Material-saving cutting table for nano circular material plate

A material board, cutting table technology, applied in the nano field, can solve the problem of automatic induction cutting and other problems, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

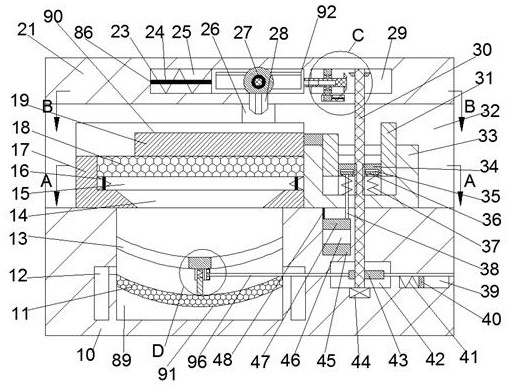

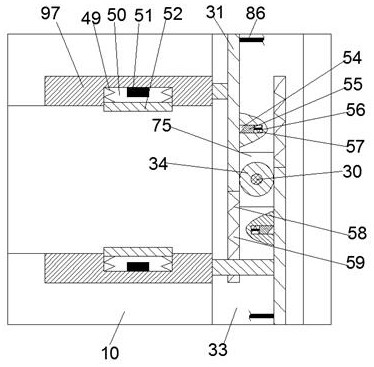

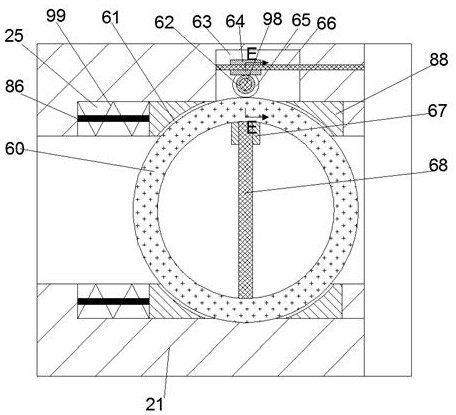

[0020] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] combined with Figure 1-6 The material-saving cutting table for a nano-circular material plate includes a base 10, the upper end surface of the right end of the base 10 is fixed with a transmission block 33, and the upper left end of the base 10 is provided with a width detection mechanism for placing raw materials to be cut 90, the upper side of the base 10 is provided with a circular cutting mechanism 92 for cutting materials, and the base 10 is provided with an environmental protection drainage mechanism 91 for environmentally friendly discharge of cutting waste water, and the circular cutting mechanism 92 includes a fixed Two connection plates 32 at the front and rear ends...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap