Bond head structure of 180-degree die bonder

A technology of solid crystal machine and head, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low work efficiency, processing accuracy and reliability, and achieve increased space utilization and reduced swing The effect of the arm occupying volume and improving the efficiency of die bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

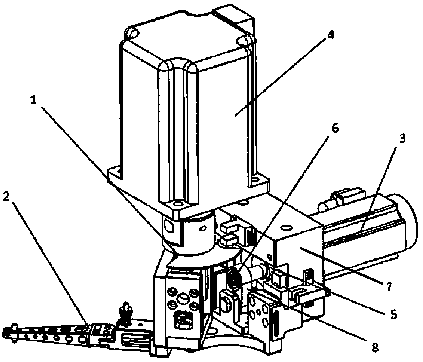

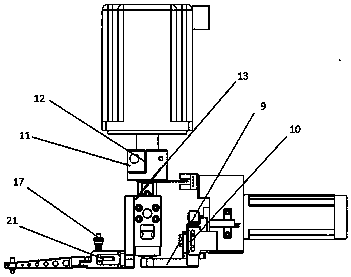

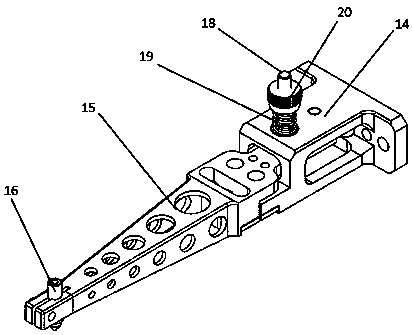

[0021] as attached figure 1 , 2 As shown in and 3, the present invention discloses a head structure of a 180 ° solid crystal machine, including a driving device and a swing arm mechanism 2, and the driving device includes a Z-axis motor 3 and a rotating motor 4, and the Z-axis motor 3 is mounted on On the Z-axis mount 7, the motor shaft of the Z-axis shaft motor 3 is equipped with an eccentric shaft 6 through a bearing 5, and a connecting rod 8 is mounted on the eccentric shaft 6, and the connecting rod 8 is equipped with a Z-axis connecting block 9, and the rotating motor 4 The motor shaft is equipped with a rotating shaft 11, and the rotating shaft 11 is provided with a swing arm guide rail 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com