Preparation method of LED lamp bead with built-in drive IC

A technology of LED lamp beads and light-emitting chips, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems that affect the welding quality of light-emitting chips, and the position of the driver IC is difficult to fix, so as to improve the efficiency of die-bonding and accurate positioning , the effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

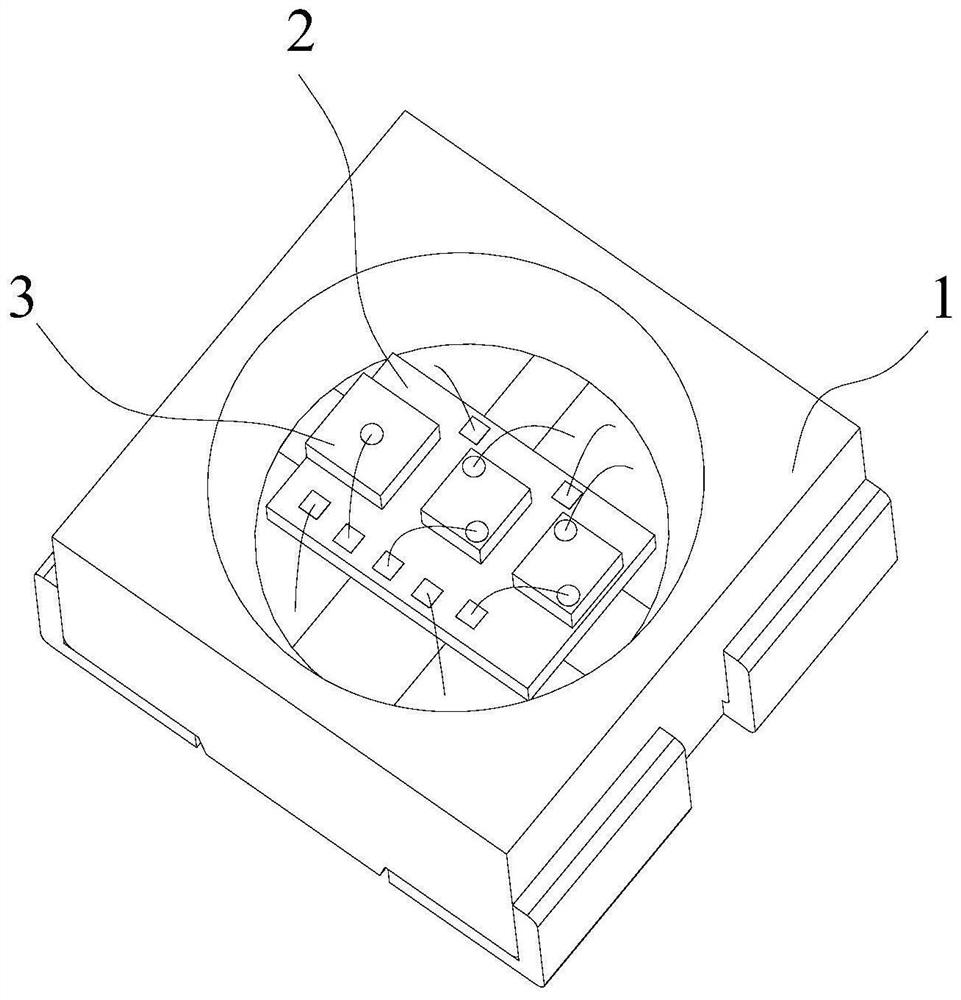

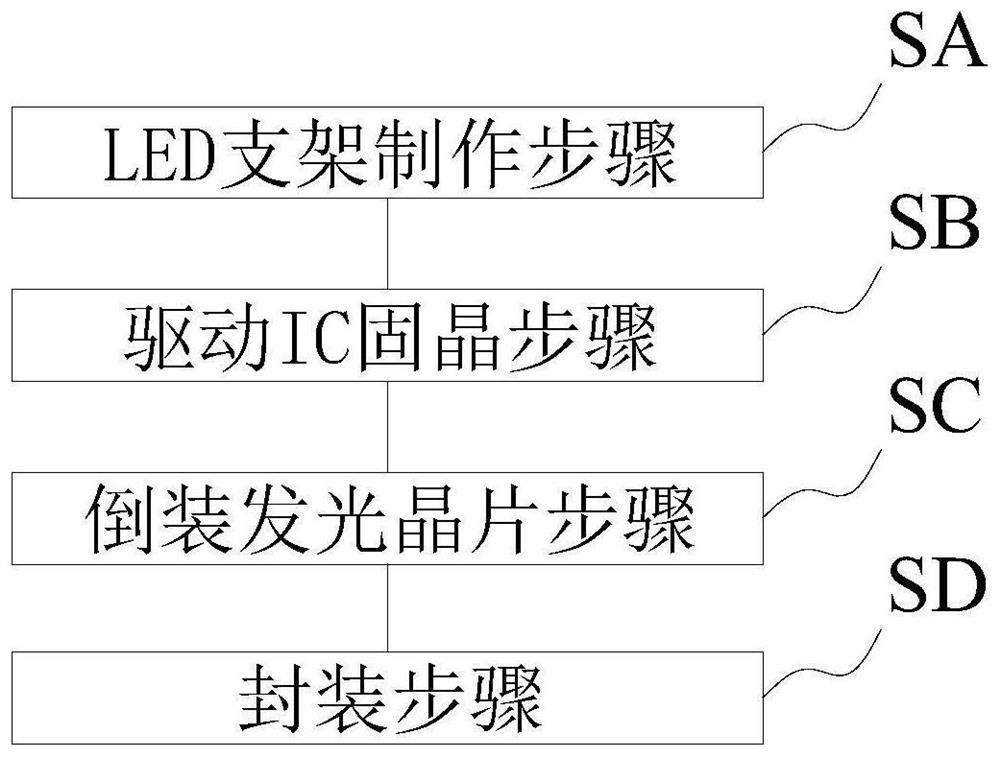

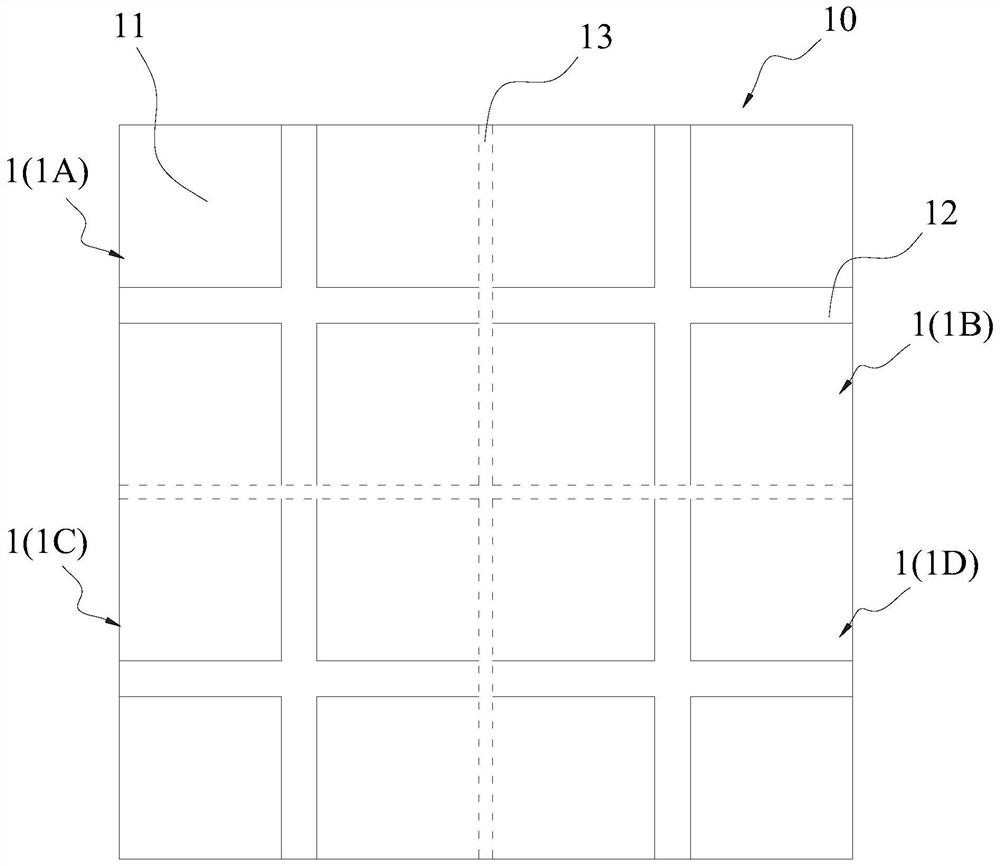

[0068] This example will specifically describe the preparation method of the LED lamp bead with a built-in driver IC provided by the present invention. The LED lamp bead in this example may adopt a CHIP structure or a TOP structure. The so-called TOP structure refers to the structure in which PLCC (full name in Chinese: plastic chip carrier with leads; full name in English: Plastic Leaded Chip Carrier) plastic bracket is used as the base bracket 1, and the pins of the PLCC plastic bracket packaging structure (not shown in the figure) out) bend inward at the bottom. The process is well known to the public, and generally includes metal strip punching, electroplating, PPA (polyphthalamide) injection molding, bending, five-sided three-dimensional inkjet and other processes. Its core is to form a chip mounting surface through a metal strip on the surface of the plastic bracket; and pins are extended from the chip mounting surface and bent inward at the bottom and then attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com