Coating machine for polyimide film preparation

A technology of polyimide film and coating machine, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., which can solve the problem of wasting materials and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

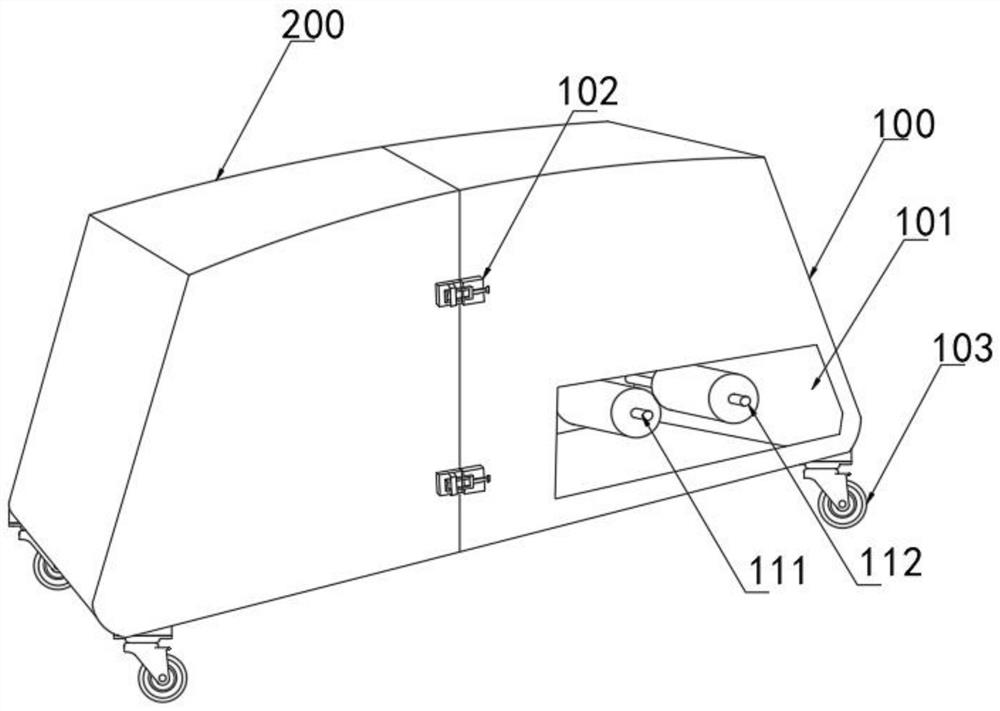

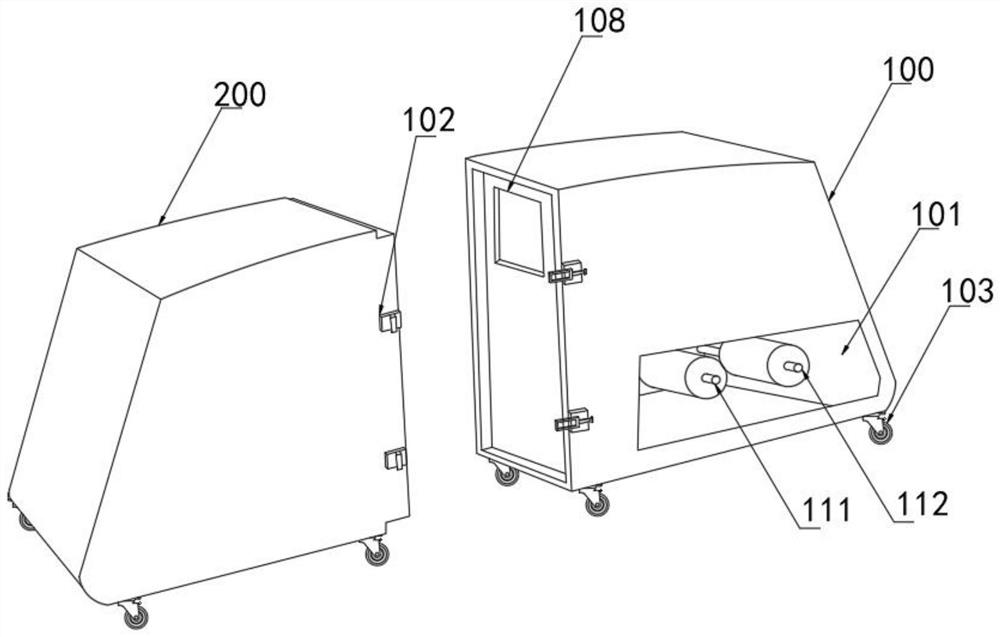

[0040] Example 1, with reference to the attached Figure 1-14, a coating machine for preparing polyimide film provided by the present invention includes a body 100, a body 2 200, a tensioning device 1 300, a coating device 400 and a tensioning device 2 500;

