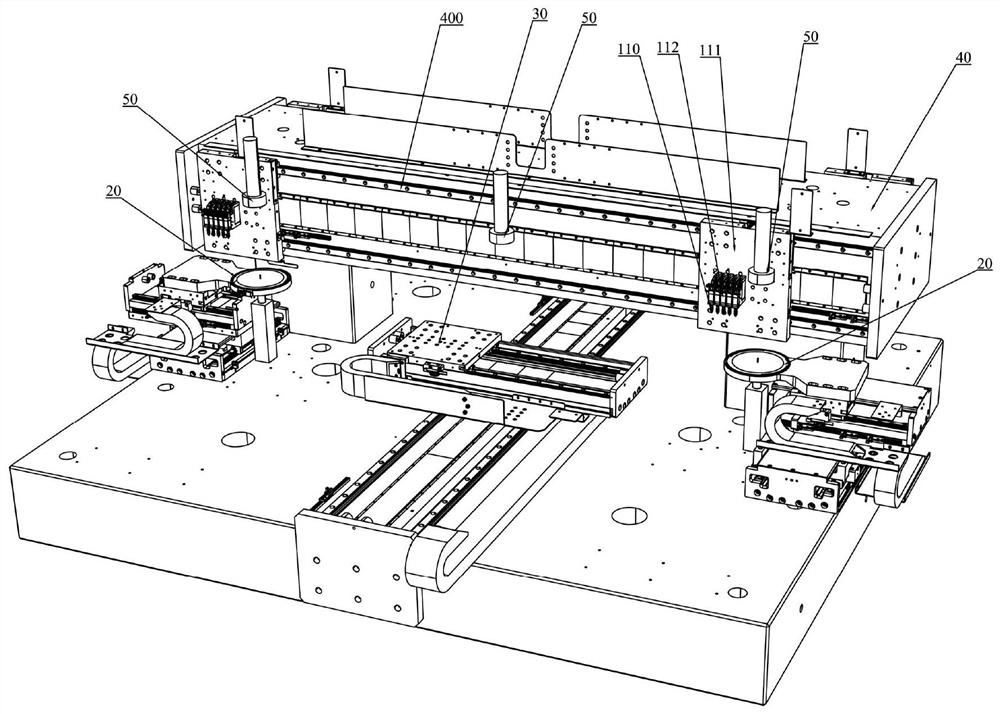

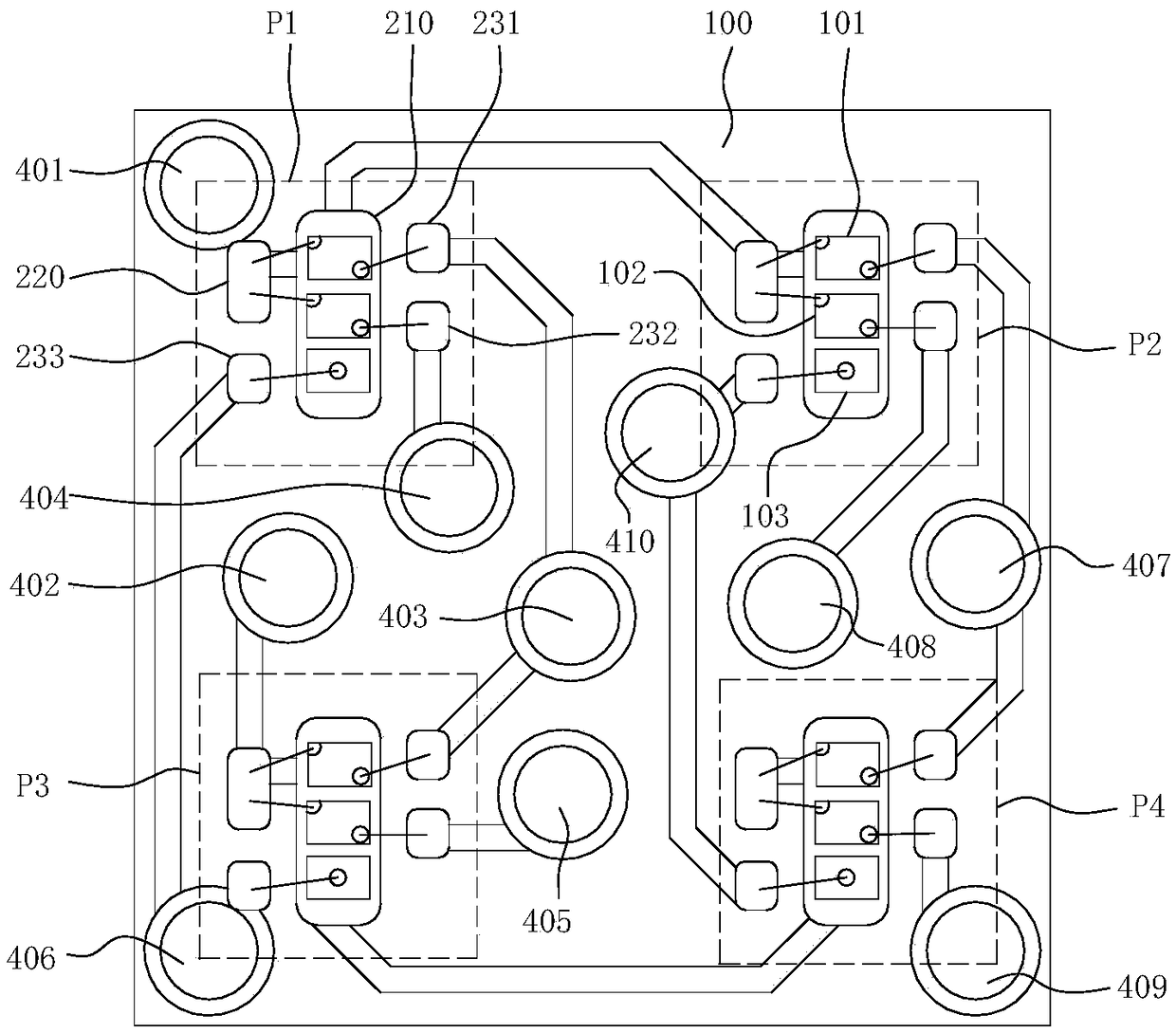

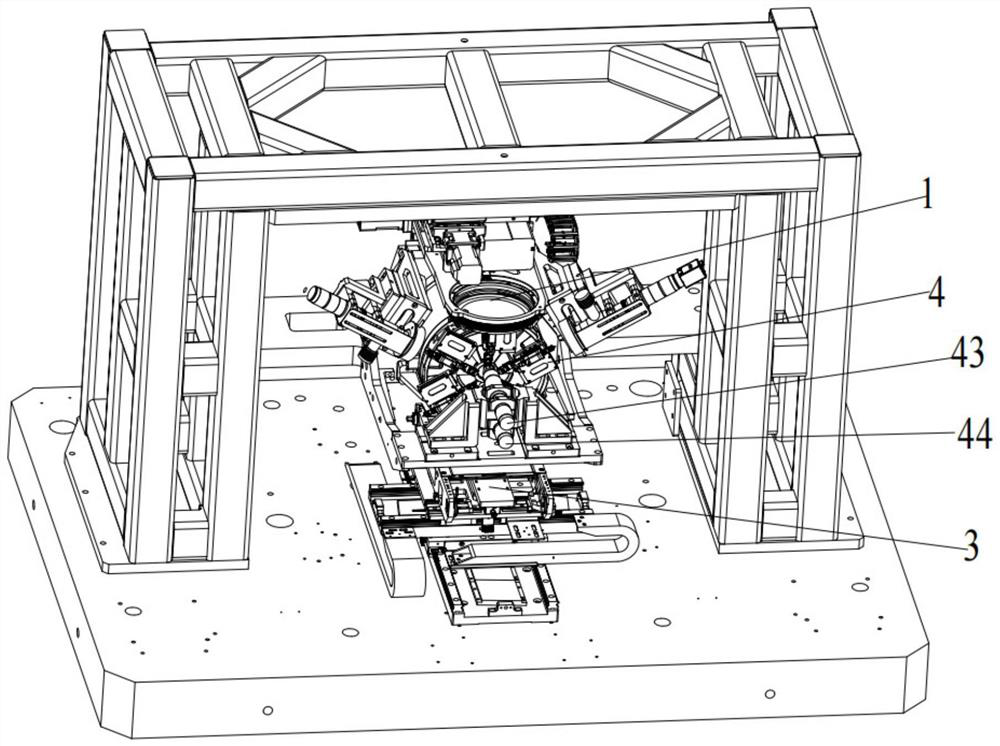

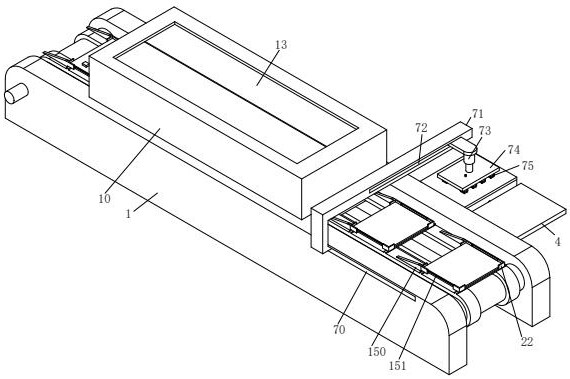

Die bonder

ActiveCN111370350AGuaranteed dispensing accuracyEnsure dispensing qualitySemiconductor/solid-state device manufacturingWaferingElectric machinery

The invention provides a die bonder. The die bonder comprises a rack; a dispensing device; a dispensing shifting mechanism; a feeding mechanism; a die bonding swing arm device; a crystal supply platform; a die bonding displacement mechanism; and a material receiving mechanism. The die bonding swing arm device comprises a rotating frame, a plurality of die bonding swing arms, a lifter and a die bonding motor, and each die bonding swing arm is provided with a suction nozzle; the dispensing device comprises a plurality of dispensing modules. The invention provides a die bonder. According to the invention, the plurality of dispensing modules are combined with the plurality of die bonding swing arms, so that the operation speeds of the plurality of dispensing modules can be adjusted to be matched with the operation speeds of the plurality of die bonding swing arms on the premise of ensuring the dispensing precision and quality and ensuring the wafer taking and placing precision, the idle time of each dispensing module and each die bonding swing arm is reduced, and the die bonding efficiency is greatly improved.

