Continuous die bonding device and die bonding method of light emitting diode (LED)

A technology of LED chips and solid crystals, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems that have not been seen involving continuous SiC free thin-film ceramic heat-dissipating substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the purpose, technical solutions and advantages of the present invention more clear and understandable, the present invention will be described below in conjunction with exemplary embodiments and with reference to the accompanying drawings.

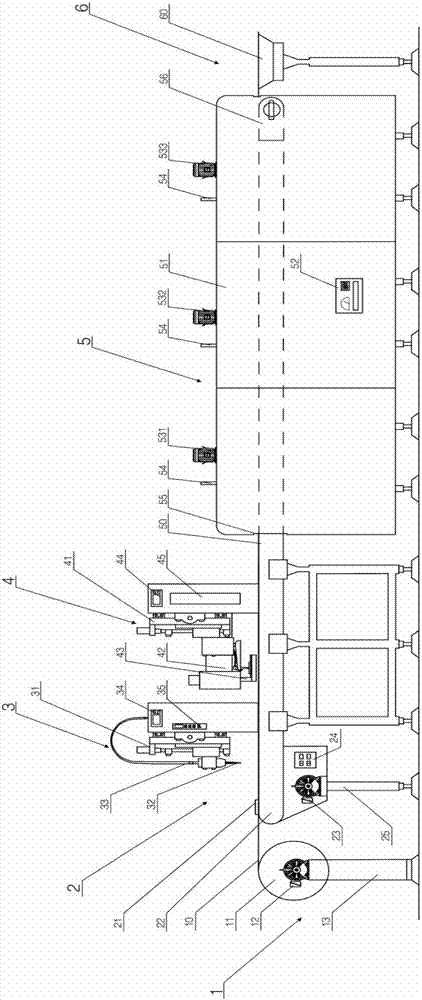

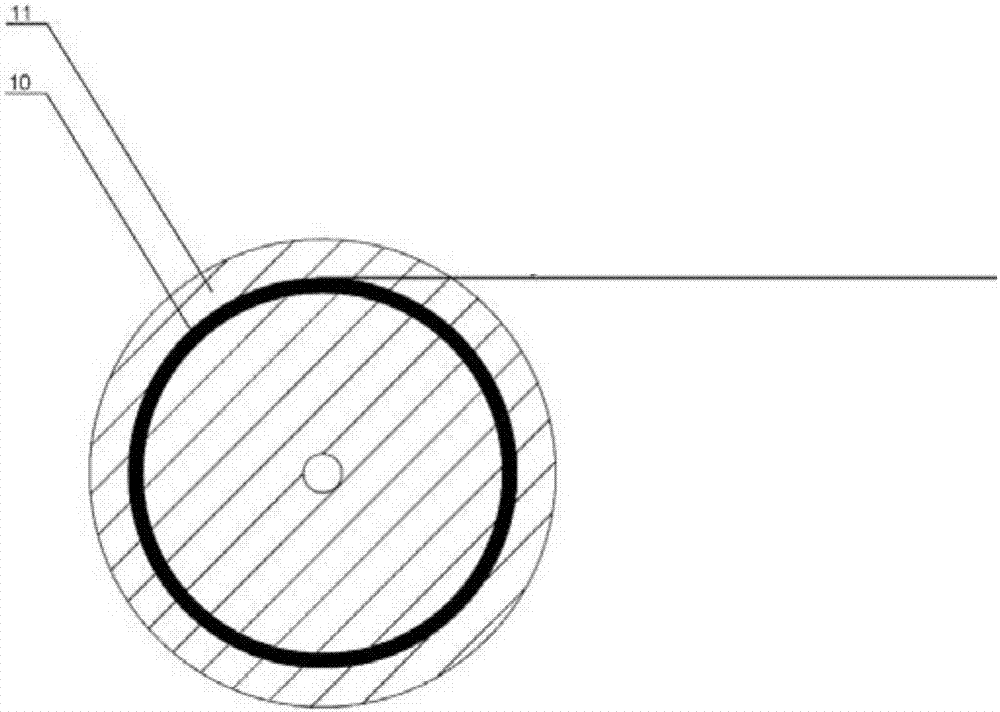

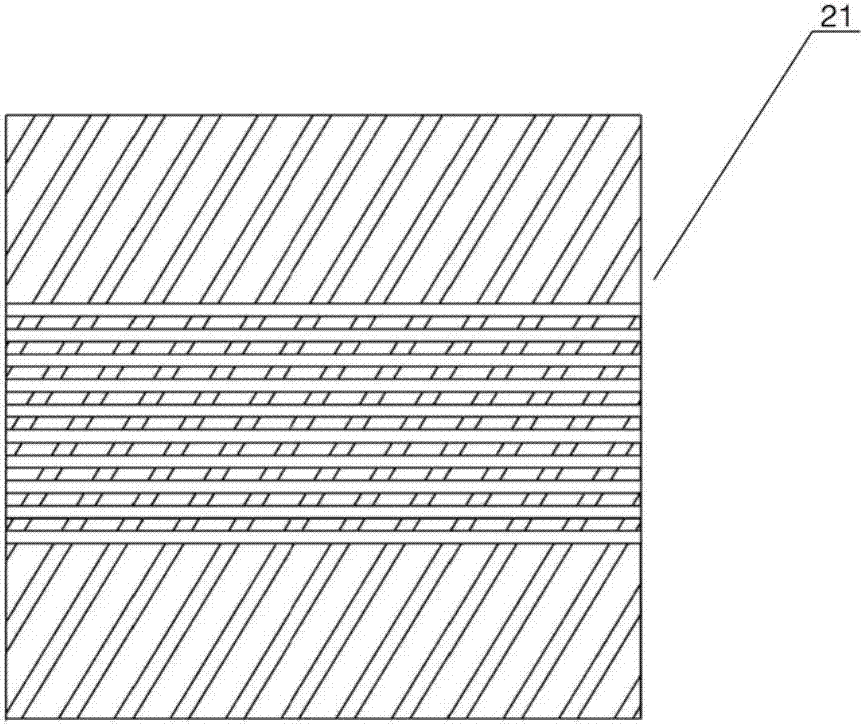

[0069] This kind of LED continuous crystal bonding device provided by the present invention, such as figure 1 As shown, it includes: a substrate film delivery system 1 , a transmission system 2 , a dispensing system 3 , a crystal bonding system 4 , a heating system 5 and a substrate film delivery system 6 . The substrate film-out system 1 includes a silicon carbide thin film substrate 10 to be solidified, a substrate reel 11 , a rotating motor 12 and a support 13 . In the transmission system 2 , it includes a positioning track 21 located at the front end of the conveyor belt 22 , a high temperature resistant rubber conveyor belt 22 , a motor 23 , a control panel 24 for rotation speed, and supporting legs 25 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com