Double-swing-arm die-bonding device for LED die bonding and die bonding method thereof

A double-swing arm and LED bracket technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced speed and precision, increased inertia, and low work efficiency, and achieves good adaptability, compact structure, and improved solid state. Effect of Crystal Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1. The specific structure of the present invention is as follows:

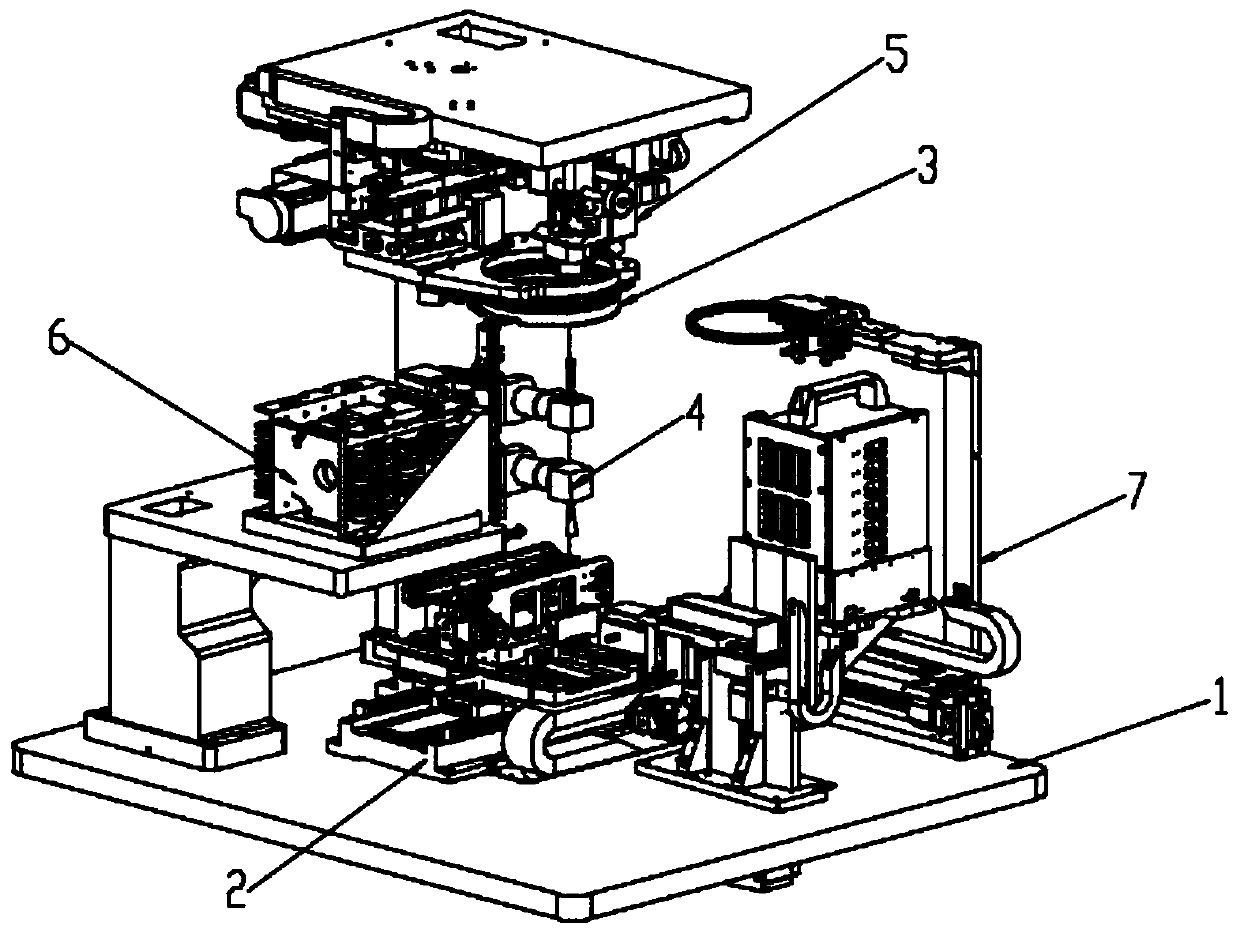

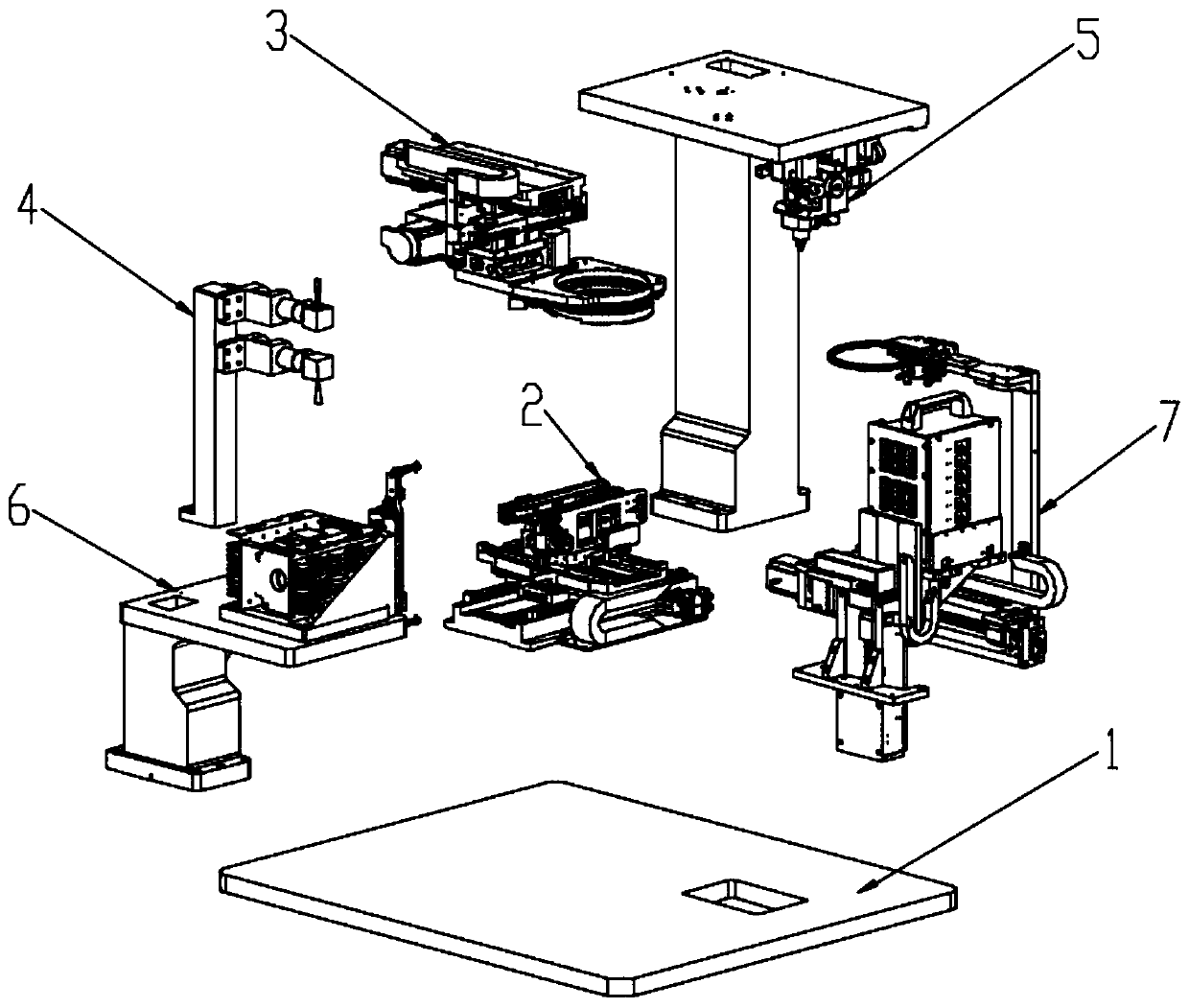

[0050] Please refer to the attached Figure 1-8 , A double-swing arm die-bonding device for LED die bonding of the present invention, the double-swing arm die-bonding device includes:

[0051] Platen 1;

[0052] It also includes those set on the platen 1:

[0053] The die-bonding mechanism 6 is provided with two die-bonding pendulum arms 6-4, a telescopic drive mechanism 6-3 that drives the two die-bonding pendulum arms 6-4 to move toward or in the opposite direction, and connects and drives the telescopic drive mechanism 6-3 The rotation driving mechanism 6-2 that drives the two die-bonding swing arms 6-4 to rotate;

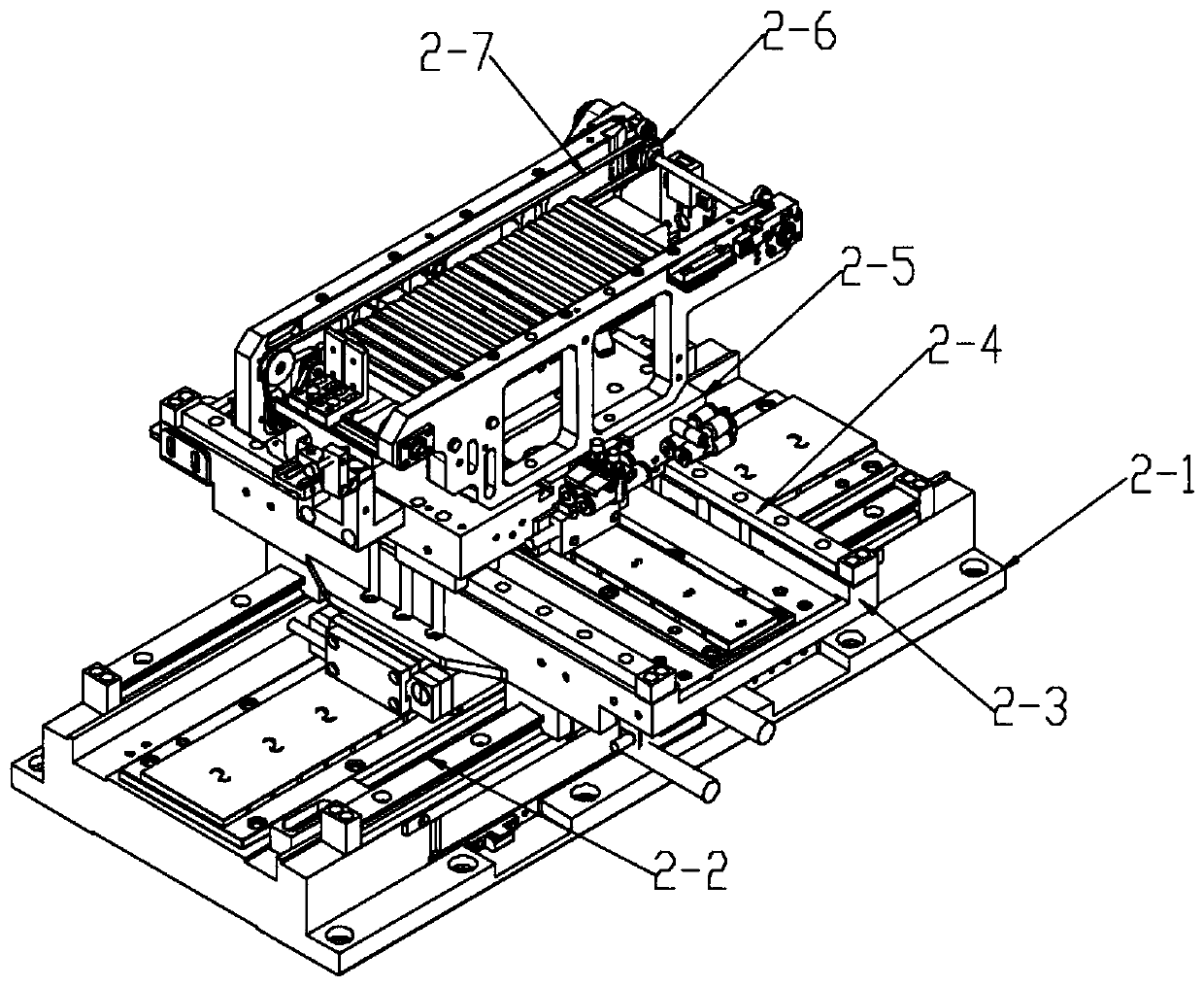

[0054] The fixture moving platform 2 is arranged on the adjacent side of the crystal bonding mechanism 6, and is provided with a first transverse slide rail mechanism, a first longitudinal slide rail mechanism seated on the first transverse slide rail mechanism, and a The pulley assembly...

Embodiment 2

[0072] Embodiment 2: A method for bonding a dual-swing arm bonding device of an LED bonding machine of the present invention, the method includes the following steps:

[0073] Step 1: With the assistance of the die-bonding lens assembly 4-2, the system controls the fixture moving platform 2 to move horizontally and vertically to drive the LED bracket on it to move to the die-attach position;

[0074] Step 2: With the assistance of the crystal lens assembly 4-1, the system control ring mobile platform assembly 3 performs horizontal and vertical movement, thereby driving the crystal ring located on it to move to the specified position and correct it;

[0075] Step 4: The rotary drive mechanism 6-2 drives one of the die-bonding swing arms 6-4 to rotate and move to the top of the wafer, the ejector pin assembly 5 ejects an LED chip on the die ring, and the driven die-bonding swing arm 6 -4 Take the ejected chip and rotate it 180° to fix it on the LED bracket. At the same time, another di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com