Owner:SHENZHEN XINYICHANG TECH CO LTD

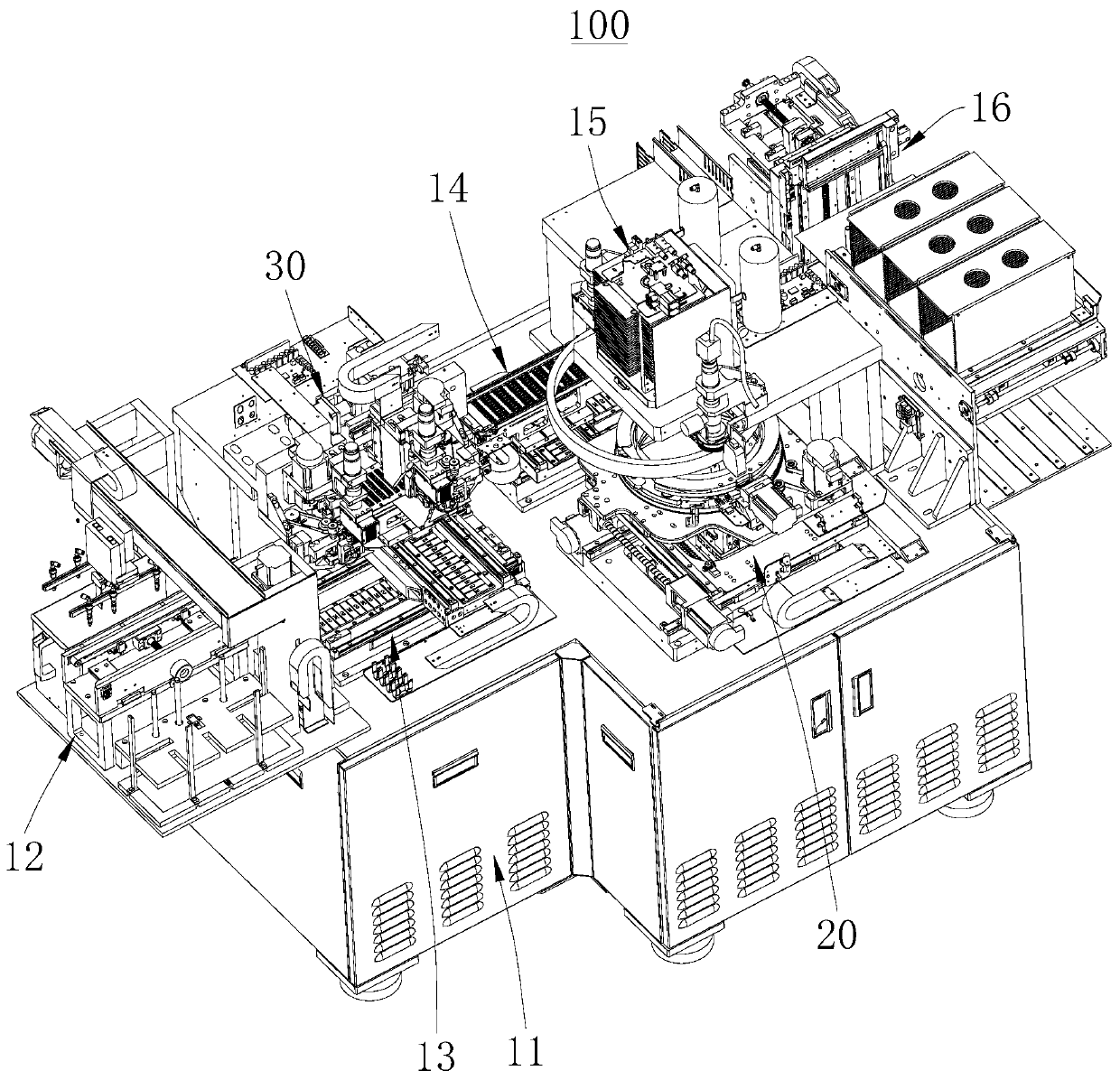

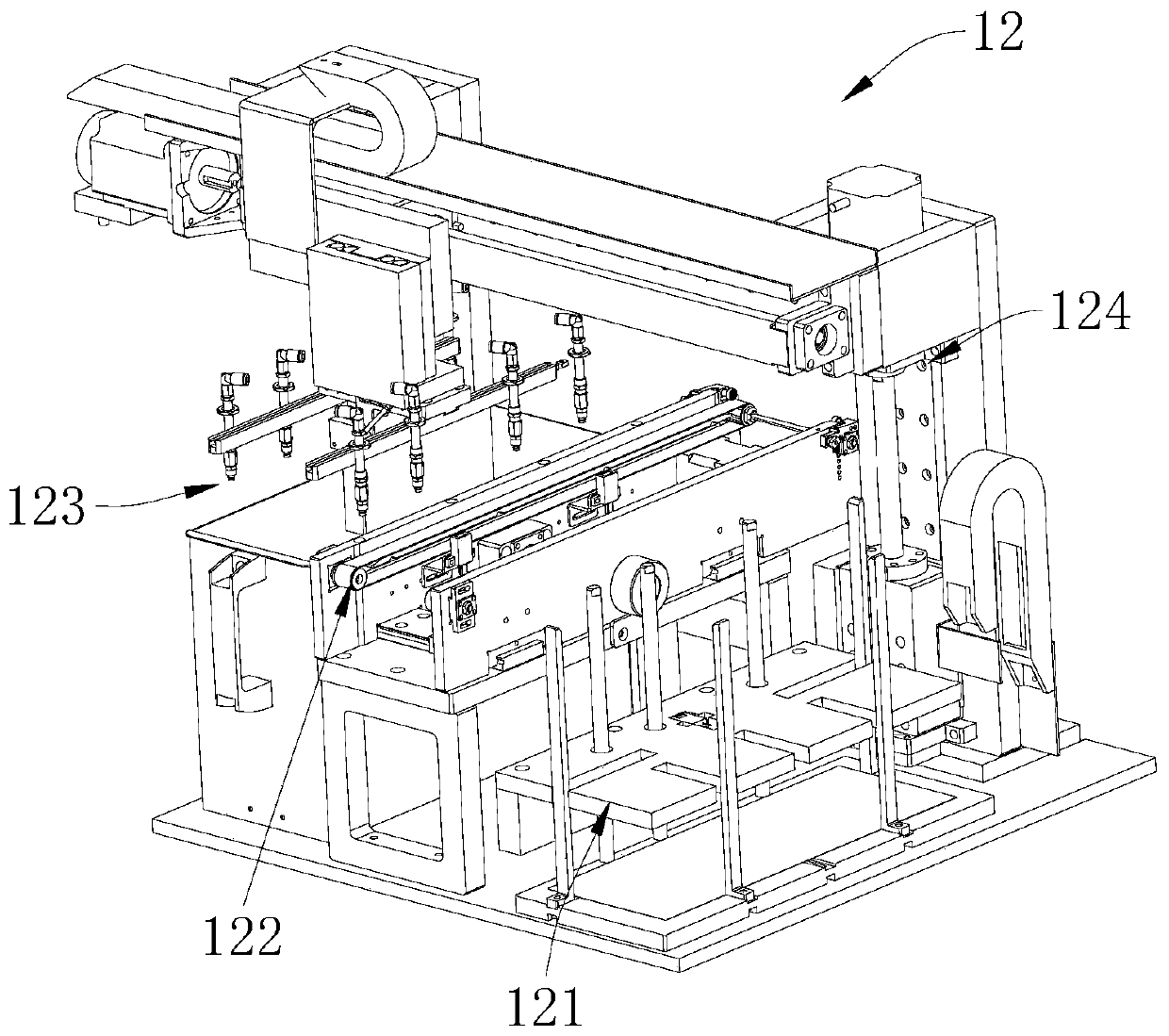

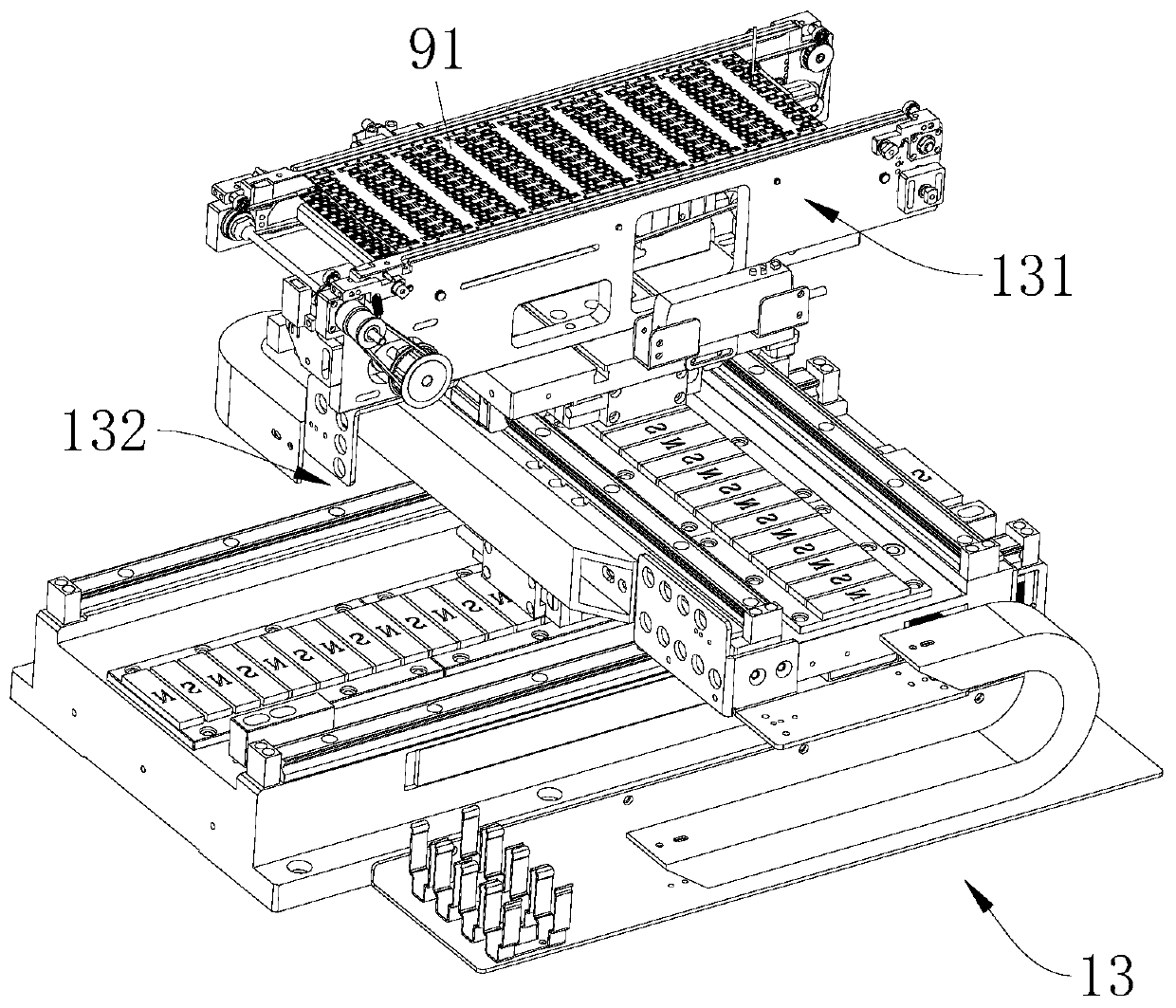

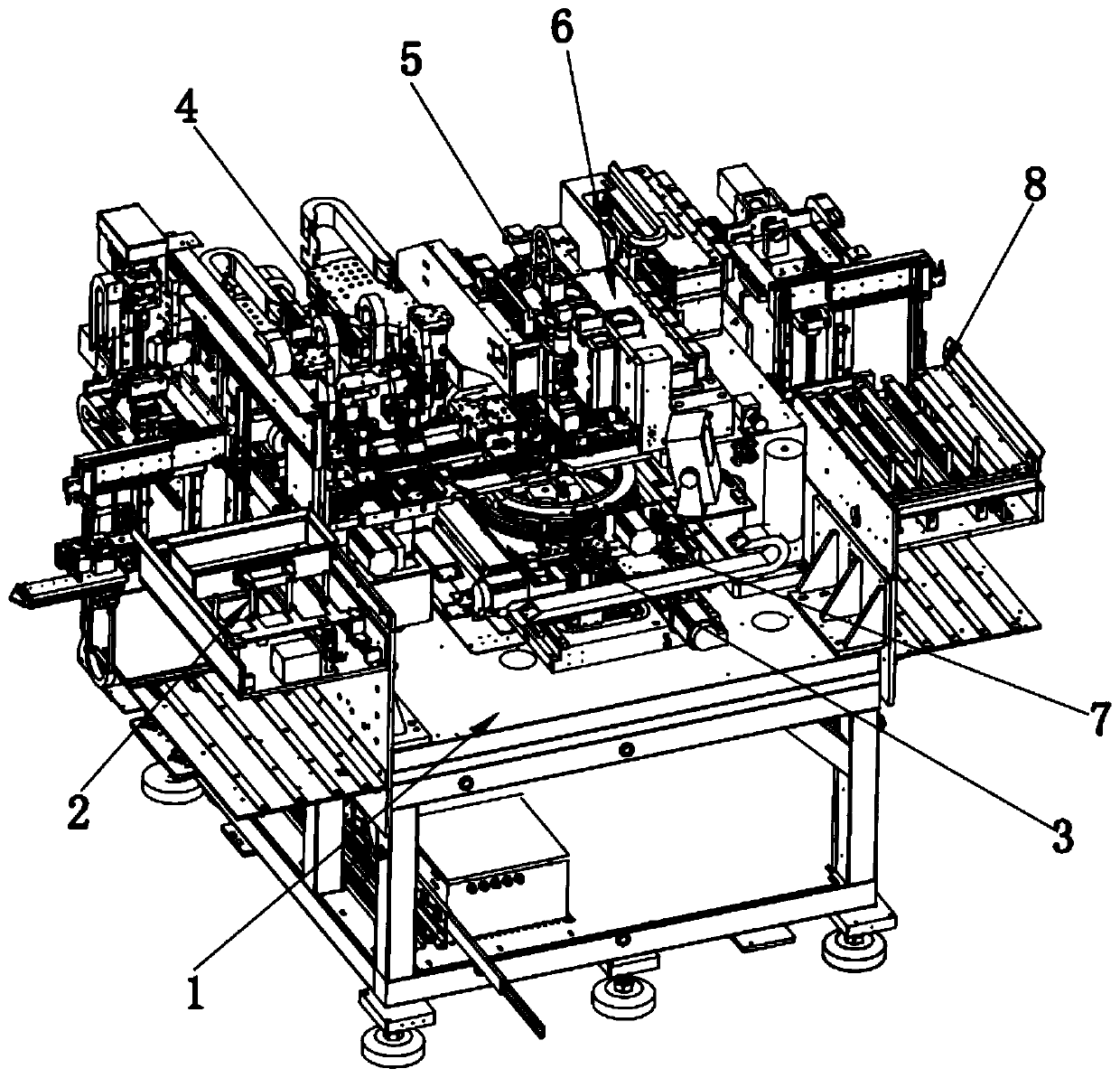

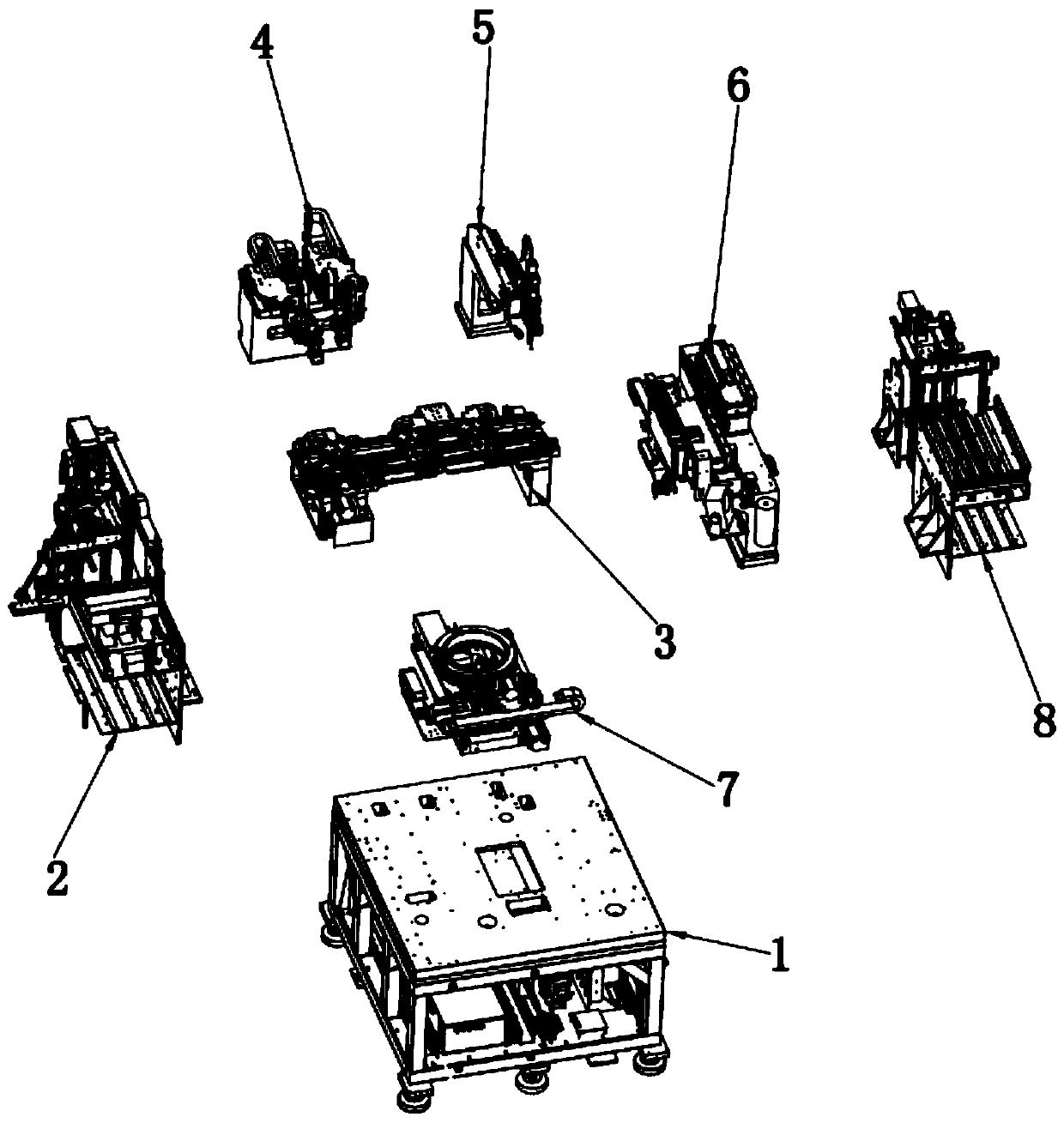

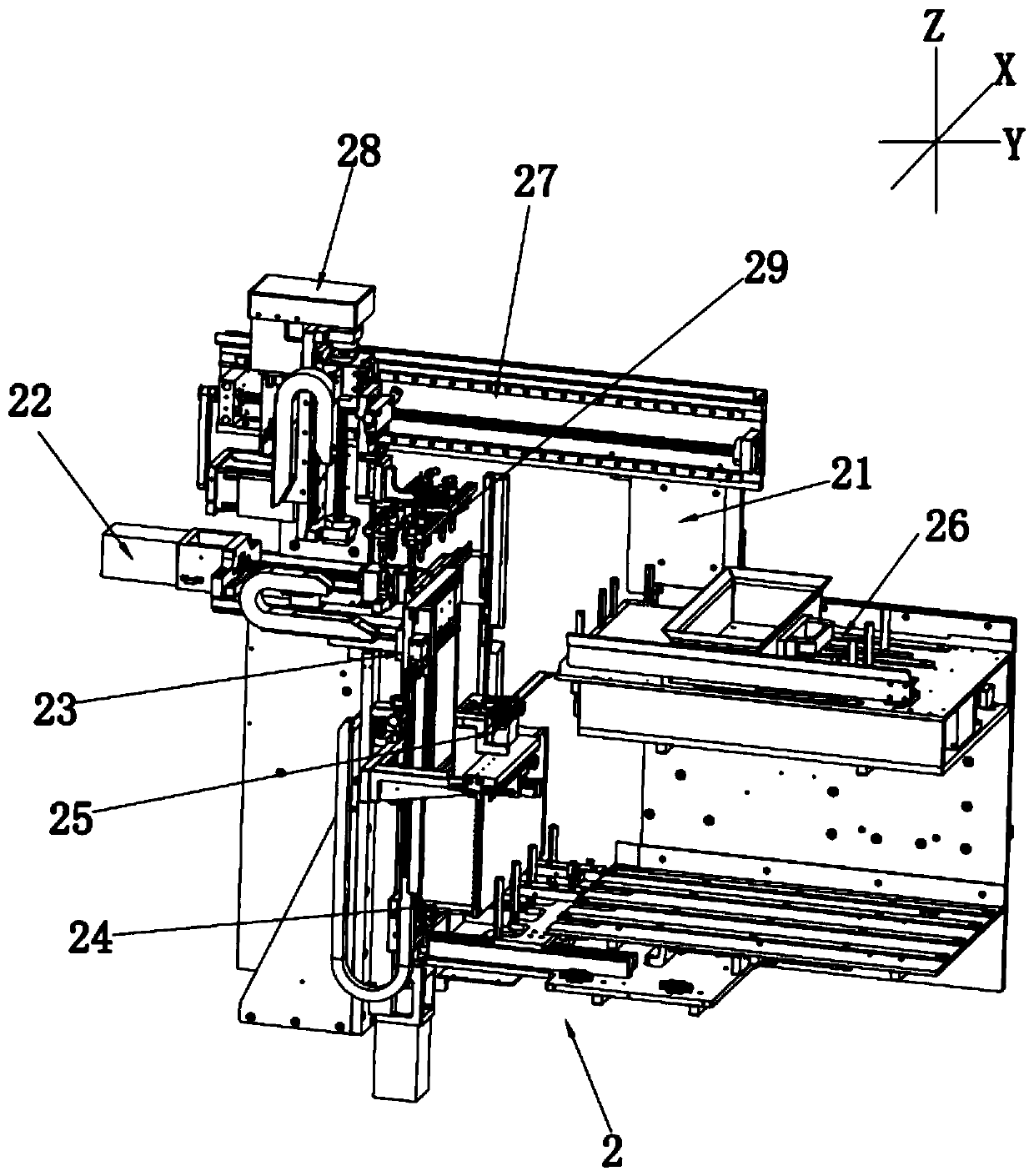

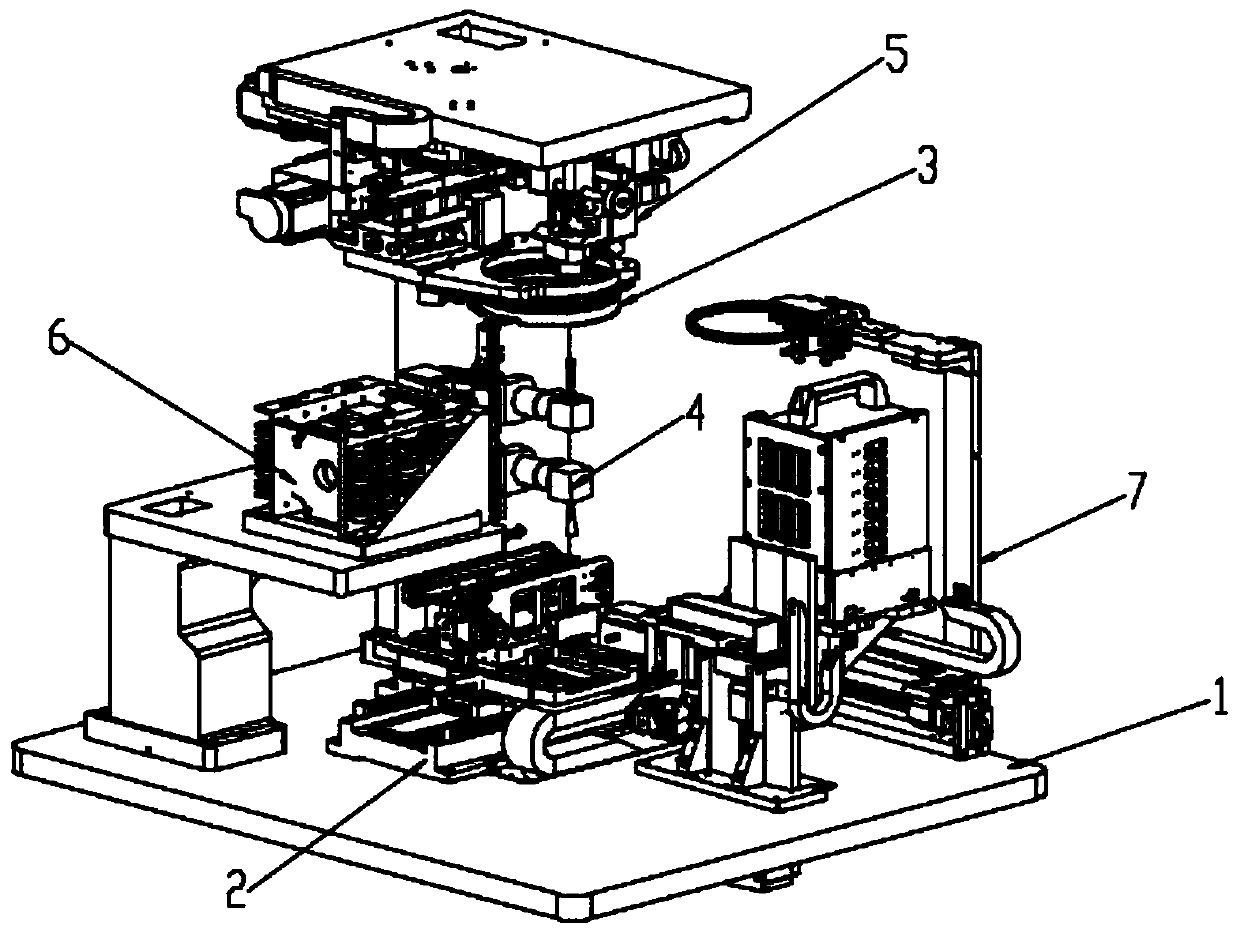

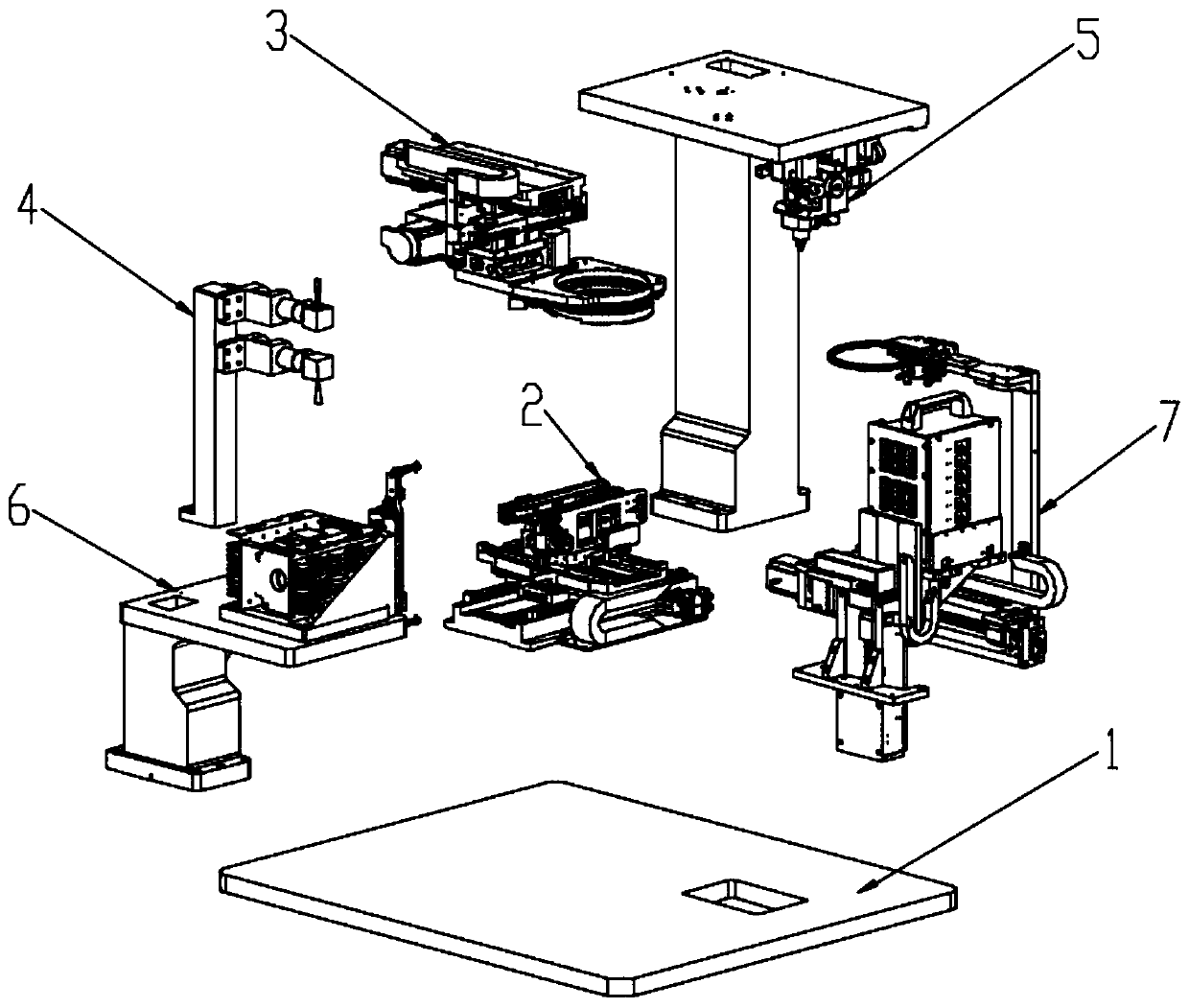

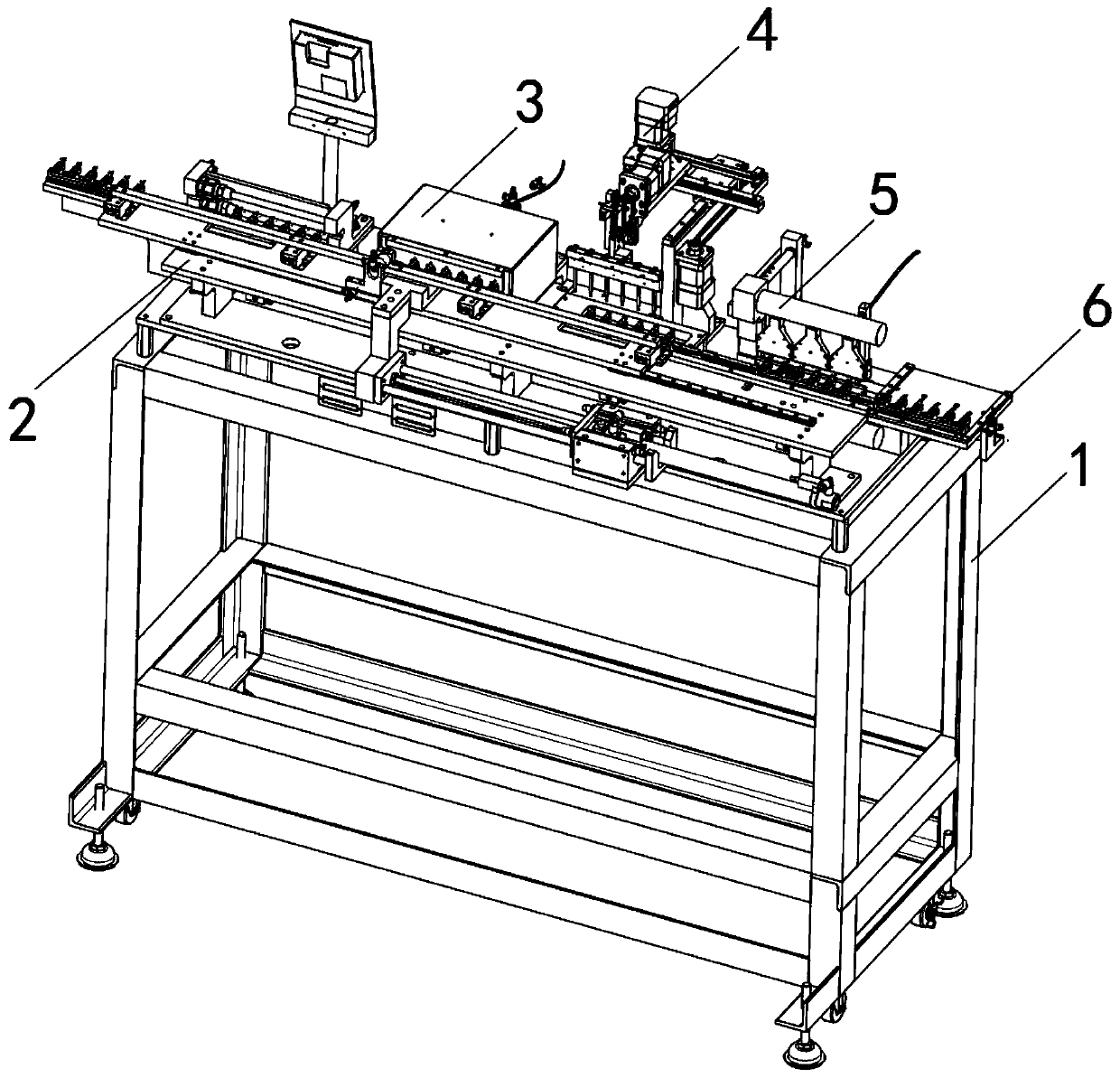

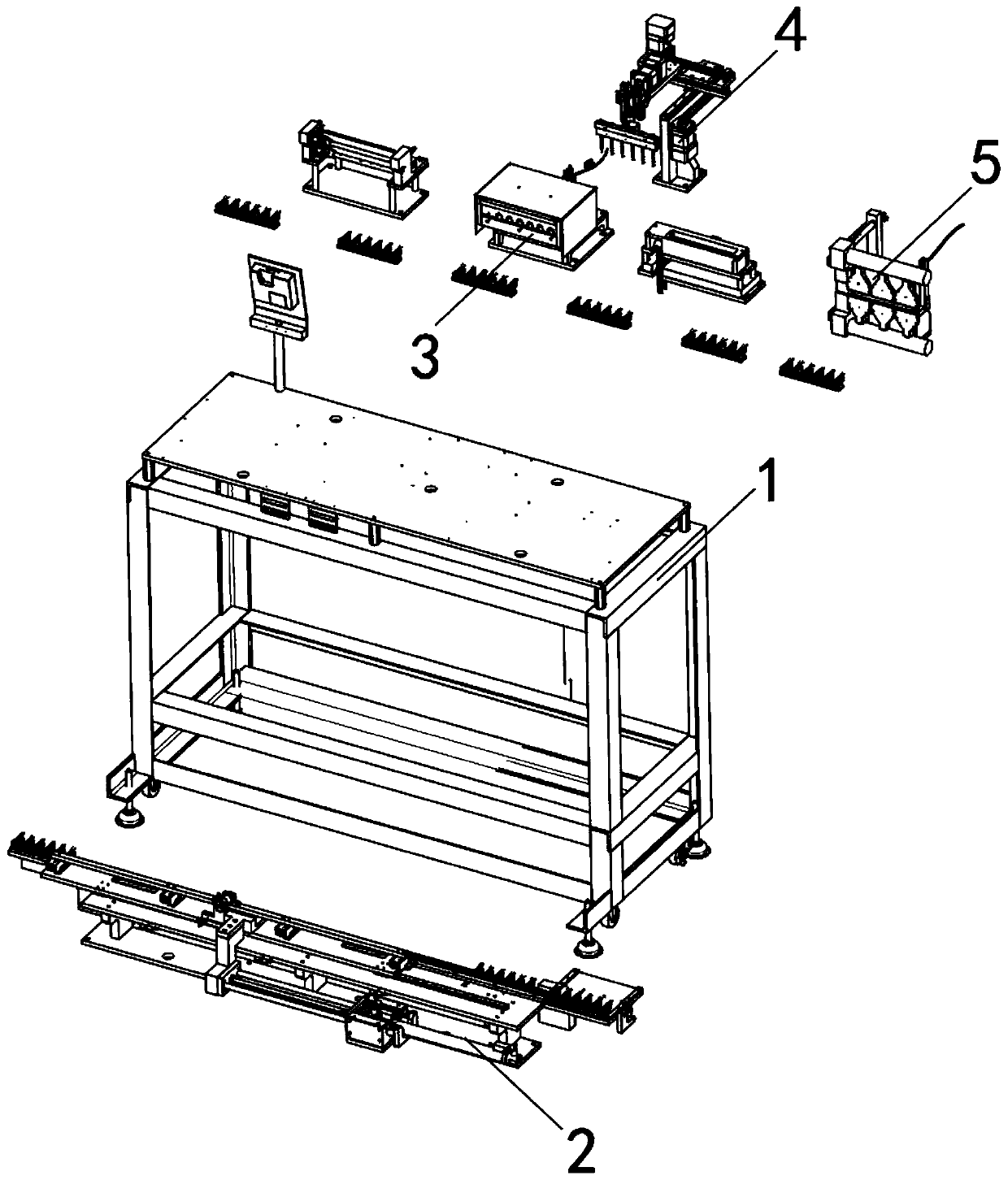

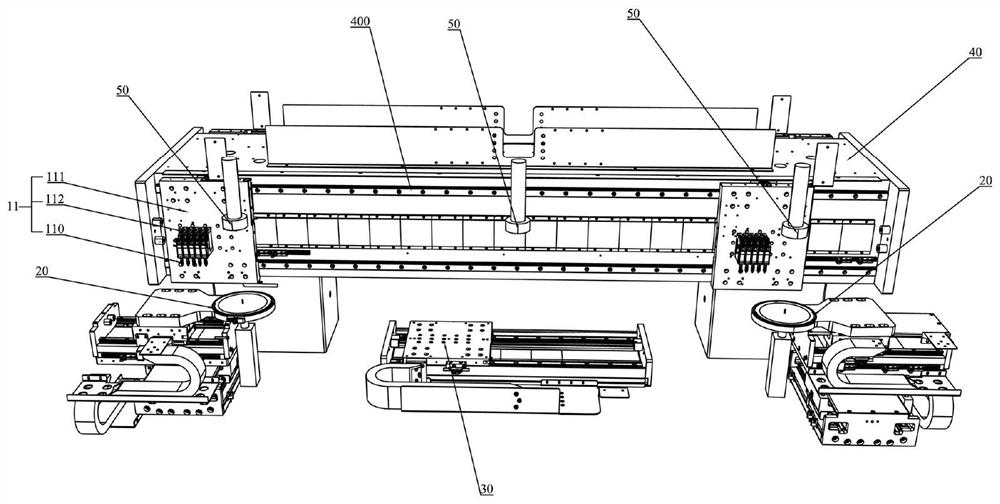

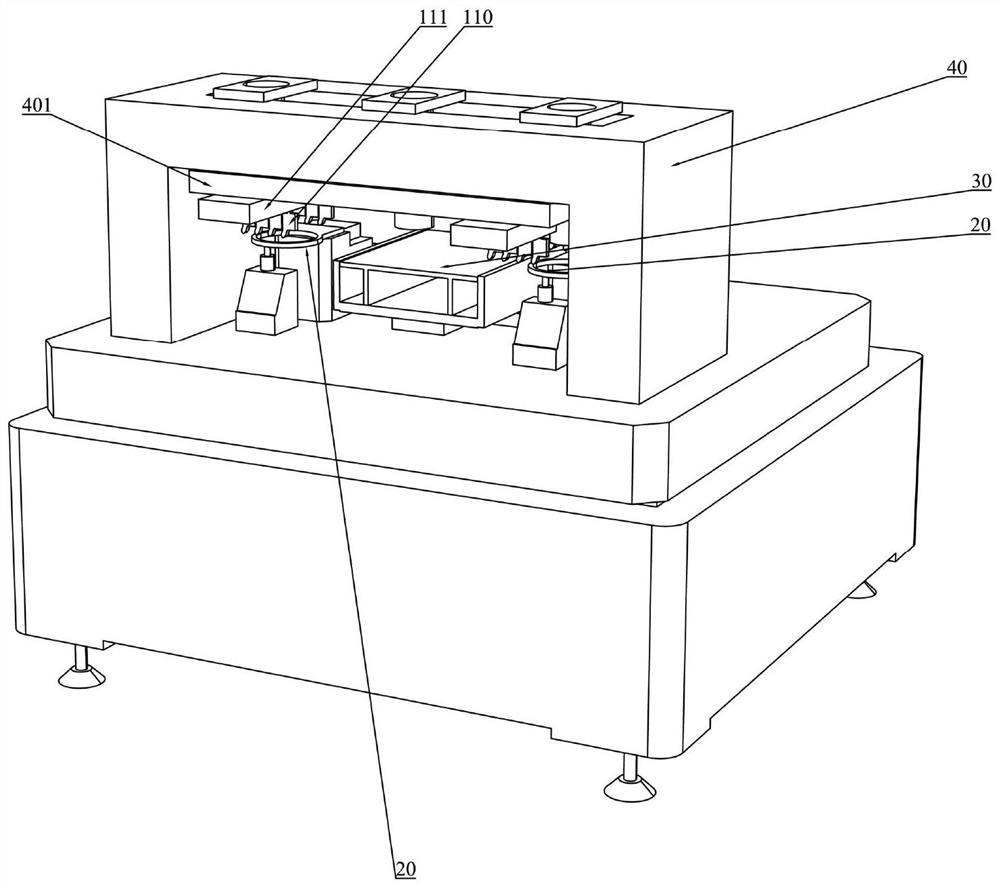

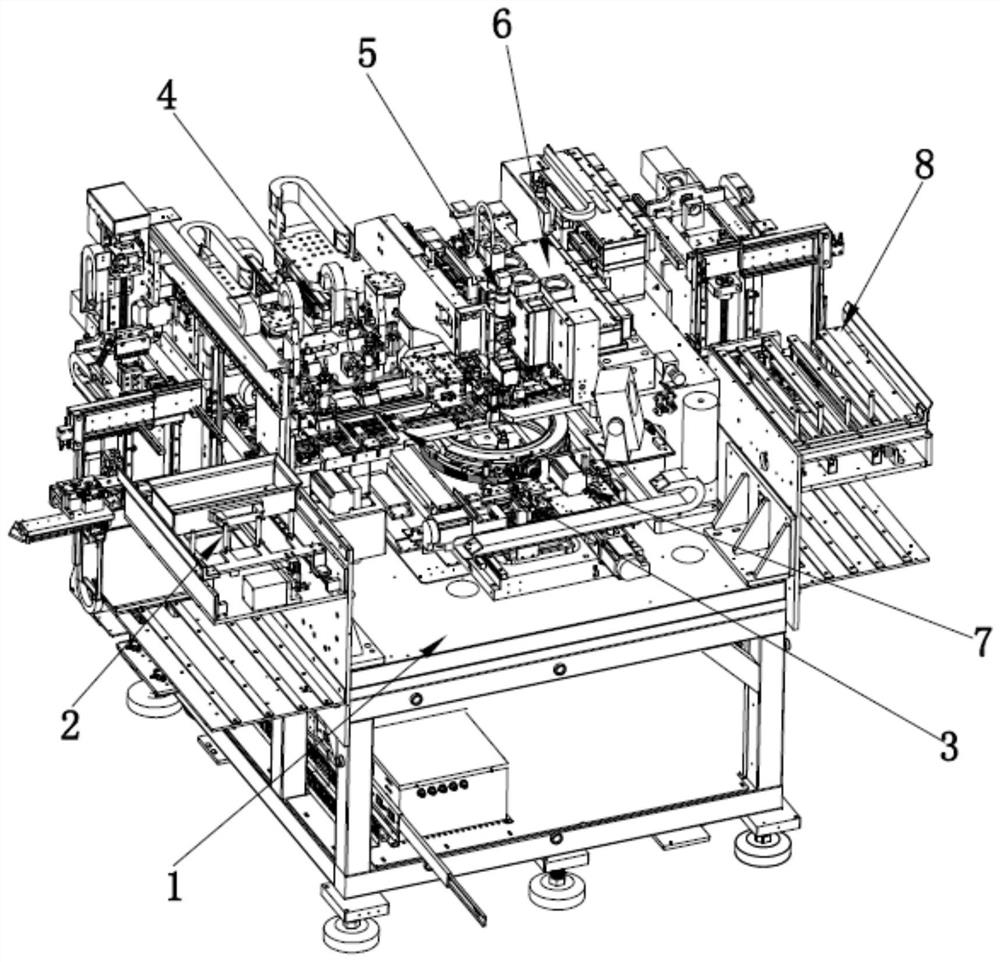

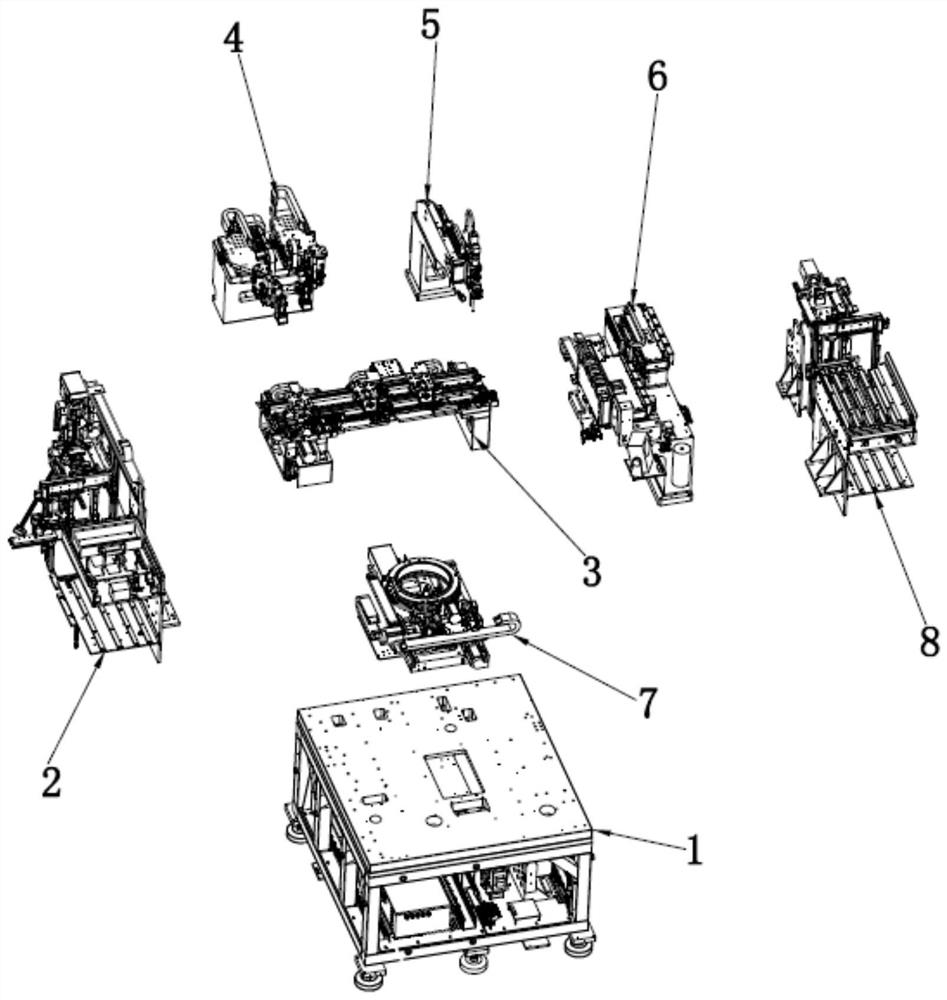

Full-automatic planar IC die bonder and die bonding method

ActiveCN111490147APrevent solidificationShorten the timeSemiconductor devicesWaferingStructural engineering

The invention provides a full-automatic planar IC die bonder and a die bonding method. The die bonder comprises a rack, a feeding mechanism and a receiving mechanism which are arranged at two ends ofthe rack respectively, a rail mechanism which is arranged between the feeding mechanism and the receiving mechanism; a dispensing mechanism, a lens mechanism and a welding head mechanism which are arranged on a side of the rail mechanism, and a film expanding and crystal ejecting mechanism which is arranged below the rail mechanism. The feeding mechanism is used for feeding an LED support to the rail mechanism, the rail mechanism is used for receiving and transferring the LED support, the dispensing mechanism is used for dispensing the LED support, and the film expanding and wafer jacking mechanism is used for jacking out a wafer on a blue film and fixing the wafer to the LED support under the cooperation of the lens mechanism and the welding head mechanism; the dispensing mechanism comprises a dispensing stand column fixed to the rack, a first dispensing assembly and a second dispensing assembly, wherein the first dispensing assembly and the second dispensing assembly are arranged onthe dispensing stand column. By arranging the two dispensing assemblies, the dispensing efficiency is greatly improved such that the die bonding efficiency is effectively ensured.

Owner:SHENZHEN XINYICHANG TECH CO LTD

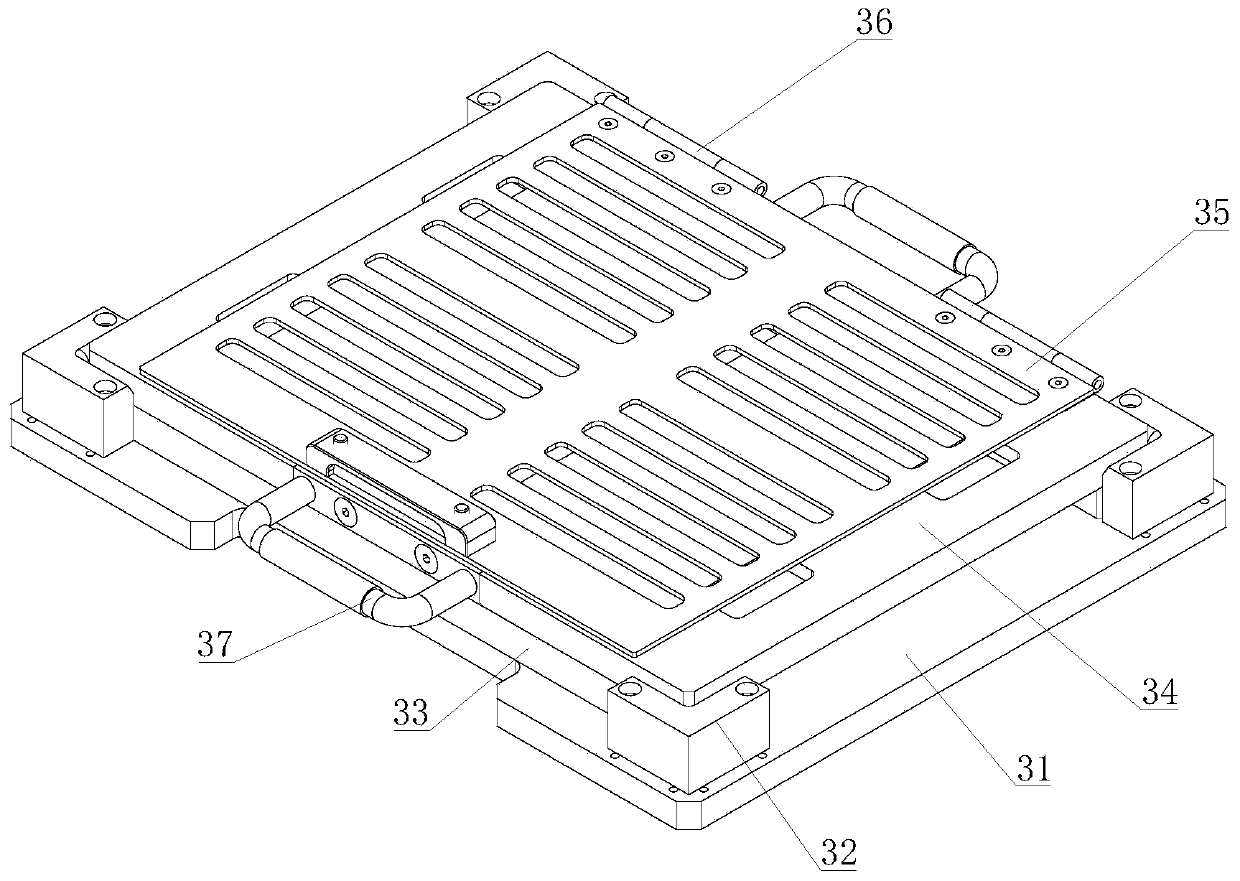

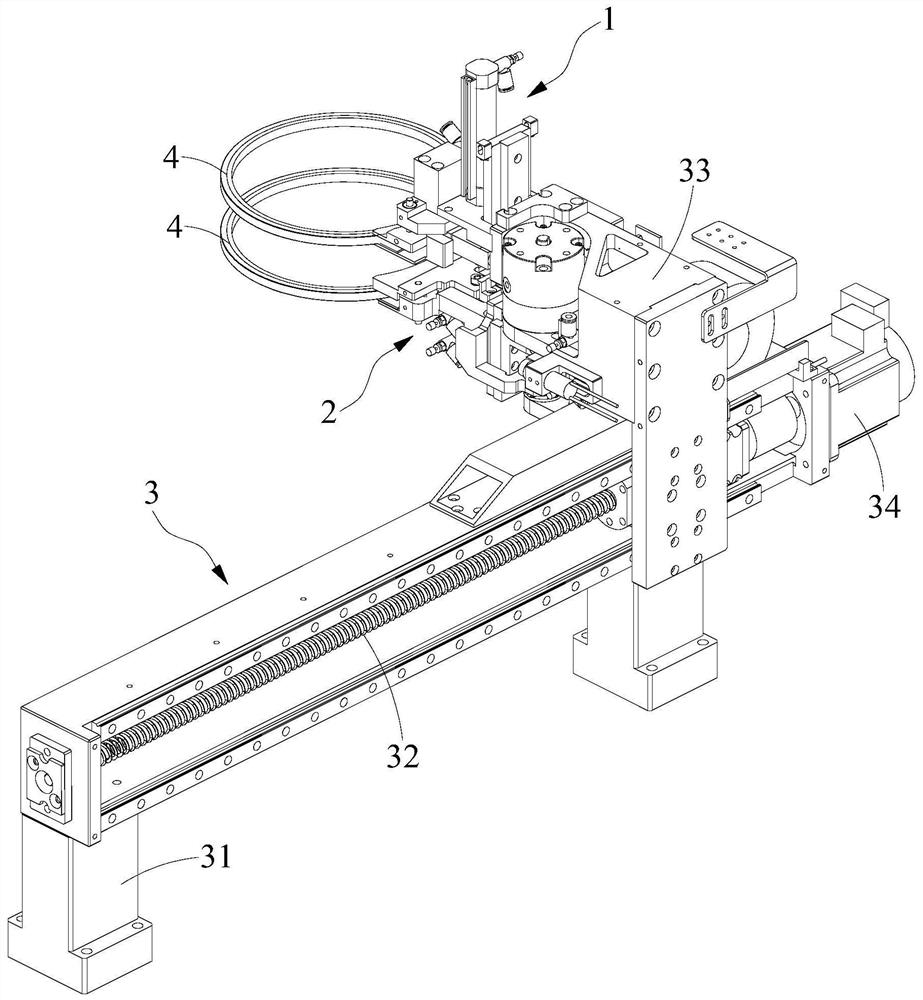

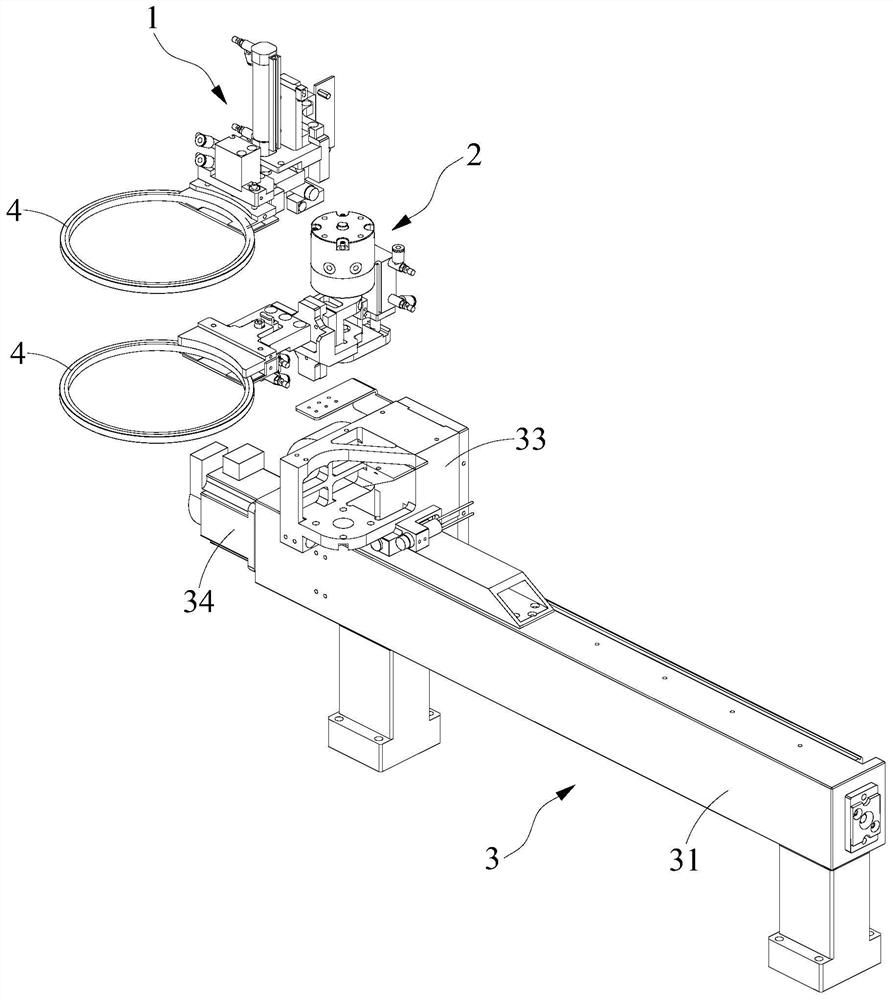

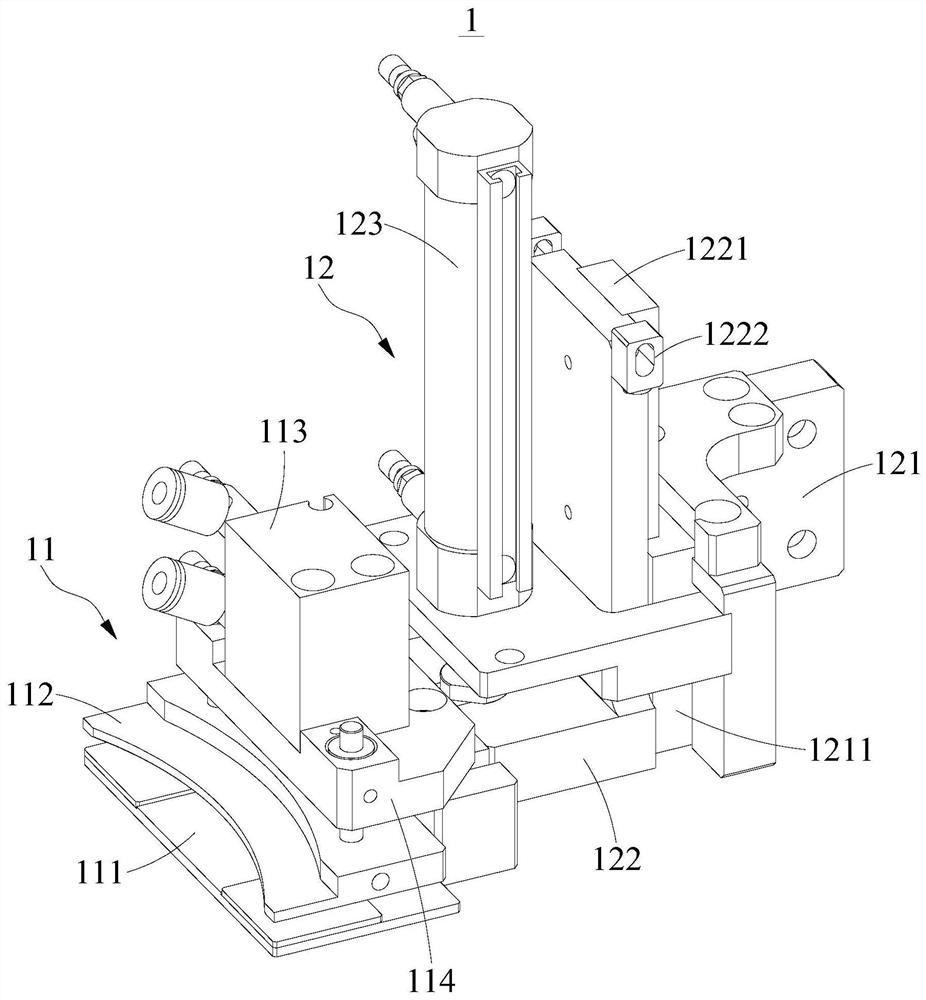

Double-swing-arm die-bonding device for LED die bonding and die bonding method thereof

PendingCN110224052AImprove Die Bonding EfficiencySave production spaceSemiconductor devicesEngineeringMechanical engineering

The invention discloses a double-swing-arm die-bonding device for LED die bonding and a die bonding method thereof. The die-bonding device comprises a table board, and a double-swing-arm die-bonding mechanism arranged on the table board, wherein a crystal ring moving platform is arranged above the double-swing-arm die-bonding mechanism, and a clamp moving platform is arranged below the double-swing-arm die-bonding mechanism; an automatic crystal ring feeding mechanism is arranged on one side of the clamp moving platform, while a lens assembly is arranged on the other side of the clamp moving platform; and an ejector pin assembly is further arranged above the crystal ring moving platform. The lens assembly is used for assisting the crystal ring moving platform and a clamp to move to a designated position. The ejector pin assembly is used for ejecting an LED wafer on the crystal ring moving platform; the double-swing-arm die-bonding mechanism drives the two die-bonding arms to rotate ina plane perpendicular to the horizontal plane, and then sucks ejected wafers to fix the ejected wafers to an LED bracket; the automatic crystal ring feeding mechanism is used for feeding or recoveringthe crystal ring; and compared with a traditional crystal fixing mode, the die bonding device is used for carrying out continuous die bonding by arranging the two die-bonding swing arms to rotate, sothat the die bonding speed is increased, and the application range is wide.

Owner:SHENZHEN XINYICHANG AUTOMATIC EQUIP

Die bonding device for processing music chip of music player and using method thereof

ActiveCN110473825AEasy to fixIncrease capacityLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringMusic player

The invention discloses a die bonding device for processing a music chip of a music player and a using method thereof. The die bonding device comprises a supporting table, a transmission disc, a die bonding box, a glue smearing table and a die pressing seat, the transmission disc is arranged on one side of the upper portion of the supporting table, the cuboid die bonding box is arranged on one side of the transmission disc, the glue smearing table is arranged on one side of the die bonding box, and the die pressing seat is arranged on one side of the glue smearing table. The beneficial effectsof the invention are that: the music chips and the wafers on the plurality of mounting blocks are respectively coated with dot die bonding glue through the dispensing nozzles on the plurality of glueoutlet pumps to improve the die bonding efficiency of the music chips by the device; and when the dispensing nozzles are used for dispensing the die bonding glue, the motor I drives the chips and thewafers in the plurality of buckling frames to continuously and slowly rotate through a rotary mounting block, so that the position of the device for dispensing the die bonding glue is more comprehensive, the automation degree of the device is higher while the die bonding work of the device is more efficient, and the device is very time-saving and labor-saving to use.

