Reverse electrodialysis power generation device

A reverse electrodialysis and power generation device technology, applied in the direction of generators, generators/motors, electrical components, etc. that convert kinetic energy into electrical energy, can solve problems such as low energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

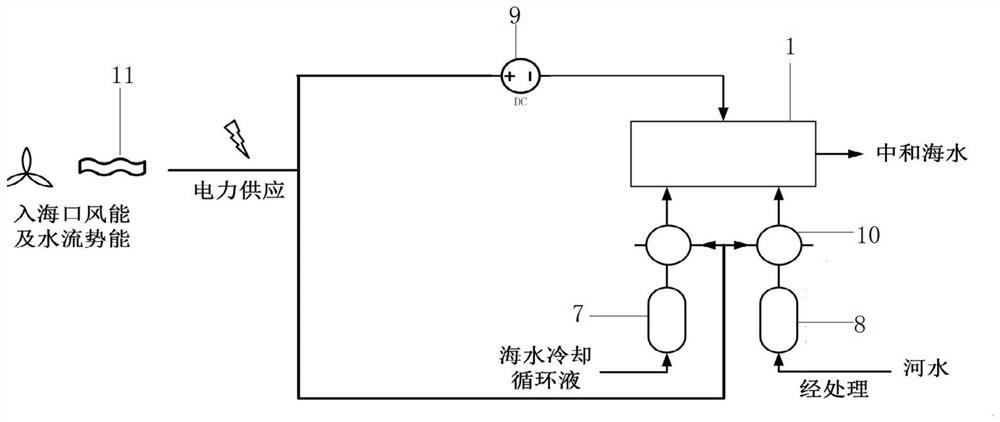

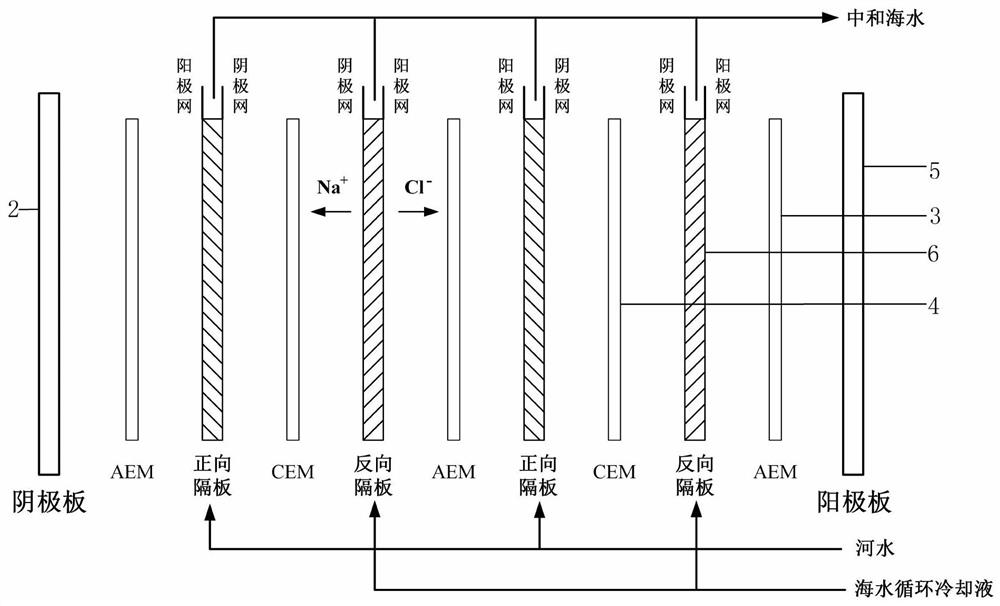

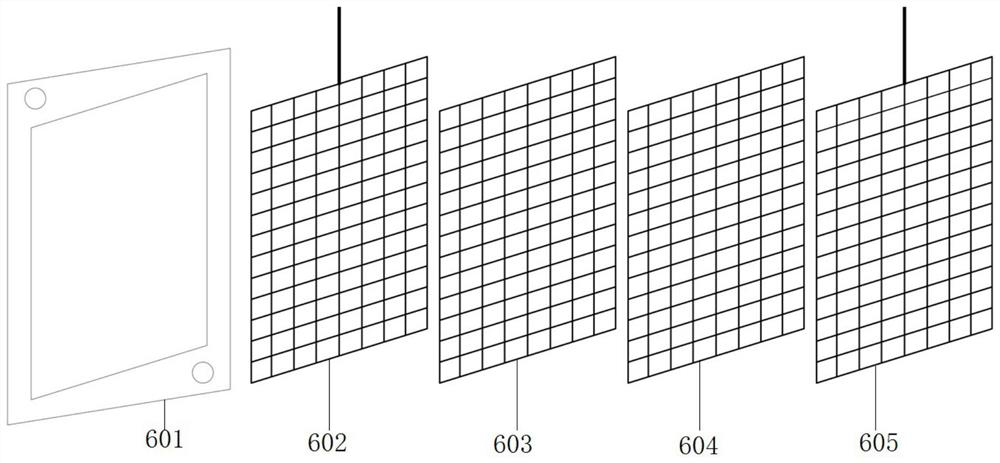

[0021] A reverse electrodialysis power generation device, such as figure 1 As shown, including reverse electrodialysis membrane stack 1, such as figure 2 As shown, the reverse electrodialysis membrane stack 1 includes cathode plates 2 arranged in sequence, alternately arranged anion exchange membranes 3 and cation exchange membranes 4, and anode plates 5, and the alternately arranged anion exchange membranes 3 and cation exchange membranes 4 pass through the separator 6 interval, such as image 3 As shown, the separator 6 includes a separator pad 601 on which an anode mesh 602, an anion exchange mesh layer 603, a cation exchange mesh layer 604, and a cathode mesh 605 are laminated in sequence; The separator 6 between the two is a forward separator (the separator 6 is placed forward, and the left side is an anion exchange network layer 603)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com