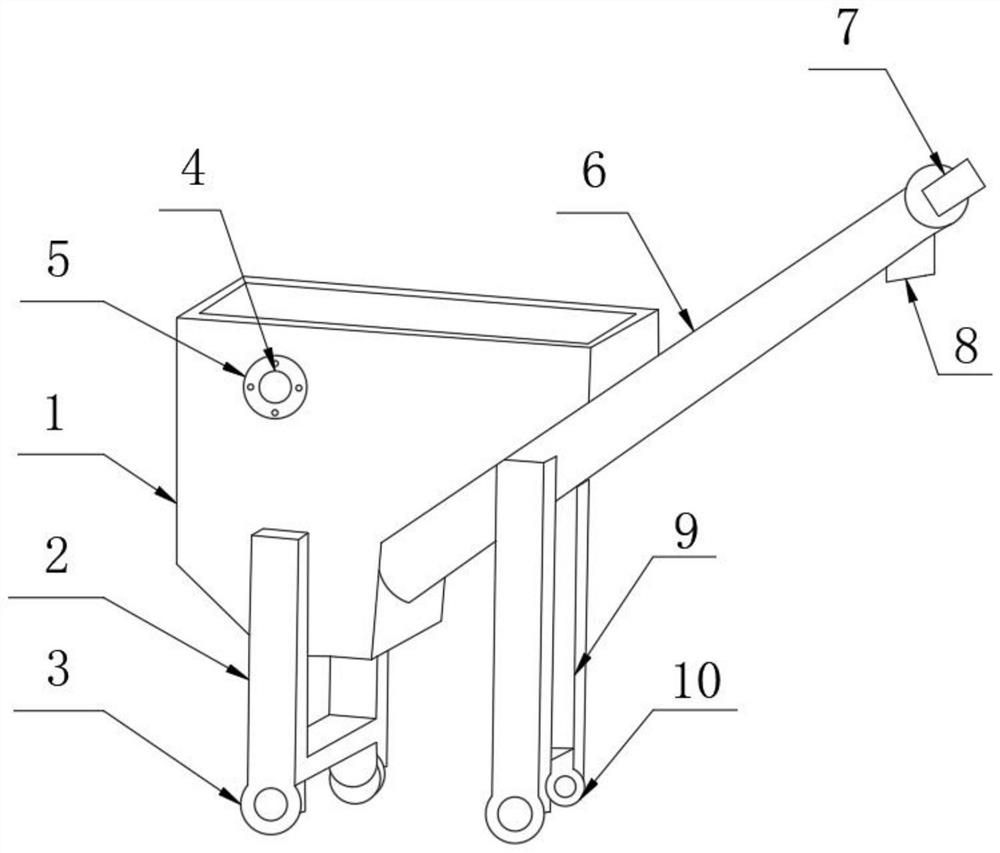

Sand-water separator

A sand-water separation and separation device technology, which is applied in the direction of centrifugal separation of water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of increased transportation costs, environmental pollution, and reduced work efficiency, and achieve Effects of increasing transportation costs, saving water resources, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

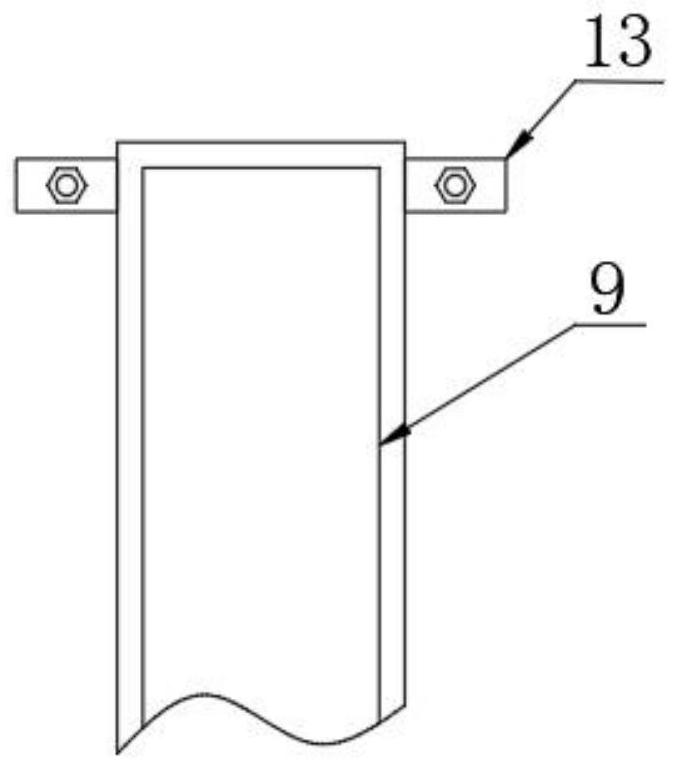

[0025] The specific embodiment is as follows: through the mutual cooperation between the filter screen 121 and the activated carbon screen 122, the effect of waste water recycling is achieved, the practicability of the device is enhanced and water resources are saved;

[0026] By providing the mounting plate 131, the cooperation between the bolts 132 and the nuts 133 achieves the effect of being convenient to carry and enhances the practicability of the device.

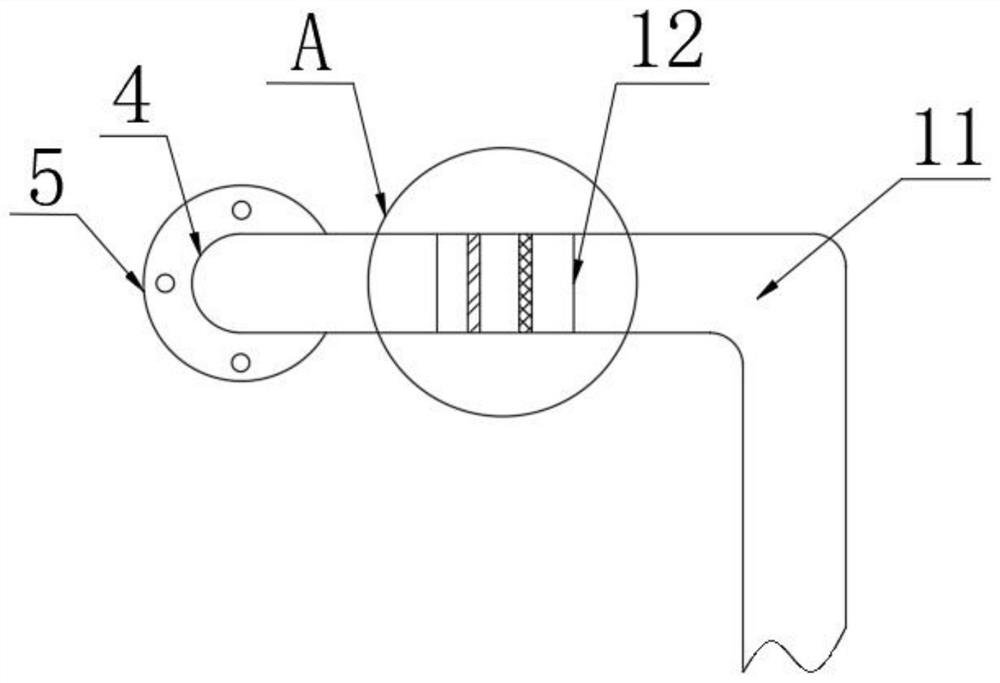

[0027] The specific reference manual is attached figure 2 , the surface of the overflow port 4 is adapted to one side of the water suction pipe 11, and the shape of the water suction pipe 11 is a 7-shaped shape.

[0028] The specific embodiment is: the water suction pipe 11 is provided to facilitate the export of waste water, and then filter and recycle.

[0029] The specific reference manual is attached image 3 , the number of mounting devices 13 is four, which are respectively located on the top surfaces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com