Owner:YANTAI VOCATIONAL COLLEGE

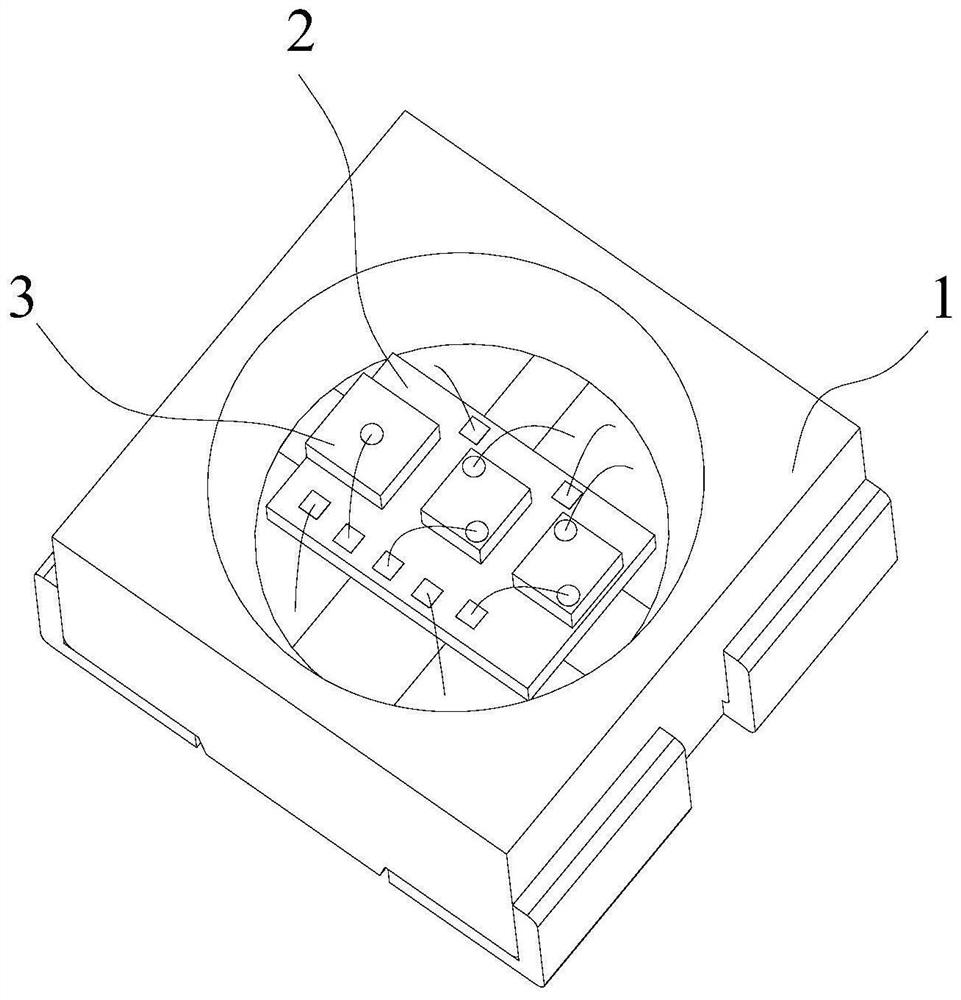

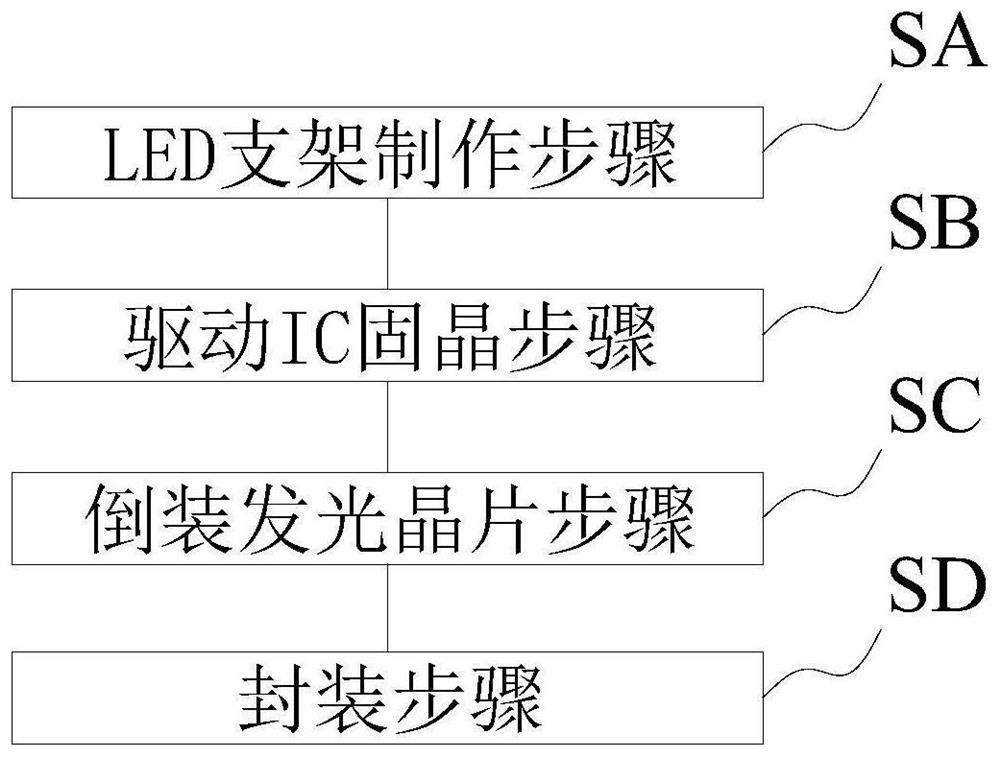

Preparation method of LED lamp bead with built-in drive IC

InactiveCN111933624AGuarantee welding qualityImprove Die Bonding EfficiencySolid-state devicesSemiconductor devicesManufacturing cost reductionWafering

The invention provides a preparation method of an LED lamp bead with a built-in drive IC; and aims to solve the problems that in the prior art, when a drive IC is subjected to die bonding, the position of the drive IC is difficult to fix, errors are caused by machine errors or heating, and the welding quality of a light-emitting wafer on the drive IC is affected. According to the preparation method, the drive IC is formed on a drive wafer, the drive IC is not cut into single drive ICs, instead, batch of light-emitting wafers are inversely arranged on the drive wafer on which the drive IC is manufactured; thus, bonding pads on the drive IC can be positioned more accurately, errors are reduced, the welding quality of the light-emitting wafers on the drive IC is guaranteed, meanwhile, the diebonding efficiency of the light-emitting wafers can be improved through the batch inversion mode, and the manufacturing cost is reduced.

Owner:SHENZHEN NEXNOVO TECH CO LTD

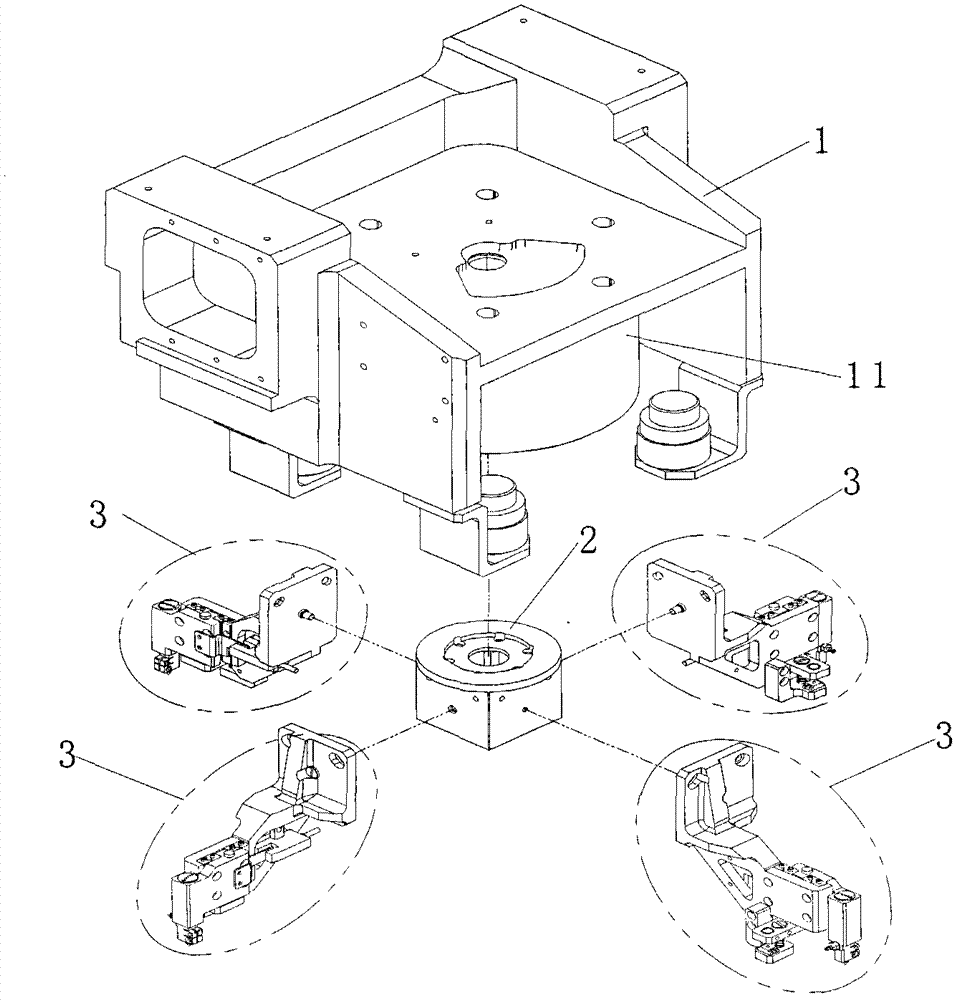

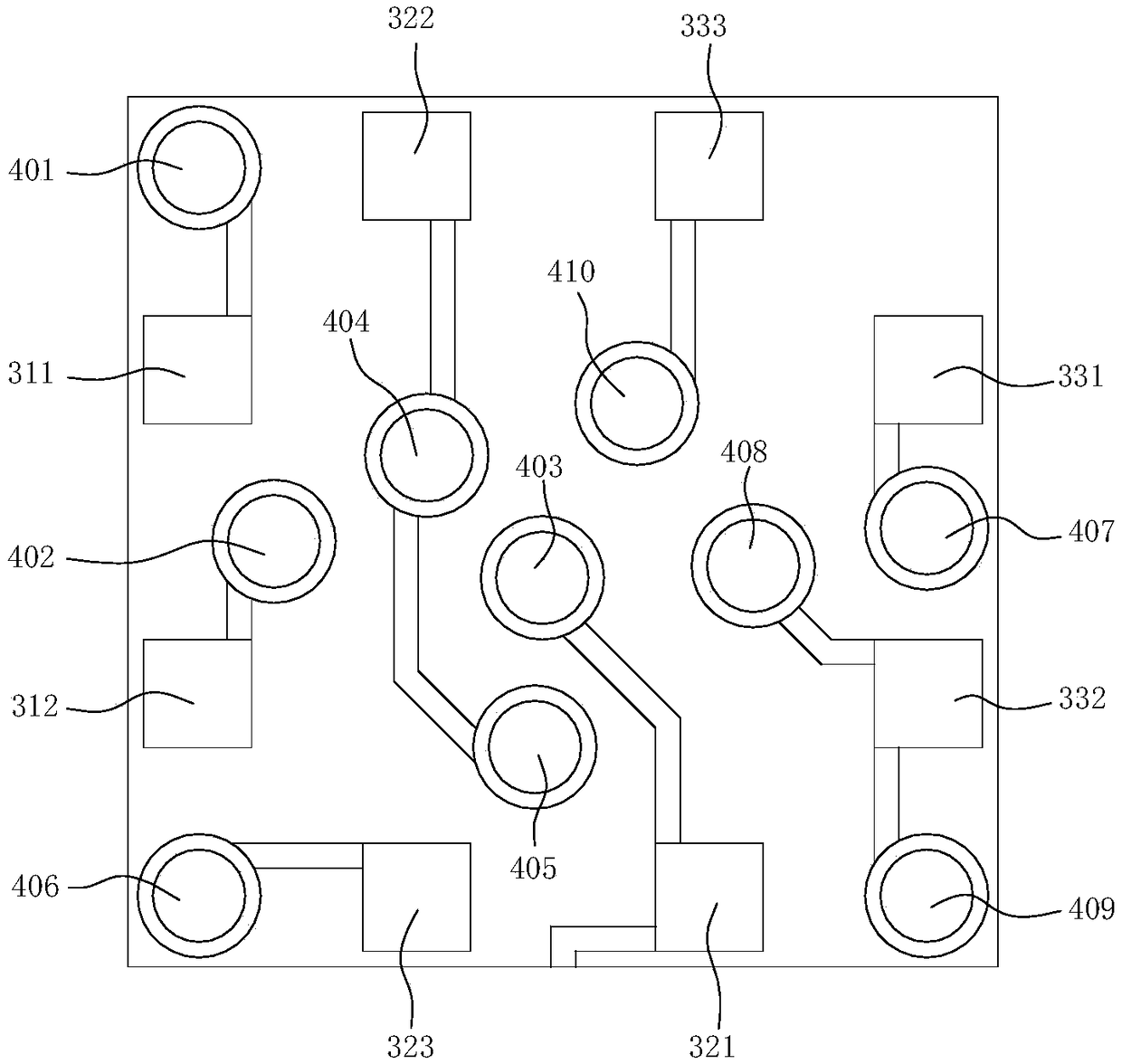

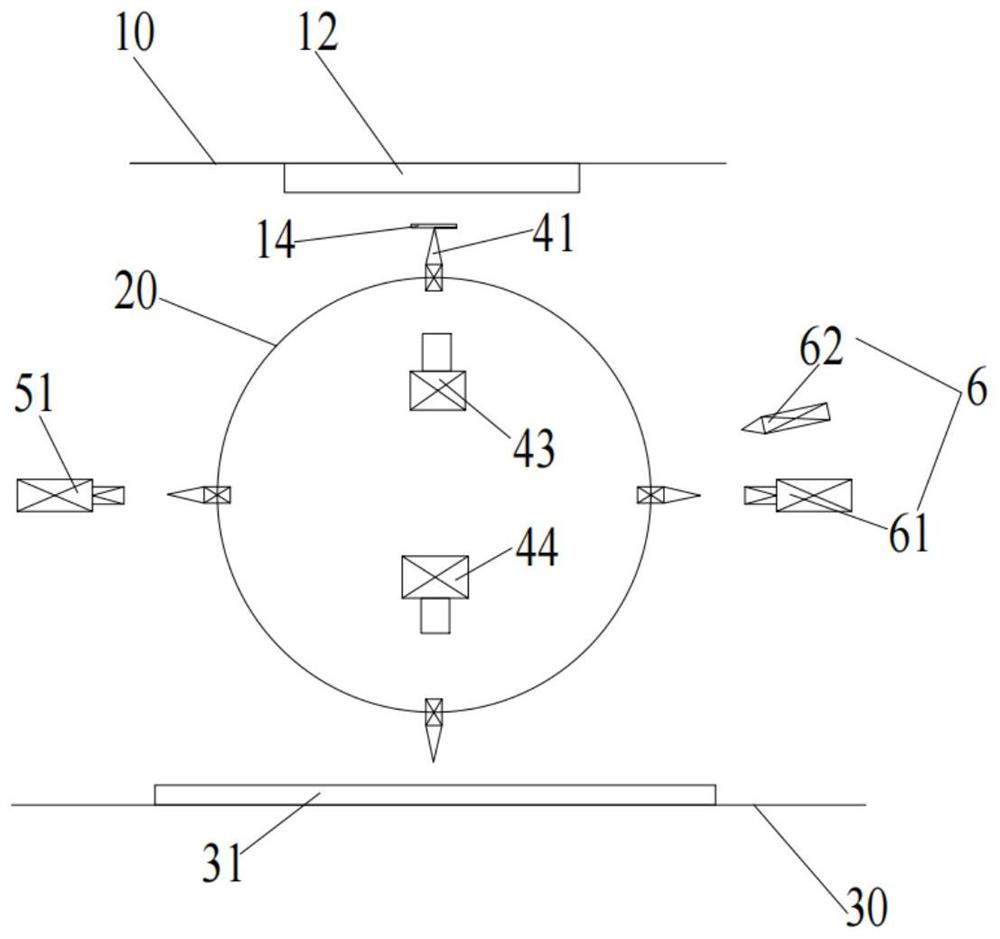

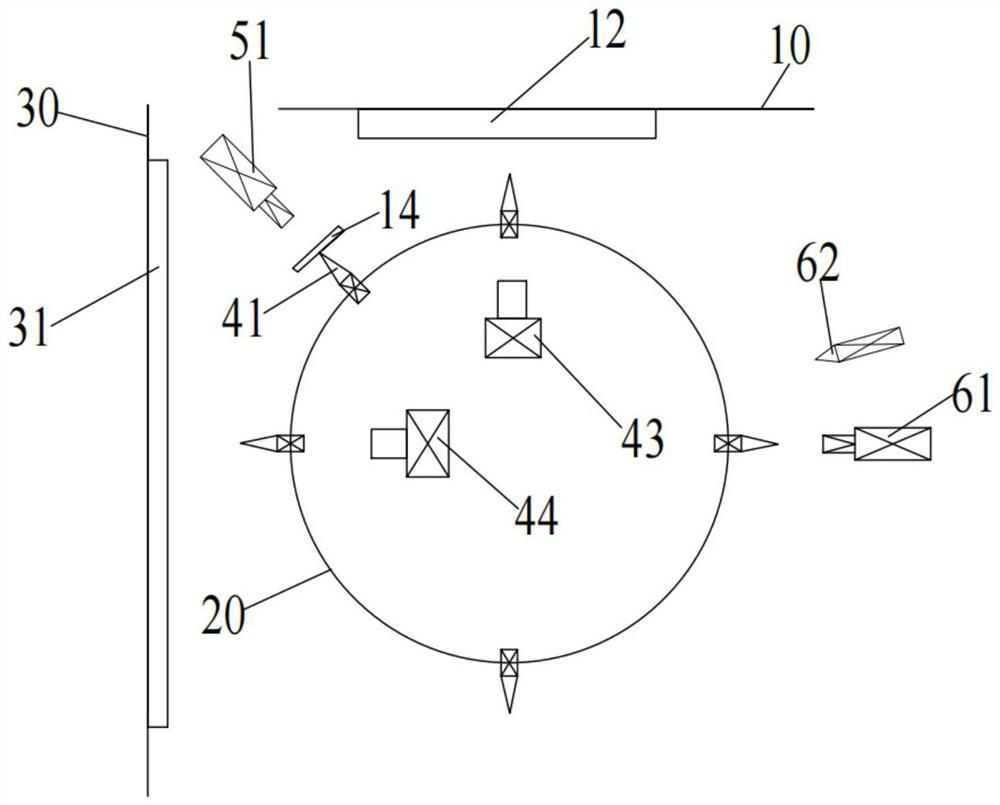

Die bonder detection mechanism and continuous detection method

InactiveCN103681401AShort timeImprove Die Bonding EfficiencySemiconductor/solid-state device testing/measurementSolid-state devicesOptical axisComputer module

The invention is applied to the technical field of semiconductor die bonding and discloses a die bonder detection mechanism and a continuous detection method. The die bonder detection mechanism comprises a translation motor disposed on a frame. The rotation shaft of the translation motor is connected with a rotation welding arm connection seat; the rotation welding arm connection seat is provided with four welding arms; each welding arm is provided with a wafer suction nozzle; a reflective mirror is arranged right below the wafer suction nozzles below the rotation welding arm connection seat; one side of the reflective mirror is provided with a camera connected with a control module; the wafer suction nozzles are disposed right above the reflective mirror during detection; and a wafer image reflected by the reflective mirror shares the same optical axis with the camera. During working, at least one wafer is disposed at a die bonding position, and the other wafer is disposed at a detection position. Since the other wafer is detected at the time of die bonding, the two processes of detection and die boding can be simultaneously carried out on the two wafers, i.e., when die bonding is performed on one wafer, the other wafer is detected so that the problem of long time for solidifying a unit amount of wafers when detection is performed first and die bonding is performed afterwards can be avoided, and the die bonding efficiency is improved.

Owner:THE CATHAY ROBOTICS

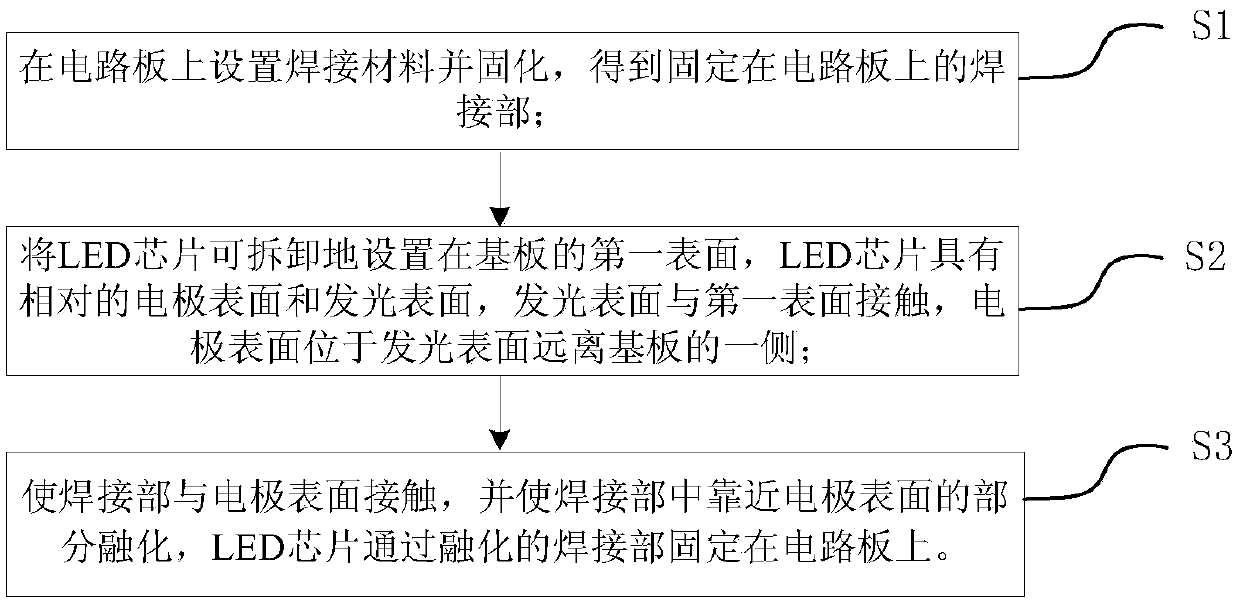

LED chip die-bonding method and package method of display module having same

ActiveCN109673110AImprove yieldWill not short circuitPrinted circuit assemblingIdentification meansElectrode ContactDie bonding

The invention provides a LED chip die-bonding method and a package method of a display module having the same. The LED chip die-bonding method comprises the steps of: S1, disposing a welding materialon a circuit board for curing to obtain a welding portion fixed on the circuit board; S2, detachably disposing a LED chip on the first surface of the substrate, wherein the LED chip has an electrode surface and a light emitting surface which are opposite, the light emitting surface is in contact with the first surface, and the electrode surface is located on one side, far away from the substrate,of the light emitting surface; and S3, making the welding portion and the surface of the electrode contact, and allowing the portion, close to the surface of the electrode, of the welding portion to be melted, and fixing the LED chip on the circuit board through the melted welding portion. The LED chip die-bonding method cannot pull the LED chip and cannot cause short-circuit of positive and negative electrodes so as to improve the yield of the die-bonding process; and compared to the prior art, the LED chip die-bonding method can perform die-bonding of hundreds of LED chips each time so as toimprove the die-bonding efficiency.

Owner:LEYARD

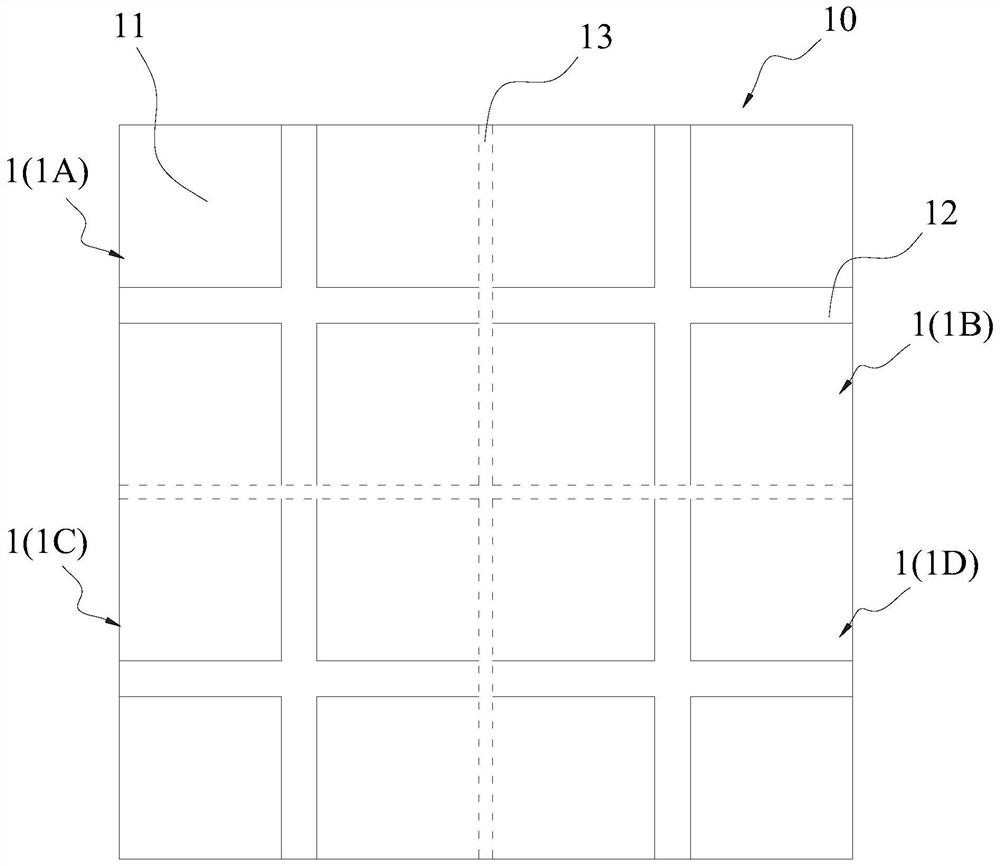

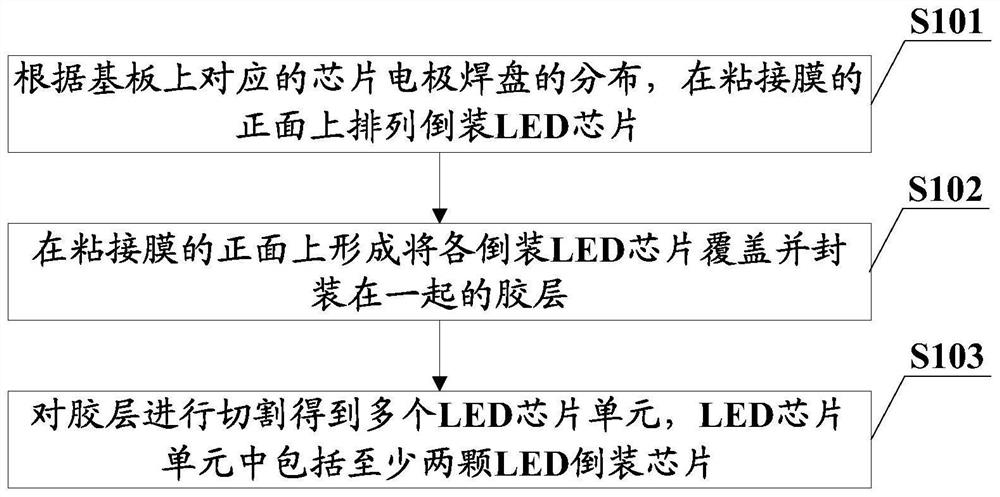

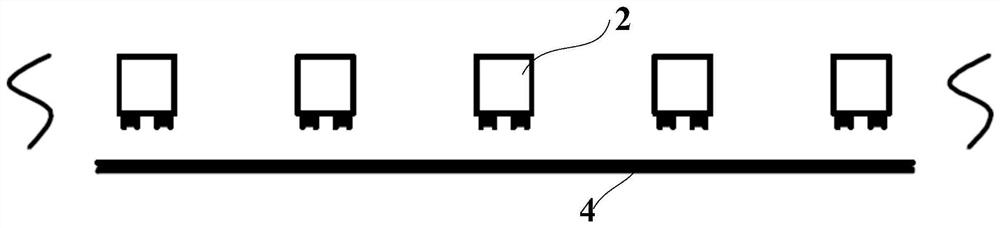

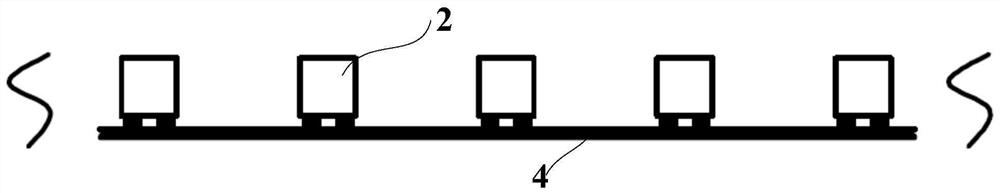

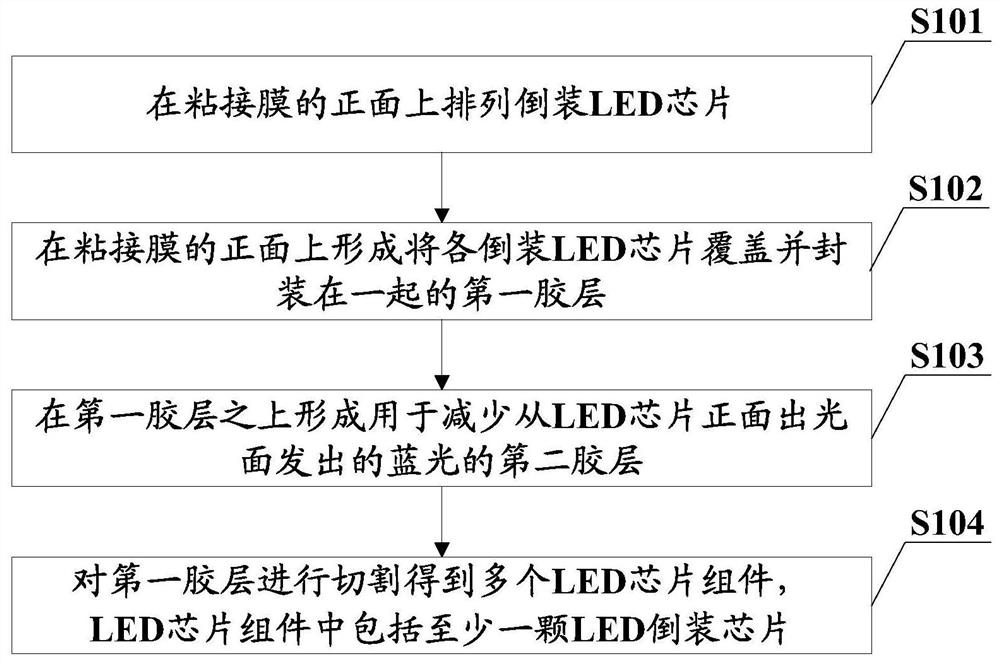

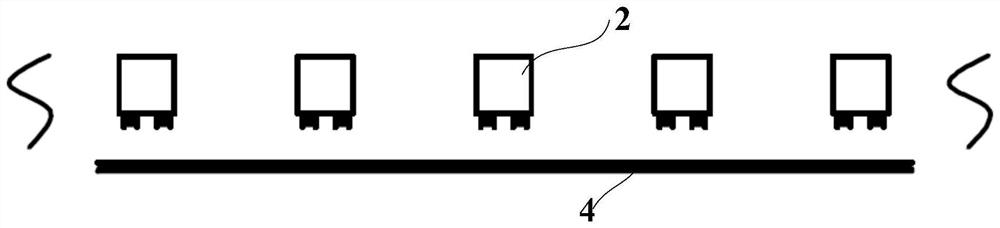

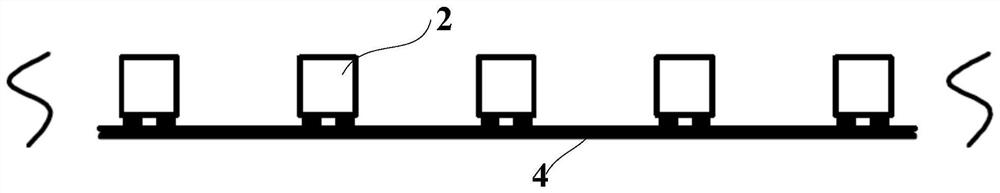

LED chip unit and LED device, and manufacturing methods thereof

PendingCN113054072AImprove Die Bonding EfficiencyQuality improvementSemiconductor devicesEngineeringSolder paste

The invention provides an LED chip unit and an LED device, and manufacturing methods thereof. Flip LED chips are arranged on the front surface of an adhesive film according to the distribution of corresponding chip electrode bonding pads on a substrate, and an adhesive layer which covers and packages the flip LED chips together is formed on the front surface of the adhesive film; and the adhesive layer is cut to obtain a plurality of LED chip units, each LED chip unit comprises at least two LED flip chips, and the LED flip chips are correspondingly distributed according to the distribution of corresponding chip electrode bonding pads on the substrate. When the LED chip unit is used for manufacturing the LED device, the LED chip unit comprising a plurality of LED chips can be transferred to the substrate, and the positive electrode and the negative electrode of each LED chip in the LED chip unit are electrically connected with the corresponding chip electrode bonding pads on the substrate respectively, so the die bonding efficiency of the LED chip can be multiplied, and the viscisity and the conductivity of elargol and solder paste printed on the bonding pad of the substrate are prevented from becoming poor due to long die bonding time, and the quality and the reliability of an LED device product are improved.

Owner:SHENZHEN JUFEI OPTOELECTRONICS

Die bonder

ActiveCN112928052AReduce waiting timeRealize automatic replacement workSemiconductor/solid-state device manufacturingConveyor partsWaferingEngineering

The invention provides a die bonder. The die bonder comprises a rack, a support feeding assembly, a support transferring assembly, a crystal ring feeding assembly, a crystal ring rotating assembly, a crystal jacking assembly, a crystal ring transferring assembly, a suction nozzle, a wafer fixing swing arm assembly, a suction nozzle receiving and feeding assembly and a material receiving assembly. A support can be supplied to the support transferring assembly through the support feeding assembly, a crystal ring on the crystal ring feeding assembly can be transferred to the crystal ring transferring assembly through the crystal ring transferring assembly, the used crystal ring on the crystal ring rotating assembly is removed, and a wafer on the crystal ring can be ejected to a wafer supply position through the wafer ejecting assembly. The wafer at the wafer supply position can be transferred to the support transferring assembly through the suction nozzle and the wafer fixing swing arm assembly, and wafer fixing operation of the wafer and the support is completed. The synchronous operation of feeding and discharging of the crystal ring can be realized through the crystal ring transferring assembly, the waiting time of feeding and discharging of the crystal ring is reduced, and the improvement of the die bonding efficiency is facilitated. Moreover, the suction nozzle can be automatically replaced through the suction nozzle receiving and supplying assembly, time and labor are saved, and the efficiency is high.

Owner:SHENZHEN XINYICHANG TECH CO LTD

COB die bonder

PendingCN111863685AFast tempoImprove Die Bonding EfficiencySolid-state devicesSemiconductor/solid-state device manufacturingCircular discWafer

The invention provides a COB die bonder. The die bonder comprises a support, a die bonding table, wafer disc conveying mechanisms and swing arms, wherein the die bonding table and the wafer disc conveying mechanisms are respectively arranged on the support, the two wafer disc conveying mechanisms are respectively positioned on two sides of the die bonding table, the two swing arms are respectivelypositioned between the die bonding table and the wafer disc conveying mechanisms, the swing arms are provided with Z-axis motors of which the position can be adjusted up and down, one end of each swing arm is a rotating end, the other end of each swing arm is a wafer grabbing and fixing end, the rotating end of each swing arm is correspondingly connected with a swing arm driving motor, and the swing arm driving motors drive the wafer grabbing ends of the swing arms to reciprocate between the wafer disc conveying mechanisms and the wafer fixing table. The die bonding table is advantaged in that the two swing arms are matched with the two wafer disc conveying mechanisms to carry out die bonding on the die bonding table together so that the die bonding production takt is improved, and die bonding efficiency is improved.

Owner:SHEN ZHEN TALUER TECH CO LTD

LED chip assembly, manufacturing method thereof, LED device and manufacturing method of LED device

PendingCN113053865AReduce light energyImprove uniformitySolid-state devicesSemiconductor devicesLight energyEngineering

The invention provides an LED chip assembly, a manufacturing method thereof, an LED device and a manufacturing method of the LED device. Inverted LED chips are arranged on the front face of a bonding film, and the positive electrode and the negative electrode of each LED inverted chip are bonded to the front face of the bonding film; a first adhesive layer is formed on the front surface of the adhesive film, wherein the first adhesive layer is used for covering and packaging the flip LED chips together; a second adhesive layer used for reducing light energy emitted from the light-emitting surfaces of the front faces of the LED chips is formed on the first adhesive layer, and the second adhesive layer at least partially covers the light-emitting surfaces of the front faces of the flip LED chips and does not cover the first adhesive layer between the adjacent LED chips; and the first adhesive layer is cut to obtain a plurality of LED chip assemblies. The second adhesive layer used for reducing light energy is formed on the front surface of each LED flip chip, so that the difference between the light energy in the forward normal direction of the flip LED chips and the light energy of the four side surfaces can be reduced, and the uniformity of light emitting colors is improved.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

Die bonding mechanical arm and die bonding equipment

ActiveCN113539916AImprove Die Bonding EfficiencyRaise the upper limitSemiconductor/solid-state device manufacturingConveyor partsCircular discWafering

The invention relates to a die bonding mechanical arm and die bonding equipment. The die bonding mechanical arm comprises a base body and a first driving mechanism, and the first driving mechanism is used for driving the base body to move between a wafer disc used for placing wafers and a carrying table used for placing a target substrate; the substrate is provided with a plurality of die bonding heads, and the plurality of die bonding heads are arranged in m rows and n columns. Each die bonding head comprises a lifting mechanism and a suction nozzle, the suction nozzle is arranged on the lifting mechanism, and the suction nozzle can suck a wafer, pick and place the wafer and fix the wafer on the die bonding head. According to the die bonding mechanical arm, a plurality of wafers can be taken from the wafers placed on the wafer disc at the wafer disc at a time and temporarily stored on the plurality of die bonding heads, the plurality of wafers temporarily stored on the plurality of die bonding heads are transferred and installed on the target substrate placed on the carrying table at a time, and die bonding efficiency is high; moreover, the improvement of the die bonding efficiency is not realized by purely depending on the increase of the number of the die bonding mechanical arms, and the upper limit of the die bonding efficiency is higher.

Owner:SHEN ZHEN TALUER TECH CO LTD

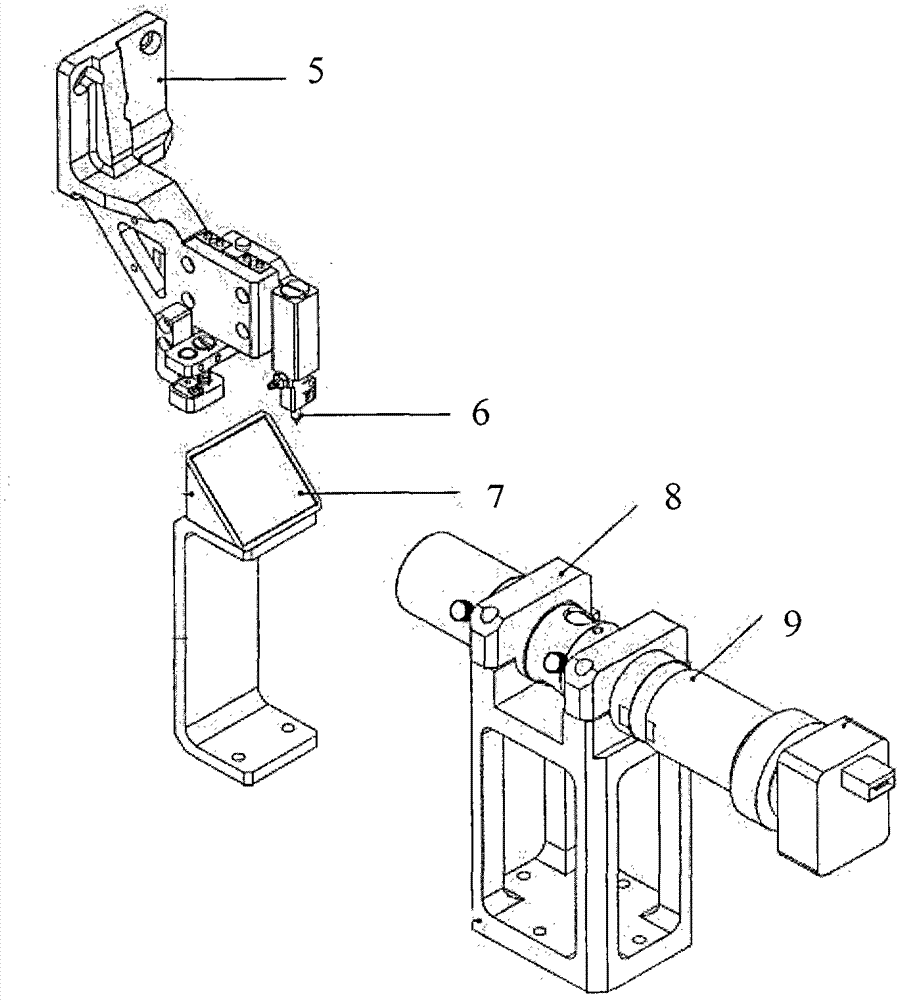

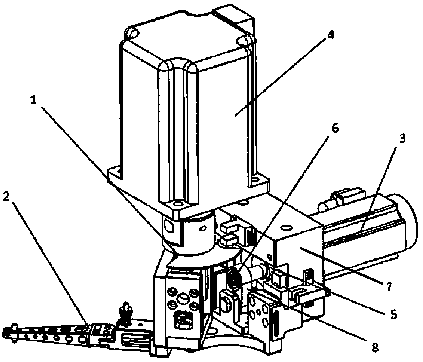

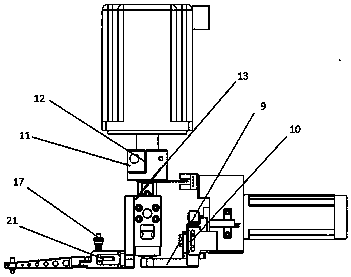

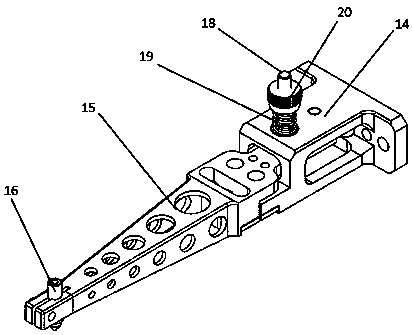

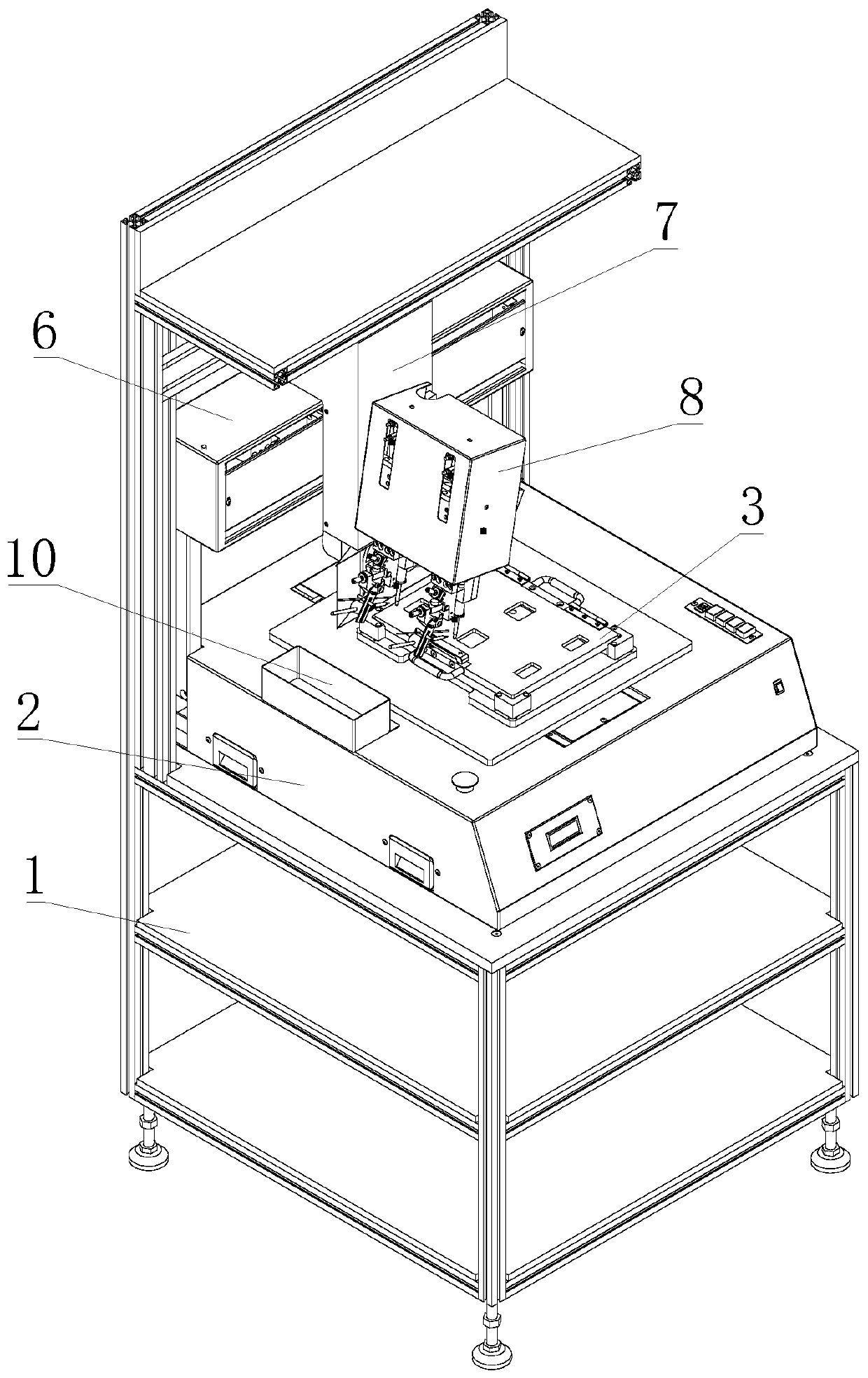

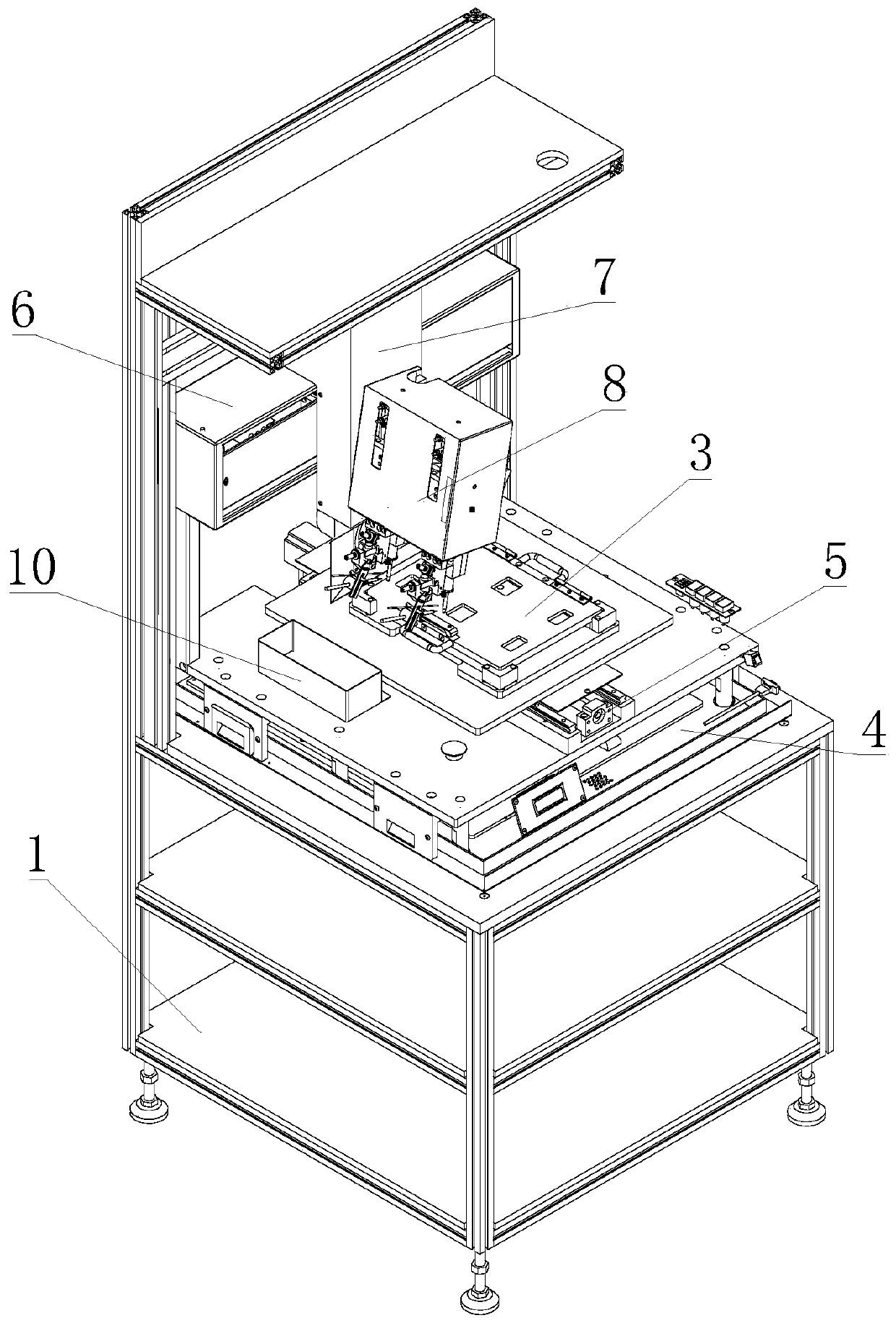

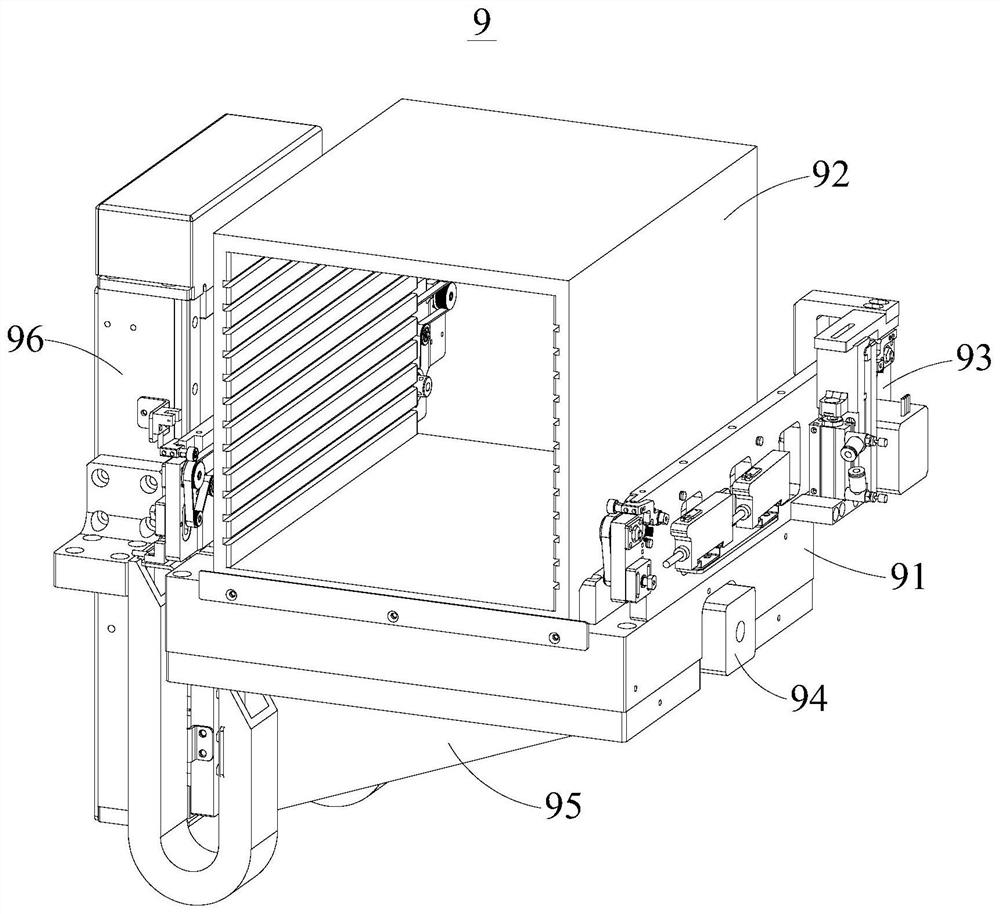

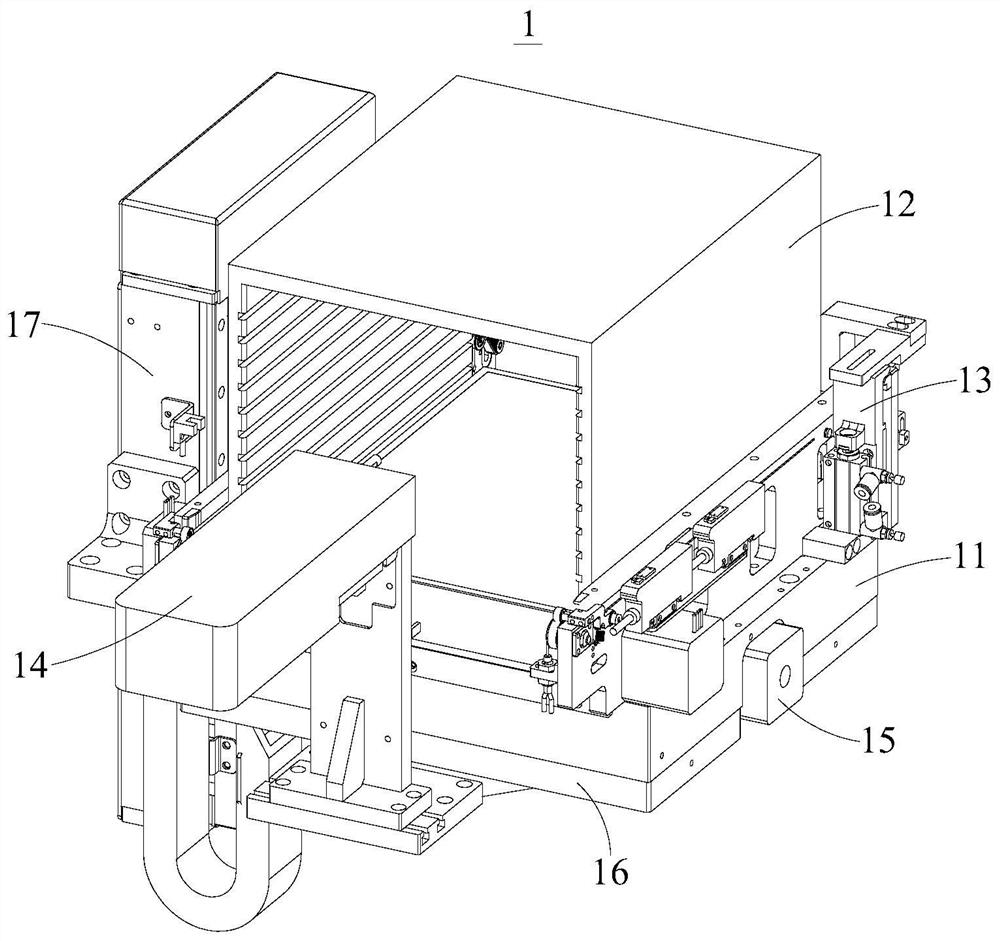

Bond head structure of 180-degree die bonder

PendingCN107808841ASmall footprintOptimize layoutSemiconductor/solid-state device manufacturingSemiconductor devicesRotational axisElectric machinery

A bond head structure of a 180-degree die bonder comprises a driving device and a swing arm mechanism, wherein the driving device comprises a Z-axis motor and a rotating motor; the Z-axis motor is arranged on a Z-axis installing seat; a motor shaft of the Z-axis motor is connected with an eccentric shaft through a bearing; the eccentric shaft is connected with a connecting rod; the connecting rodis connected with a Z-axis connecting block; a motor shaft of the rotating motor is connected with a rotating shaft; the rotating shaft is provided with a swing arm guide rail; the swing arm guide rail is provided with a swing arm connecting block in a clamping way; the swing arm connecting block is rotationally connected with the Z-axis connecting block through a fixed shaft and is locked througha nut; the swing arm mechanism is fixedly connected with the swing arm connecting block; the rotating motor drives the swing arm mechanism to swing within a 180-degree range. According to the bond head structure disclosed by the invention, a flexible swing arm structure is adopted, the stress of a swing arm can be regulated, and the flexibility of the swing arm can be increased; due to the designof the bond head structure of the 180-degree die bond, the die bonding speed can be increased while the layout of effectively reducing the volume of a bond head zone and optimizing all components iscarried out.

Owner:深圳市佳思特光电设备有限公司

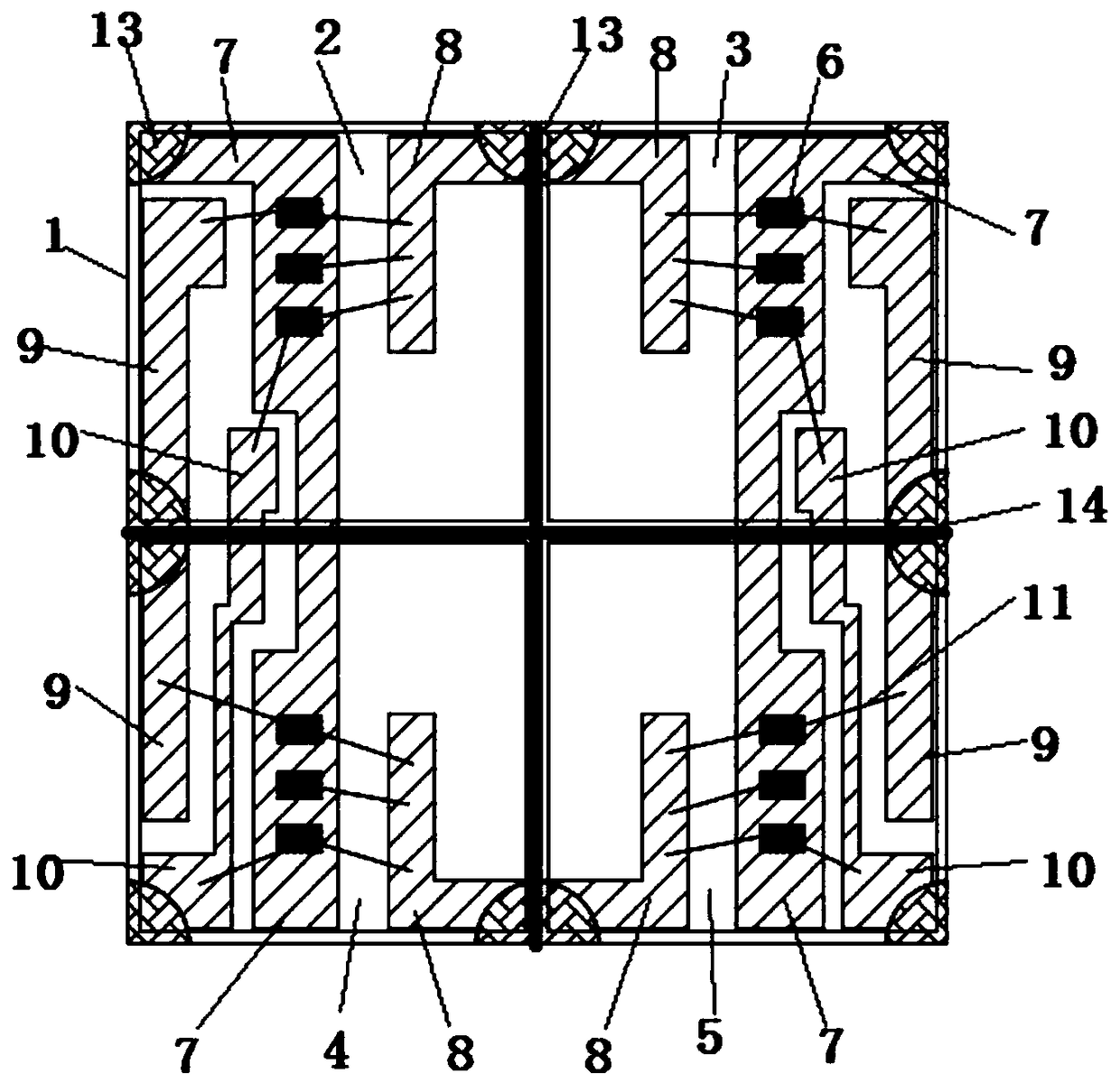

An LED display unit group and a display panel

PendingCN109244102AHigh positioning accuracyImprove Die Bonding EfficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringSurface plate

The invention discloses an LED display unit group, comprising a circuit board, and a pixel unit array composed of n rows and m columns of pixel units on the circuit board, wherein n and m are positiveintegers greater than or equal to 2; Wherein each pixel unit comprises at least two LED light-emitting chips of different light-emitting colors, the LED light-emitting chips comprising A poles and Bpoles with opposite polarities; At least one LED light-emitting chip in each pixel unit is a dual-electrode chip, and A pole and B pole of that dual-electrode chip are positioned on the same surface of the dual-electrode chip; In all pixel cells, the direction of the A-to B-pole connection of the two electrode chips of the same light emitting color points in the same direction. The LED display unit group provided by the invention can improve the fixing efficiency and ensure the positional accuracy of the chip by pointing to the same direction of the A-to-B-pole connection line of the double-electrode chip with the same light-emitting color.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

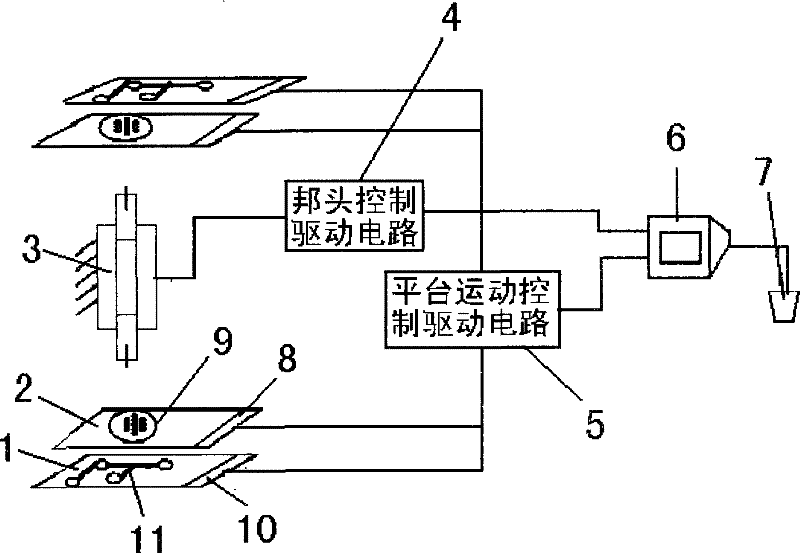

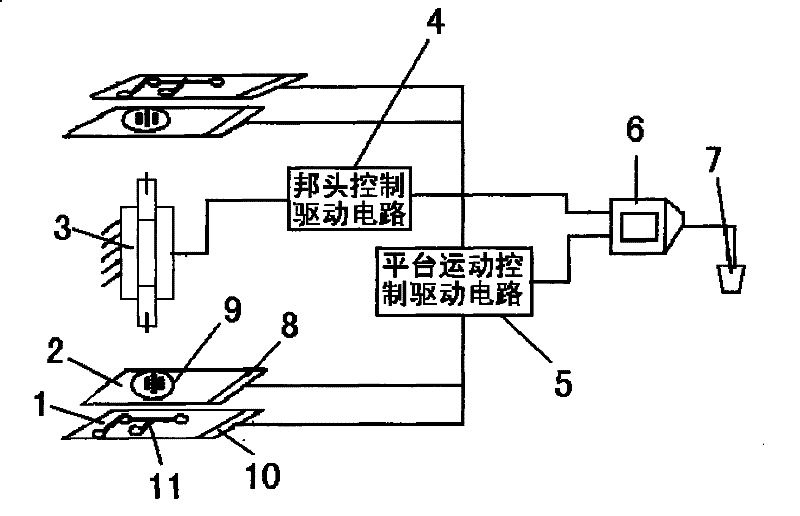

Die bonding method for automatic quartz alignment by image recognition

InactiveCN101488552BImprove Die Bonding EfficiencyLow costSemiconductor/solid-state device manufacturingProgramme total factory controlAutomatic quartzDie bonding

Owner:NANCHANG HANGKONG UNIVERSITY

Die bonding device of die bonder and working method thereof

InactiveCN110911329AEnsure stabilityImprove the crystal bonding effectSemiconductor/solid-state device manufacturingCleaning using gasesWaferingStructural engineering

The invention discloses a die bonding device of a die bonder and a working method thereof. The device comprises a device rack, a die bonding base, a horizontal moving mechanism, a vertical moving mechanism and a die bonding welding mechanism. A die bonding table is arranged on the device rack. A die bonding base is fixedly mounted on the die bonding table. A die bonding moving mechanism is fixedlymounted on the die bonding base. The die bonding base is connected to the die bonding moving mechanism. The die bonding base comprises a mounting bottom plate, a die bonding base plate and a hinge. Alimiting block and a supporting plate are arranged on the mounting bottom plate, the die bonding base plate is connected to the supporting plate, a positioning cover plate is rotatably connected to the die bonding base plate through the hinge, and a handle is arranged on the die bonding base plate. The replacement of the wafer is slow, the die bonding mechanism cannot move to influence the die bonding efficiency of the LED wafer, and the LED wafer processing mechanism is single and poor in universality, so that the production and processing cost of the LED wafer is improved.

Owner:马鞍山三投光电科技有限公司

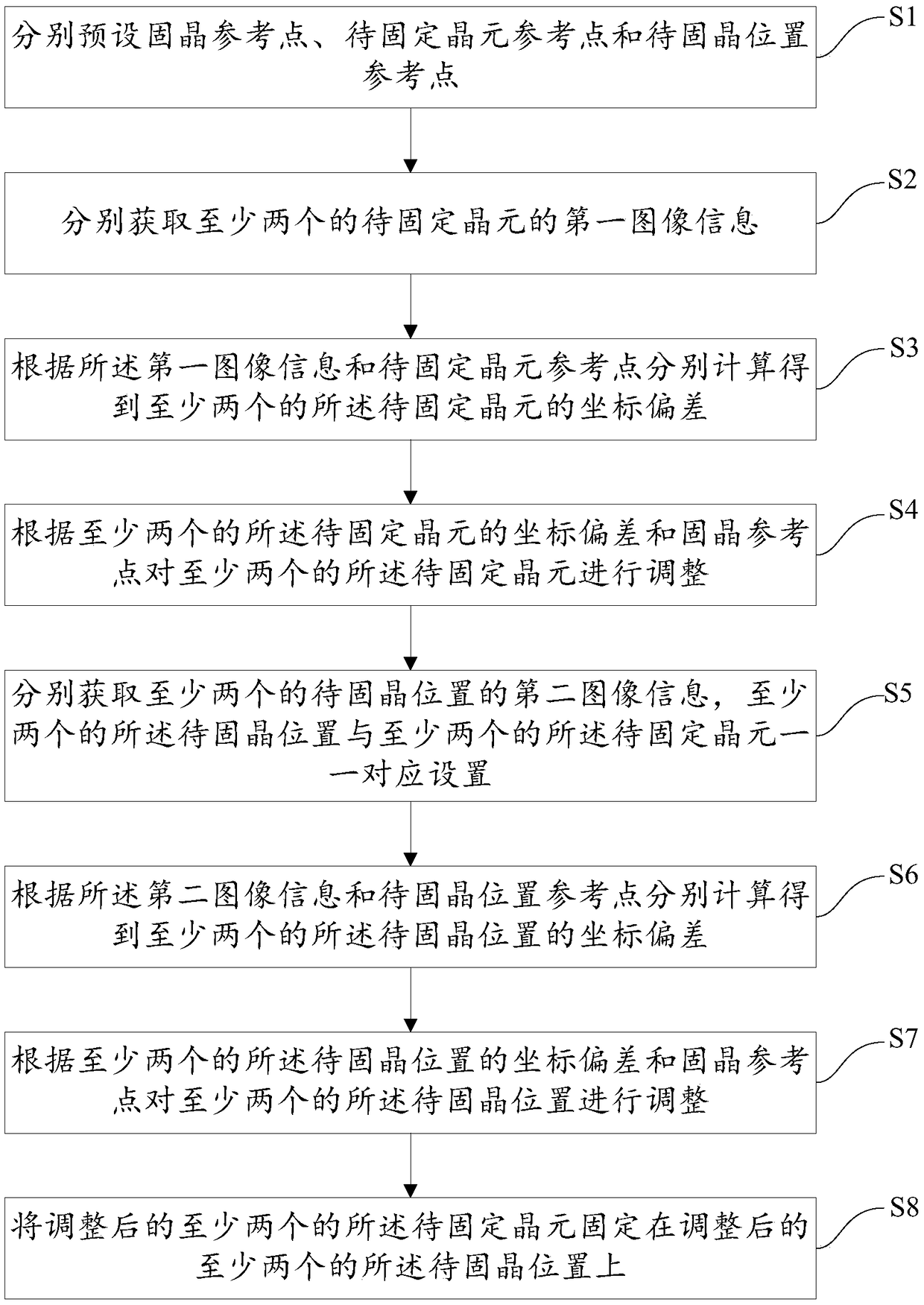

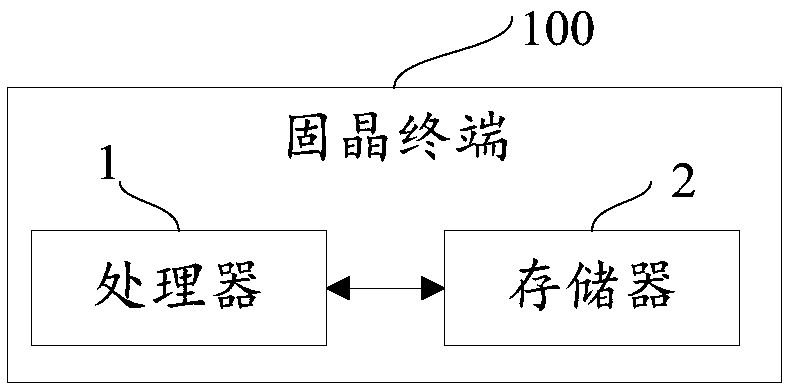

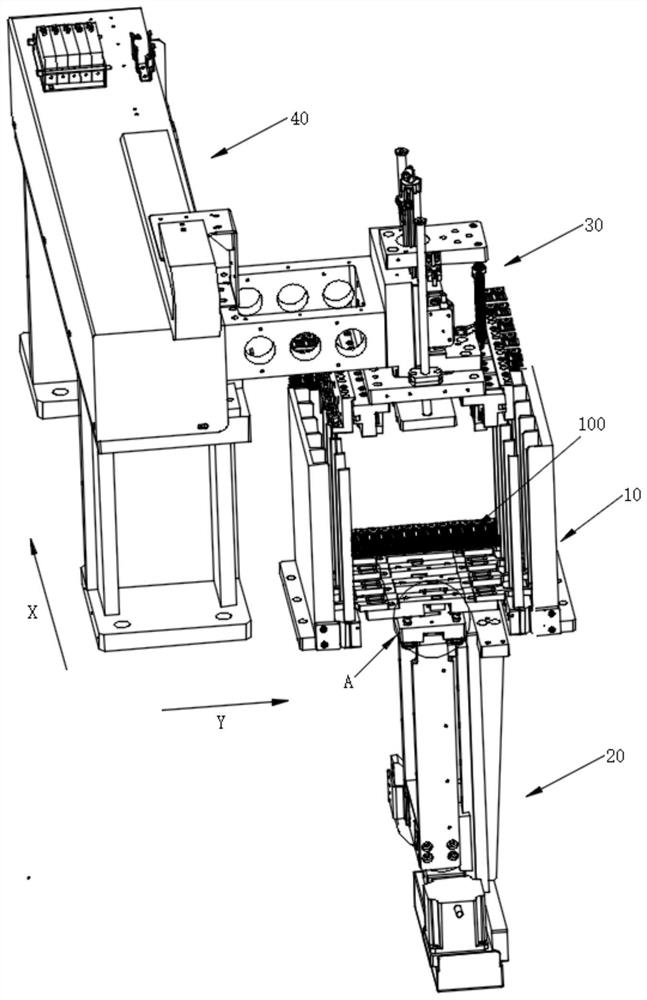

Die bonding method and terminal

ActiveCN109285933AImprove Die Bonding PrecisionImprove Die Bonding EfficiencySemiconductor devicesDie bondingComputer science

The invention discloses a die bonding method and terminal. The die bonding method comprises the steps of respectively obtaining first image information of at least two wafers to be bonded; respectively calculating the coordinate deviation of the wafers to be bonded according to the first image information and reference points of the wafers to be bonded; adjusting the at least two wafers to be bonded according to the coordinate deviation of the wafers to be bonded and the die bonding reference points; respectively obtaining second image information of at least two die bonding positions; respectively calculating the coordinate deviation of the die bonding positions according to the second image information and die bonding position reference points; adjusting the at least two die bonding positions according to the coordinate deviation of the die bonding positions and the die bonding reference points; and bonding the at least two adjusted wafers to be bonded at the at least two adjusted die bonding positions. The die bonding method can greatly improve the die bonding efficiency and die bonding accuracy, and is applicable to carrying out batch die bonding on Mini LEDs.

