Raw material polishing device for machining

A technology for mechanical processing and raw materials, which is applied in the field of raw material grinding devices for mechanical processing, can solve the problems of only one workpiece being polished, low grinding efficiency, and increased grinding costs, so as to achieve intelligent control of work efficiency, improve grinding practicability, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

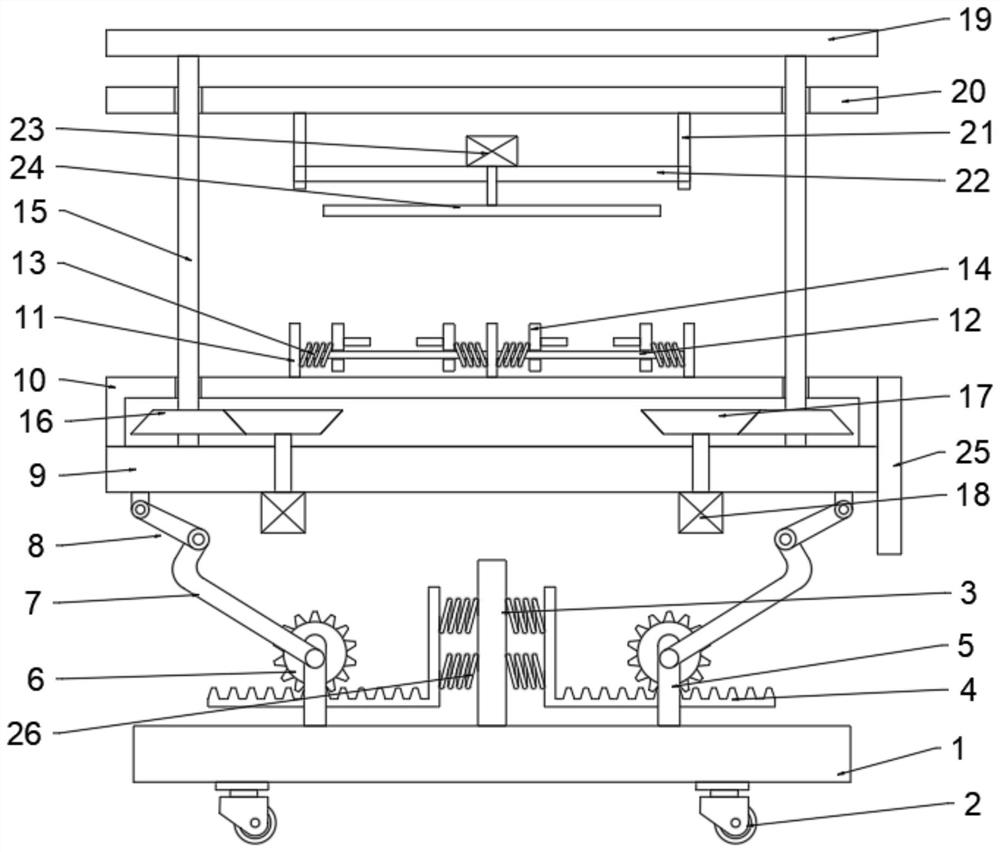

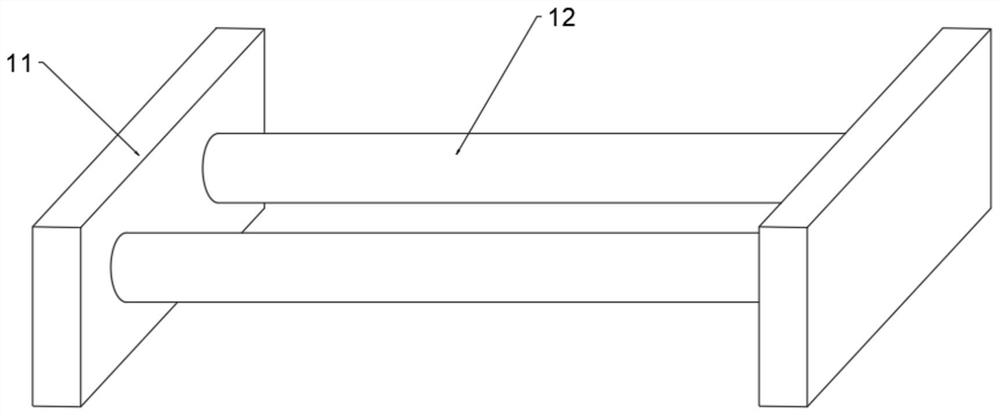

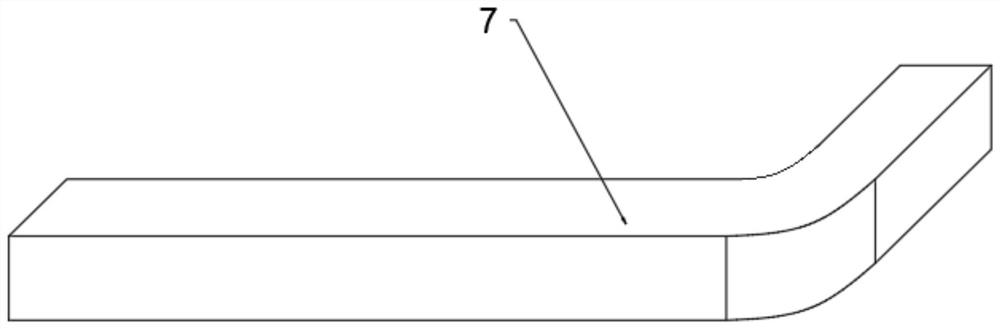

[0025] see Figure 1 ~ Figure 3 , a raw material grinding device for mechanical processing, comprising a base plate 1, universal wheels 2 are installed at the four corners of the bottom of the base plate 1, and the upper part of the base plate 1 is fixedly connected with a support plate 9 through a buffer and shock absorbing assembly, and the support plate A cover plate 10 is connected above the support plate 9, and a lifting assembly is provided between the support plate 9 and the cover plate 10. The lifting assembly runs through the cover plate 10 and is rotatably connected with the top plate 19. A threaded plate 20 is provided below the top plate 19. The bottom of the threaded plate 20 is provided with a grinding assembly, and the top of the cover plate 10 is provided with a fixed assembly. The shock absorbing assembly is used to effectively reduce the vibration generated during the working process of the device. Through the fixed assembly, multiple The workpiece to be poli...

Embodiment 2

[0032] see Figure 1 ~ Figure 4, as a raw material grinding device for mechanical processing in Example 1, including a base plate 1, universal wheels 2 are installed at the four corners of the bottom of the base plate 1, and the upper part of the base plate 1 is fixed with a support plate 9 by a buffer and shock absorbing assembly connection, a cover plate 10 is connected above the support plate 9, a lifting assembly is arranged between the support plate 9 and the cover plate 10, the lifting assembly runs through the cover plate 10 and is connected with the top plate 19 in rotation, and the bottom of the top plate 19 There is a threaded plate 20, the bottom of the threaded plate 20 is provided with a grinding assembly, and the upper part of the cover plate 10 is provided with a fixed assembly, which can effectively reduce the vibration generated during the working process of the device by using the buffer and shock absorbing assembly. , can quickly fix multiple workpieces to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com