Air source system for railway vehicle and railway vehicle

A rail vehicle and wind source technology, which is applied in the field of rail vehicles, can solve the problems of poor support stability and affect other air springs, so as to achieve the effect of stable body and prevent excessive inclination angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present application are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary, and are only for explaining the present application, and should not be construed as limiting the present application.

[0031] Unless otherwise specified, the front-rear direction in this application refers to the longitudinal direction of the vehicle, namely the X direction; the left-right direction refers to the transverse direction of the vehicle, namely the Y direction; the up-down direction refers to the vertical direction of the vehicle, namely the Z direction.

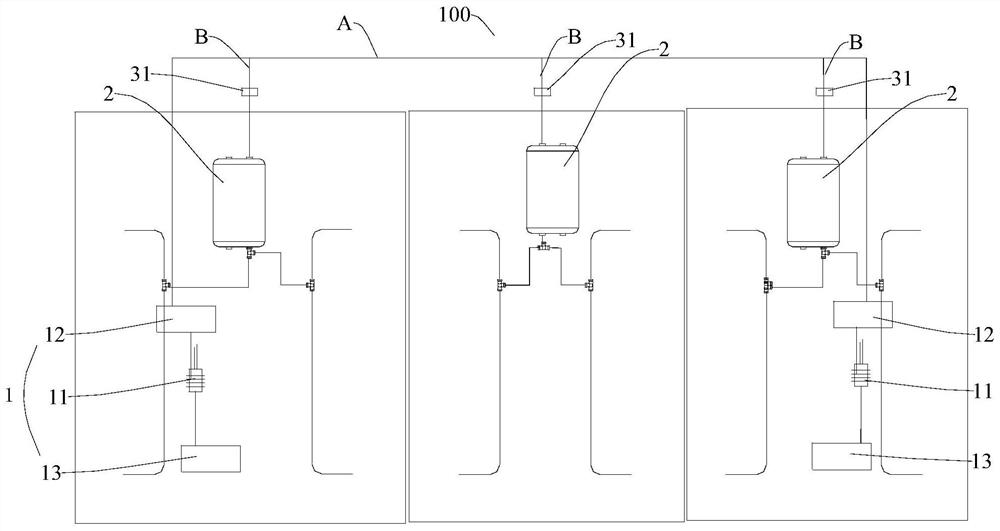

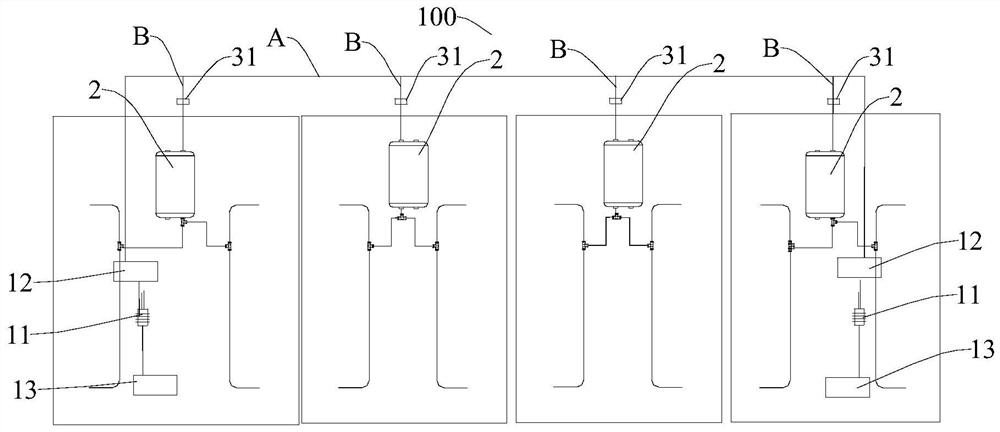

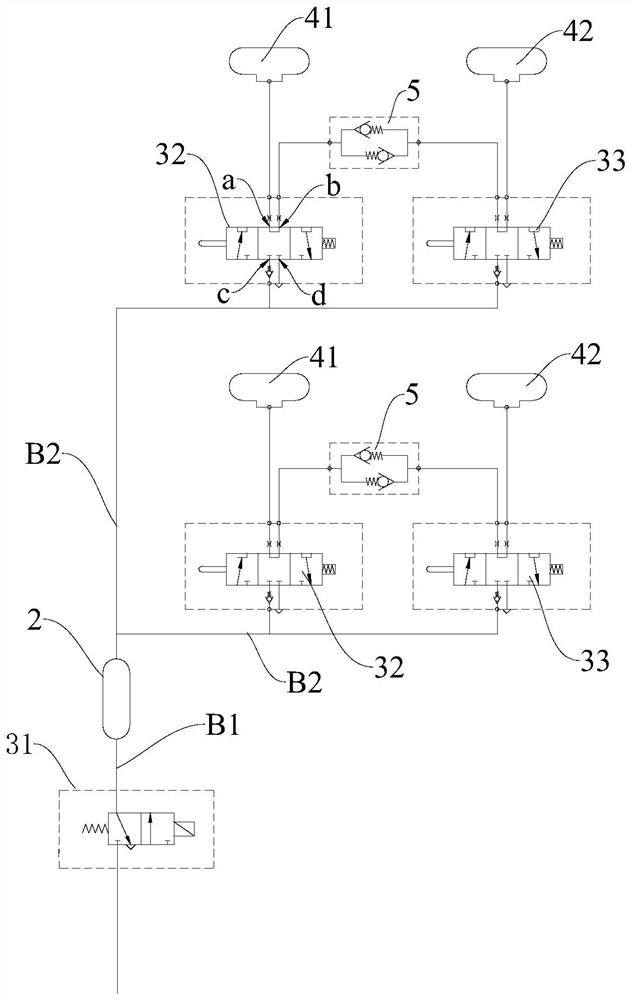

[0032] Refer below Figure 1-Figure 5 Describe the wind source system 100 for rail vehicles according to the embodiment of the present application, the gas storage part and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com