Owner:江苏佑光科技股份有限公司

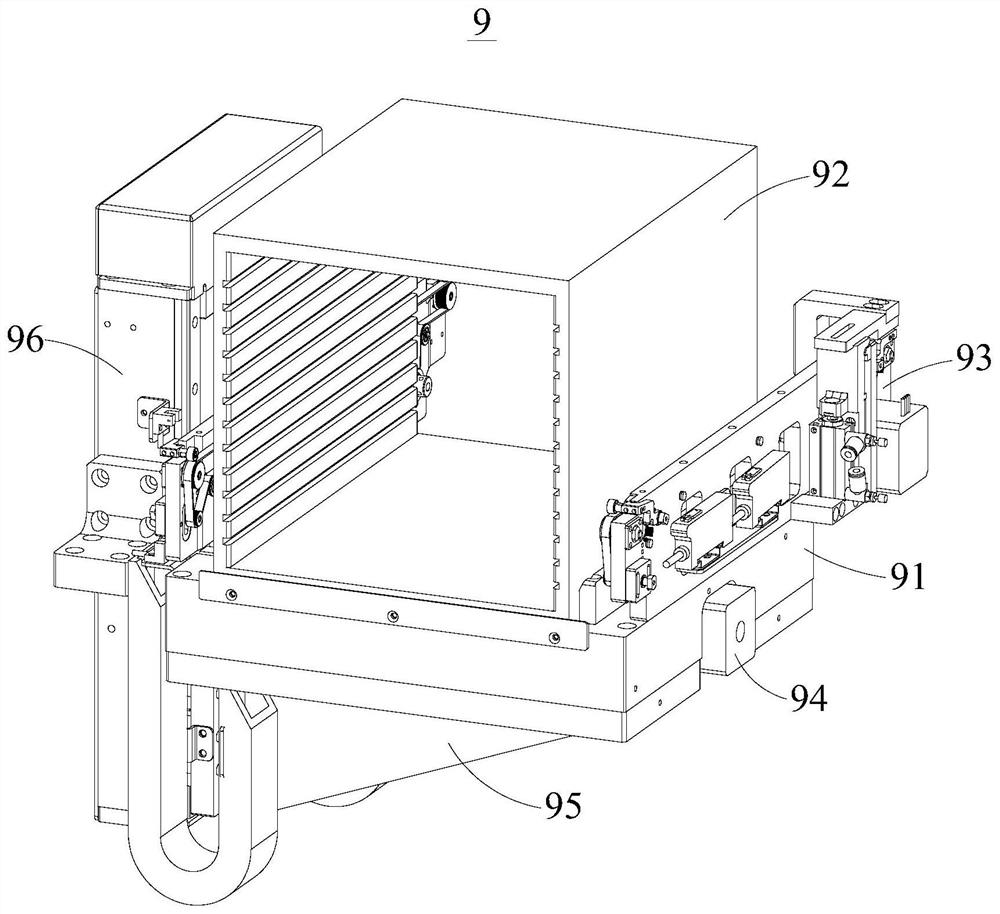

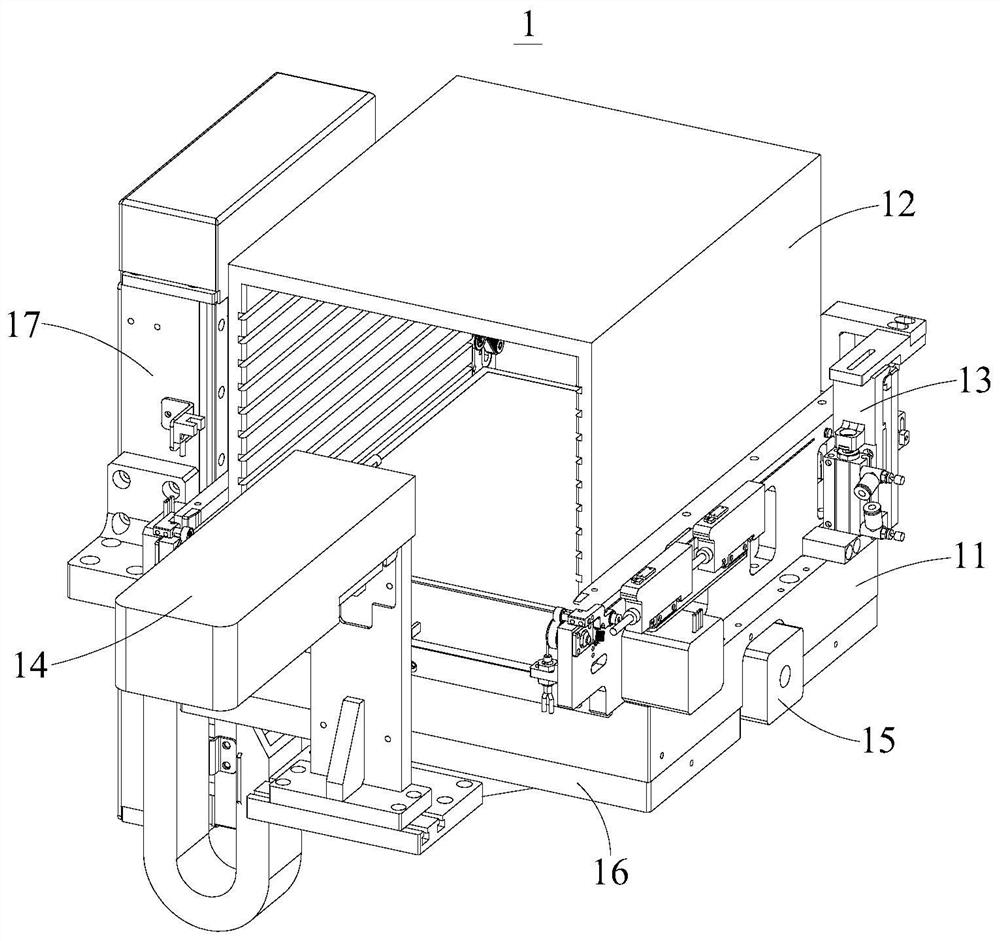

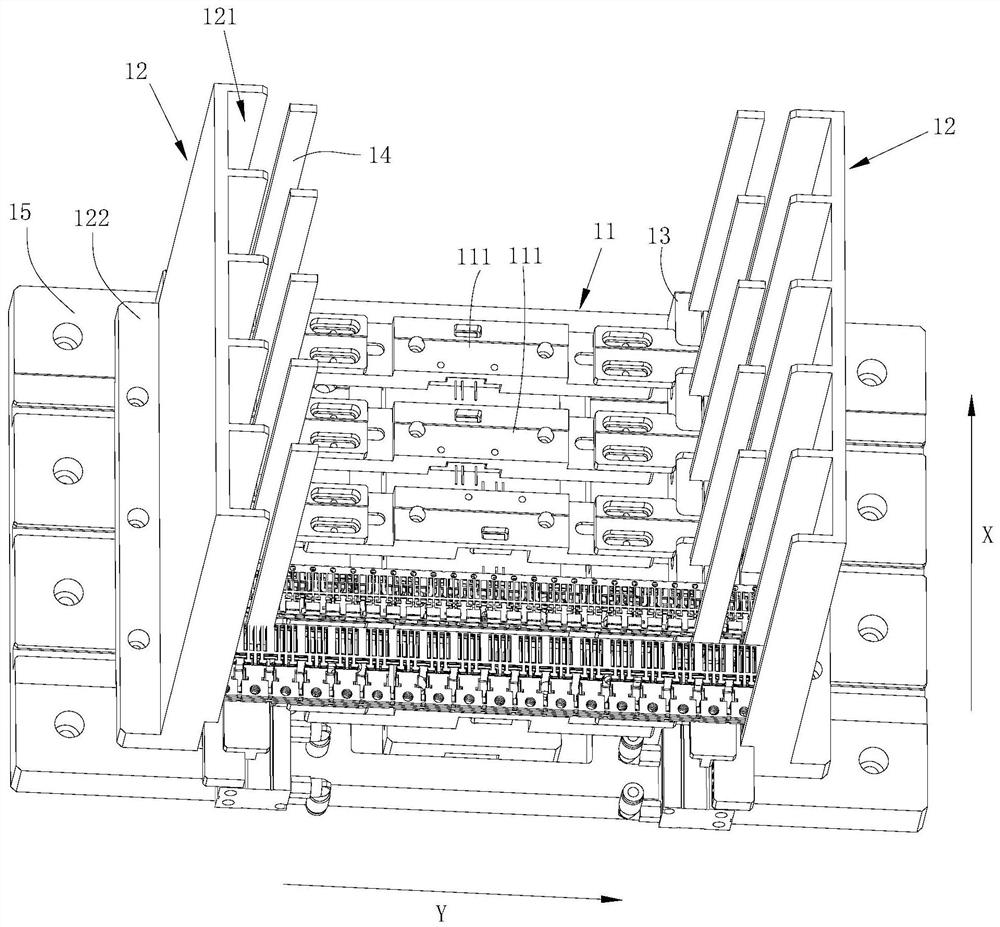

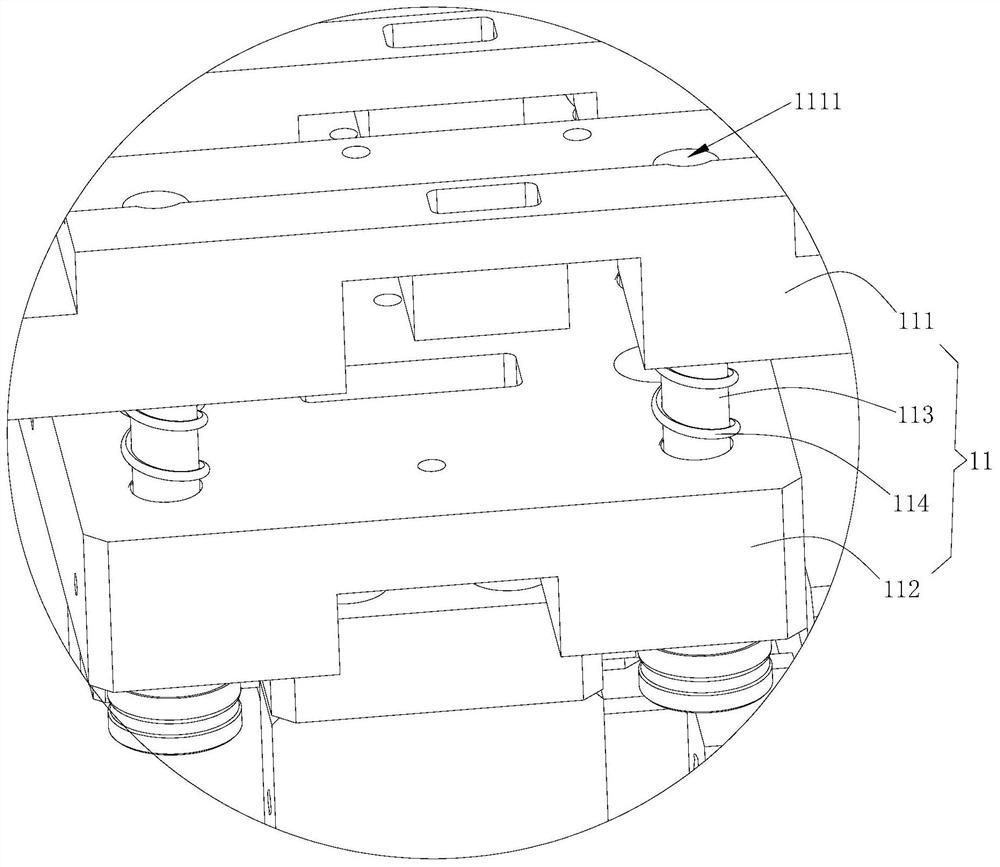

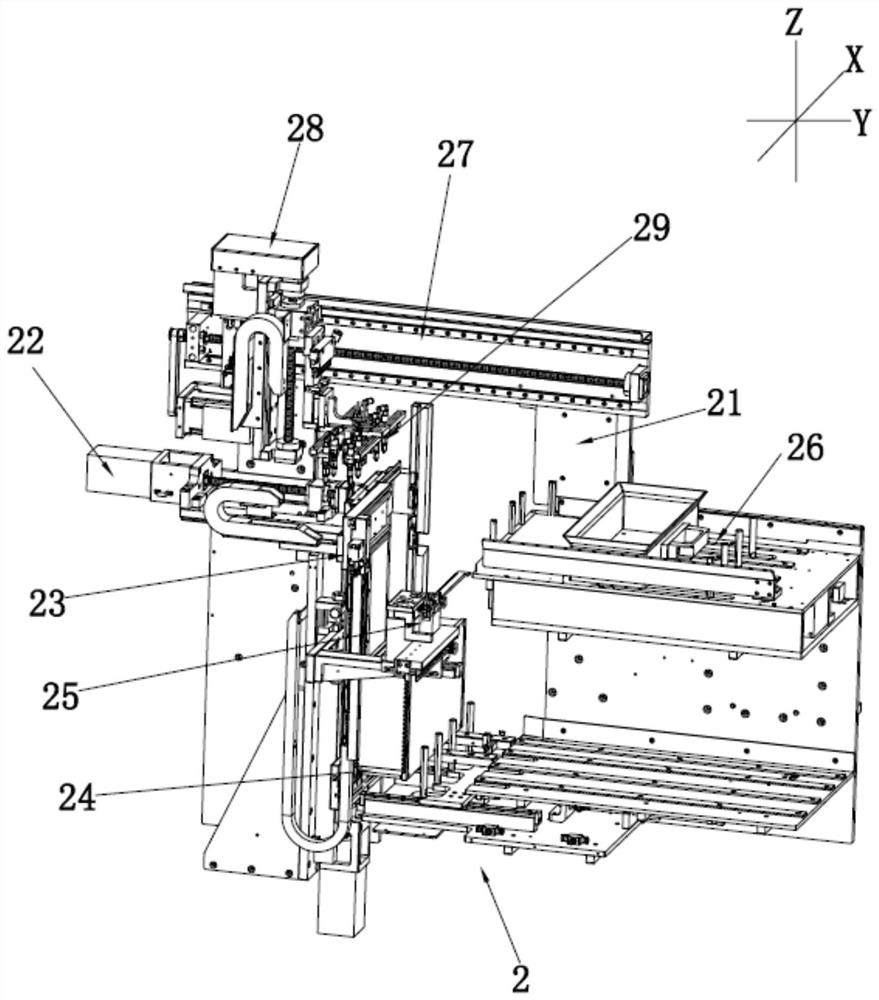

LED bracket feeding device and LED solid crystal equipment

ActiveCN111430284BImprove feeding efficiencyAvoid offsetSemiconductor/solid-state device manufacturingConveyor partsEngineeringStructural engineering

The invention provides an LED support feeding device which comprises a feeding box, a lifting mechanism, a gripper mechanism and a driving mechanism. The feeding box comprises a supporting plate assembly, and a plurality of piles of LED supports can be placed on the supporting plate assembly. The lifting mechanism is used for driving the supporting plate assembly and multiple piles of LED supportsto ascend and descend so that all the LED supports located on the topmost layer can be located on the to-be-grabbed station. The driving mechanism is used for driving the gripper mechanism to move tothe position above multiple piles of LED supports, and the gripper mechanism is used for gripping and transferring the LED supports located on the to-be-gripped station; the gripper mechanism comprises a pre-pressing assembly, a limiting assembly and a gripper assembly, the pre-pressing assembly is used for pressing all the LED supports in advance, the limiting assembly is used for limiting all the LED supports in the horizontal direction, and the gripper assembly is used for gripping all the LED supports. The invention also provides LED die bonding equipment which comprises the LED support feeding device. According to the LED support feeding device, the feeding efficiency of the LED support is improved.

Owner:SHENZHEN XINYICHANG TECH CO LTD

A kind of LED continuous crystal bonding device and its crystal bonding method

InactiveCN107146839BImprove accuracyImprove Die Bonding EfficiencySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringDie bonding

The invention provides a continuous die bonding device and die bonding method of a light emitting diode (LED), and relates to package of an LED chip. The device is provided with a substrate film sending system, a transmission system, a dispersion glue system, a die bonding system, a heating system and a substrate film outlet system, wherein substrate film sending system, a transmission system, the dispersion glue system, the die bonding system, the heating system and the substrate film outlet system are sequentially arranged on a ground surface. The die bonding method comprises the steps of installing the substrate film sending system and the transmission system, and transmitting a substrate by the substrate film sending system and the transmission system; performing dispersion glue on the substrate by the dispersion glue system; performing LED die bonding on the substrate by the die bonding system; curing silver glue by the heating system; and firmly pasting the LED chip on the substrate. By the device and the die bonding method, a high-quality continuous silicon carbide ceramic substrate package product can be obtained, continuous and automatic die bonding of the LED chip on a board of the continuous silicon carbide thin film substrate and industrial production of the package product are achieved, and an LED finished device with more excellent performance is obtained.

Owner:XIAMEN UNIV

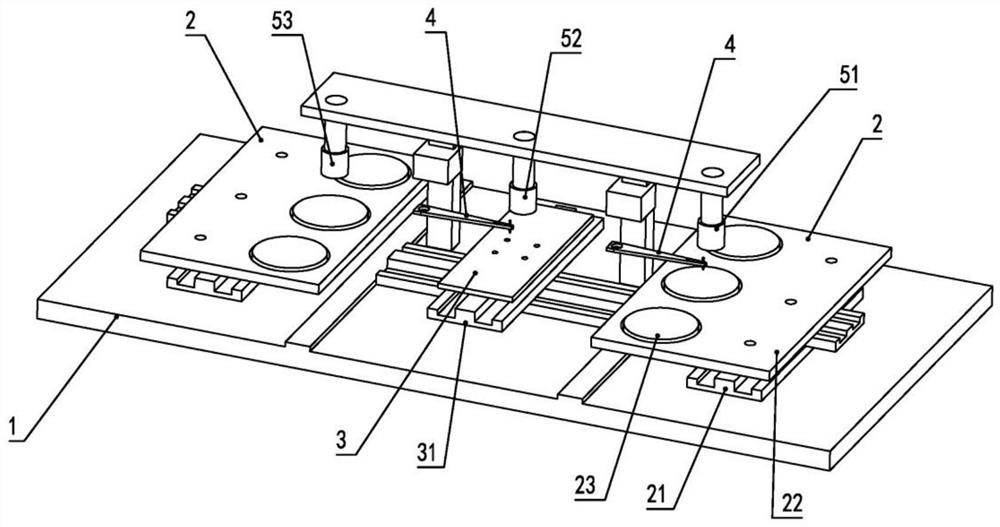

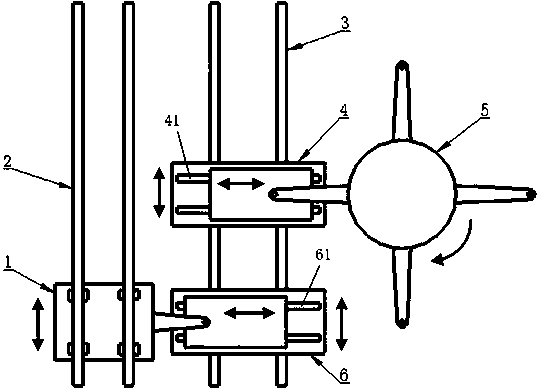

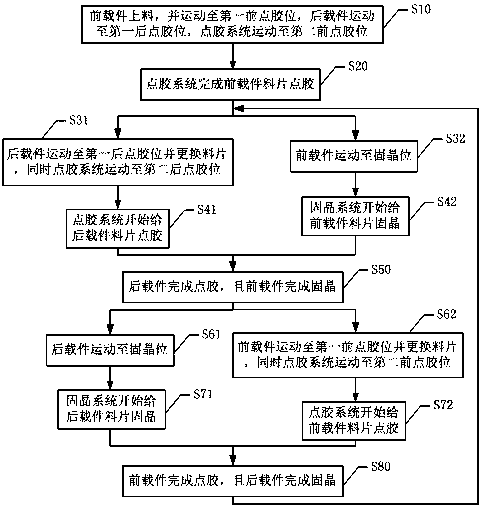

A kind of LED solid crystal dispensing system and method

InactiveCN105405936BDoes not occupy the die-bonding cycleImprove Die Bonding EfficiencySemiconductor devicesDie bondingLight-emitting diode

The invention discloses an LED (Light Emitting Diode) die bonding and dispensing system and method. The LED die bonding and dispensing system comprises a carrier guide rail, two carriers which are arranged on the carrier guide rail to reciprocate along the carrier guide rail and are used for loading tablets, a dispensing system which is arranged at one side of the carrier guide rail and is used for dispensing the tablets on the carriers, and a die bonding system which is arranged at the other side of the carrier guide rail and is used for carrying out die bonding on the tablets on the carriers, wherein the dispensing system is independent, and the die bonding system carries out die bonding on the tablet on one carrier while the dispensing system carries out dispensing on the tablet on the other carrier. The LED die bonding and dispensing system is provided with the die bonding system, two carriers and the independent dispensing system, and dispensing and die bonding cannot grab one station, so that a series connection on a timing sequence is changed into a parallel connection, and when the carriers change the tablets, the carriers and the dispensing system have a series relation on the time sequence, so that a die bonding period is not occupied, and the die bonding efficiency is greatly improved.

Owner:深圳翠涛自动化设备股份有限公司

Die bonder

ActiveCN111370350BGuaranteed dispensing accuracyEnsure dispensing qualitySemiconductor/solid-state device manufacturingWaferingElectric machinery

Owner:SHENZHEN XINYICHANG TECH CO LTD

Die bonder

ActiveCN114141670AImprove Die Bonding EfficiencySemiconductor/solid-state device manufacturingConveyor partsWaferingEngineering

The invention provides a die bonder which comprises the components of a wafer supply mechanism which comprises a wafer ring which is provided with a wafer supply position for supplying a wafer; the rotating mechanism comprises a rotating disc, the rotating disc is rotationally arranged on one side of the wafer ring, and the rotating plane of the rotating disc is perpendicular to the wafer ring; the bearing mechanism comprises a substrate, the substrate is arranged on one side of the turntable, a wafer fixing position for fixing a wafer is arranged on the substrate, and the substrate is perpendicular to the rotating plane of the turntable; the pick-and-place mechanism comprises a wafer suction nozzle, and the wafer suction nozzle is arranged on the turntable and used for sucking the wafer; according to the die bonder provided by the invention, two actions of die taking and die bonding can be realized in one period of rotation of the turntable, and the die bonding efficiency can be improved.

Owner:SHEN ZHEN TALUER TECH CO LTD

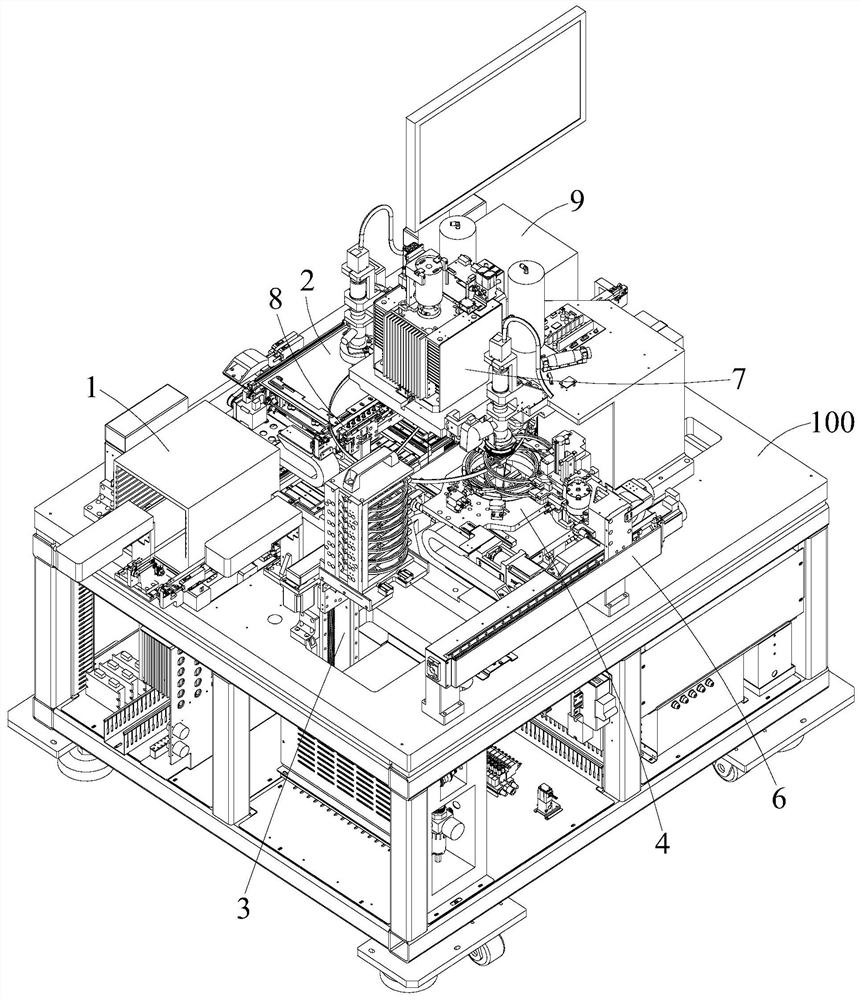

A LED high-speed crystal-bonding equipment and its automatic loading and unloading device

ActiveCN112436084BImprove Die Bonding EfficiencyIncrease productivitySemiconductor/solid-state device manufacturingConveyor partsWire rodElectric machinery

