Electronic component production die bonding equipment and use method thereof

A technology for electronic components and crystal bonding, which is applied in the field of crystal bonding equipment for the production of electronic components. It can solve the problems of not being able to fix multiple chips, waste, and insufficient amount of bonding glue, and achieve the effect of improving the baking effect and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

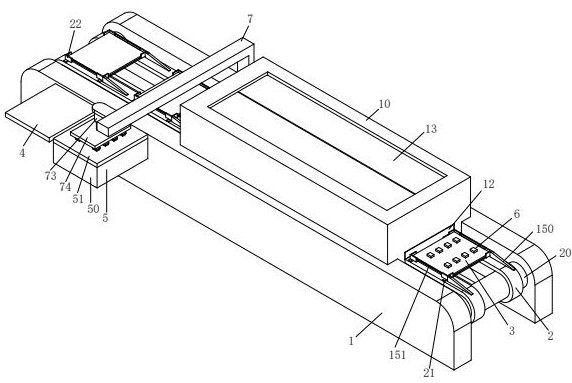

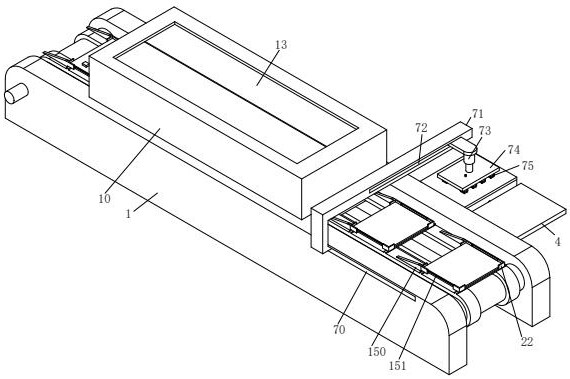

[0035] see figure 1 , an electronic component production die-bonding equipment, comprising two support tables 1, a conveyor 2 for conveying a substrate 3 is installed between the two support tables 1, and one of the support tables 1 is installed on the end face away from the conveyor 2 along The placing table 4 and the plastic box 5 are arranged in sequence in the conveying direction of the conveyor 2. The placing table 4 is used to place the wafer 6, the plastic box 5 is used to store the die-bonding glue, and another support table 1 is installed on the other support table 1 to suck and fix the wafer 6. The drive assembly 7.

[0036] see figure 1 and figure 2, the conveyor 2 is composed of two conveyor rollers 20 and two conveyor belts, the two conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com