Crystal ring device

A technology of driving mechanism and rotating parts, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of hidden quality problems, unfavorable visual inspection, and high cost, and achieve the goal of improving the precision of die bonding, improving the quality of die bonding, and high die bonding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

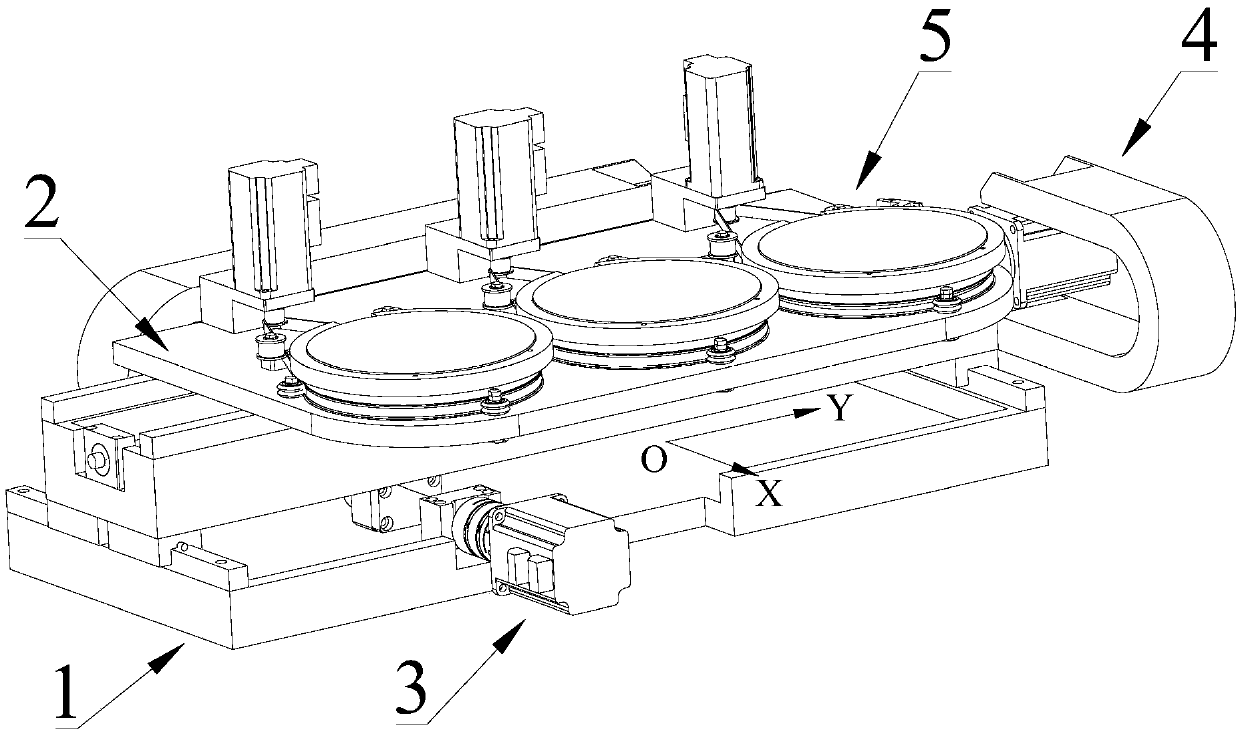

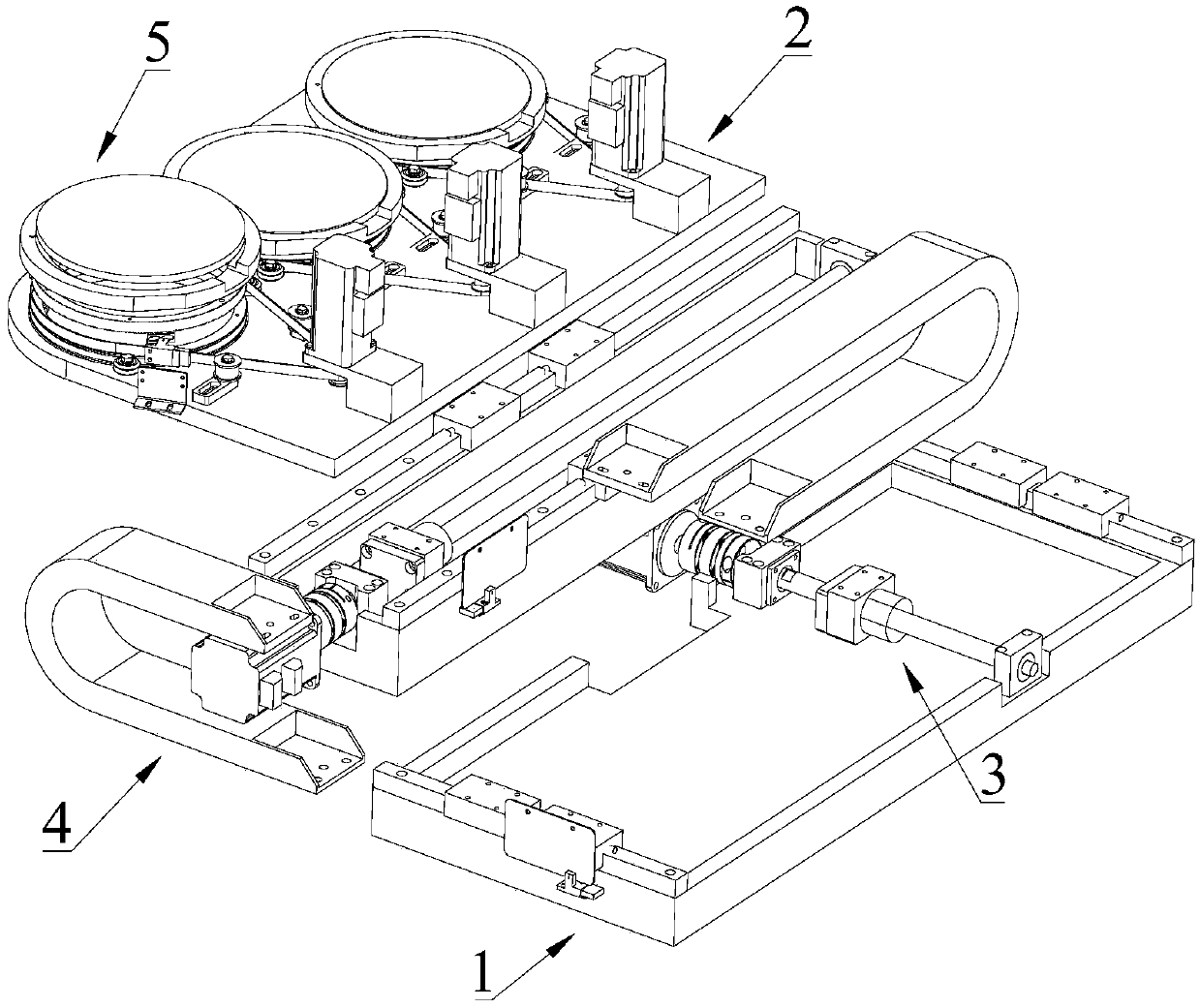

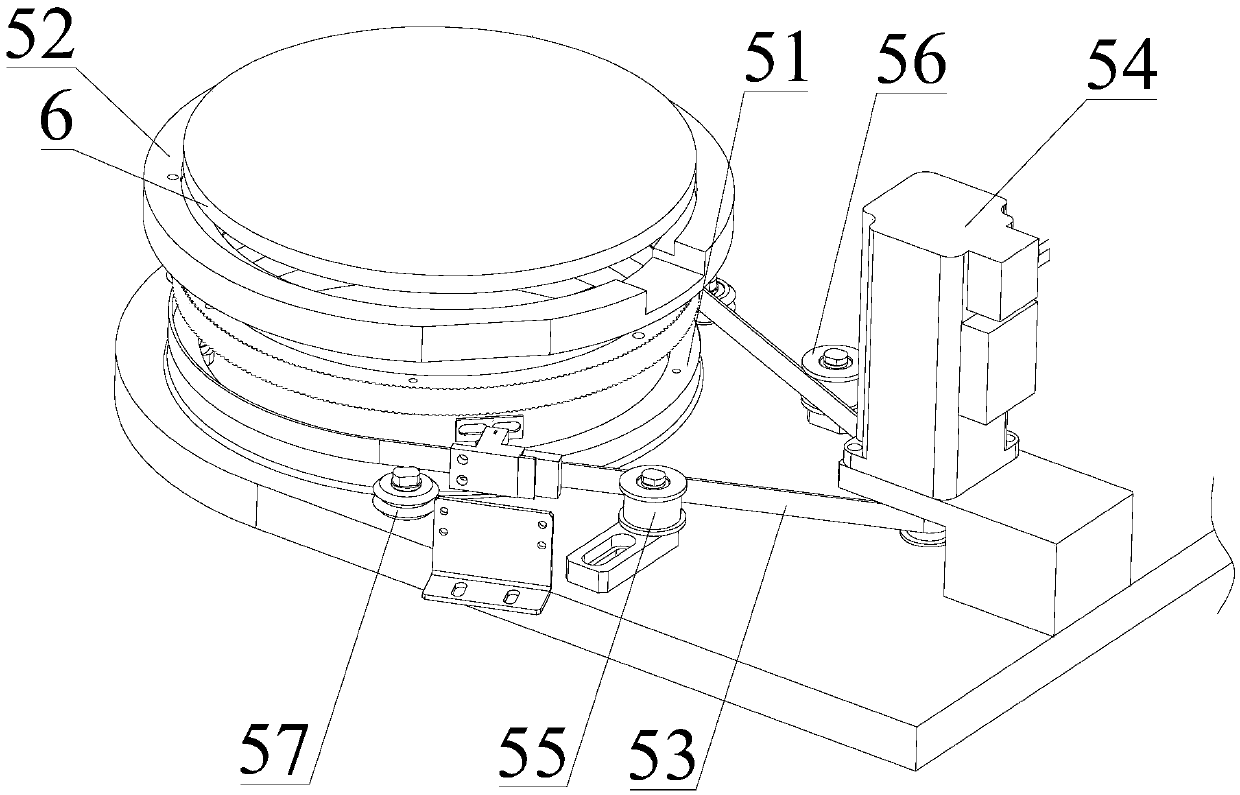

[0030] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention is:

[0031] A crystal ring device such as figure 1 and figure 2 As shown, it includes a base 1, a support 2, a first drive mechanism 3 that drives the support 2 to move along the X-axis direction, and a second drive mechanism 4 that drives the support 2 to move along the Y-axis direction. The first drive mechanism 3 and the second driving mechanism 4 are fixedly arranged on the base 1 . The first drive mechanism 3 can be driven by a motor to drive the screw to drive the bracket 2 to move along the X-axis direction; the second drive mechanism 4 can be driven by a motor to drive the screw to drive the bracket 2 to move along the Y-axis direction, The guide rail can be set to play a guiding role. The crystal ring device also includes three fixing mechanisms 5 for fixing the crystal ring 6, and the three fixing mechanisms 5 are arranged at intervals on the support 2, and between two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com