Owner:YANCHENG DONGSHAN PRECISION MANUFACTURING CO LTD

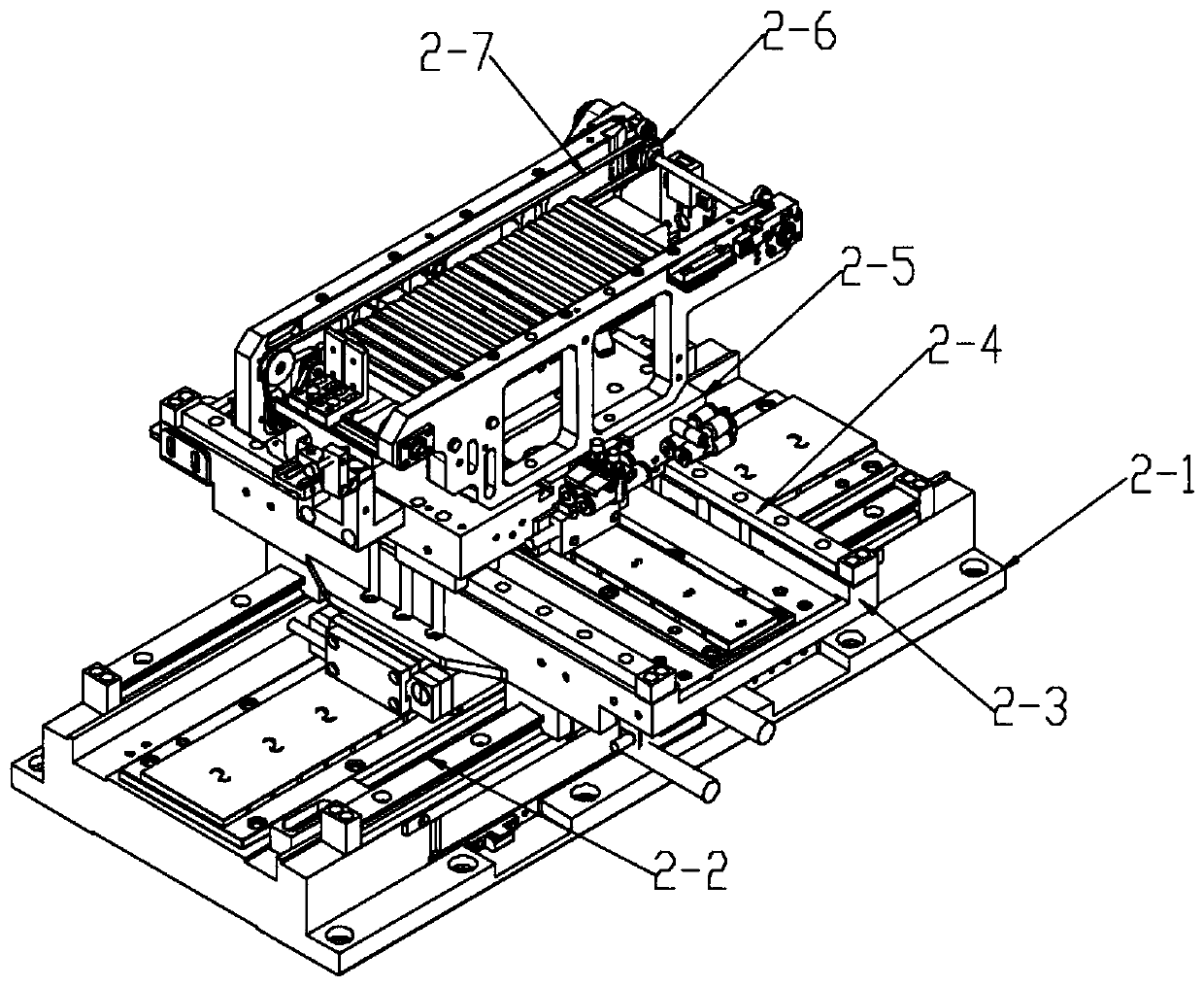

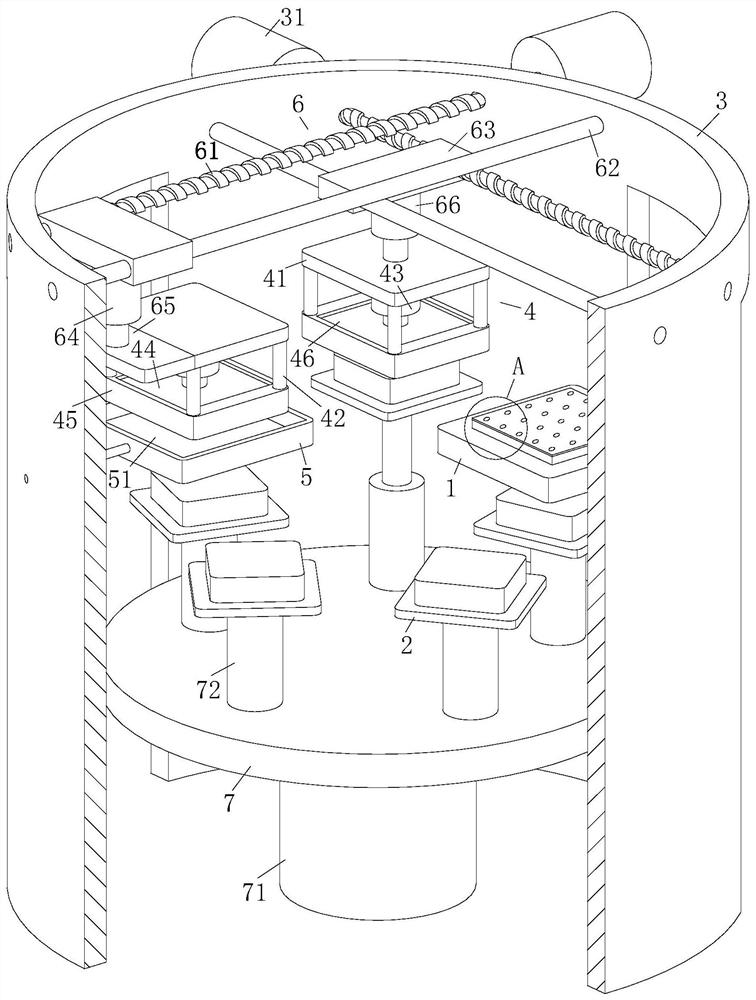

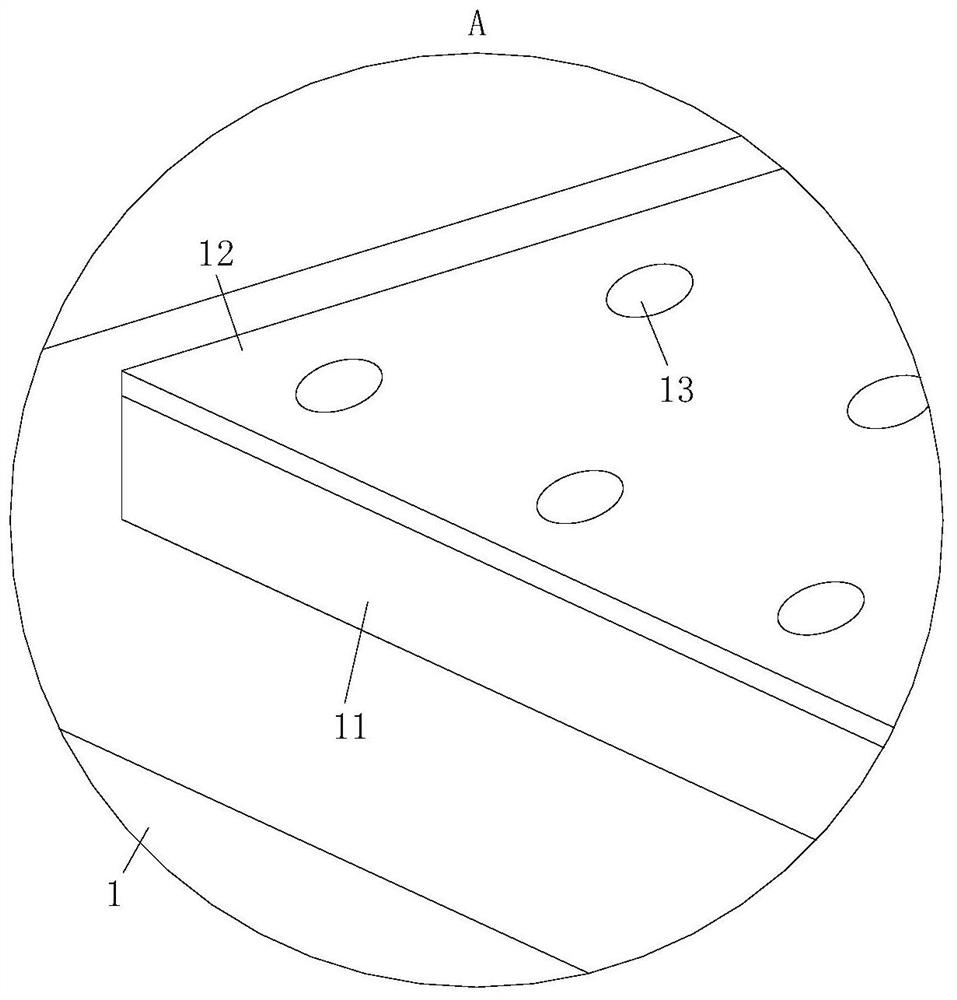

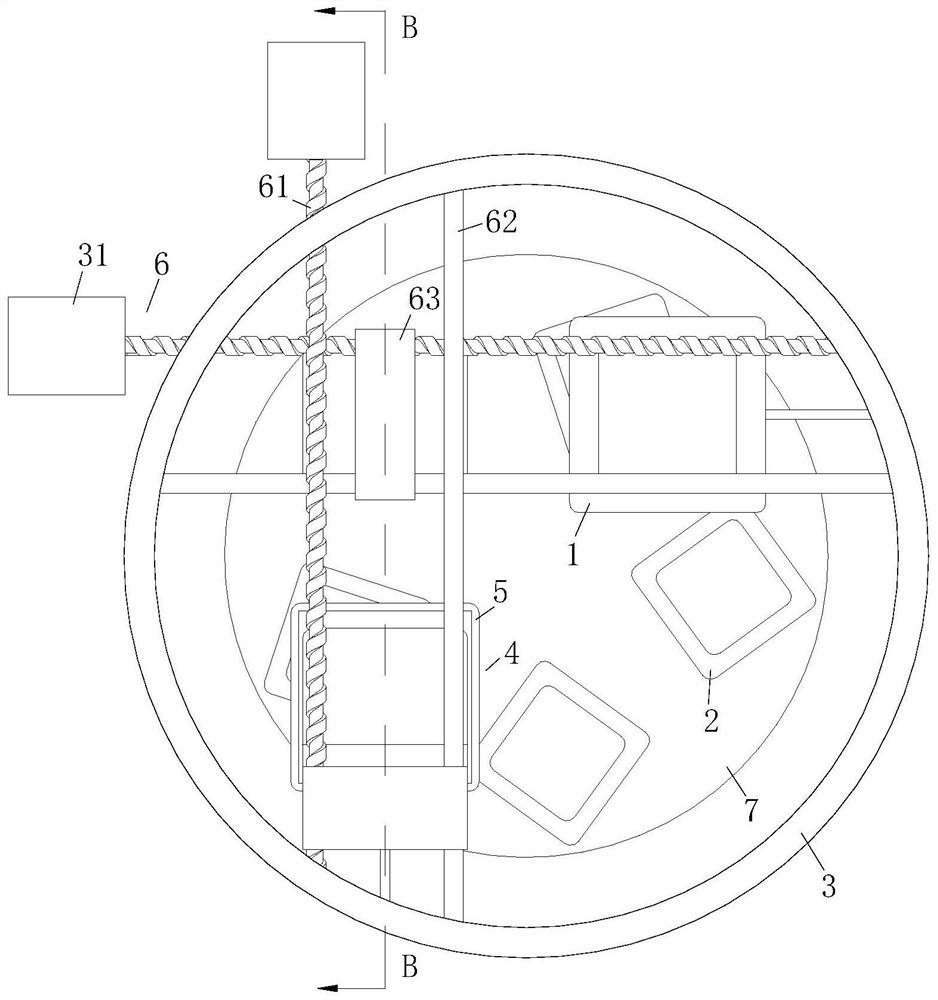

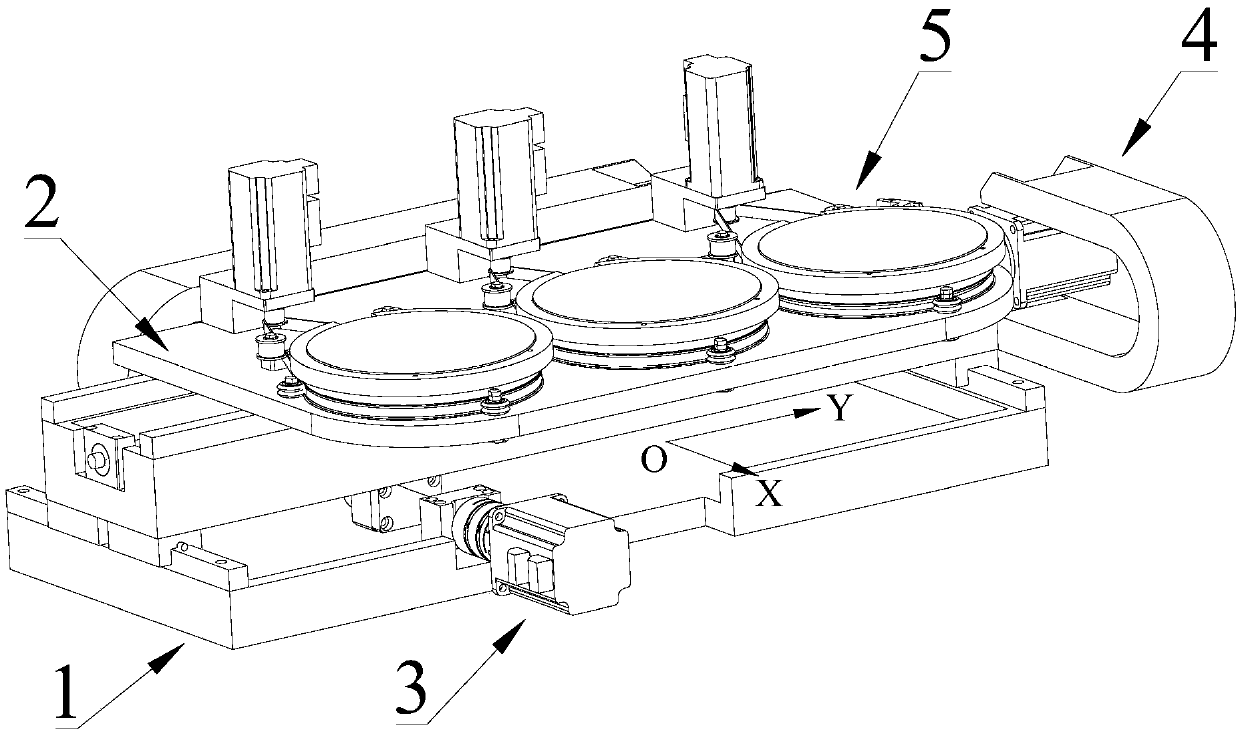

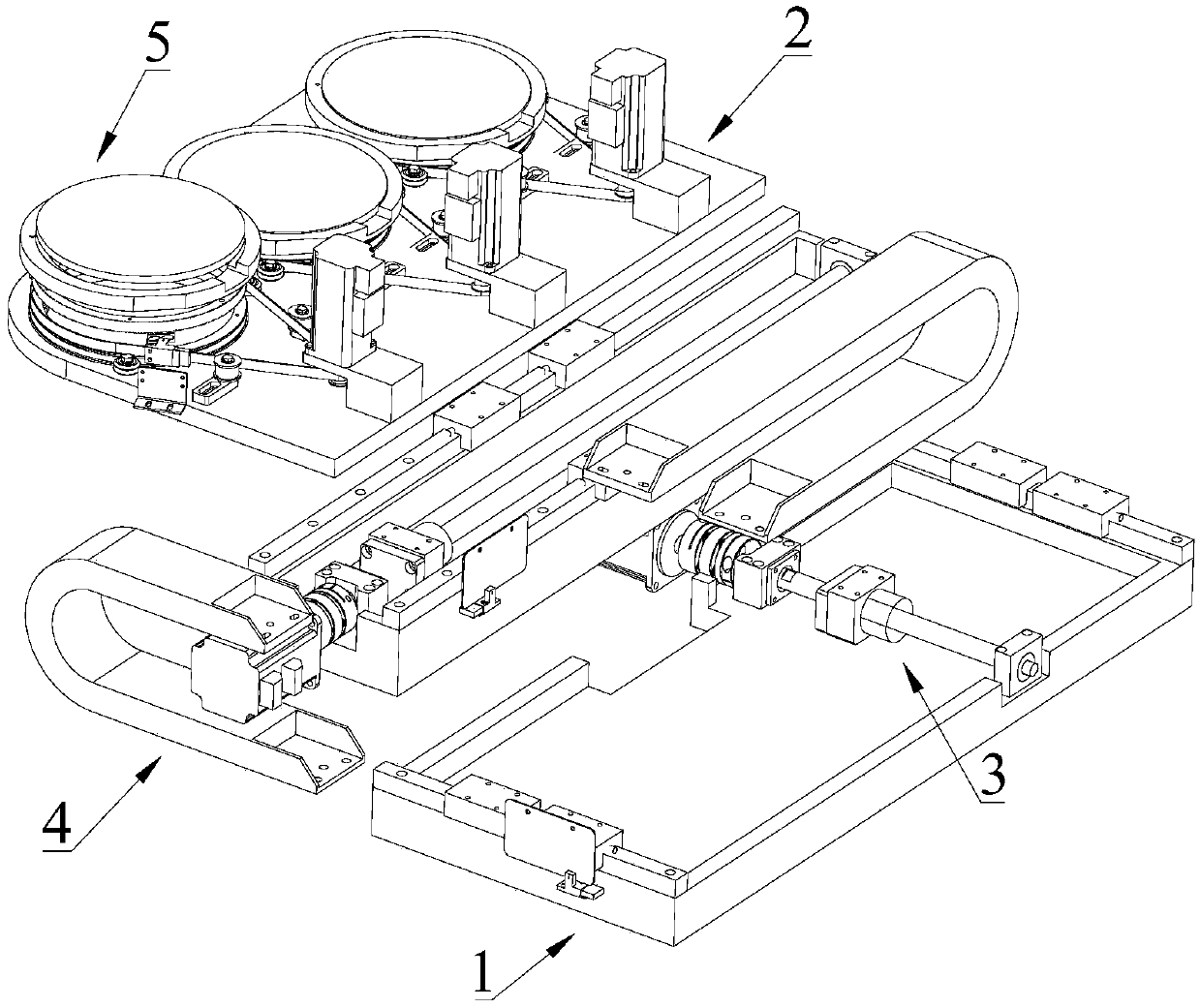

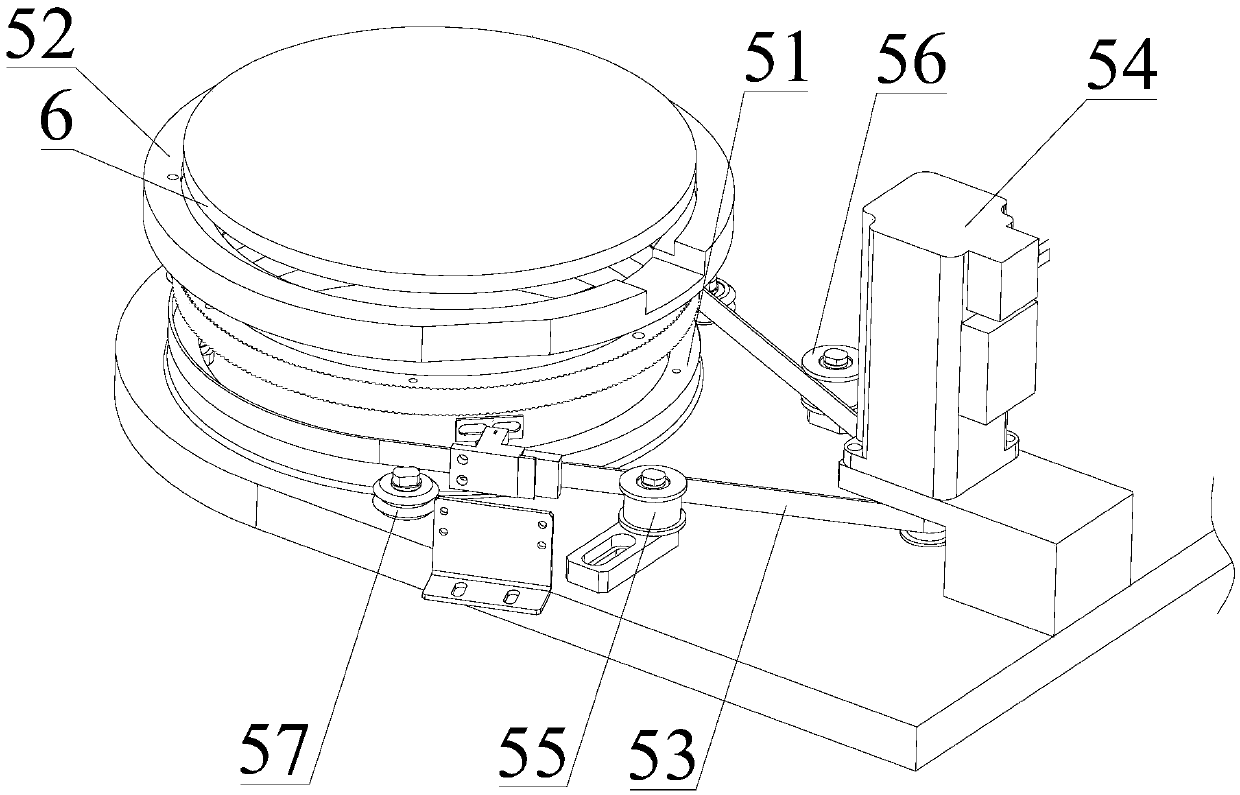

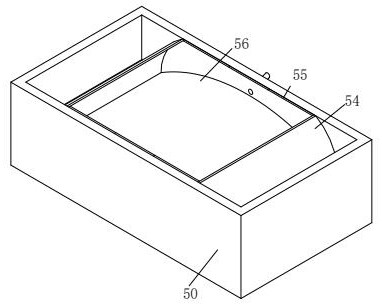

Crystal ring device

PendingCN109638142AImprove Die Bonding EfficiencyShorten the timeSemiconductor/solid-state device manufacturingSemiconductor devicesRing deviceEngineering

The present invention discloses a crystal ring device including a bracket, a first driving mechanism for driving the bracket to move in an X-axis direction, a second driving mechanism for driving thebracket to move in a Y-axis direction, and three fixing mechanisms for fixing a crystal ring. The three fixing mechanisms are spaced apart on the bracket, the fixing mechanism includes rotating members, fixing members for fixing the crystal ring and third driving components for driving the rotating members to rotate for 360 degrees, and the fixing members are fixedly arranged on the rotating members. According to the crystal ring device, three chips of different colors can be fixed on the same piece of equipment at the same time, the crystal fixation efficiency is high, the switching of materials between machines is not needed, the time can be saved, and the crystal fixation quality can be improved.

Owner:先进光电器材(深圳)有限公司

Double arm crystal ring changing mechanism

The present application provides a double-armed crystal ring exchange mechanism, including a first transport arm; a second transport arm; The second transport arm reciprocates between the crystal ring upper material level and the crystal ring lower material level. The present application can move the crystal ring containing the wafer on the crystal ring upper material level to the crystal ring lower material level through the first transport arm, so that the wafer on the crystal ring can be ejected by the crystal lifting mechanism; The used crystal ring is taken out at the lower material level of the ring, which is convenient for the first conveying arm to load the crystal ring; the first conveying arm and the second conveying arm can be driven by the conveying drive unit to the material level of the crystal ring and the crystal ring unloading Move back and forth between bits. In this way, the loading operation of the crystal ring can be completed by the first conveying arm, and the unloading operation of the crystal ring can be completed by the second conveying arm, thereby helping to improve the speed of loading and unloading the crystal ring and reducing the waiting time for loading and unloading the crystal ring , thereby improving the die-bonding efficiency.

Owner:SHENZHEN XINYICHANG TECH CO LTD

Electronic component production die bonding equipment and use method thereof

ActiveCN114864455AImprove Die Bonding EfficiencyPrevent solidificationSemiconductor/solid-state device manufacturingWaferingEngineering

The invention relates to the technical field of die bonding, in particular to electronic component production die bonding equipment and a use method thereof, the electronic component production die bonding equipment comprises two supporting tables, a conveyor for conveying a substrate is mounted between the two supporting tables, and a placement table and a glue box which are sequentially arranged in the conveying direction of the conveyor are mounted on the end face, away from the conveyor, of one supporting table. According to the die bonding equipment for electronic component production, a plurality of wafers can be fixed on the substrate at the same time, and the die bonding glue in the charging hopper is shaken and stirred in the process of coating the wafers with the die bonding glue, so that the problem of poor fixing effect between the wafers and the substrate caused by solidification of the die bonding glue is prevented; and the bottoms of a plurality of wafers are simultaneously inserted into the inserting and coating through grooves for gluing, so that not only can the die bonding efficiency of the electronic element be improved, but also the problem of waste of the die bonding glue caused by directly coating more die bonding glue on the substrate is avoided.

Owner:江苏丰源电子科技有限公司

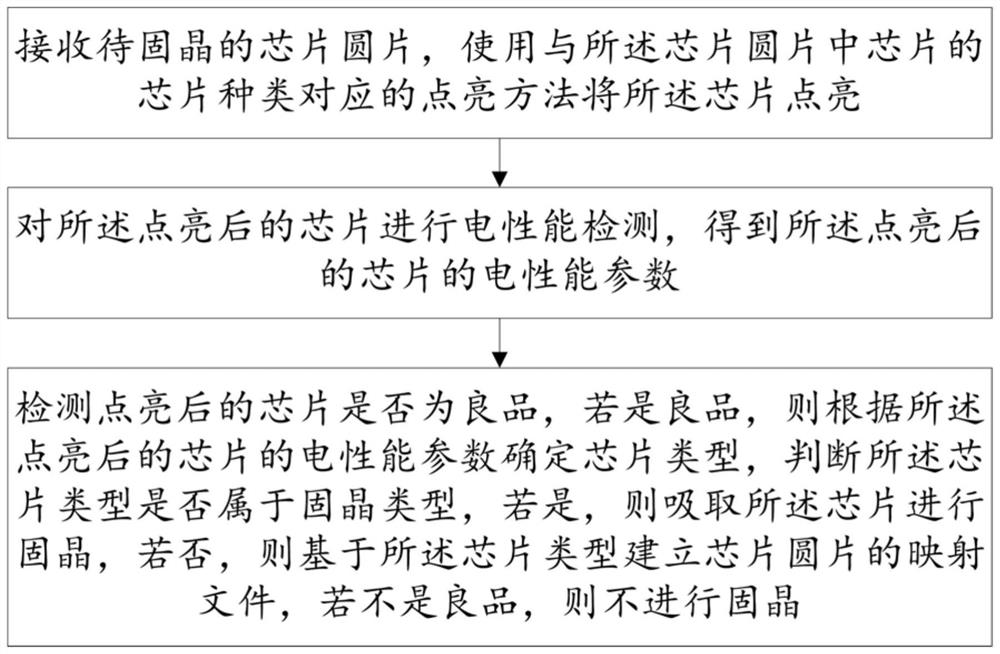

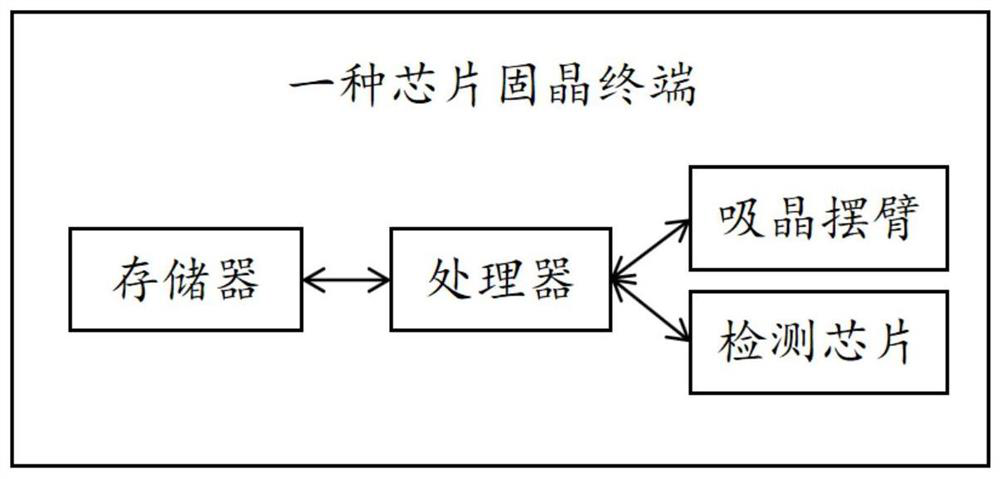

A chip bonding method and terminal

ActiveCN113066917BEasy to read intuitivelyImprove Die Bonding EfficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringElectrical performance

Owner:江苏佑光科技股份有限公司

A kind of fully automatic planar ic crystal bonding machine and bonding method

ActiveCN111490147BPrevent solidificationShorten the timeSemiconductor devicesWaferingStructural engineering

The invention provides a full-automatic planar IC die bonder and a die bonding method. The die bonder comprises a rack, a feeding mechanism and a receiving mechanism which are arranged at two ends ofthe rack respectively, a rail mechanism which is arranged between the feeding mechanism and the receiving mechanism; a dispensing mechanism, a lens mechanism and a welding head mechanism which are arranged on a side of the rail mechanism, and a film expanding and crystal ejecting mechanism which is arranged below the rail mechanism. The feeding mechanism is used for feeding an LED support to the rail mechanism, the rail mechanism is used for receiving and transferring the LED support, the dispensing mechanism is used for dispensing the LED support, and the film expanding and wafer jacking mechanism is used for jacking out a wafer on a blue film and fixing the wafer to the LED support under the cooperation of the lens mechanism and the welding head mechanism; the dispensing mechanism comprises a dispensing stand column fixed to the rack, a first dispensing assembly and a second dispensing assembly, wherein the first dispensing assembly and the second dispensing assembly are arranged onthe dispensing stand column. By arranging the two dispensing assemblies, the dispensing efficiency is greatly improved such that the die bonding efficiency is effectively ensured.

Owner:SHENZHEN XINYICHANG TECH CO LTD

Die bonder

ActiveCN112928052BReduce waiting timeRealize automatic replacement workSemiconductor/solid-state device manufacturingConveyor partsWaferingEngineering

The application provides a crystal bonding machine, which includes a frame, a bracket feeding component, a bracket transferring component, a crystal ring feeding component, a crystal ring rotating component, a top crystal component, a crystal ring transferring component, a suction nozzle, a solid crystal Swing arm assembly, suction nozzle supply assembly and material receiving assembly. The bracket can be supplied to the bracket transfer component through the bracket feeding component, and the crystal ring on the crystal ring feeding component can be transferred to the crystal ring transfer component through the crystal ring transfer component, and the crystal ring rotation component can be used After the crystal ring is removed, the wafer on the crystal ring can be ejected to the crystal supply position through the crystal top assembly, and the wafer at the crystal supply position can be transferred to the support transfer assembly through the suction nozzle and the solid crystal swing arm assembly. Complete the die bonding operation of the wafer and the bracket. The crystal ring transfer component can realize the simultaneous operation of crystal ring loading and unloading, which reduces the waiting time for crystal ring loading and unloading, and helps to improve the efficiency of die bonding. Moreover, the automatic replacement of the suction nozzles can be realized through the suction nozzle receiving and supplying assembly, which saves time and labor and has high efficiency.

Owner:SHENZHEN XINYICHANG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com