[0041] Further, connection buckles 102 are provided on both sides of the first body 100 and the second body 200. Specifically, a universal wheel 103 is fixedly installed at the bottom of the first body 100 and the second body 200. Supporting and moving, the first body 100 and the second body 200 are movably connected through the connecting buckle 102, and the connecting buckle 102 has a connecting effect on the first body 100 and the second body 200. The inner wall of the body one 100 is provided with a tensioning device 1 300, and the tensioning device 1 300 has the effect of adjusting and tensioning the polyimide film. The left side of the tensioning device 300 is provided with a smearing device 400. The smearing device...

Embodiment 2

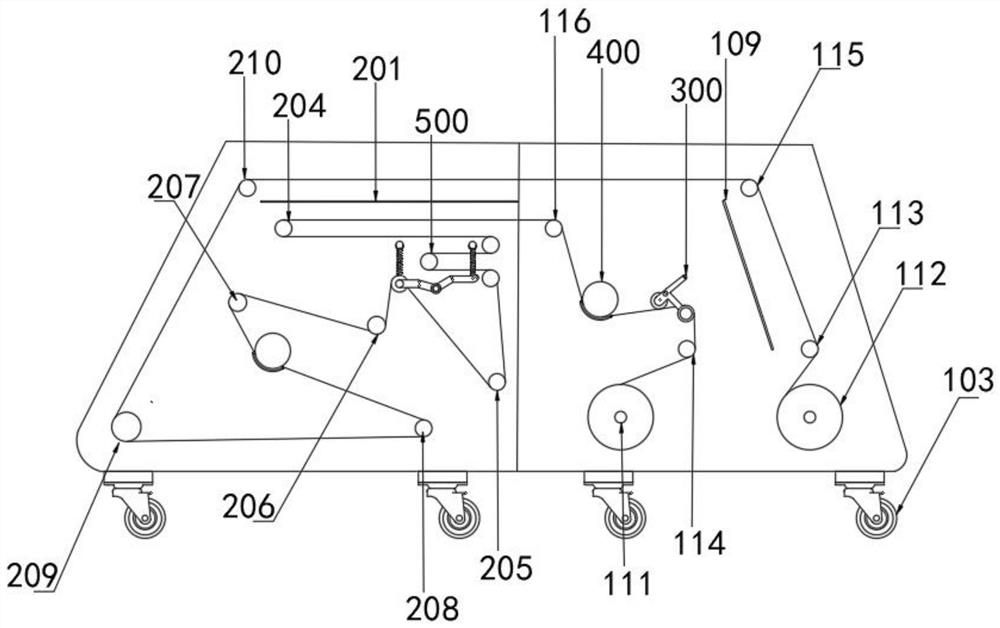

[0055] Refer to the manual attached Figure 15 , a coating machine for preparing a polyimide film of this embodiment further includes a body-100, a tensioning device-300 and a coating device 400;

[0056]Further, the inner wall of the first body 100 is provided with a tensioning device 1 300, the left side of the tensioning device 1 300 is provided with a smearing device 400, the smearing device 400 is fixedly installed on the inner wall of the body 1 100, and the bottom of the tensioning device 1 300 is provided with a roller shaft 2 114. Roller shaft two 114 is provided with roller shaft four 116 at the top of the left side, roller shaft three 115 on the right side of roller shaft four 116, roller shaft one 113 at the bottom of roller shaft three 115, roller shaft one 113, roller shaft two 114 , Roller shaft three 115 and roller shaft four 116 are fixedly installed on the inner wall of body one 100, roller shaft one 113 and roller shaft three 115 are provided with a partitio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap